Carboxymethyl Starch Synthesis from Breadfruit Starch (Artocarpus

Communis) through Esterification Reaction with Monochloro Acetate

Cut Fatimah Zuhra

1*

, Mimpin Ginting

1

, Arny Masyita

1

and Wilza Fithri Az-zahra

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Breadfruit Flesh, Carboxymethyl Starch (CMS), Monokloroacetate, Starch.

Abstract: The synthesis of carboxymethyl starch from breadfruit starch (Artocarpuscommunis) has been done through

the etherification reaction with monochloroacetate. The first stage is the isolation of starch from the fruits of

breadfruit fruits, where the results of FTIR analyzed obtained spectra with 3402, 2931, 1080, 1018 cm-1

waves indicating the presence of O-H, C-H stretching and C-O-C bonds, illustrating that the compound is a

starch compound. The second stage is the etherification process with monochloroacetate using NaOH

reagent and isopropanol as solvent. The carboxymethylation process using monochloroacetate was carried

out with variations in the addition of monochloroacetate 1.5; 3; 4.5; 6; 7.5 grams and 90 times variations;

120; 150 minutes and neutralization using 2N CH

3

COOH. The resultant carboxymethyl starch shows the

appearance of peaks at the wavenumbers 1604 cm-1 and 1419 cm-1 in the analysis using FTIR spectroscopy

showing the presence of carbonyl groups. Then the carboxymethyl starch produced was calculated by

degrees of substitution and SEM analysis was performed. The highest degree of substitution was 1.8412 in

weight gain of 6 grams of monochloroacetic acid with reaction time of 2 hours and obtained a rougher

surface shape due to the presence of granules and a more unified appearance.

1 INTRODUCTION

Breadfruit (Artocarpus communis) has the potential

as a national food security reserve because breadfruit

can produce throughout the year. Besides, breadfruit

contains nutrients that are not inferior to corn or

tubers. This plant has long been cultivated by the

people of Indonesia, but for the people of Indonesia

consumption of breadfruit is generally still limited as

a snack and vegetable (Pitojo, 1992). As one

alternative food source, breadfruit is proven to have

high nutritional content (Widowati, 2003).

Breadfruit has high carbohydrate content because it

is a valuable source of starch. Starch obtained from

breadfruit produces 18.5 g / 100 g with a purity of

98.86% with an amylose content of 27.68% and

amylopectin 72.32% (Rincom, A.M. & Fanny,

2004).

The use of starch in the industry is very broad,

both in the field of food and non-food because of the

ease of getting raw materials and the price is

relatively cheap. However, some properties of

natural starch become an obstacle if used as

industrial raw materials, including the nature of

starch which is easily damaged by heat and acid

(Sangseethong et al., 2005). The commonly used

way to overcome these weaknesses is to change the

molecular structure of starch physically, chemically

or combine which will improve the properties of

natural starch (Liu, 2005).

Modification of starch is done by cutting the

molecular structure, rearranging the molecular

structure through oxidation or substitution of

functional groups in starch molecules (Wurzburg,

1989). Carboxymethylation is a modification

method by substituting the starch molecular function

groups. This modification produces starch with low

gelatinization temperature, high solubility and high

shelf life (Sangseethong et al., 2005). The

carboxymethylation process takes place by

substituting a natural starch hydroxyl group (-OH)

with a carboxymethyl group (-CH

2

COO-) to produce

Na-carboxymethyl starch or carboxymethyl starch

(CMS) (Sangseethong et al., 2005). Utilization of

Na-carboxymethyl starch, among others, as a

disintegrant in the pharmaceutical industry (Shah &

Augsburger, 2002) and as a sizing and printing agent

in the textile industry (Ragheb et al., n.d.).

(Fachrudin, 2013) has researched Na-

Carboxymethyl starch production with different

Fatimah Zuhra, C., Ginting, M., Masyita, A. and Fithri Az-zahra, W.

Carboxymethyl Starch Synthesis from Breadfruit Starch (Artocarpus Communis) through Esterification Reaction with Monochloro Acetate.

DOI: 10.5220/0010137800002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 143-148

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

143

types of stirring at the alkalization stage, the results

obtained show that the greater the concentration of

NaOH and on the type of stirring carried out with

homogenizer will produce higher substitution

degrees. Synthesis and antibacterial of

carboxymethyl starch poly-branch (vinyl imidazole)

against some plant pathogens produce a degree of

substitution of 0.81 and rupture of starch granules

under the influence of alcohol, alkali and heat

environment which replaces OH groups with

carboxymethyl groups and afterwards N-vinyl

imidazole is grafted to CMS in water using

potassium persulfate as an initiator at 450C (El-

Hamshary et al., 2014).

From the background described above,

researchers are interested in examining the synthesis

of carboxymethyl starch through the reaction of

breadfruit starch etherification with variations in the

addition of Monochloro Acetate and reaction time.

2 MATERIALS AND METHODS

2.1 Materials

The materials used in this study include: Breadfruit,

Aquadest, Isopropanol, NaOH, Monochloroacetic

Acid, Acetic Acid, Acetone, HCl, Ethanol, PP

indicators.

2.2 Methods

2.2.1 Isolation of Starch from Breadfruit

Breadfruit that is old or whose skin begins to turn

yellow is peeled and the fruit stalk is removed. After

peeling, the breadfruit is washed until it is free of

dirt and sap. Then breadfruit cut into small pieces,

then mashed using a blender. Breadfruit that has

been mashed is filtered using gauze, the filtrate from

the filter is left to form a precipitate. The precipitate

obtained is washed repeatedly with water until the

upper layers are clear. The starch obtained was dried

in an oven at 45°C for 24 hours. The dried starch is

then mashed, sieved, weighed and stored in a

desiccator. Subsequently analyzed by IR

spectroscopy.

2.2.2 Preparation of Carboxymethyl Starch

from Pati Breadfruit

Add 5 grams of starch and 210 mL of isopropanol

and 30 mL Aqudest into a three-neck flask, then the

mixture is stirred with a magnetic stirrer at a speed

of 400 rpm for 4 hours at a temperature of 35°C.

Then 1.6 grams of NaOH has been dissolved with 25

mL aqua dest while stirred for 45 minutes and the

temperature raised to 45°C. Then added 1.5 grams of

Monochloro acetate which has been dissolved in

12.5 mL isopropanol and mixed with 1.5 grams of

NaOH dissolved in 12.5 mL Aquadest and stirred for

2 hours. Then cooled and then the mixture was

neutralized with 2 N. acetic acid. Then added

acetone and filtered. The precipitate was washed

with acetone-water (60:40 v/v) and pure acetone.

And the end product carboxymethyl starch is dried

in an oven 50°C.

The procedure was carried out with the variation

in weight of Monochloro acetate 1.5; 3; 4.5; 6; 7.5

grams and reaction time of 1.2; 2; 2.5 hours.

Carboxymethyl starch obtained was analyzed by FT-

IR and SEM, the degree of substitution was

calculated.

2.2.3 Determination of Degree of

Substitution (ISO 11216-1998)

Carboxymethyl starch samples were converted to

acidic form with the addition of HCl. A sample of

1.5 g was added with 45 ml of acetone, added with

3.75 ml of HCl 6M and stirred with a stirrer for 30

minutes. The filtered solution is then dispersed in

80% ethanol, filtering the solution to neutral pH.

The filtration results are dispersed in absolute

ethanol, then filtered and dried for 24 hours in an

oven at 50°C. 0.5 g of sample was dissolved in 25

ml of 0.1 M NaOH and added with 75 ml of distilled

water. Samples were then titrated using 0.1 M HCl

with phenolphthalein indicator (ISO 11216-1998).

2.2.4 Functional Group Analysis with FT-IR

Spectroscopy

Carboxymethyl starch was mashed with pestle and

mortar and then made into pellets with KBr and

spectra were measured with FT-IR spectroscopy.

2.3.5 SEM Analysis (Scanning Electron

Microscopy)

The sample is placed in a cell holder with a double

lid. The sample is inserted into a Scanning Electron

Microscopy (SEM), then the surface image is

observed and magnified as desired. Then a

photoshoot is taken.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

144

3 RESULTS AND DISCUSSION

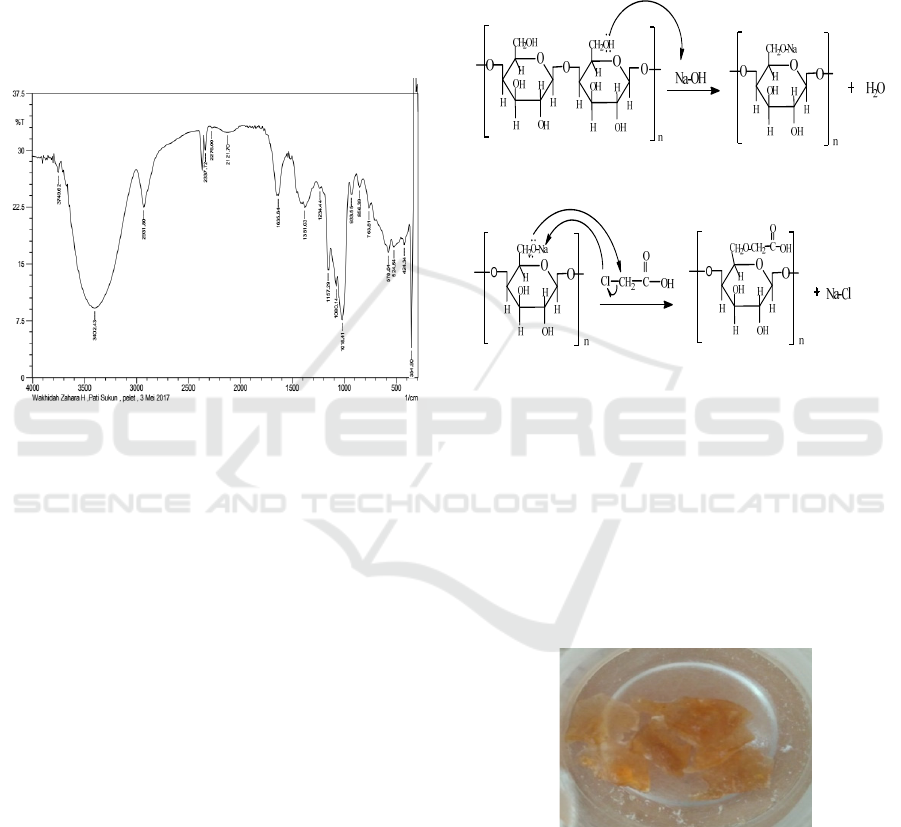

3.1 FTIR Spectrophotometer Analysis

of Breadfruit Starch

Isolated starch from 8 breadfruits with a mass of

about 18 kg is 470 grams (2.61%). FT-IR

spectroscopy data of breadfruit starch provide

spectrum with vibrational peaks in the region of

wave numbers 3402, 2931, 2121, 1381, 1080, and

1018 cm-1 (Figure 1).

Figure 1: FTIR spectroscopy of breadfruit starch.

The spectrum shown from FT-IR data gives

support that the starch obtained has an OH group

with the emergence of a vibration peak at wave

number 3402 cm-1, supported by the emergence of a

stretching CH group at number 2931 cm-1, and the

carbonyl group (C = O) at 1635 cm-1 (Figure 1)

corresponding to commercial starch (Nurafrida,

2011) and COC bonds shown at numbers 1080 and

1018 cm-1 (Ochoa, 2013).

3.2 Carboxymethyl Starch

Carboxymethyl starch is produced through the

process of etherification with Monochloro acetate

(MCA) in an alkaline atmosphere. The first stage is

alkalization with NaOH as a promoter and producing

alkaline starch. Starch before entering the

alkalization stage is dispersed first in an isopropanol

solvent. Isopropanol functions as a reaction medium,

besides that isopropanol, will also dissolve minor

components such as fiber, ash, fat, and protein. The

dispersed starch then undergoes a stirring process.

The alkalization stage is the opening step to

activate the starch hydroxyl group (St-OH) into a

negatively charged alkoxide group (St-O-). The

alkalization stage creates a stress-strain on adjacent

starch molecules, this will weaken the starch double

helix bond area and damage the starch crystalline

structure (Chen & Jane, 1994). This condition will

facilitate the solvent and MCA to enter the starch

granules and substitute the alkoxide group with the

carboxymethyl group from the MCA (Kooijman et

al., 2003).

Figure 2: The reaction mechanism of an experiment

making carboxymethyl starch.

The variation made in this study is the weight

variation of Monokoloroetetat which is 1.5, 3, 4.5, 6,

and 7.5 grams and the reaction time is 90, 120 and

150 minutes. The carboxymethyl starch obtained in

the form of a carboxymethyl solid can theoretically

be seen in Figure 3. The light brown color is

transparent, where the carboxymethyl starch

resulting from synthesis is 4,50 g respectively; 4.82

g; 4.77g; 4.95 g; 4.65 g; and 4.71 g; 4.95 g; 4.54g.

Figure 3: Synthesis of carboxymethyl starch.

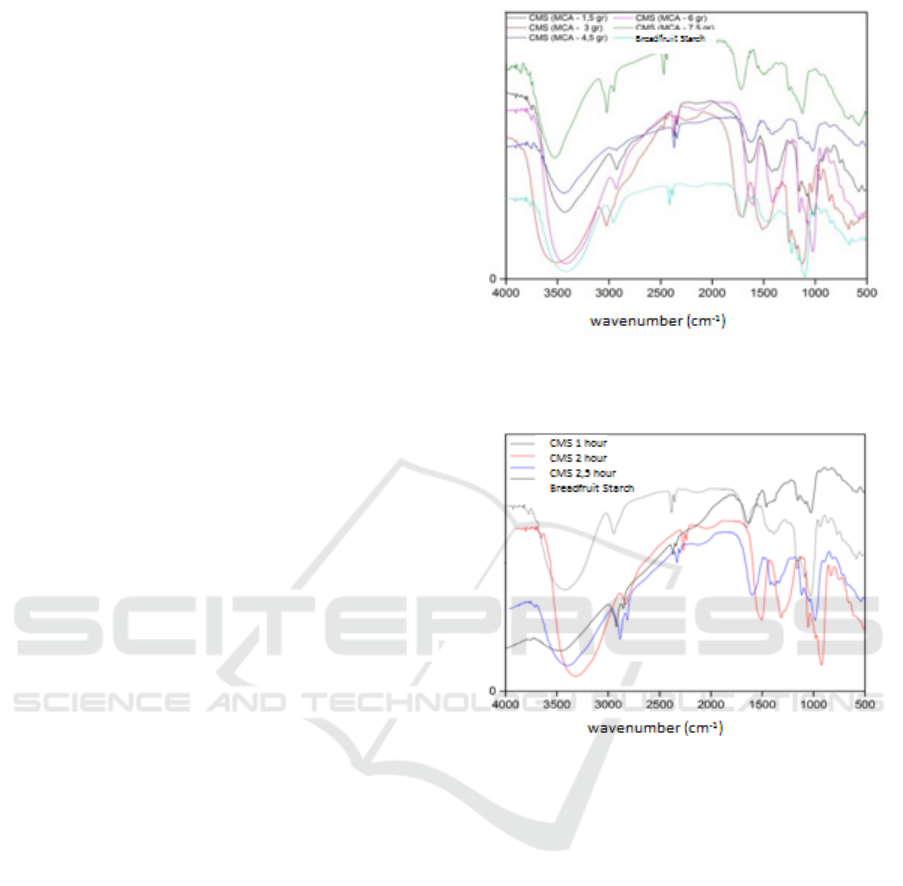

3.3 FTIR Spectrophotometer Analysis

of Carboxymethyl Starch

Carboxymethyl starch was analyzed using FT-IR

spectroscopy. FT-IR spectrum results using 1.5 gram

Monocloroacetate; monochloroacetate 3g; 4.5g

monochloroacetate; 6g monochloroacetate;

Carboxymethyl Starch Synthesis from Breadfruit Starch (Artocarpus Communis) through Esterification Reaction with Monochloro Acetate

145

Monochloroacetate 7.5g and with an etherification

reaction time of 90 minutes; etherification reaction

time of 120 minutes; the etherification reaction time

of 150 minutes has shown vibrations in the region of

wave numbers 3417, 2931, 1604, 1419, 1373, and

1026 cm

-1

.

The formation of carboxymethyl starch was

shown in the results of FT-IR analysis of

monochloroacetate weight variation and reaction

time. Characterized by the emergence of vibration

peaks in the region of wave numbers 1601-1408

cm

-1

which shows the COO region (El-Hamshary et

al., 2014). It was also stated by (Zhang, 2012) and

(Ochoa, 2013) that the emergence of the COO group

was marked by the peak spectra of 1618 cm

-1

and

1424 cm

-1

as well as 1605 cm

-1

and 1417 cm

-1

. In

starch carboxymethyl, there was a change in the

intensity of the carbonyl group in the 1604 cm

-1

and

1419 cm

-1

regions. Changes in the intensity of starch

carboxymethyl carbonyl groups with variations in

the weight of monochloroacetate 1.5; 3; 4.5; 6; and

7.5 grams with a 120 minute etherification reaction

time of 1635 cm

-1

and 1419 cm

-1

; 1604 cm

-1

and

1411 cm

-1

; 1620 cm

-1

and 1419 cm

-1

; 1604 cm

-1

and

1419 cm

-1

; 1620 cm

-1

and 1458 cm

-1

. From the FT-

IR data, the highest intensity of the carbonyl group

is at 6 grams of monochloroacetate weight. Starch

weighing 6 grams of monochloroacetate was

continued with time variations of 90 and 150

minutes, and the intensity of the carbonyl group was

1635 cm

-1

and 1458 cm

-1

; 1635 cm

-1

and 1458 cm

-1

.

This shows the occurrence of the addition of

carboxylic groups to starch carboxymethyl. From

this data, the most optimum is carboxymethyl starch

with 6 gram Monocloroacetate weight with 120

minutes reaction time, because the highest intensity

of the carboxylate group is 11,072. Comparison of

the FT-IR spectrum of monochloroacetic weight

variation and reaction time variation can be seen in

Figure 4 and Figure 5.

Figure 4: FTIR spectrum of carboxymethyl starch by

monochloroacetate weight variation.

Figure 5: FTIR spectrum of carboxymethylstarch variation

in reaction time.

3.4 Determination of Substitution

Degree

Determination of the degree of substitution titration

method based on ISO 11216-1998. In the weight

variation of monocloroacetate, the highest

carboxylate content was obtained, with 6 grams of

monocloroacetate treatment at 1.8412 per AGU. The

results of determining the degree of substitution with

variations in weight Monocloroacetate and

variations in the time of the etherification reaction as

in Table 1 and Table 2.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

146

Table 1: Degrees of starch carboxymethyl substitution

with variation in weight Monochloroacetate.

Weight

(

C

8

H

12

O

8

)

n

(g)

Degree of Substitution

(

by

AGU

)

1.5

3

4.5

6

7.5

0.1669

0.5823

1.1036

1.8412

0.8160

Table 2: Degrees of starch carboxymethyl substitution

with variations in reaction time

.

Esterification

Time (minutes)

Degree of Substitution

(by AGU)

90

120

150

0.2772

1.8412

1.4379

In this study DS results obtained ranged from

0.1669 - 1.8412. Where the highest DS of 1.8412

comes from carboxymethyl starch with 6 grams of

monochloroacetate weight. In the manufacture of

carboxymethyl starch when monochloroacetate is

added too little so that the substituted is too little and

will cause a reaction that occurs less than the

maximum, whereas if the monochloroacetate added

too much will react with NaOH to form Sodium

glycolic acid. This is because in the starch

carboxymethyl synthesis reaction using the

Williamson reaction is carried out in the presence of

a strong base to increase the nucleophilicity of the

hydroxyl group and to help breakdown starch

particles, but side reactions can also occur with

sodium hydroxide, producing glycols (Lawal et al.,

2007).

3.5 SEM Analysis Results

SEM testing was carried out on breadfruit starch and

carboxymethyl starch with the highest degree of

substitution which was in the 6 grams MCA

treatment and 120 minutes reaction time as in Figure

6 and Figure 7.

Figure 6: Surface Morphology of Breadfruit Starch

(Magnification 2500x).

Figure 7: Morphology of Carboxymethyl Starch Surface

(Magnification 2500 x).

SEM analysis is performed to see the

morphology of the modified starch compounds

obtained. In this study, the SEM test was only

performed on carboxymethyl starch with the highest

DS, carboxymethyl starch by adding 6 grams of

MCA weight with a reaction time of 120 minutes,

with an enlarged image of 2500 times. The surface

shape of breadfruit starch at a magnification of 2500

times (figure 6) can be seen clearly that breadfruit

starch consists of finely spaced granules and oval or

egg granules as reported by (Ahmad et al., 1999) and

the carboxymethyl starch surface shape (figure 7)

showing a rougher surface shape because there are

granules around it, with a smaller distance so it

looks like it blends in comparison with the original

breadfruit starch.

4 CONCLUSIONS

From the results of the research that has been done,

the following conclusions can be drawn:

1. The carboxymethyl starch synthesis process uses

2 steps, namely the alkalization process and the

carboxymethylationprocess. The optimum

Carboxymethyl Starch Synthesis from Breadfruit Starch (Artocarpus Communis) through Esterification Reaction with Monochloro Acetate

147

conditions for the 6 grams monocloroacetate

weight gain treatment with an etherification

reaction time of 120 minutes showed a

substituted degree of 1.8412.

2. SEM analysis results show starch surface shape

is smoother, round with a large cavity. While the

carboxymethyl starch surface shape is coarser,

granules have granules around it, have a smaller

distance so it looks like they are fused.

REFERENCES

Ahmad, F. B., Williams, P. A., Doublier, J. L., Durand, S.,

& Buleon, A. (1999). Physico-chemical

characterisation of sago starch. Carbohydrate

Polymers, 38(4), 361–370.

Chen, J., & Jane, J. (1994). Preparation of granular cold-

water-soluble starches by alcoholic-alkaline treatment.

Cereal Chem, 71, 71: 618 – 622.

El-Hamshary, M.G. Fouda, M., MeeraMohideen, El-

Newehy, H. M., Al-Deyab, S. S., & Abdel-Megeed, A.

. (2014). Synthesis and Antibacterial of

Carboxymethyl Starch-Grafted Poly(vinyl imidazole)

Against Some Plant Pathogens. Elsevier.

Fachrudin, R. (2013). Produksi Pati Na-Karboksimetil

dengan Perbedaan Tipe Pengadukan padaTahap

Alkalisasi. IPB Pres.

Kooijman, M., Ganzeveld, J., Manurung, R., & Heeres, H.

(2003). Experimental studies on carboxymethylation

of arrowroot starch in isopropanol-water media.

Starch, 55, 495 – 503.

Lawal, O., Lechner, M., & Kulicke, W. (2007). Single and

multistep carboxymethylation of water yam

(Dioscoreaalata) starch: synthesis and characterization.

Int J BiolMacromol, 429 – 435.

Liu, Q. (2005). Understanding starches and their role in

foods.in: Food Carbohydrates: Chemistry, Physical

Properties, and Applications. Taylor & Francis.

Nurafrida. (2011). Pembuatan Carboxymethil Strach Graft

Polyacrylamide dan Karakterisasinya.

Ochoa, N. (2013). Modified Cassava Starches as Potential

Corrosion Inhibitors for Sustainable Development.

Pitojo, S. (1992). Budidaya Sukun. Kanisius.

Ragheb, A., El-Sayiad, H., & Hebeish, A. (n.d.).

Preparation and characterization of carboxymethyl

starch (CMS) products and their utilization in textile

printing. Starch, 49(Starch), 238 – 245.

Rincom, A.M., & Fanny, C. P. (2004). Physicochemical

properties of Venezuelan breadfruit (Artocarpus

altilis) starch. Arch Latinoam Nutr, 54(4), 449–456.

Sangseethong, K., Ketship, S., & Sriroth, K. (2005). .

2005. The role of reaction parameter on the

preparation and properties of carboxymethyl cassava

starch. Starch., 57, 345 – 359.

Shah, U., & Augsburger, L. (2002). Multiple sources of

sodium starch glycolate, NF: evaluation of functional

equivalence and development of standard performance

tests. Pharm Develop Technol, 7, 345 – 359.

Widowati, S. (2003). Prospek Tepung Sukun Untuk

Berbagai Produk Makanan Olahan Dalam Upaya

Menunjang Diversifikasi Pangan

.

Wurzburg, O. (1989). Modified Starches: Properties and

Uses. CRC Press.

Zhang, B. (2012). Synthesis and characterization of

carboxymethyl potato starch and its application in

reactive dye printing. Elsevier Inc.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

148