A New Adsorbent Chitosan-based That Modified using

Epichlorohydrin and Diethylene Triamine for Treating Heavy Metal

(Cu

2+

, Zn

2+

and Fe

2+

)

Silitonga Regina Dewi

1

, Ginting Mimpin

1

and Kaban Jamaran

2

1

Postgraduated Chemistry Study Programme, Universitas Sumatera Utara, Medan, Indonesia

2

Department of Chemistry, Universitas Sumatera Utara , Medan, Indonesia

Keywords: Adsorption, Chitosan, Diethylen Triamin, Epichlorohydrin, Grafting, Heavy Metal

Abstract: In the current study, chitosan was modified using epichlorohydrin and diethylene triamine. Grafting

diethylene triamine chitosan is synthesized through alkylation of chitosan with epichlorohydrin and

followed by amination with diethylene triamine. The formation of chitosan grafted diethylene triamine was

confirmed using FT-IR spectrum which has a band at 1581 cm

-1

that assigned as C-N-C (secondary amine).

The morphological analysis using SEM showed the surface became smoother after grafting process. As

adsorbent, the chitosan grafted diethylene triamine had the adsorption capacity 72, 67, and 63 ppm for Cu

2+

,

Zn

2+

, and Fe

2+

, respectively.

1 INTRODUCTION

As a developing country, the government set the

industrial sector to be the first priority. The growth

of new industries gives many negative impacts to the

environment, in the form of solid and liquid waste

that quite dangerous for human (Cahayaningrum et

al., 2011). In the study that conducted by Laksono et

al. (2008), in the solid or liquid waste it will be

common to obtain the presence of heavy metal

waste, as the example in the painting industry, in the

liquid waste will be found the ion of Cu, Fe, Cr, Ni,

and Zn.

The current pattern of industrial activity alters

the natural flow of materials and introduces novel

chemicals into the environment (Faisal & Hasnain,

2004). The rate at which effluents are discharged

into the environment especially water bodies have

been on the increase as a result of urbanization.

Most of these effluents contain toxic substances

especially heavy metals. The presence of heavy

metals in the environment is of major concern

because of their toxicity, bio-accumulating tendency,

threat to human life and the environment (Horsfall &

Spiff, 2005; Igwe & Abia, 2003).

Several treatments have been developed to solve

this kind of issue, i.e. precipitation, ion exchange

resin, filtration, and adsorption (Tangio, 2013).

Adsorption technique is the quite effective method

because of the low operational cost, high efficiency

and easy method for regenerating (Juir et al., 2017).

This method can be done by utilizing natural

polymers (biopolymers) as an adsorbent with one of

them, namely chitosan (Schumul et al., 2001).

Chitosan is the result of deacetylation of chitin

that commonly found in crabs, shrimp and squid

(Bhatnaga & Sillanpaa, 2009). Chitosan consist of

glucosamine unit and N-acetyl glucosamine unit

(Ngah & Fatinathan, 2010). Chitosan as an

adsorbent has highest adsorption capacity when

compared activated carbon, peat, biomass,

agricultural solid waste, industrial by products,

silica, zeolite and clay (Crini & Badot, 2008).

Abudantly the availability and ease of modification

process make chitosan become one of the

ingredients adsorbents are widely use in process

adsorption (Ngah & Fatinathan, 2010).

Adsorption is the ability of the adsorbate to

adhere or attach to the adsorbent. It is a well

established separation technique to remove dilute

pollutants as well as to recover valuable products

from aqueous streams. In the conventional

adsorption process, the particle size of the adsorbent

is restricted because of hydrodynamic phenomena

such as pressure drop.

Regina Dewi, S., Mimpin, G. and Jamaran, K.

A New Adsorbent Chitosan-based That Modified using Epichlorohydrin and Diethylene Triamine for Treating Heavy Metal (Cu2+, Zn2+ and Fe2+).

DOI: 10.5220/0010133400002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 65-70

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

65

Solid surfaces that come into contact with a

solution tend to collect layers of solute molecules on

their surface due to an imbalance of forces on the

surface. Chemical adsorption results in the formation

of a monomolecular layer of adsorbate on the

surface through the forces of the residual valence of

the molecules on the surface. Physical adsorption

results from molecular condensation in the

capillaries of the solids. In general, elements with

greater molecular weight will be more easily

adsorbed. There is a rapid formation of an

equilibrium interface concentration, followed by

slow diffusion into carbon particles. The overall

adsorption rate is controlled by the diffusion rate of

solute molecules in the capillary pores of carbon

particles (Malkoc et al., 2006).

The use of the neat chitosan as adsorbent is not

effective due to its high solubility in the acid

medium, especially in acetic acid solution, HNO

3

,

HCl, etc. To resolve the issue, a modification

technique is needed to improve the performance of

chitosan, this modification can give several

advantages, i.e. could be use for several cycles and

enhance the stability of chitosan. If an amine

compound added to the chitosan’s structure, at the

end the number of amine group in chitosan will

increase. As the impact, it will improve the

adsorption capacity due to the new bond, also the

selectivity and stability of adsorption.

This study is involved with the introduction of

diethylene triamine into chitosan backbone through

the reaction of an intermediate of epoxy activated

chitosan and diethylene triamine. On the other hand,

several studies have indicated that amino groups in

chitosan are the main sites for the adsorption. Yi et

al. (2006) synthesized chitosan diethylene triamin

(DETA) epoxy and compared the capacity of

crosslinked chitosan and diethylene triamin chitosan

epoxy in adsorbing Pd

2+

, Ag

+

, Ni

2+

, Cu

2+

, Cd

2+

and

Co

2+

. Yan et al. (2013) carried out the preparation

and adsorption properties of chitosan granules

modified with diethylene triamine for acid dye

adsorption. Juir et al. (2017) crosslinked

epichlorohydrin with chitosan to test the mechanical

properties and absorption as an adsorbent.

Based on the description above, in this study

synthesis of chitosan compound which has been

grafting with diethylene triamin (DETA) which

occurs through alkylation with epichlorohydrin and

amination with diethylene triamin (DETA) and

adsorption testing of Cu

2+

, Fe

2+

and Zn

2+

metal ions.

2 MATERIAL AND METHODS

2.1 Material

Chitosan was purchased from Merck (DDA 80%).

Acetic acid glacial, sodium hydroxide, methanol,

ethanol, acetone, ether, nitric acid, copper sulfate

pentahydrate, iron sulfate heptahydrate, and zinc

sulfate heptahydrate were obtained from Merck.

Epichlorohydrin and

diethylene triamine were

purchased from TCI.

2.2 Characterization

The functional group of material was determined

using FT-IR (Shimadzu). The morphological surface

material was analyzed using SEM (JSM-35 C

Sumandju). The

presence on heavy metal in the

material after adsorption process was determine

using atomic absorption spectrometer (GF Perkin

Elmer).

2.3 Synthesis of Epoxy Chitosan

About 3 g of chitosan was suspended in 250 mL of

sodium hydroxide 0.4 M and 30 mL of

epichlorohydrin, the mixture was stirred for 5 h at

temperature of 50

o

C. The obtained residue was

washed using distillate water, acetone, and ether,

respectively. The residue was dried until the

constant weight was obtained

2.4 Chitosan Grafted Diethylene

Triamine

About 0.5 g of epoxy chitosan was suspended in 30

mL of sodium hydroxide 0.1 M and 0.5 g of

diethylene triamine, this mixture was stirred for 4 h

at temperature of 60

o

C. the obtained residue was

washed using distillate water, alcohol, and acetone,

respectively. The residue was dried until the

constant weight was obtained. The above procedure

was repeated for the other variation of diethylene

triamine (1 and 1.5 g).

2.5 Adsorption of Heavy Metal

Solution

The adsorption of heavy metal ion was performed

using the sulfate salt solution of each heavy metal,

i.e.CuSO

4

.5H

2

O, FeSO

4

.7H

2

O, ZnSO

4

.7H

2

O. About

0.01 g chitosan grafted diethylene triamine was

weighed and suspended in 50 mL of the heavy metal

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

66

solution (200 ppm). The mixture was stirred for 20

min at room temperature and then filtered. The

obtained filtrated was added with concentrated nitric

acid and the pH was adjusted into 3. The final

solution then was measured using AAS.

The capacity adsorption of modified chitosan can

be determined using the following equation:

𝑞

𝐶𝑜 𝐶

𝐶𝑜

100%

where, q was the percentage of capacity adsorption.

Co and C was the heavy metal ion concentration

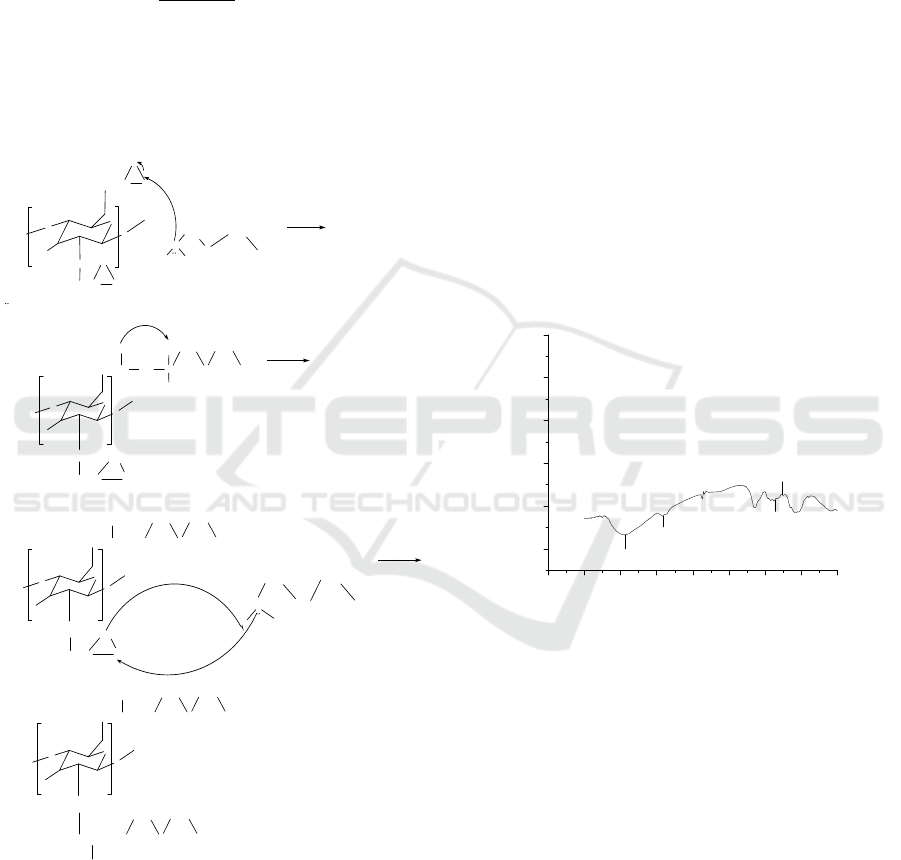

before and after treatment (ppm). In Fig. 1 below

showed the proposed mechanism of the formation of

chitosan grafted diethylene triamine.

CH2CH CH

2

O

CH2CH CH

2

O

O

O

O

NH

HO

O

n

Epoksi Kitosan

+

N

CH

2

CH

2

H

H

N

H

CH

2

CH

2

NH

2

CH

2

CH

2

CH

2

CH

2

NH

2

NH

N

O

O

O

HO

O

n

CH2CH CH

2

O

H

H

NaOH

NaOH

NH

CH2CH

O

CH

2

CH

2

CH

2

CH

2

CH

2

NH

2

NH

HN

O

O

O

HO

O

n

CH

2

CHCH

2

OH

NH

CH2CH

O

CH

2

N

CH

2

CH

2

H

H

NH

CH

2

CH

2

NH

2

CH

2

CH

2

CH

2

CH

2

NH

2

NH

HN

O

O

O

HO

O

n

CH

2

CHCH

2

OH

NH

CH

2

CHCH

2

+

OH

CH

2

CH

2

CH

2

CH

2

NH

2

NH

HN

Figure 1: Proposed mechanism of the formation of

chitosan grafted diethylene triamine.

3 RESULT AND DISCUSSION

3.1 FT-IR

Chitosan grafted diethylene triamine was

synthesized using chitosan, epichlorohydrin, and

diethylene triamine. This synthesis was performed in

two steps, i.e. the formation of epoxy chitosan and

the grafting of diethylene triamine

.

In the first step, alkylation reacts with chitosan

with epichlorohydrin. Where the OH group changes

in chitosan to C-O-C epoxy. The FT-IR spectrum

(Figure 2) shows that the wave number 3448.72 cm

-1

shows the -OH and -NH

2

groups (Sastrohadmijojo,

2018). At wave number 2924.09 cm

-1

shows

stretching –CH (sp

3

) bonds (Hartomo & Purba,

1986). The amine C-N group appears at wave

number 1381.03 cm

-1

. For C-O-C epoxy groups

appear at wave number 1319 cm

-1

. At wave number

1072.42 cm

-1

is a C

1

-C

5

bond and is a β-1,4-

glycosidic bond (Pavia, 2001).

4500 4000 3500 3000 2500 2000 1500 1000 500

0

20

40

60

80

100

Transmitation

wavelength

OH, -NH

C-H (sp

3

)

C-N

C-O-C epoxy

Figure 2: FT-IR Result of Epoxy Chitosan.

In the second step, the formation of diethylene

triamin chitosan grafting through the epoxy chitosan

amination with diethylene triamin. The FT-IR

spectrum (Figure 3) shows the -OH and -NH

2

groups

that appear at the wave number 3425.58 cm

-1

(Sastrohadmijojo, 2018). At wave number 2924.09

cm

-1

indicates the presence of –CH (sp

3

) bonds

(Hartomo & Purba, 1986). The formation of C-N-C

groups in diethylene triamin chitosan grafting

compounds appears at wave number 1458.18 cm

-1

.

The amine C-N group appears at wave number

1381.03 cm

-1

. At wave number 1080.14 cm

-1

is a C

1

-

C

5

bond and is a β-1,4-glycosidic bond (Pavia,

2001).

A New Adsorbent Chitosan-based That Modified using Epichlorohydrin and Diethylene Triamine for Treating Heavy Metal (Cu2+, Zn2+

and Fe2+)

67

4500 4000 3500 3000 2500 2000 1500 1000 500

0

10

20

30

40

50

60

Transmitation

wavelength

OH,-NH

CH (sp

3

)

C-N

C-N-C

Figure 3: FT-IR spectrum of modified chitosan (chitosan

grafted DETA (with varian DETA).

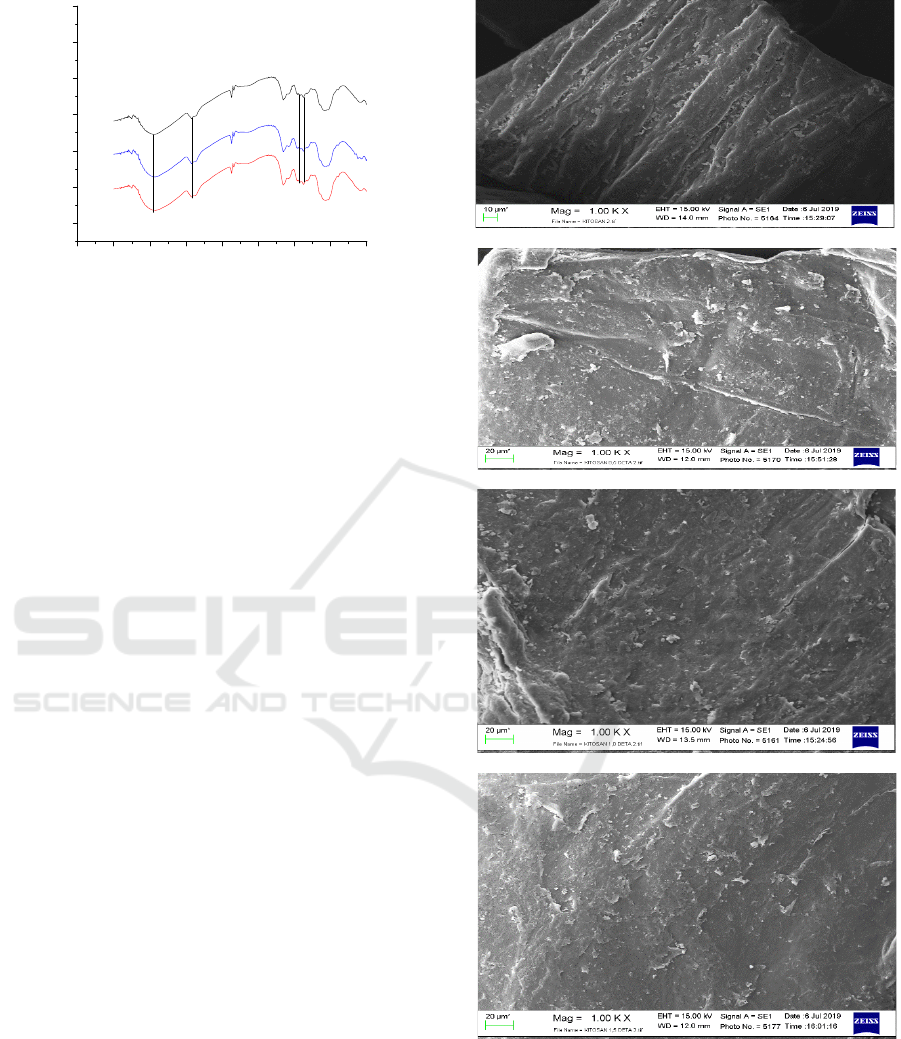

3.2 Scanning Electron Microscopy

(SEM)

Fig. 4 showed the morphological surface of chitosan

and modified chitosan which has a significant

difference. The number of chitosan fibril on the

surface was decrease after the addition of

epichlorohydrin and diethylene triamine. The

increase of diethylene triamine caused the film’s

surface became smoother. The presence of tiny

particle and crust layer on the film’s surface can be

indicated as the successful of grafting process. The

change of surface morphology as the result of

chemical interaction between the hydroxyl and aine

of chitosan. With this change in the film’s

morphology could improve the adsorption

performance.

3.3 Adsorption of Heavy Metal

Adsorption performance of modified chitosan to

Cu

2+

, Zn

2+

dan Fe

2+

can be seen in Table 1 and Table

2. Chitosan grafted with 1.5 g diethylene triamine

showed the highest performance to adsorb Cu

2+

, with

adsorption capacity 72.0 ppm. It adsorbed 36% of

Cu

2+

that presence in the solution of Cu

2+

200 ppm.

The obtained of this result as the impact of the

modification of chitosan structure. This modification

improves the reactivity of chitosan due to the

presence of new amine group from diethylene

triamine in the modified chitosan. The increase of

amine group improves the ability of modified

chitosan to form a chelate with the heavy metal ion,

it means the adsorption capacity will enhance. The

lone pairs electron in nitrogen can be used to form a

complex with transition metal through coordination

bonding (Lerivrey et al., 1986).

(a)

(b)

(c)

(d)

Figure 4: SEM images of a) chitosan b) chitosan grafted

0.5 g diethylene triamine, c) chitosan grafted 1.0 g

diethylene triamine, d) chitosan grafted 1.5 g diethylene

triamine.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

68

Table 1: The adsorption capacity of modified chitosan.

Adsorbent

Adsorption capacity

(mg/L)

Cu

2+

Zn

2+

Fe

2+

Chitosan 25.7 27.0 37.2

Chitosan grafted 0.5 g

diethylene triamine

51.8 48.8 58.9

Chitosan grafted 1.0 g

diethylene triamine

64.3 52.1 62.4

Chitosan grafted 1.5 g

diethylene triamine

72.0 67.0 63.9

Table 2: Adsorp of modified chitosan.

Adsorbent

% Adsorb

Cu

2+

Zn

2+

Fe

2+

Chitosan 12.8 13.5 18.6

Chitosan grafted 0.5 g

diethylene triamine

25.9 24.4 29.5

Chitosan grafted 1.0 g

diethylene triamine

32.2 26.1 31.2

Chitosan grafted 1.5 g

diethylene triamine

36.0 33.5 32.0

Figure 5: Adsorption capacity curve of modified chitosan.

According to Fig. 5, the highest performance

from three kinds of modified chitosan is shown in

chitosan grafted with 1.5 g diethylene triamine,

especially for adsorbing Cu

2+

. This is caused by the

highest acidity level of Cu

2+

compared to Zn

2+

and

Fe

2+

, it caused Cu

2+

is easier to form complex with

chitosan. The ability of adsorbent to adsorb the

specific component is influenced by pH, related to

protonation or deprotonation of adsorbent’s active

site. The system’s pH will influence the charge on

the adsorbent surface, degree of ionization, and the

species that able to absorb in the process.

4 CONCLUSIONS

Chitosan grafted diethylene triamine was

synthesized through alkylation and amination using

epichlorohydrin and diethylene triamine,

respectively. The formation this modified chitosan

was confirmed from FT-IR spectrum with the

presence of C-N-C vibration at 1581 cm

-1

. The

morphological analysis showed the surface became

smoother after grafting process. The modified

chitosan has specific adsorption capacity for each

heavy metal ion, i.e. Cu

2+

= 72,0 ppm; Zn

2+

= 67.0

ppm dan Fe

2+

= 63.9 ppm.

ACKNOWLEDGEMENTS

The authors would like to thank to University of

North Sumatera, Medan for their support in use of

laboratories and for my supervisor who has provided

the benefits of guidance and advice in conducting

this research.

REFERENCES

Bhatnaga, A., & Sillanpaa, M. (2009). Applications of

chitin- and chitosan-derivatives for the detoxification

of water and wastewater. Adv Colloid Interfac, 152,

26–38.

Cahayaningrum, S. E., Narsito, N., Santoso, S. J., &

Agustini, R. (2011). Adsorption of Mg (II) ion from

aqueous solution on Chitosan bends and chitosan

powder. Journal of Coustal Development, 13(3), 179–

184.

Crini, G., & Badot, P.-M. (2008). Application of chitosan,

a natural aminopolysaccharide, for dye removal from

aqueous solutions by adsorption processes using batch

studies: A review of recent literature. Progress in

Polymer Science, 33(4), 399–447.

https://doi.org/https://doi.org/10.1016/j.progpolymsci.

2007.11.001

Faisal, M., & Hasnain, S. (2004). Microbia conversion of

Cr(vi) into Cr(iii) in industrial effluent. African J.

Biotechnol., 3(11), 610–617.

Hartomo, A. J., & Purba, A. V. (1986). Penyidikan

spektrometrik senyawa organik. Erlangga.

Horsfall, M. J., & Spiff, A. I. (2005). Effects of

temperature on the sorption of ob2+ and cd2+ from

aqueous solution by caladium bicolor (wild cocoyam)

0,0%

10,0%

20,0%

30,0%

40,0%

0246

%Adsoprtion

AdsorptionCapacity

Cu2+

Zn2+

Fe2+

A New Adsorbent Chitosan-based That Modified using Epichlorohydrin and Diethylene Triamine for Treating Heavy Metal (Cu2+, Zn2+

and Fe2+)

69

biomass. Electronic Journal of Biotechnology, 8(2).

Igwe, J. C., & Abia, A. A. (2003). Maize Cob and Husk as

Adsorbents for removal of Cd, Pb and Zn ions from

wastewater. The Physical Sci., 2, 83–94.

Juir, N., Rahmi, & Marlina. (2017). Pengaruh penambahan

epiklorohidrin terhadap sifat mekanik dan daya serap

film khitosan sebagai adsorben. Jurnal Rekayasa

Kimia Lingkungan, 12(1), 31–36.

https://doi.org/https://doi.org/10.23955/rkl.v12i1.5094

Laksono, W. L., Projosantoso, A. K., & Ihsan, J. (2008).

Adsorpsi kitosan terhadap ion logam Ni (II) dan Mn

(II) pada berbagai pH. Penelitian Saintek, 13, 95–109.

Lerivrey, J., Dubois, B., Decock, P., Micera, G.,

Urbanska, J., & Kozłowski, H. (1986). Formation of

D-glucosamine complexes with Cu(II), Ni(II) and

Co(II) ions. Inorganica Chimica Acta, 125(4), 187–

190.

Malkoc, E., Nuhoglu, Y., & Abali, Y. (2006). Cr (VI)

adsorption by waste acorn of Quercus ithaburensis in

fixed beds: Prediction of Breaktrough curves.

Chemical Engineering Journal, 119, 61–68.

Ngah, W. S. W., & Fatinathan, S. (2010). Adsorption

characterization of Pb(II) and Cu(II) ions onto

chitosan-tripolyphosphate beads: kinetic, equilibrium

and thermodynamic studies. Journal of Environmental

Management, 91(4), 958–969.

Pavia, L. K. (2001). Introduction to Spectroscopy A guide

for students of organic chemistry (Third).

Sastrohadmijojo, H. (2018). Dasar-dasar spektroskopi.

UGM Press.

Schumul, R., Krieg, H. M., & Keizer, K. (2001).

Adsorption of Cu (II) and Cr (IV) by chitosan.

Kinetics and Equilibirium Studies Water, 27(1), 1–8.

Tangio, J. S. (2013). Adsorpsi logam Pb (Timbal) dengan

menggunakan biomassa enceng gondok (Eichhornia

crassipes). Jurnal Entropi, 8(1), 500–506.

Yan, Y., Xiang, B., Li, Y., & Jia, Q. (2013). Preparation

and adsorption properties of diethylenetriamine‐

modified chitosan beads for acid dyes. Journal of

Applied Polymer Science, 130(6), 4090–4098.

https://doi.org/https://doi.org/10.1002/app.39691

Yi, Y., Wang, Y., & Ye, F. (2006). Synthesis and

properties of diethylene triamine derivative of

chitosan. Colloids and Surfaces A: Physicochemical

and Engineering Aspects, 277(1–3), 69–74.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

70