Analysis of Lard Adulterated in Beef Sausages:

Influence of n-hexane Concentration and Maceration Time

Desi Ardilla

1*,

Muhammad Taufik

2

, Dafni Mawar Tarigan

1

, Muhammad Thamrin

1

, Mariany Razali

3

,

Revi Trisna Siregar

1

, Irfan Kurniawan

1

, Nur Waridah Angriani Nasution

1

, Rika Astuti Pulungan

1

and

Sri Dewi Sihotang

4

1

Agricultural Technology Department, Universitas Muhammadiyah Sumatera Utara, Medan, Indonesia

2

Chemistry Department, Universitas Sumatera Utara, Medan, Indonesia

3

Pharmacy Department, Universitas Tjut Nyak Dhien, Medan, Indonesia

4

Pharmacy Department, Universitas Muslim Nusantara Al Washliyah, Medan, Indonesia

irfankurniawan0987, nurwaridahnst}@gmail.com, {rikaastuti, sridewi}@yahoo.com

Keywords: Beef Sausages, Nohexane, Lard, Concentration, Solven.

Abstract: Prime food products must pay attention to product halal factors that have an impact on consumers. some

products that are circulating in the general public are often adapted with other ingredients. Beef sausages is

a processed product that is often adulterated with lard. This work aims to study the comparison of solven

concentration (n-hexane) and maceration time on the analysis of beef sausage hat were added with lard. The

Factorial Completely Randomized Design (CRD) was developed used two (2) replications. Factor I was the

Solvent Concentration (C) which consists of four levels : C

1

= 20%, C

2

= 30%, C

3

= 40%, C

4

= 50% and

Factor II was the maceration time (W) consisting of four levels : W

1

= 6 Hours, W

2

= 12 Hours, W

3

= 18

Hours, W

4

= 24 Hours. The results showed that the concentration of n-hexane in beef sausages adulterated

with lard gave a significant difference (P> 0.01) on specific gravity, a significantly different effect (P> 0.01)

on iodine numbers. Real and tangible realization (P <0.05) to iodine numbers. The maceration gives a

significant difference (P> 0.01) to the specific gravity, the difference is significantly different (P> 0.01) with

respect to iodine number. The Concentration of lard at C

1

W

1

, C

2

W

2

, C

3

W

3

and C

4

W

4

were analyzed using

UV spectroscopy respectively 23, 35, 41, and 54%.

1 INTRODUCTION

At the present time it often happens important food

ingredients in the form of processed or raw from

other countries to Indonesia without going through

in-depth testing. The rate of increase in population

followed by improvement in living standards and

changes in consumer tastes have changed

consumption patterns that lead to animal protein

(Fadzlillah et al., 2011). Meat is a food that is widely

used as an ingredient for food diversification,

because meat contains many nutrients and can be

processed into a variety of dishes (Liu et al., 2018).

The increase in beef consumption has not been

offset by an increase in domestic production, both in

quality and quantity, resulting in an increasingly

large gap between demand and supply. Based on the

prognosis of beef production in the country in 2017

amounted to 354.770 tons, while the estimated

domestic demand for beef in 2017 amounted to

604.968 tons (Doosti & Dehkordi, 2014).

The halalness of a food product is very important

to be considered in consuming food products

(Sukmawati, 2018). For the category of processed

food, the halal status of a food product is highly

dependent on halal and the prohibition of raw

materials and additives about food (Hilda & Si,

2014). Explanation of the Food Law states that the

implementation of food safety for activities or

processes of food production for consumption must

be done through food sanitation, regulation of food

additives, setting food packaging standards,

providing food safety guarantees and food quality,

and guaranteeing halal products for the required

(Burlian, 2013).

One of the halal concepts in Islam is that food

does not contain "lard" or food fat derived from pigs.

Ardilla, D., Taufik, M., Mawar Tarigan, D., Thamrin, M., Razali, M., Trisna Siregar, R., Kurniawan, I., Waridah Angriani Nasution, N., Astuti Pulungan, R. and Dewi Sihotang, S.

Analysis of Lard Adulterated in Beef Sausages: Influence of n-hexane Concentration and Maceration Time.

DOI: 10.5220/0010137900002775

In Proceedings of the 1st Inter national MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 149-154

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

149

The presence of this component of lard, as low as

any of its ingredients in food, will bring the food to

be forbidden for consumption (Mayasari, 2019).

Several studies have been conducted to find the right

method to detect the presence of lard in food. In

previous studies identification of lard in vegetable

oils was carried out with Gas-Liquid

Chromatography combined with multivariate

analysis. Using GLC, lard of 2% can be detected in

vegetable oils (Naquiah et al., 2017). In addition to

GLC, HPLC has also been used to identify lard by

5% in meat products. However, most of these

methods require a lot of time and are impractical to

apply. This requires the development of a fast and

practical method for identification of lard (Lopes et

al., 2017).

Another method that can be used to identify the

presence of lard in beef is the Fourier Transform

Infra Red (FTIR) method to analyze the presence of

lard in goat and beef fat combined with multivariate

PLS analysis. Multivariate PLS analysis was used to

detect lard in the mixture with goat fat for detection

of lard in the mixture with beef fat. Lard

identification with FTIR combined with

Discriminant Analysis and PLS Analysis (Rohman

& Fadzillah, 2018). The FTIR method has the

potential to be used as a tool to detect lard quickly

with consistent results. This is because FTIR can

provide analysis results of fat from pigs that are

mixed with other fats consistently, even with a low

content . The weakness of the FTIR method is only

able to detect contamination if the prediction model

is made according to the sample being tested. This

becomes very difficult if the food sample to be

tested is unclear, and its exact composition is not

known (Fadzlillah et al., 2011). This work aims to

study the comparison of hexane concentration and

time to the analysis of beef sausage which has been

adulterated with lard

2 METHOD

Materials

The ingredients used in this research are processed

sausage and lard products. The chemicals used in

this study were n-hexane, PP indicator, KOH /

NaOH, amylum indicator, Diethyl Ether, Na

2

SO

4,

Ethanol, Aquades, Iodine, KI, CHCl

3

, Saturated

Solution, , Nutriet Agar, and Chloroform.

Equipment

In this work, we used erlenmeyer, biuret, glass

beaker drop pipette separating funnel, analytical

balance, gloves, test tube, knife, clamp, oven,

laminar, incubator, autoclave, spreader, flannel, tube

racks ice cream cup, hotplate, stirrer, cotton, plastic

wrap and petridish.

Research method

This research method was described a factorial

completely randomized design (CRD) method

consisting of 2: Factor I: Solvent Concentration

consisting of 4 levels, They are : C

1

= 20%, C

2

=

30%, C

3

= 40%, C

4

= 50% . Factor II: Maceration

Time consisting of 4 levels, namely: W

1

= 6 Hours,

W

2

= 12 Hours, W

3

= 18 Hours, W

4

= 24 Hours. The

number of treatment combinations (Tc) is 4 x 4 = 16,

so the number of replications (n) wasv as follows:

Tc (n-1) ≥ 15

16 (n-1) ≥ 15

16 n-16 ≥ 15

16 n ≥ 31

n ≥ 1,937.............rounded to n = 2

then for the accuracy of the study, repeated 2 (two)

times.

Preparation and maceration

Samples to be tested are processed products of pork

sausage and lard. Both samples were mixed. Sample

Extraction Preparation, including weighing the

sample (pork sausage and lard), smoothed material

(cut into cubes), put into a container, then add the

solvent according to the concentration and

maceration according to the specified factors.

Observation parameters

Observation parameters are based on analysis which

includes: specific gravity and iodine numbers.

Spectrofotometry UV analysis

UV spectroscopy Beckman DU640 UV / Vis was

used analyzing the lard contained in beef corneds. In

this work, the wavelangth was used in the range 200

- 400 nm. The standard of lard was determined at 5,

10, 15, 20, 25%.

3 RESULT

3.1 Statistical Test Measurement

Base of the statistical tests, in general it shows that

the concentration of n-hexane affects the observed

parameters. Data on the average observations of the

effect of n-hexane concentration on each parameter

can be seen in Table 1.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

150

Table 1: Effect of N-Hexane concentration.

n-hexanne

Concentration

(C) (%)

Specific

gravity

(g/ml)

Iodine

number

(mg/g)

K

1

= 20 % 0.950 70.397

K

2

= 30 % 0.959 71.920

K

3

= 40 % 0.975 74.965

K

4

= 50 % 0.993 76.584

Maceration time after being tested statistically

ifluences the observed parameters. Data on the

average observation results of maceration time can

be seen in Table 2.

Table 2: Effect of maceration time.

n-hexanne

Concentration

(C) (%)

Specific

gravity

(g/ml)

Iodine

number

(mg/g)

W

1

= 6 0.942 69.850

W

2

= 12 0.958 73.251

W

3

= 18 0.972 74.314

W

4

= 24 1.002 76.452

Table 2 shown the effect of maceration time on

specific gravity and iodine number acid number,

iodine number, and the number of microbes was

increasing.

3.2 Specific Gravity

Effect of N-Hexane Concentration

Based on the list of variance it can be seen that the

concentration of N-Hexane has a significantly

different effect (P> 0.01) on specific gravity. The

level of difference has been tested with the average

difference test can be seen in Table 3.

Table 3: Average difference test results on the effect of

maceration time on specific gravity.

Distance

LSR Treatment

Average

Notation

0,05 0,01 C 0,05 0,01

- - - 20 0.950 cd CD

2 0.017 0.021 30 0.962 bc BC

3 0.018 0.022 40 0.975 b AB

4 0.018 0.023 50 0.993 a A

Table 3 shown that C

1

is not significantly different

from C

2

and very significantly different from C

3

, and

C

4

. C

2

is not significantly different from C

3

and C

4

.

C

3

is not significantly different from C

4

. The highest

type of weight is in the K4 treatment that is 0.994 gr

/ ml and the lowest is in the K1 treatment that is

equal to 0.945 gr / ml. For more details can be seen

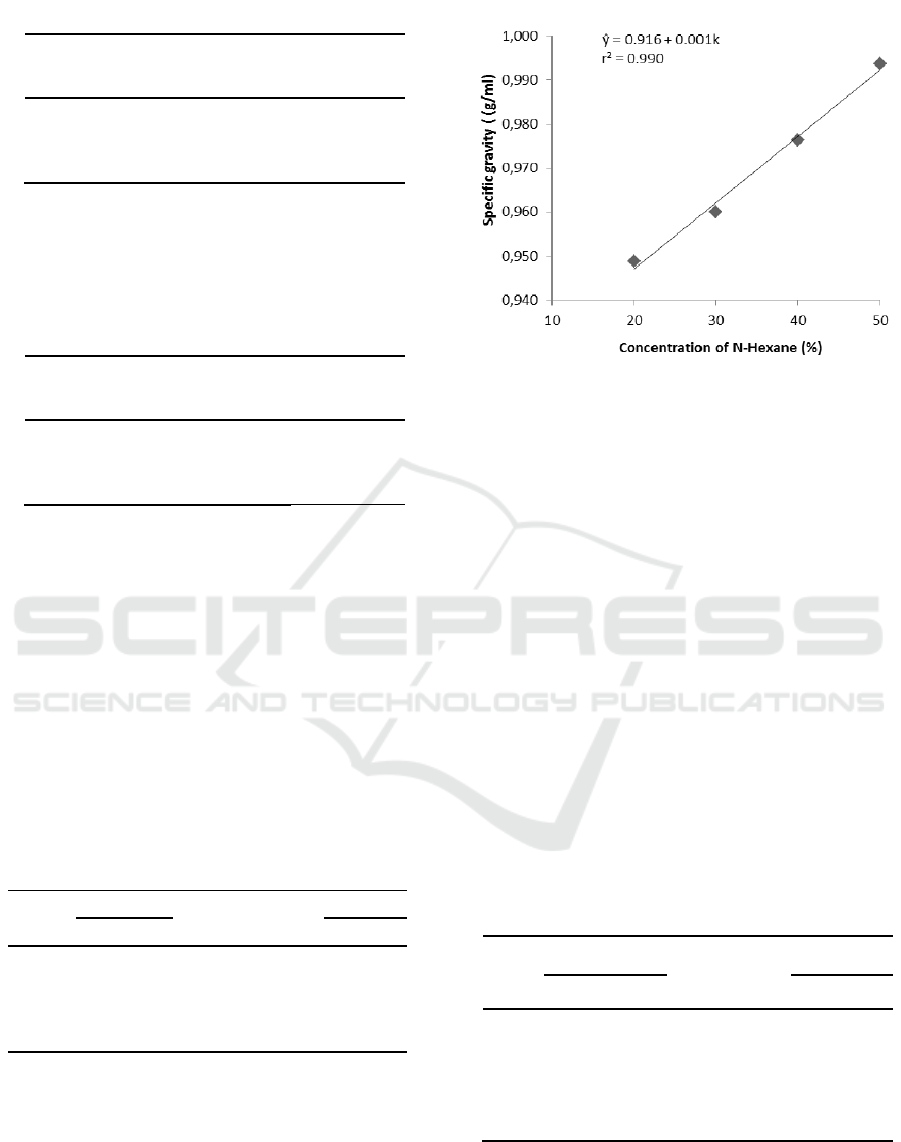

in Figure 1.

Figure 1: Relationship of N-Hexane solvent concentration

to weight.

Figure 1 shown the concentration of n-Hexane to

specific gravity. The more concentration of n-hexane

solvent used, the specific gravity is also increasing,

namely 0.994 g / ml. This is because the number of

other components contained in beef sausage and

mixing with the components contained in lard causes

the specific gravity increases. The substance has a

large mass then the probability of its specific gravity

also becomes greater. The high specific gravity

produced from the sample is caused by other

compositions contained in lard.

Effect of maceration time

Based on the list of variance, it can be seen that the

maceration time has a very significant effect (P>

0.01) on specific gravity.

The level of difference has been tested with the

average difference test can be seen in Table 4.

Table 4: Average difference test results on the effect of

maceration time on specific gravity.

Dis

tance

LSR

Treat

ment

Ave

rage

Notation

0,05 0,01 W 0,05 0,01

- - - 6 0.943 d CD

2 0.016 0.022 12 0.960 bc BC

3 0.017 0.023 16 0.968 b B

4 0.017 0.024 24 1.009 a A

Note: Different letters in the notation column show

significantly different effects at the level (P <0.05)

and very significantly different at the level (P>

0.01).

Analysis of Lard Adulterated in Beef Sausages: Influence of n-hexane Concentration and Maceration Time

151

Table 4 shown that W

1

is not significantly

different from W

2

, and very significantly different

from W

3

and W

4

. W

2

is not significantly different

from W

3

and very significantly different from W

4

.

W

3

is very different from W

4

. The highest type of

weight was found in the W

4

treatment that was 1,009

gr / ml and the lowest was in the W

1

treatment which

was 0,943 g / ml. For more details can be seen in

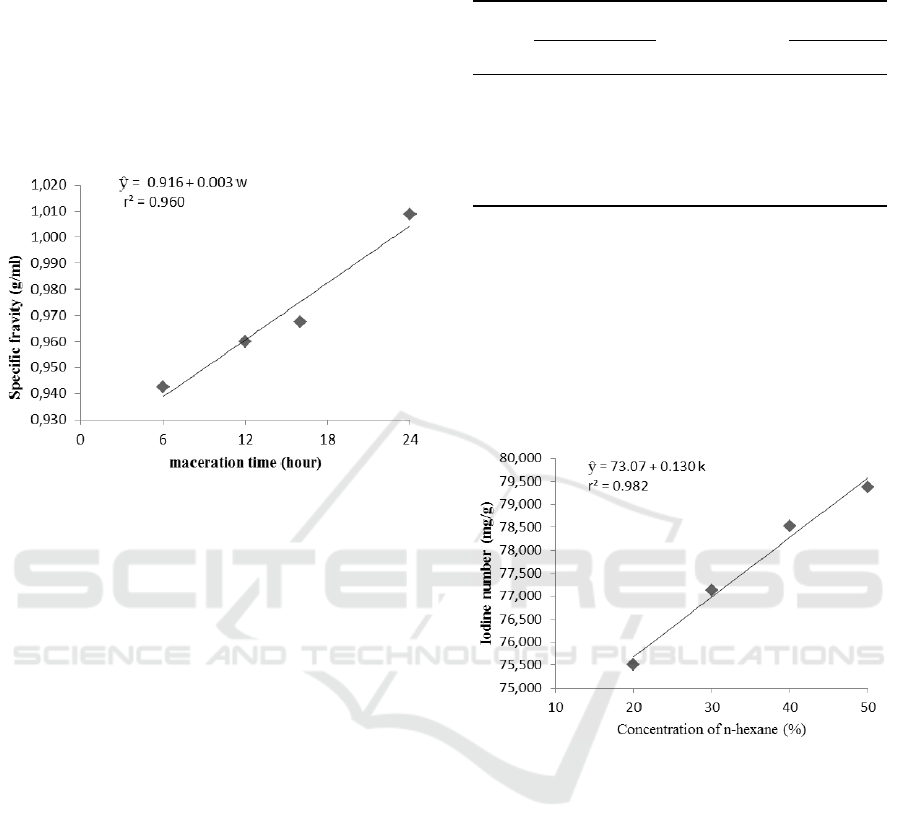

Figure 2.

Figure 2: Relationship of macerated time to weight of

types of processed products of beef sausage adulterated

with lard.

Figure 2 shown the maceration time of specific

gravity in beef sausages adulterated. The longer of

the extraction time, the greater the specific gravity

value obtained. Maceration is done by immersing

simplex powder in a liquid solution. The search

liquid will penetrate the cell wall and enter the cell

cavity which contains the active substance, the

active substance will be dissolving at the difference

concentration. The active substance solution was

pushed out. Figure 2. shown the greater the

comparison of maceration time, the resulting yield

increases. The longer the maceration time used

would also increase the amount of dissolved

compounds (Mas et al., 2019). As a result, the

extraction rate will increase.

3.3 Iodin Number

The concentration N-hexane effect

Based on the list of variance, it can be seen that the

concentration of N-Hexane (solvent) has a

significantly different effect (P> 0.01) on the iodine

numbers. The level of difference has been tested

with the average difference test can be seen in Table

5.

Tabel 5: Average difference test results effect of the

concentration of N-Hexane on iodine numbers.

Dis

tance

LSR

Treat

ment

Ave

rage

Notation

0,05 0,01 C 0,05 0,01

- - - 6 69.859 d D

2 0.589 0.811 12 73.254 c C

3 0.618 0.852 18 74.300 b B

4 0.634 0.873 24 76.459 a A

Table 5 shown that C

1

(Concentration 1) differs

very significantly from C

2

(Concentration 2), C

3

(Concentration 3) and C

4

(Concentration 4). C

2

(Concentration 2) was very different than C

3

(Concentration 3) and C

4

(Concentration 4). The C

3

was very different than C4 (Concentration 4). The

highest iodine number in C

4

treatment is 76.459 mg

/g and the lowest in C

1

treatment is 69.859 mg /g.

This data was showed at Figure 3.

Figure 4: Relationship of N-Hexane solvent concentration

to iodine numbers.

Figure 4 shown the concentration of n-hexane

with iodine number. Iodine number gave a

determination of the level of unsaturation of a fat or

oil, therefore iodine number is equal to the

unsaturation of an acid or fat. From the above data in

this study produced a fairly high of iodine number.

Where the more the concentration of n-hexane

solvent is used, the iodine number was increasing at

76.459 mg / g. This is due to the fact that n-hexane

has better solubility or reaction (Nees et al., 2017). If

iodine number is getting higher, then the double

bond contained in lard will also be more. The more

of double bonds in the melting point of lard will be

lower and cause lard to be more easily oxidized so

that the number of peroxides is higher (Liu et al.,

2018).

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

152

Effect of maceration time

Based on the list of variance it can be seen that the

maceration time has a very significant effect (P>

0.01) on iodine numbers.

3.4 Analysis UV Spectroscopy Data

UV spectroscopy using DU640 UV / Vis type using

a wavelength of 200-400 nm. The standard lard

solution is made in concentrations of 5, 10, 15, 20,

25%. This method measured relative light energy if

the energy obtained from the sample is transmitted,

reflected or emitted as a function of the wavelength.

In this work, UV-Vis (Ultra Violet-Visible)

spectrophotometer was chosen from many

instruments commonly used in analyzing lard in

animals. Spectrophotometers are commonly used

because of their ability to analyze so many chemical

compounds and their practicality in terms of sample

preparation when compared with several methods of

analysis. The concentration of the solution analyzed

will be proportional to the amount of light absorbed

by the substance contained in the solution. The

optimum wavelength is obtained at 270 nm with the

absorbance value obtained in Figure 5.

Figure 5: UV spectrum at 270 nm.

Figure 5 shown that the UV spectral at 270 nm of

the optimum wavelength. The Concentration of lard

at W1K1, W2K2, W3K3 and W4K4 were analyzed

using UV spectroscopy respectively 23, 35, 41, and

54%.

4 CONCLUSIONS

Beef sausages was adulterated with lard have

spesification of physical properties. This product

that is often adulterated with lard. The concentration

of n-hexane in beef sausages adulterated with lard

was a significant difference (P> 0.01) on specific

gravity, gave a significantly different effect (P>

0.01) on iodine numbers, and not significant (P

<0.05) of acid numbers. Real and tangible

realization (P <0.05) to iodine numbers. The

maceration gives a significant difference (P> 0.01)

to the specific gravity, the difference is significantly

different (P> 0.01) with respect to iodine, the

difference was not significant (P <0.05) with respect

to the acid number. The Concentration of lard at

W

1

K

1

, W

2

K

2

, W

3

K

3

and W

4

K

4

were analyzed using

UV spectroscopy respectively 23, 35, 41, and 54%.

ACKNOWLEDGEMENTS

This study funded by DRPM (2019) of Ministry of

Research Technology and High Education of the

Republic of Indonesia Year.

REFERENCES

Burlian, P. (2013). Reformulasi Yuridis Pengaturan

Produk Pangan Halal. Ahkam, XIV, 43–52.

Doosti, A., & Dehkordi, P. G. (2014). Molecular assay to

fraud identification of meat products. J Food Sci

Technol, 51(January), 148–152.

https://doi.org/10.1007/s13197-011-0456-3

Fadzlillah, N. A., Man, Y. B. C., & Jamaludin, M. A.

(2011). Halal Food Issues from Islamic and Modern

Science Perspectives. 2011 2nd International

Conference on Humanities, Historical and Social

Sciences IPEDR.

Hilda, L., & Si, M. (2014). Analisis Kandungan Lemak

Babi dalam produk pangan di Padangsidimpuan secara

kualitatif dengan menggunakan Gas Kromatografi

(GC). Tazkir, 9, 1–15.

Liu, M., Lampi, A., & Ertbjerg, P. (2018). Unsaturated fat

fraction from lard increases the oxidative stability of

minced pork. Meat Science, 143, 87–92.

https://doi.org/10.1016/j.meatsci.2018.04.028

Lopes, M., Gomes, A. S., Silva, C. M., & Belo, I. (2017).

Microbial lipids and added value metabolites

production by Yarrowia lipolytica from pork lard

Microbial lipids and added value metabolites

production by Yarrowia lipolytica from pork lard.

Journal of Biotechnology, 265, 76–85.

https://doi.org/10.1016/j.jbiotec.2017.11.007

Mas, F., Bangngalino, H., Indriati, S., Todingbua, A., &

Sayuti, M. (2019). Model development to enhance the

solvent extraction of rice bran oil. OCL Journal,

26(16), 1–9.

Mayasari, N. E. (2019). Perlindungan hukum pada kasus

suplemen makanan yang mengandung babi. 1.

Analysis of Lard Adulterated in Beef Sausages: Influence of n-hexane Concentration and Maceration Time

153

Naquiah, A. N., Marikkar, J. M. N., Mirghani, M. E. S.,

Nurrulhidayah, A. F., & Yanty, N. A. M. (2017).

Differentiation of Fractionated Components of Lard

from Other Animal Fats Using Different Analytical

Techniques. Sains Malaysiana, 46(2), 209–216.

Nees, C., Blume, N., Wardatun, S., Rustiani, E., Alfiani,

N., & Rissani, D. (2017). Study Effect Type of

Extraction Method And Type of Solvent To

Cinnamaldehyde and Trans-Cinnamic Acid Dry

Extract Cinnamon. J Young Pharm, 9(1), 49–51.

https://doi.org/10.5530/jyp.2017

Rohman, A., & Fadzillah, N. A. (2018). 21 - Lipid-based

techniques used for halal and kosher food

authentication. In Preparation and Processing of

Religious and Cultural Foods. Elsevier Ltd.

https://doi.org/10.1016/B978-0-08-101892-7.00021-3

Sukmawati. (2018). Total Microbial Plates on Beef and

Beef Offal. Bioscience, 2(1), 22–28.

https://doi.org/10.24036/02018219825-0-00

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

154