Corrosion Inhibitors Activity of Schiff Base from Condensation of

Ethylenediamine with Furfural from Sugarcane Bagasse

Mimpin Ginting, Dasron Bulolo, Herlince Sihotang

and Indra Masmur

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Schiff Base, Ethylenediamine, Furfural, Corrosion Inhibitor, Zinc.

Abstract: Schiff Base from condensation of ethylenediamine as the source of primary amine with furfural from

sugarcane bagasse as the source of carbonyl has been synthesized and tested for its corrosion inhibitors

activity. The yield of furfural from 100 g of sugarcane bagasse is 12.6 g. Qualitative analysis shows the

existence of furfural in brick red colour by using aniline : acetic acid (1:1 v/v) as solvent. FT-IR

Spectroscopy shows vibration in wavenumber 1677 cm

-1

as C=O and 1573 cm

-1

as cyclic C=C.

Condensation 9.6 g of furfural with 2.4 g of ethylenediamine in reflux condition for 5 hours using ethanol as

solvent yields 8.64 g (70.55%) of Schiff Base. FT-IR Spectroscopy for Schiff Base analysis shows vibration

of –C=N- in 1647 cm

-1

. The test of corrosion inhibitor activity is by weighting the decrease mass of zinc in

HCl 0.1 N with concentration 7000 ppm for each compound. The efficiency value of corrosion inhibitor are

69.06% for furfural, 53.67% for ethylenediamine, and 82.20% for synthesized Schiff Base.

1 INTRODUCTION

Sugarcane bagasse is a solid part of cane from

extracted cane stem. Sugarcane bagasse consists of

C (carbon) 47%, H (hydrogen) 6.5%, O (oxygen)

44%, and ash 2.5%. Based on Pritzelitz formula

(Hugot, 1986) every kilogram of sugarcane bagasse

contains 2.5% sugar which produce 1825 kcal/kg.

Composition of sugarcane bagasse are 3.82% ash,

22.09% lignin, 37.65% cellulose, 27.97% pentosan,

3.01% silica, and 3.3% reduction sugar. Basically,

fiber of sugarcane bagasse consists of cellulose,

pentosan, and lignin. Composition of each

component is vary depend on the variety of cane

(Mubin & Ratnanto, 2005) Sugarcane bagasse also

contains polysaccharides which can be converted

into many industry production. One of

polysaccharides components in sugarcane bagasse is

pentosan (20-27%).

With high concentration, pentosan from

sugarcane bagasse can be converted into furfural.

Furfural has aldehyde carbonyl functional group

which can be transformed into its derivatives like

alcoholic furfuryl, furan, etc. Schiff Base is one of

organic compounds which contain imine (-HC=N-)

which can be synthesized from condensation of

carbonyl group like aldehyde or ketone with primary

amine (Cinerman et al., 1997). Schiff Base is one of

organic compound with many uses. It can be use as

pigment and dye, catalyst, intermediate in organic

synthesize, and polymer stabilizer (Dhar & Thappo,

1982). Some of research have found that Schiff Base

can be used as corrotion inhibitor for metal which

spontaneously form a layer to protect materials and

friendly environmentally (Li et al., 1999). Previous

researchers have synthesized Schiff Base from

cynnamaldehyde with 2-aminophenol as corrotion

inhibitor for iron in HCl 0.5 N as media with

inhibitor efficiency 92% (Qasim, 2011). Schiff Base

from condensation of cynnamaldehyde as the source

of carbonyl with ethylenediamine as the source of

amine in concentration 7000 ppm for zinc in HCl

0.1N as media with inhibitor efficiency 90.17%

(Ginting et al., 2016). Corrotion is a decrease quality

of metal because electrochemical reaction with

environment. (Trethewey and Chamberlain,

1991).Corrotion is a big problem for metal-formed

material thing like car, bridge, ship machine, etc

(Riegher, 1992). Metals can be broken and lost its

function because of corrotion. Corrotion in many

things can not be prevented but the rate of corrotion

can be inhibited (Callister, 1991). Based on the

descrioption, we interest to synthesize Schiff Base

from furfural from sugarcane bagasse isolation

wirhethylenediamine. The result obtained is

expected has corrotion inhibitor activity and can be

tested in rusty zinc with HCl 0.1 M as media.

Ginting, M., Bulolo, D., Sihotang, H. and Masmur, I.

Corrosion Inhibitors Activity of Schiff Base from Condensation of Ethylenediamine with Furfural from Sugarcane Bagasse.

DOI: 10.5220/0010136500002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 71-77

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

71

2 RESEARCH METHODOLOGY

2.1 Materials and Methods

Used equipments in this research are : condenser,

hotplate stirrer, thermometer, vacuum distillation

tools, analytical balance, UV-Vis

Spectrophotometer, FT-IR Spectrophotometer,

desiccators, and glasswares. Then used materials in

this research are sulfuric acid (p.a), ethanol (p.a),

ethylenediamine (p.a), furfural, zinc plate, aquadest,

sugarcane bagasse, sodium chloride (p.a), and

hidrocloric acid (p.a).

2.2 Isolation of Furfural from

Sugarcane Bagasse

Put 100 grams of dried sugarcane bagasse in one-

neck flask 250 ml then add 100 grams of NaCl and

H

2

SO

4

10% until sink and stir until homogeneous.

Arrange distillation tools and reflux the mixture for

5 hours in 106

o

C. Furfural and water will be

condensed to distillation flask then put the drop of

liquid into Erlenmeyer which contain chloroform.

Furfural will be soluted in chloroform and water will

be separated in two layers (top layer is water and

bottom layer is furfural/chloroform). The mixture of

water and chloform is separated by dropping funnel.

Then, add 1 gram Na

2

SO

4

anhidrous to chloroform

layer to separate water and filter it. The filtrate then

distillate in 61

o

C-65

o

C to evaporate chloroform.

Furfural residue is purified by vacuum distillation

where furfural is in destilate form in 130

o

C/8

mmHg. Identify the colour by using aniline acetate

(1:1 v/v) as solvent, then analysed by UV-Vis

Spectrophotometer and FT-IR Spectrophotometer.

2.3 Synthesize Schiff Base from

Condensation of Furfural with

Ethylenediamine

Put 9.6 grams (0.1 mol) of furfural in two neck flask

250 ml then soluted with 25 ml ethanol absolute.

Arrange reflux tools with magnetic bar,

thermometer, and water trap. Put 2,4 grams (0.04

mol) of ethylenediamine which soluted with 25 ml

ethanol absolute and drop slowly by dropping funnel

and stir with reflux condition for 5 hours. The

solution then evaporate by rotaryevaporator, then

excess furfural is evaporated by vacuum distillation.

Then, dry residue from evaporation in desiccators

and weight on analytical balance and analyse by FT-

IR Spectroscopyparagraphs.

2.4 Determination of Inhibitor

Efficiency

Soaking solution for zinc plate is taken from

inhibitor solution 1000 ppm, put 150 ml in a

glassware. Soak sanded zinc 5 cm x 1 cm in the

solution for 24 hours. Take the plate from media,

wash carefully, then dry for 5 minutes and weigh the

final weight. Calculate inhibitor efficiency by using

this formula (Chitra et al., 2010):

%EI

W

W

W

100%

Where

EI = Inhibitor Efficiency

W

0

= The lost of weigh without inhibitor use

W

1 =

Thelost of weigh with inhibitor use

As comparation (control) use solution without

inhibitor. With the same procedure, do the same

thing with corrotion inhibitor variation 3000 ppm,

5000 ppm, and 7000 ppm in 48, 72, 96, and 120

hours. Do the same procedure for furfural,

ethylenediamine, and Schiff Base.

3 RESULT AND DISCUSSION

3.1 Isolation of Furfural

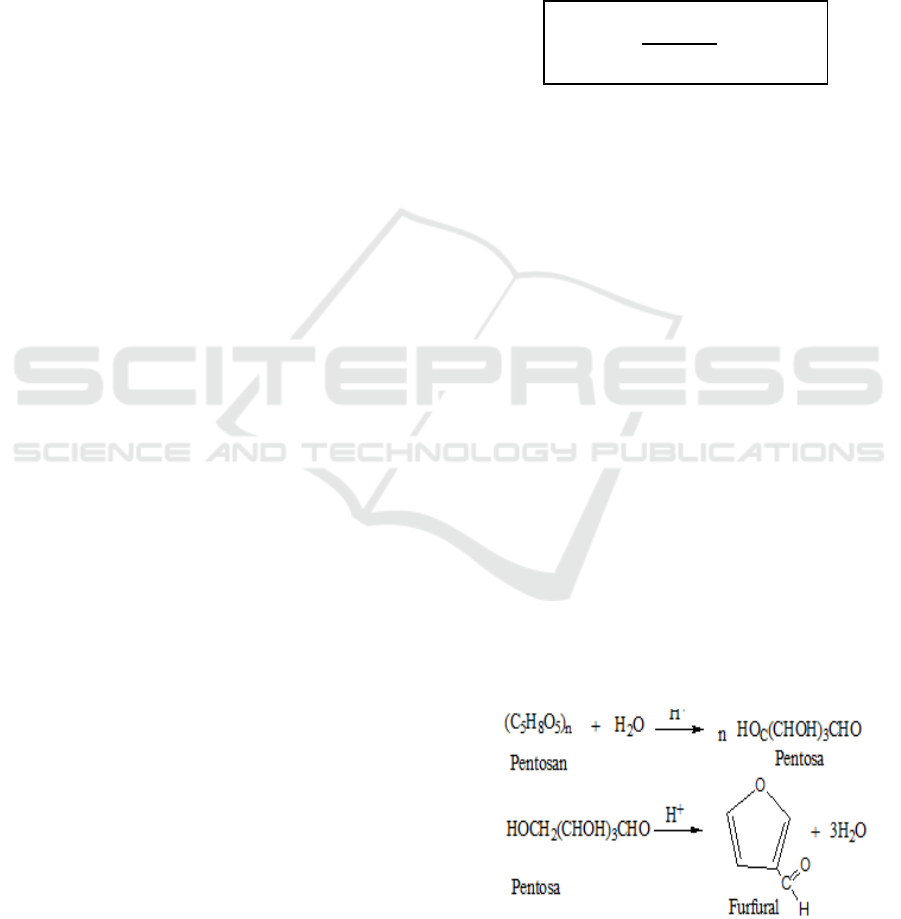

Isolation of furfural is by hydrolysis pentosan from

sugarcane bagasse to pentose by HCl and

dehydration pentose by sulfuric acid to form

furfural. Qualitative analysis for furfural by use

aniline acetate shows brick red colour. 100 g

sugarcane bagasse yields 5.2 g (5.2%) furfural. HCl

is produced by reaction between NaCl with excess

H

2

SO

4

then excess H

2

SO

4

is used as dehydrator to

form furfural (figure 1).

Figure 1: Furfural Formation Reaction.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

72

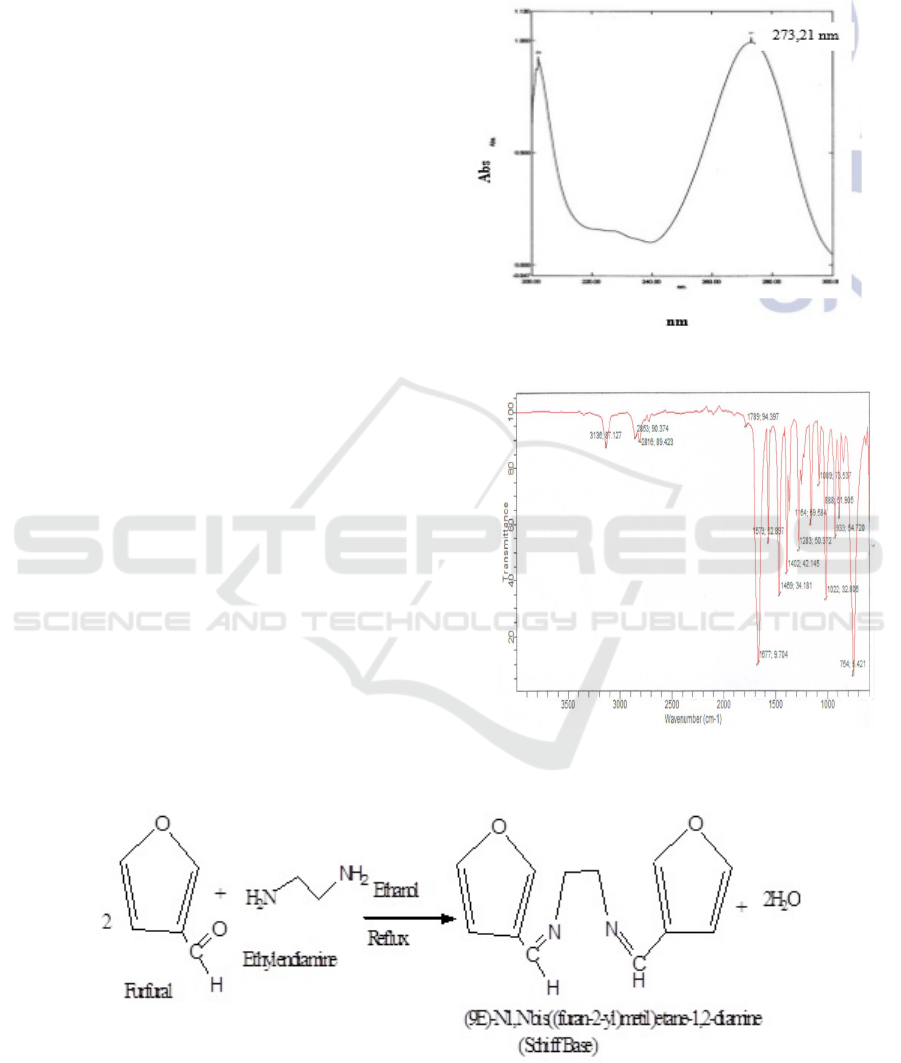

UV-Vis spectroscopy analysis shows λmax in 273.1

nm which indicate furfural have conjugated diene

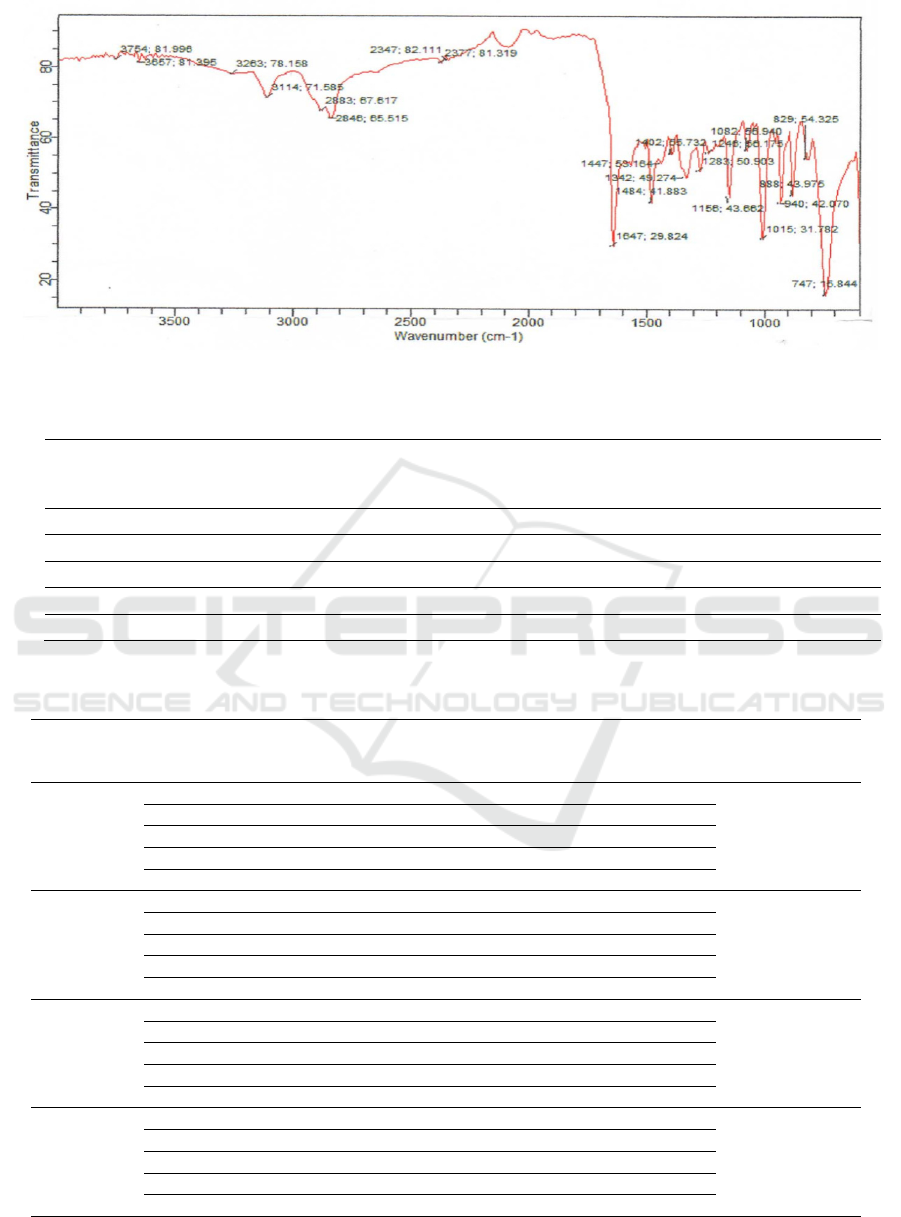

bond (picture 2). FT-IR Spectroscopy result for

furfural shows spectrum peak in 3100 cm

-1

for

stretching aromatic C-H, 2900-2800 cm

-1

for

stretching C-H aldehyde, 1740-1720 cm

-1

for

stretching C=O, 1600-1475 cm

-1

for aromatic C=C,

1300-1000 cm

-1

for stretching C-O-C, and 1500-

1300 cm

-1

for bending C-H aldehyde (figure 3).

3.2 Synthesize of Schiff Base (9E)-

N

1

,Nbis((furan-2-yl)metil)etane-1,2-

diamine from Condensation of

Furfural with Ethylenediamine

Schiff Base is produced by condensation between

furfural and ethylenediamine as the Schiff Base is

produced by condensation between furfural and

ethylenediamine as the source of primary amine with

ethanol as the solvent reflux for 5 hours (picture 4).

The product then purified by vacuum distillation.

Condensation of 9.6 g (0.1 mol) furfural with 2.4 g

(0.04 mol) ethylenediamine yields 8.64 g (70.55%)

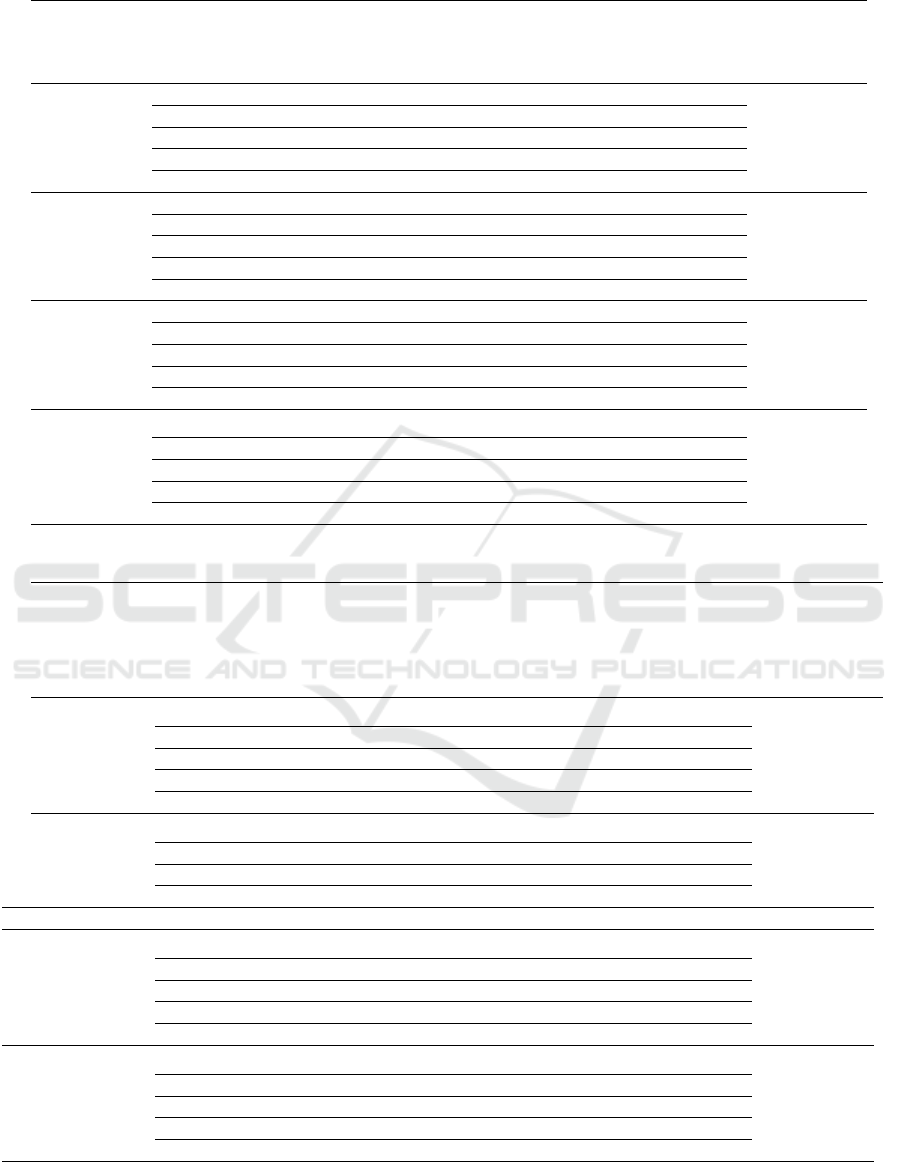

Schiff Base. Spectroscopy analysis for Schiff Base is

indicated by vibration peak in 1647 cm

-1

as –HC=N

3.3 Corrotion Inhibitor Efficiency

Calculation

Inhibitor efficiency is tested by soaking zinc plate in

corrotion media solvent HCl 0.1 N by using furfural,

ethylenediamine, Schiff Base as inhibitor and media

without inhibitor. Time variation are 24 hours, 48

hours, 72 hours, 96 hours, and 120 hours. Variation

of inhibitor concentration are 1000 ppm, 3000 ppm,

5000 ppm, and 7000 ppm. Average inhibitor

efficiency value can be look in table 1, 2, 3, and 4

source of primary amine with ethanol as the solvent

reflux for 5 hours (picture 4). The product

Figure 2: UV-Vis Spectrum for Isolated Furfural.

Figure 3: FT-IR Spectrum for Furfural.

Figure 4. Formation and reaction of Schiff Base by condensation furfural with ethylenediamine.

Corrosion Inhibitors Activity of Schiff Base from Condensation of Ethylenediamine with Furfural from Sugarcane Bagasse

73

Figure 5: FT-IR Spectrum of Schiff Base (9E) )-N

1

,N

2

-bis((furan-2-yl)methyl)etane-1,2-diamine.

Table 1: Result of Zinc Plate Soaking without inhibitor in Corrosive Media Solution HCl 0.1 N.

Inhibitor

Concentration

(ppm)

Soaking

Time

(hours)

Zinc

Initial

Weight (g)

Zinc

Final

Weight (g)

Lost of

Weight

(g)

Inhibitor

Efficiency

(%)

0 24 2.9909 2.8811 0.1098

0 48 3.3514 3.2309 0.1205

0 72 3.2925 3.1623 0.1302

0 96 3.2750 3.1047 0.1703

0 120 3.2957 3.0613 0.2344

Table 2: Result of Zinc Plate Soaking with Schiff Base (9E)-N

1

,N

2

-bis((furan-2-yl)methyl)etane-1,2-diamine as inhibitor in

Corrosive Media Solution HCl 0.1 N.

Inhibitor

Concentratio

n

(ppm)

Soaking

Time

(hours)

Zinc Initial

Weight (g)

Zinc Final

Weight (g)

Lost of

Weight (g)

Inhibitor

Efficiency

(%)

Average Inhibito

r

Efficiency (%)

1000

24 3.503

1

3.4522 0.0509 53.64

49.48

48 3.422

1

3.3644 0.0577 7.38

72 3.334

2

3.2548 0.0794 39.01

96 3.302

1

3.2518 0.0503 70.46

120 3.235

8

3.1817 0.0541 76.91

3000

24 3.213

3

3.2133 0.0381 68.38

59.71

48 3.110

6

3.0612 0.0494 55.00

72 3.124

4

3.0580 0.0664 61.00

96 3.752

5

3.6832 0.0693 70.43

120 2.410

5

2.3373 0.0732 43.77

5000

24 3.277

7

3.2540 0.0237 71.41

77.88

48 3.514

9

3.4819 0.033 72.61

72 3.516

7

3.4827 0.034 73.88

96 3.386

0

3.3544 0.0316 81.44

120 3.512

5

3.4729 0.0396 83.10

7000

24 3.253

0

3.2310 0.022 79.96

82.20

48 3.641

4

3.6119 0.0295 75.51

72 3.112

1

3.0912 0.0209 83.94

96 3.556

6

3.5214 0.0352 79.33

120 3.134

7

3.1166 0.0181 92.27

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

74

Table 3: Result of Zinc Plate Soaking with Furfural as Inhibitor in Corrosive Media Solution HCl0.1 N.

Inhibitor

Concentration

(ppm)

Soaking

Time

(hours)

Zinc

Initial

Weight(g)

Zinc

Final

Weight (g)

Lost of

Weight

(g)

Inhibitor

Efficiency

(%)

Average

Inhibitor

Efficiency

(%)

1000

24 2.3305 2.2880 0.0425 61.29

45.60

48 2.1419 2.0972 0.0447 60,90

72 3,5105 3.4533 0.0572 56.06

96 3.6501 3.5012 0.1489 12.56

120 3.4551 3.3033 0.1518 35.23

3000

24 3.0941 3.0357 0.0584 46.81

51.10

48 3.2933 3.2139 0.0794 34.10

72 3.3144 3.2519 0.0625 51.99

96 3.9606 2.8909 0.0697 59.07

120 3.5411 3.4557 0.0854 63.56

5000

24 3.1454 3.0964 0.049 55.37

62.89

48 3.1520 3.1012 0.0508 57.84

72 3.1358 3.0822 0.0536 58.83

96 3.1314 3.0757 0.0557 67.29

120 3.2515 3.1932 0.0583 75.12

7000

24 3.2219 3.1844 0.0375 65.84

69.06

48 3.2116 3.1737 0.0379 68.54

72 3.0415 3.3572 0.0443 65.97

96 3.1725 3.1240 0.0485 71.52

120 3.1443 3.0821 0.0622 73.46

Table 4: Result of Zinc Plate Soaking with Ethylenediamine as Inhibitor in Corrosive Media Solution HCl 0.1 N.

Inhibitor

Concentration

(ppm)

Soaking

Time

(hours)

Zinc

Initial

Weight (g)

Zinc

Final

Weight (g)

Lost of

Weight

(g)

Inhibitor

Efficiency

(%)

Average

InhibitorEffic

iency

(%)

1000

24 3.2418 3.1862 0.0556 49.36

40.35

48 3.1776 3.1082 0.0694 42.40

72 3.5145 3.4373 0.0772 40.70

96 3.3858 3.3010 0.0848 50.20

120 3.3211 3.1315 0.1896 19.11

3000

24 3.3116 3.2486 0.0630 42.62

43.88

48 3.3355 3.2551 0.0804 33.27

72 3.3845 3.3143 0.0702 46.08

96 3.5643 3.4665 0.0978 42.57

120 3.3442 3.2385 0.1057 54.90

5000

24 3.5110 3.4312 0.0789 28.14

49.02

48 3.3651 3.3120 0.0531 55.93

72 3.2741 3.2114 0.0627 51.84

96 3.3315 3.2418 0.0897 47.32

120 3.1308 3.0415 0.0893 61.90

7000

24 3.2182 3.1887 0.0295 73.13

53.67

48 3.3888 3.2080 0.0808 32.94

72 3.4141 3.3215 0.0926 28.87

96 3.2388 3.1811 0.0577 66.11

120 3.2146 3.1380 0.0766 67.32

Corrosion Inhibitors Activity of Schiff Base from Condensation of Ethylenediamine with Furfural from Sugarcane Bagasse

75

3.4 Result of Determination Inhibitor

Efficiency

Determination of corrotion inhibitor efficiency is by

soaking zinc plate in HCl 0.1 N as media for 24, 48,

72, 96, and 120 hours with concentration variation

1000 ppm, 3000 ppm, 5000 ppm, and 7000 ppm.

Efficiency inhibitor is tested in zinc because it is an

active metal and always used in industry (Shah et al.,

2011). The metal will be reduced and oxidized.

3.5 The Effect of Soaking Time to the

Lost Weight of Zinc in Corrotion

Media HCl 0.1 N

The effect of soaking time to the corrotion increase

in HCl 0.1 N based on variation time 24, 48, 72, 96,

and 120 hours is very high. It proves that hidrocloric

acid solution is a corrosive media. The speed of

corrotion for zinc is parallel with the length of

soaking time (table 1).

3.6 The Effect of Inhibitor

Concentration to the Lost Weight

of Zinc in Corrosive Solution

Media HCl 0.1 N

The increase of inhibitor concentration is parallel

with the decrease of lost weight in zinc. It is because

adsorption of inhibitor molecules in the surface of

zinc platecan form shielding layer from free electron

in atoms like O, N, and phi bonding which limit O

2

diffusion in zinc surface.

3.7 The Effect of Increasing Inhibitor

Concentration to Inhibitor

Efficiency in Zinc Plate with HCl

0.1 N as Corrotion Media

Inhibitor compounds in this research are furfural,

ethylenediamine, and Schiff Base. The compounds

are active as corrotion inhibitor. Inhibitor efficiency

is increase parallel with the increase of inhibitor

concentration in HCl 0.1 N as corrosive media.

Figure 7: Graph of The Effect of Inhibitor Concentration

to Inhibitor Efficiency.

4 CONCLUSSIONS AND

SUGGESTIONS

4.1 Conclusions

Based on the research result and data analysis, the

conclusions are:

1. Schiff Base can be synthesized by condensation

ethylenediamine with furfural from sugarcane

bagasse. The percentage of furfural from

sugarcane bagasse is 5.2%. The rendemen of

Schiff Base is 70.55%.

2. The result of Inhibitor efficiency test for zinc in

HCl 0. 1 N as corrosive media with concentration

7000 ppm are 82.20% for Schiff base, 53.67% for

ethylenediamine, and 69.06% for furfural.

4.2 Suggestions

The next researcher is expected to compare Schiff

base efficiency from furfural with another primary

amine source and the test of corrotion inhibitor in

metal with many corrosive media.

REFERENCES

Callister, W. D. (1991). Material Science and

Enggineering.An Introduction (2nd ed.).

Chitra, S., Parameswari, K., & Selvaraj, A. (2010).

Dianiline Schiff Base as Inhibitor of Mild Stell

Corrosion in Acid Media. Int. J. Electro Chemistry,

5(11), 1675–1697.

0

10

20

30

40

50

60

70

80

90

1000 3000 5000 7000

EficiencyInhibitor(%)

ConcentrationofInhibitor(ppm)

Ethylenediamine

Furfural

SchiffBase

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

76

Cinerman, Z., Galic, N., & Bosner, B. (1997). No Title.

..Anal.Chim.Acta., 343(1997), 145–151.

Dhar, D. N., & Thappo, C. L. (1982). Schiff Bases and

their Aplications. J. Sci. Ind. Res, 41(8), 501–506.

Ginting, M., Sihotang, H., & Manalu, R. (2016). Sintesis

Basa Schiff dari Hasil Kondensasi Sinama ldehida

Dengan Etilen diamina dan Fenil Hidrazin dan

Pemanfaatannya Sebagai Inhibitor Korosi Pada Logam

Seng. Prosiding Semirata, 1992–1998.

Hugot. (1986). Handbook of Cane Sugar Enginering (3rd

ed). Elsevier.

Li, S., Chen, S., Ma, H., Yu, R., & Liu, D. (1999).

Investigation on some Schiff bases as HCl

corrosioninhibitors for copper. Corrosion Science,

41(7), 1273–1287.

https://doi.org/https://doi.org/10.1016/S0010-

938X(98)00183-8

Mubin, A., & Ratnanto, F. (2005). Upaya Penurunan

Biaya Produksi dengan Memanfaatkan Ampas Tebu

sebagai Pengganti Bahan Penguat dalam Proses

Produksi Asbes Semen, Jurnal teknik Gelagar . 16(1),

10–19.

Qasim, M. (2011). Synthesis and characterization of new

Schiff bases and evaluation as Corrosion Inhibitor.

Riegher, H. . (1992). Electro chemistry. Chapman and

Hall Inc.

Shah, M. ., Patel, A. ., Mudaliar, G. ., & Shah, N. . (2011).

Schiff Bases of Triethylenetetramine as Corrosion

Inhibitors of Zinc in Hydrochloric Acid. Chemistry

Departement School of Sciences, Gujarat

University:Ahmedabad.

Corrosion Inhibitors Activity of Schiff Base from Condensation of Ethylenediamine with Furfural from Sugarcane Bagasse

77