Designing Performance Measurement Model for

Green Supply Chain Pulp

Kimberly Febrina Kodrat

1

, Novizar Nazir

2

and Derlini

1

1

Faculty of Engineering, Institut Teknologi Medan, Jalan Gedung Arca No. 54 Medan, Indonesia

2

Faculty of Agricultural Technology, Universitas Andalas, Padang, Indonesia

Keywords: Firm Performance, Performance Measurement Model, Supply Chain Performance.

Abstract: Measuring performance is necessary to do in order to know the effectiveness and efficiency of the supply

chain in the aspect of reducing costs and environmental impacts. The objective of this research is to

integrate the concept of lean and green supply chain to design performance measurement model for pulp

supply chain. This research was carried out only to the stage of designing system structure of supply chain

performance measurement conceptually. Integrating the green concept was designed using a Balanced

Scorecard (BSC) perspective covering financial, customer, internal process business and learning and

growth. Key Performance Indicators (KPI) was grouped according to the BSC perspective. Next, a paired

comparison process was carried out to get the weight of each KPI. The paired comparison assessment of

each KPI was based on the opinion of the selected experts referring to the experiences and knowledge

relevant to this research. Paired comparison was intended to get the weight of each KPI using the Analytical

Hierarchy Process (AHP) method. The weight generated from each KPI will be ordered in descending for

priority determination. The performance measurement model will be validated using face validity method.

The designed structure of the model showed that the customer perspective is a priority aspect in the pulp

supply chain at PT TPL. The implementation of this model requires coordination for easy access to

information among departments and the involvement of all company employees.

1 INTRODUCTION

Pulp or commonly called as paper pulp is paper

making material. Paper is a thin and flat material

produced by compression of fibers derived from

pulp containing cellulose and hemicellulose. Pulp is

the basic material of various paper-based products

ranging from boards used in factories to daily

necessities such as paper, tissue, tea bags, and

magazines. Pressures and movements influenced by

globalization drive companies to improve

environmental performance (Zhu & Sarkis, 2006).

The importance of relationships among

organizations encourages companies to integrate

networks with suppliers and consumers to create the

concept of Supply Chain Management (SCM).

Sustainable development relates to

environmental aspects. The concept of sustainable

development appears along with human awareness

to the environment. Sustainable development is

developed due to the anxiety of low earth ability

to support life. It happens as the effect of explosion

of high population, the increasing of human activity,

the intensity of natural resources explotation which

are accompanied by an increase in the waste

released by nature.

The capacity support of the environment is

decreasing day after day because pollution tends to

increase (Setiawan et al, 2011). Therefore, the

environmental aspect should be considered in the

pulp industry. Pollution produced from the pulp

industry is contamination from liquid, solid and air

waste. In addition to environmental conditions,

natural resources and the role of government in

supporting the sustainability of the pulp industry, the

supply chain management should also be improved

so that all business processes can run well. In

improving the quality and quantity of pulp, effective

strategies and performance of the industry supply

chain flow are needed.

The concept of supply chain management is

needed by companies for the selection of activities

in order to increase the added value, meet customer

needs and deliver products to the end users. The

78

Febrina Kodrat, K., Nazir, N. and Derlini, .

Designing Performance Measurement Model for Green Supply Chain Pulp.

DOI: 10.5220/0010136600002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 78-85

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

supply chain covers all stages involved both directly

or indirectly in meeting customer demand including

producers, suppliers, transporters, warehouses,

retailers and customers (Chopra & Peter, 2007).

Supply Chain Management (SCM) is a method, tool

or approach to supply chain management (Pujawan,

2005). In this series of supply chain activities, there

is an integrated and transparent flow of information

from suppliers to end customers making it easier to

control their implementation.

The issues of supply chain are currently starting

to develop and should be implemented by

companies, namely Green Supply Chain

Management (GSCM). All stages in GSCM affect

the environmental burden from resource extraction,

manufacturing, distribution, product use, waste

disposal and other activities. Risks associated with

the environment include: excessive use of water and

energy without conservation, use of hazardous

chemicals, pollution and so forth. Various ideas are

emerged from researchers and academics to

integrate environmental aspects into the

management of business processes so that the

GSCM concept was created (Shang et al., 2010).

According to (Mudgal et al., 2009), he explains

the benefits and importance of implementing green

supply chain in companies in reducing supply chain

costs and the environmental impact produced by the

company. The concept of GSCM itself is based on

an environmental perspective, namely how to reduce

waste and environmental impacts caused by

industrial company supply chain activities.

PT. Toba Pulp Lestari (TPL), a company owned

by Asia Pacific Resources International Limited

(APRIL) was established in 1992 producing pulp

located in Porsea, Toba Samosir Regency. The

production level produced by PT. TPL uses raw

material for eucalyptus trees. In producing pulp and

in marketing its products overseas, it is necessary to

apply the supply chain concept to help to select

activities to increase added value in meeting

customer needs and delivering products to end users.

Also, it is necessary to measure the performance of

the supply chain to see the level of effectiveness and

efficiency.

The principle of sustainability is emphasized in

vision of company, namely : be one of the largest,

well-managed, most productive, sustainable pulp

companies and loved by consumers and the public.

The vision and mission can be realized with concrete

strategies and objectives. A performance

measurement system for GSCM for pulp products is

needed to see the effectiveness and productivity of

the supply chain and realize the company's

sustainable principles.

The GSCM concept is urgently required in

designing a performance measurement system with

the perspective of the Balanced Scorecard (BSC) to

achieve an effective and efficient supply chain.

Measuring performance using BSC includes

financial perspectives, customers, internal business

processes, growth and learning. Therefore, the BSC

can accommodate important aspects in performance

measurement and is often used as a method of

measuring the performance of a company's supply

chain (Kaplan & Norton, 1996).

In the design of a system for measuring the

performance of pulp concepts based on the concept

of green, it is used to analyze the procurement of

raw materials, production to marketing the pulp.

Also, it is used to know whether it has applied the

concept of green in the sense of friendly-

environment or does not cause environmental

impacts and waste minimization caused by pulp

supply chain activities. The Implementation of this

green concept will produce important indicators that

indicate the level of their respective interests in

company performance so that companies can

determine the right company policies to improve the

effectiveness and efficiency of the supply chain

(Duarte et al., 2011).

2 RESEARCH METHODOLOGY

2.1 Study Site

This research was conducted at PT. Toba Pulp

Lestari located in Porsea District, Toba Samosir

Regency. The research took place from May 2019 -

August 2019. The research focused throughout the

supply chain from suppliers to pulp distributors.

2.2 Data Collection

Data collected in this study are data on pulp supply

chain business processes, production processes, raw

materials used and the area of raw material

suppliers, transportation, distribution areas and

marketing data regarding the parties involved

(stakeholders), company profile data, vision and

mission of the company, organizational structure and

line of business, various literatures related to

research, such as the concept of green to formulate

key performance indicators (KPI). The required data

are collected using the methods of observation,

Designing Performance Measurement Model for Green Supply Chain Pulp

79

literature study, interviews, KPI weighting

questionnaires and experts' opinion.

2.3 Research Implementation

The steps to carry out this research are as follows:

1. Understanding and analyzing PT. Toba Pulp

Lestari.

2. Formulating KPI from GSCM.

3. Grouping of GSCM KPIs in a BSC perspective.

4. Weighting and Determination of KPI priorities.

5. Designing a GSCM performance measurement

model in a BSC perspective.

6. Verificating and validating the performance

measurement model created.

2.4 Data Processing

The techniques used in analyzing data in this study

are as follows:

1. Analytical Hierarchy Process (AHP), AHP is used

to weigh each KPI to get the biggest weight of KPI.

The KPI which has the highest weight will be as the

priority of other KPIs.

2. Verification, Verification is carried out on the KPI

with the interview method, which is a direct

discussion to ensure that the results of the design of

the supply chain performance measurement system

can be correctly implemented. Then, it is analyzed to

know whether the KPI that is formulated has

covered all aspects needed in accordance with the

objectives and can be operated.

3. Validation, Validation is carried out to prove that

the results of the design of the supply chain

performance measurement system are feasible to be

applied in the company. The validation technique

used in this study is the face validity technique

asking for opinions from people who have

knowledge about the problem and can assess

whether the theory underlying the conceptual model

of the supply chain performance measurement

system design is correct and acceptable.

3 RESULTS AND DISCUSSION

3.1 Key Performance Indicator

Formulation (KPI)

The obtained KPI at the data collection stage is

verified to the company in order to determine the

suitability of these indicators with the supply chain

system in PT.TPL. Verification results show that

there are 10 KPIs with performance which can be

measured and in accordance with the existing supply

chain system. KPI is an important indicator that can

answer the needs of all stakeholders involved in PT.

TPL. Verification of green KPI as many as 10 KPI

can be seen in Table 1.

The definitions and descriptive formulations of

every KPI are as follows:

1. Energy-efficient operation, i.e. reduction in

energy use for all supply chain operations. The

amount of energy used when operating can be seen

from the ratio index value between the total energy

used in production with the total amount of cement

produced.

2. Waste disposition, i.e. the amount of waste

discharged into the environment produced in the

activities of the cement industry plant. Waste

disposition is a ratio index value between the weight

of waste discharged into the environment and the

total waste produced.

3. The use of material that can be recycled, that is

the amount of material that can be recycled. The use

of recyclable material is a comparison of the amount

of material that can be recycled with the total

amount of material used.

4. Collaborating with certified suppliers, i.e.

establishing cooperation with ISO certified standard

environment suppliers. The percentage of suppliers

who have an environmental certificate is a

comparison between the number of suppliers who

have an environmental certificate with the total

number of suppliers registered with the company.

5. Environmental costs, namely costs incurred to

preserve the environment. Total environmental costs

represent the total costs incurred to preserve the

environment such as waste management costs,

greening costs and environmental costs to preserve

the environment.

6. Air and water emissions, namely air and water

pollution caused by industrial activities in the form

of combustion substances in the production of

cement. The number of substances as a result of

combustion in production.

7. The use of substances that are not dangerous,

namely using materials that are friendly environment

and not harmful. The use of hazardous substances

can be determined from the number of uses of non-

hazardous substances used.

8. Decreasing frequency for environmental

accidents, ie reducing accidents environmental

accidents that occur. This frequency can be

determined by the number of accidentswork that

happened.

9. The level of customer interest in environmentally

friendly products, i.e. how concerned are they with

the environmental impact caused by the products

they consume. This can be determined from the

value of the comparison between customer interest

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

80

in environmentally friendly products to the overall

existing product.

10. Recycling efficiency, namely the effectiveness

of the recycling process in terms of the length of

time and costs incurred. Recycling efficiency can be

determined by comparing the time and costs

incurred for actual recycling against the time and

costs incurred for planned recycling.

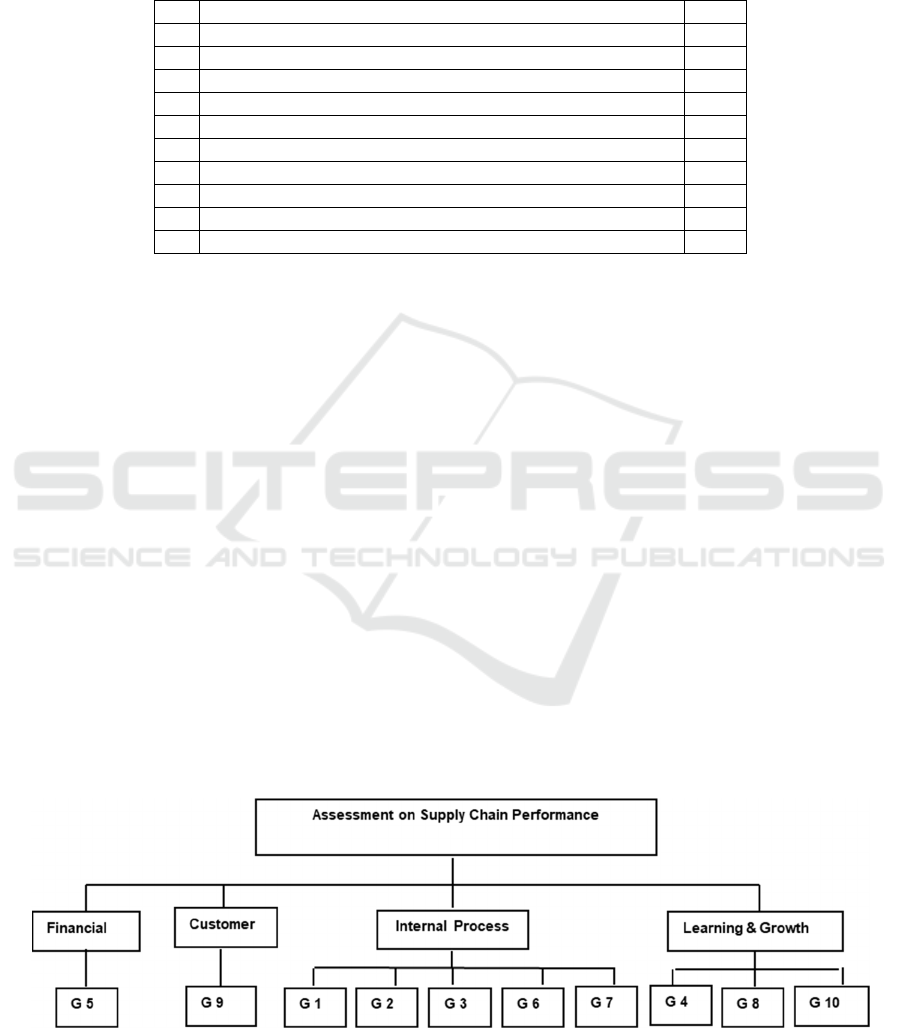

Table 1: KPI Supply Green Green Pespective.

No KPI Kode

1 Energy saving operation G1

2 Waste disposition G2

3 The use of material which can be recycled G3

4 Cooperate with certified suppliers G4

5 Environmental costs G5

6 Air and water emission G6

7 The use of substances that are not dangerous G7

8 Frequency reduction for environmental accidents G8

9 The level of customer interest in friendly enviornment products G9

10 Efficiency of recycle G10

3.2 KPI Grouping in the Balanced

Scorecard (BSC) Perspective

The formulated KPIs are then grouped into a BSC

perspective consisting of financial, customer,

internal process business and learning & growth

perspectives. This is done to make it easier to do a

pairwise comparison of each indicator where the

pairwise comparison is done for each KPI that is in

the same group in the perspective of the BSC.

Financial perspective is related to how to serve the

shareholders who specifically use the measurement

of cash flow, return on capital, sales and income

growth. Customer perspective is related to the level

of customer satisfaction that specifically adds

measurements related to the level of damage, on-

time delivery, warranty support, product

development, and others derived from direct

customer input and linked to company-specific

activities. The internal perspective of business

processes and learning and growth is related to the

main competencies and areas of operating

excellence that have effective implementation as

measured by productivity, cycle times, quality

measurements, unproductive periods, various cost

measurements and others that are input to this

perspective.

The learning and growth perspective is related to

continuous improvement and value creation that

emphasizes measurements related to innovation and

organizational learning to calculate performance in

this dimension, leadership, technology, product

development cycle times, improved operating

processes, and others. The grouping of KPIs is done

by matching the understanding of each KPI to the

understanding and scope of each BSC perspective.

In addition, the grouping also refers to several

references related to the grouping of supply chain

KPIs against the BSC perspective. This grouping

can be done by structuring an integrated green

supply chain performance appraisal model in a BSC

perspective. The structure of the integrated green

supply chain performance appraisal model can be

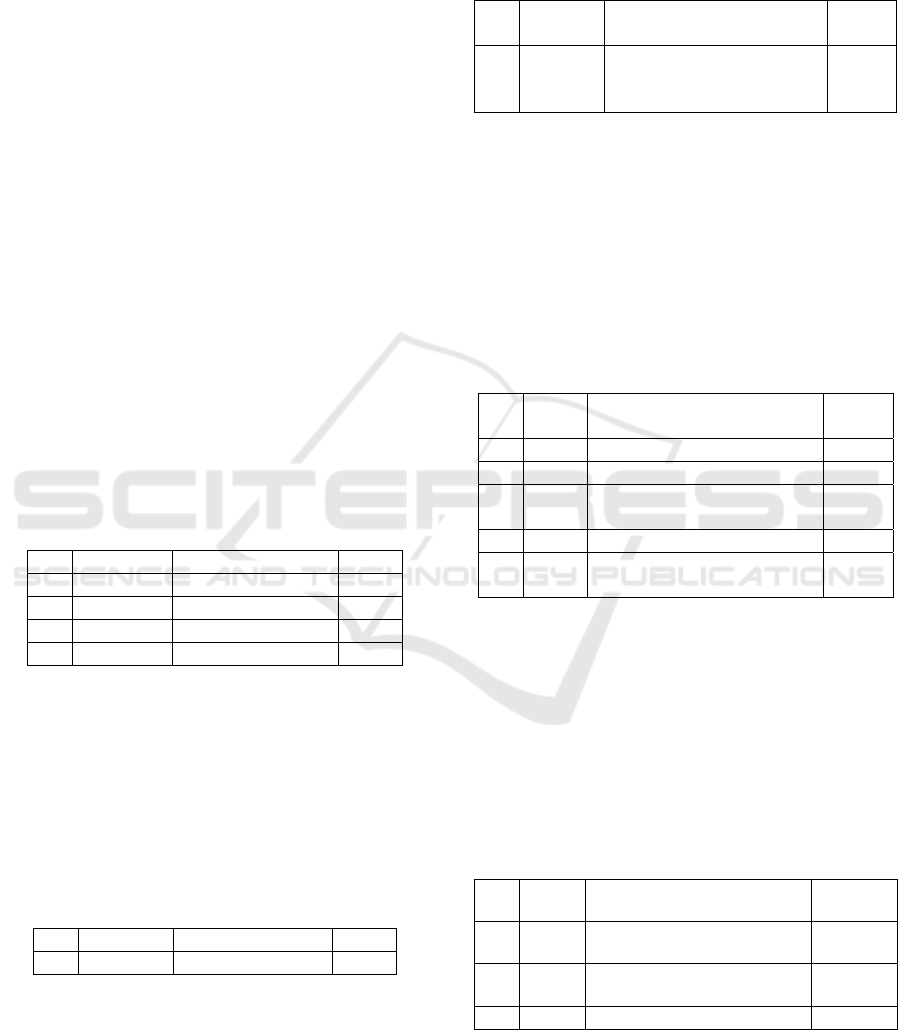

seen in Figure 1.

Figure 1: Structure of the integrated Green Supply Chain Performance Assessment Model in the BSC Perspective

.

Designing Performance Measurement Model for Green Supply Chain Pulp

81

3.3 Weighting of KPI

Weighting of KPI is done to determine the priority

level and interest of each KPI towards other KPIs.

This weighting is done by making a pairwise

comparison among KPIs using a weighting

questionnaire that is assessed by an expert at PT.

TPL, academics in the field of green supply chain

and pulp practitioners (distributors) of PT. TPL. This

pairwise comparison value is processed with the

help of expert choice software to determine the

weight value of each KPI. The higher the weight

value of a KPI, the higher the level of importance

compared to other KPIs. The weight of each KPI can

be accepted if the inconsistency ratio value is less

than 0.1. The inconsistency ratio value shows the

level of consistency of the expert in providing value

from pairwise comparisons for each KPI.

3.3.1 Indicator Weight in BSC Scope

The results of this weighting are obtained from

pairwise comparisons between the four perspectives,

namely financial perspective, customer, internal

business processes and learning and growth using

expert choice software. Weighting results can be

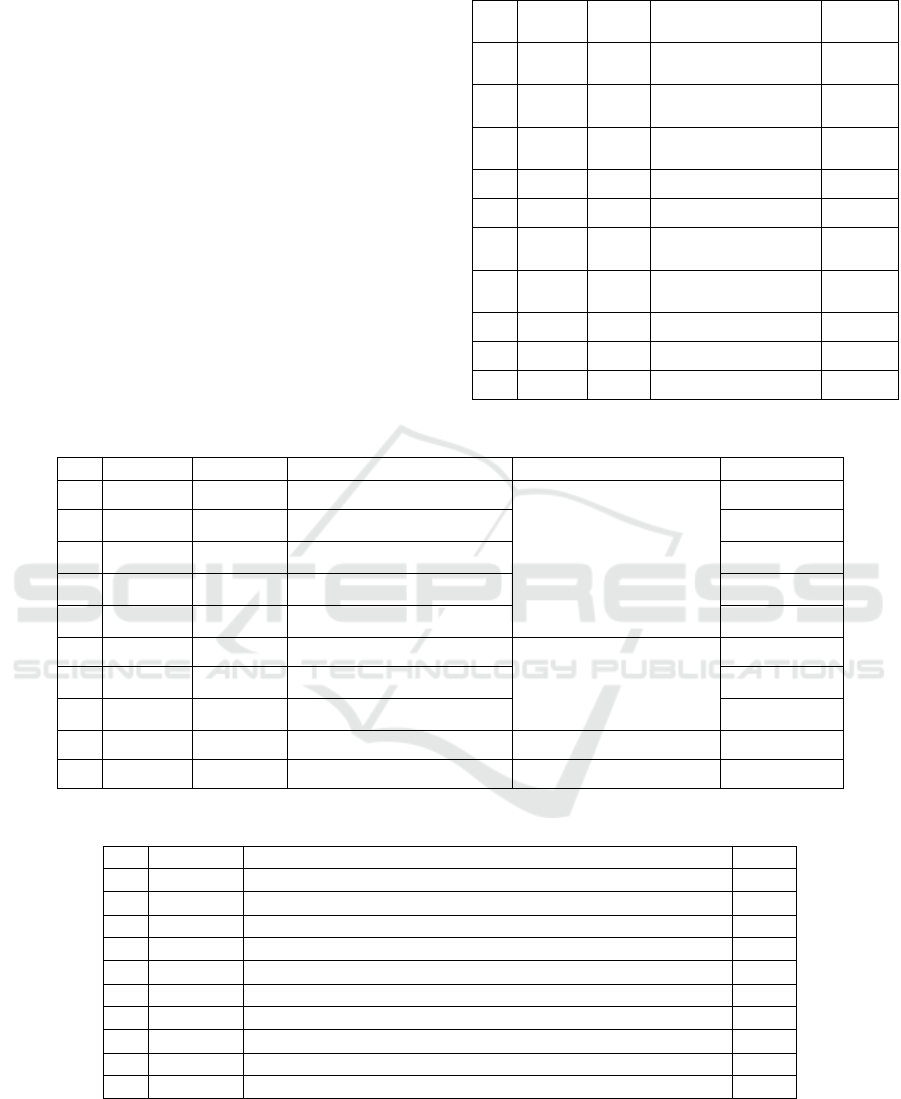

seen in Table 2.

Table 2: Indicator Weight in BSC Scope.

No KPI code Definition Score

1 F Financial 0,162

2 C Customer 0,487

3 IP Internal Process 0,223

4 LG Learning & Growth 0,127

3.3.2 Weight Indicators on the Financial

Perspective

The result of weighting in this financial perspective

is obtained from pairwise comparisons between

KPIs in a financial perspective using expert choice

software. Weighting results in can be seen in Table

3.

Table 3: Indicator Score in Financial Perspective.

No KPI code Definition Score

1 G 5 Environment Cost 0,1

3.3.3 Indicator Weight on the Customer

Perspective

The result of weighting on the customer's

perspective is obtained from pairwise comparisons

between KPIs in the customer's perspective using

expert choice software. Weighting results can be

seen in Table 4.

Table 4: Indicator Score in Customer Perspective.

No KPI

code

Definition Score

1 G 9 The level of customer

interest to the product of

friendly environment

0,1

3.3.4 Indicator Weight on the Internal

Process Business Perspective

The result of weighting in the internal business

process perspective is obtained from a pairwise

comparison between KPIs in the internal process

business perspective using expert choice software.

The results of this weighting can be seen in Table 5.

Table 5: Indicator Score in Internal Process Business

Perspective.

No KPI

code

Definition Score

1 G1 Energy saving operation 0,078

2 G2 Waste disposition 0,088

3 G3 The use of materials that can

be recycled

0,099

4 G6 Water and air emission 0,106

5 G7 The use of substances that

are not dangerous

0,094

3.3.5 Indicator Weight in the Learning and

Growth Perspective

The result of weighting in the learning and growth

perspective is obtained from pairwise comparisons

between KPIs in the learning and growth perspective

using expert choice software. The results of this

weighting can be seen in Table 6.

Table 6: Indikator Weight in Learning and Growth

Perspectives.

No KPI

code

Definition Score

1 G 4 Cooperate with certified

su

pp

liers

0,082

2 G 8 Frequency reduction for

environment accident

0,262

3 G10 Recycle efficiency 0,154

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

82

3.3.6 KPI Priorities based on Overall

Weighting Results

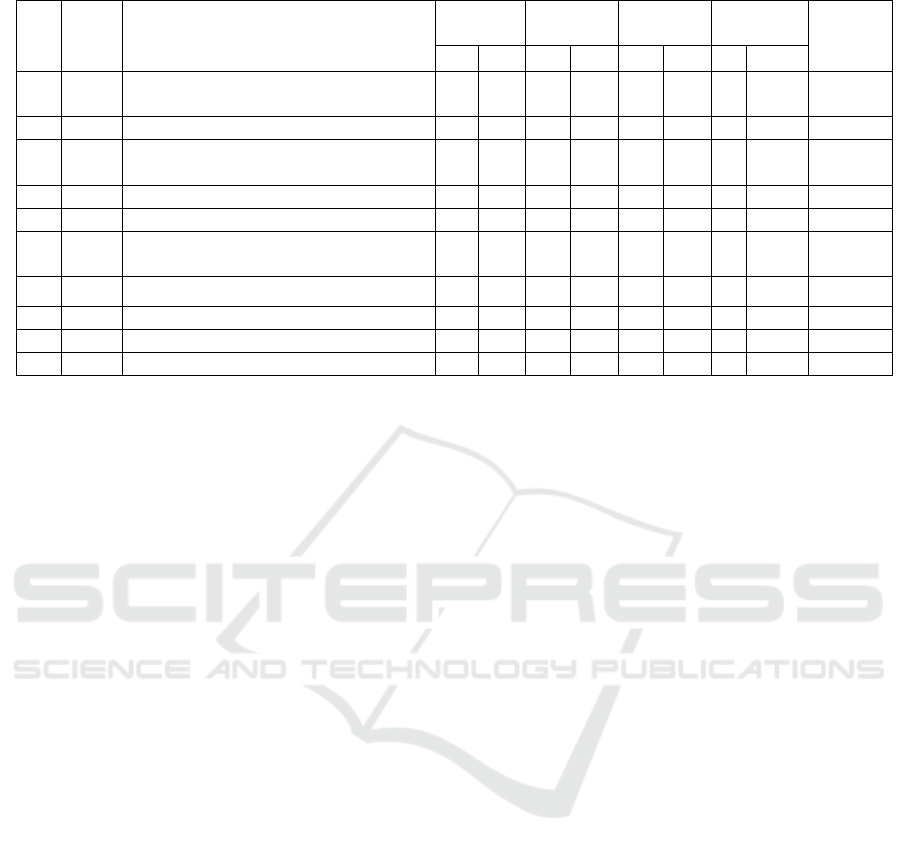

The weighting of the KPI as a whole is done by

multiplying the weight of each KPI with the weight

of the perspective where the KPIs are grouped. The

overall KPI weighting results can be seen in Table 7,

while the perspective of each KPI is determined

which can be seen in Table 8. Based on the overall

weight of each KPI, the KPI priority determination

is then carried out starting from the KPI that has the

highest weight to the KPI that has the lowest weight.

KPI priorities can be seen in Table 9.

Table 7: Score on overall KPI.

No KPI

code

KPI

score

Perspective Overall

Score

1 G 1 0,078 Internal Process &

Business

0,017

2 G 2 0,088 Internal Process &

Business

0,020

3 G 3 0,099 Internal Process &

Business

0,022

4 G 4 0,082 Learning & Growth 0,010

5 G 5 0,333 Financial 0,054

6 G 6 0,106 Internal Process &

Business

0,024

7 G 7 0,094 Internal Process &

Business

0,021

8 G 8 0,262 Learning & Growth 0,033

9 G 9 0,257 Customer 0,125

10 G 10 0,154 Learning & Growth 0,020

Table 8: Perspective of each KPI.

No KPI code KPI score Perspective Score of KPI perspective Overall Score

1 G 1 0,078 Internal Process & Business

0,104

0,017

2 G 2 0,088 Internal Process & Business 0,020

3 G 3 0,099 Internal Process & Business 0,022

4 G 6 0,106 Internal Process & Business 0,024

5 G 7 0,094 Internal Process & Business 0,021

6 G 4 0,082 Learning & Growth 0,063 0,010

7 G 8 0,262 Learning & Growth 0,033

8 G 10 0,154 Learning & Growth 0,020

9 G 9 0,257 Customer 0,125 0,125

10 G 5 0,333 Financial 0,054 0,054

Table 9: KPI Priorities.

No KPI code Definition Score

1 G9 The level of customer interest in friendly environment products 0,125

2 G5 Environment cost 0,054

3 G8 Frequency reduction for environment accident 0,033

4 G6 Water and air emission 0,024

5 G3 The use of material that can be recycled 0,022

6 G7 The use of substances that are not dangerous 0,021

7 G2 Waste disposition 0,020

8 G10 Recycle efficiency 0,020

9 G1 Energy Saving Operation 0,017

10 G4 Cooperate with certified suppliers 0,010

Designing Performance Measurement Model for Green Supply Chain Pulp

83

Table 10: Structure of the supply chain performance measurement model.

No

KPI

Code

Definition

Financial Customer

Internal

PB

Learning

&Growth

Weight

L G L G L G L G

1 G9

The level of customer interest in

friendly environment products

X

0,125

2 G5 Environment cost X

0,054

3 G8

Frequency reduction for environment

accident

X 0,033

4 G6 Water and air emission X

0,024

5 G3 The use of material that can be recycled X

0,022

6 G7

The use of substances that are not

dangerous

X

0,021

7 G2 Waste disposition X

0,020

8 G10 Recycle efficiency

X 0,020

9 G1 Energy Saving Operation X

0,017

10 G4 Cooperate with certified suppliers

X 0,010

Based on the structure of the model, it can be

seen the priority order of all KPIs starting from the

highest to the lowest based on the weight in BSC

perspective. KPI with the highest priority means that

this KPI is a critical KPI, namely KPI which has a

major contribution to the overall supply chain

performance. Based on this, the company can

determine the right policies to achieve the

effectiveness and efficiency of its supply chain.

3.4 Structure of the Supply Chain

Performance Measurement Model

Green supply chain performance measurement

model with a BSC perspective is designed in the

form of metrics. These performance measurement

metrics can be seen in Table 10. Customer

perspective is a priority based on this research. This

is evident from the three KPIs in the highest order of

weight in the supply chain performance appraisal

metric designed, namely quality improvement, level

of customer satisfaction and level of customer

interest in friendly environmental products.

In this case, it can be seen that important aspects

which are prioritized by PT. TPL is the fulfillment

of customer needs in accordance with the company's

mission. When viewed in terms of green, the

company also prioritizes cement as an friendly

environmental product that is in demand by

customers. This is also in accordance with the vision

of the company "to be a reliable, superior and

friendly environmental pulp industry".

3.5 Validation

Validation is a step that needs to be done to explain

that the supply chain performance measurement

model designed is feasible to be applied to a real

system. The aspects considered in the model

validation process are as follows:

1. KPI in accordance with the real conditions of PT.

TPL and representative.

2. KPI contained in the model can be measured its

performance in pulp supply chain activities.

3. The priority order of the KPI contained in the

model is a KPI that truly becomes a critical indicator

for the supply chain performance of PT. TPL.

4. The supply chain performance measurement

model designed can be implemented in PT. TPL to

measure the effectiveness and efficiency of pulp

supply chains.

The validation results show that the supply chain

performance measurement model designed is valid

and can be accepted by PT. TPL. This model can be

implemented to measure the performance of a

company's supply chain. Performance measurement

is carried out to see the effectiveness and efficiency

of the supply chain. The priority aspect is the

consumer aspect to increase value in order to

achieve pulp consumer satisfaction. This is

consistent with the results of determining priorities

carried out on all KPIs. The third highest priority

weighting value of all KPIs shows that improving

the quality and level of customer satisfaction with

environmentally friendly products must be a priority

on the company's target. It is also recognized by the

company that creating quality pulp with minimal

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

84

environmental impact is an important demand from

current pulp consumers.

3.6 Model Implication

The implementation of the supply chain

performance measurement model can be carried out

through the following stages:

1. Collecting data related to KPIs according to

the designed supply chain performance measurement

model.

2. Making Standard Operating Procedure to

measure the performance of the cement supply chain

and make the forms needed in measuring and

documenting the results of performance

measurements.

3. Measuring the performance of the cement

supply chain at PT. TPL and document the results of

these performance measurements.

4. Determining the right policies on the supply

chain performance of PT. TPL is based on the

results of performance measurements that have been

made for each KPI.

4 CONCLUSIONS

This research has produced a set of KPIs obtained

from the integration of the green concept in the pulp

supply chain at PT. TPL. The results of integration

are as follows:

1. KPI Formulation of 10 green supply chain of

KPIs. This KPI is an important indicator that can

answer the needs of all stakeholders involved in the

pulp supply chain at PT. TPL in terms of cost

reduction and environmental impact.

2. KPI grouping in four BSC perspectives, namely

financial perspective, perspective, internal business

process and learning and growth perspective. The

total of 10 KPI can be grouped, namely 1 KPI for

financial perspective, 1 KPI for customer

perspective, 5 KPI for internal business process

perspective and 3 KPI for learning and growth

perspective.

3. Determination of overall KPI priorities is done by

sorting KPIs starting from those with the highest

weight to the lowest weight. KPI which has the

highest priority means that this KPI is a KPI that has

a major influence on the performance of the

company's supply chain. In this study, the customer

perspective is the priority as evidenced from the 1

KPI in the highest order of weight in the valuation

model.

REFERENCES

Chopra, S., & Peter, M. (2007). Supply Chain

Management, Strategy Planning & Operation (3rd

ed.). Pearson Prentice Hall.

Duarte, S., Cabrita, R., & Machado, V. C. (2011).

Exploring Lean and Green Supply Chain Performance

Using Balanced Scorecard Perspective. Proceedings of

the 2011 International Conference on Industrial

Engineering and Operations Management, 520–525.

Kaplan, R. S., & Norton, D. P. (1996). Translating

Strategy Into Action: The Balance Scorecard. Harvard

Business School Pres.

Mudgal, R. K., Shankar, R., Talib, P., & Raj, T. (2009).

Greening the supply chain practices: an Indian

perspective of enablers`relationship. International

Journal Advanced Operations Management, 1(2/3),

151–176.

Pujawan, I. N. (2005). Supply Chain Management.

Gundawidya.

Shang, K. C., Lu, C. S., & Li, S. (2010). A taxonomy of

green supply chain management capability among

electronics-related manufacturing firms in Taiwan.

Journal of Environmental Management, 91(5), 1218–

1226.

Zhu, Q., & Sarkis, J. (2006). An Inter-Sectoral

Comparison of Green Supply Chain Management in

China: Drivers and Practices. Journal of Cleaner

Production, 14, 472–486.

Designing Performance Measurement Model for Green Supply Chain Pulp

85