The Effect of Inoculum Volume on Bioethanol Production from Saba

Banana Hump (Musa Paradisiacal. L) Starch by Zymomonas Mobilis

using Immobilization Technique

Rifqi Syahbana

1

, Emma Zaidar Nasution

2*

, Rumondang Bulan Nasution

2

1

Postgraduate Chemistry Study Programme, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

2

Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

Keywords: Bioethanol, Immobilization, Inoculum volume, Saba Banana Hump, Zymomonas Mobilis.

Abstract: Bioethanol is a liquid produced from the sugar fermentation process from carbohydrate sources by using the

microorganism. In present study, Saba banana hump (Musa paradisiacal. L) sample was isolated by

precipitating the starch with water for 12 hours. Furthermore, the starch was hydrolyzed using HCl 25%, and

14.01% of glucose solution was obtained. The starch obtained was tested using Fourier-transform infrared

spectroscopy. Then the sample was fermented using Zymomonas mobilis microorganism immobilized by Ca-

Alginate 4% with variation of inoculums 5%, 10%, 15% (v/v). Bioethanol from fermentation process was

tested using gas chromatography (GC). The highest bioethanol content is 79.01% and the highest productivity

that obtain was 2.66 g/L.Hours.

1 INTRODUCTION

Banana hump is the bottom of a banana plant that has

characteristics that are not too hard, banana hump

waste has a starch composition of approximately

70%, 20% water, the rest is protein and vitamins. For

the banana hump itself has not been used optimally,

where the banana weevil waste is sometimes only as

animal feed or left alone to rot. The carbohydrate

content of banana hump is very potential as a source

of bioethanol, so that it can increase the use value of

the banana weevil and can optimize the utilization of

the banana hump. As for one type of carbohydrate

that is in the banana weevil is starch.

Starch is a carbohydrate polymer consisting of

glucose monomers with the molecular formula

(C

6

H

10

O

5

)

n

. Starch is known as biocompatible,

biodegradable, non-toxic, environmentally friendly

and inexpensive natural polysaccharides (Atwell,

W.A., Hood, L., Lineback, D., Varriano-Morston, E.,

Zobel, 1988; Rodrigues and Emeje, 2012). Starch can

be a source of glucose in the fermentation process that

produces bioethanol by hydrolyzing starch with a

dilute acid solution or enzyme.

Bioethanol in the realm of renewable energy is

one source of energy that continues to be developed.

Bioethanol is the center of attention because this

compound can be used as fuel (Setiadji et al., 2017).

The raw materials for the bioethanol production

process are classified into three groups, namely sugar,

starch and cellulose. Sources of sugar derived from

cane sugar, beet sugar, molasses and fruits can be

directly converted to ethanol. Sources of starchy

ingredients such as corn, cassava, potatoes and plant

roots must first be hydrolyzed into sugar. Sources of

cellulose derived from wood, agricultural waste, pulp

and paper mill waste as a whole must be converted to

sugar with the help of mineral acids (Lin and Tanaka,

2006).

Z. mobilis is a gram-negative, stem-shaped

bacterium, can be found in sugar-rich sap plants, has

a length of 2-6 μm and a width of 1-1.4 μm, the

optimum temperature for growth is 25-30

o

C, and is

anaerobic. Z. mobilis can ferment glucose, fructose,

but cannot ferment silosa (Gunasekaran and Chandra

Raj, 1999; Geeta, 2007). Zymomonas mobilis

bacteria can survive on glucose level

Immobilization is the process of wrapping

(coating) a core material, in this case bacteria as a

core material by using its viability and protecting it

from damage due to environmental conditions that are

not possible (Wu, Roe and Gimino, 2000). (Pacifico,

Wu and Fraley, 2001) states that for sensitive

components such as microorganisms, it can be

Syahbana, R., Zaidar Nasution, E. and Bulan Nasution, R.

The Effect of Inoculum Volume on Bioethanol Production from Saba Banana Hump (Musa Paradisiacal. L) Starch by Zymomonas Mobilis using Immobilization Technique.

DOI: 10.5220/0010133200002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 53-58

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

53

immobilized to increase viability of shelf life.

Common ingredients used for immobilization are

various types of polysaccharides and proteins such as

starch, alginate, arabic gum, gelatin, carrageenan,

albumin, and casein.

Research has been carried out on immobilization

of zymomonas mobilis cells and saccharomyces

cerevisiae to increase the production of bioethanol

from sugar from the hydrolysis of sugarcane bagasse

waste. The results showed ethanol levels increased

using cells immobilized by the addition of sugarcane

bagasse to the modification of the calcium alginate

matrix, where the efficiency of fermentation in

zymomonas mobilis increased by 1.8 times while in

S. cerevisiae by 1.6 times (Kusumaningati, Nurhatika

and Muhibuddin, 2013).

The purpose of this study was to determine the

levels of bioethanol produced from zymomonas

mobilis fermentation with immobilization

techniques.

2 METHODS

2.1 Isolation of Starch from Kepok

Banana Weevil

Kepok banana weevil that is obtained is then peeled

and cleaned with clear water, then cut into cubes and

then put into a bucket and soaked with 0.2% Na

2

S

2

O

5

for 12 hours. Furthermore, the banana weevil is dried

in the sun, then blended until smooth and then filtered

using an 80 mesh sieve. Then dissolved with

Aquadest and deposited for 24 hours. Furthermore,

starch is separated from the solution and roasted at a

temperature of 45

o

C for 24 hours.

2.2 Starch Hydrolysis

The starch obtained was weighed as much as 20 g

then put into a 250 ml glass beaker, added as much as

100 ml 25% HCl and covered with alumanium foil.

Then it is heated at 80

o

C while stirring for 30 minutes.

After being cooled, the hydrolyzate was adjusted to

neutral pH using NaOH 0.7%.

2.3 Making YEPD (Yeast Extract

Pepton Dextrose) Media

The making of YEPD media is by dissolving 4 g

Yeast extract, 2 g KH

2

PO

4(s)

, 3 g (NH

4

)

2

SO

4(s)

, 1 g

MgSO

4

.7H

2

O

(s)

, 3.6 g Pepton and 2% Bacto agar with

1000 ml Aquadest. Then heated on a hotplate until it

is clear yellow.

2.4 Making Cell Immobilization

Nutrient media mixed with 20 gram (NH

4

) 2SO

4

18

gram starch, 10 gram NaHPO

4

, 5 gram KH

2

PO4, 5

gram MgSO

4

.7H

2

O and 1 gram yeast extract added to

culture. Put in the shaker incubator for 24 hours. Then

mixed 50 ml of nutrient media with 50 ml of 4%

alginate solution. Next 100 ml of Alginate-cell

mixture was added into 1000 ml of 2% CaCl

2

solution

until the solution was in the form of solids and

allowed to stand to harden for 30 minutes.

Subsequently washed solids with 0.85% NaCl and

incubated into the production medium with shaking

for 24 hours. Then the solid is stored in the yeast

extract at 4

o

C until the cell is used.

2.5 Hydrolyzed Fermentation using

Inoculum Z. Mobilis

Fermentation using inoculum Z. Mobilis by

dissolving 4 g Yeast extract, 2 g KH

2

PO

4(s)

, 3 g (NH

4

)

2SO

4

(s), 1 g MgSO

4

.7H

2

O

(s)

, 3.6 g Pepton and 2%

agar Bacto with 1000 ml of hydrolyzate. Then

sterilized using an autoclave for 2 hours at 121

o

C.

After the cold hydrolyzate was added inoculum Z.

Mobilis were 5%, 10%, 15% with the amount of

bacteria 9.0 x 10

8

(McFarland 3). Then it is tightly

closed using alumanium foil and plastic wrap and put

in a shaker incubator for 21 hours at 30

o

C while the

dishaker is at 100 rpm.

2.6 Separation of Bioethanol from

Fermentation Solutions

500 ml fermentation solution was put into 1000 ml

rotav flask then CaO was added to the fermentation

solution at a ratio of 1:2 (g / ml) and then in the rotary

evaporator at 78

o

C for 1 hour. Then the ethanol

qualitative test on the distillate obtained.

2.7 Quantitative Analysis of Bioethanol

using GC

Fermentation solution as much 500 ml was put into a

1000 ml rotav flask then CaO was added to the

fermentation solution at a ratio of 1:2 (g / ml) and then

in the rotary evaporator at 78

o

C for 1 hour. Then the

ethanol qualitative test on the distillate obtained.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

54

3 RESULTS AND DISCUSSION

3.1 Isolation of Starch from Saba

Banana Hump

The results of isolation of starch from Saba Banana

Hump by stopping the browning process using 0.2%

Na

2

S

2

O for 12 hours, so that the squeeze process will

produce a white milk solution and deposited for 24

hours. From 1000 grams of saba banana hump

obtained 157 grams of starch banana weights that are

milky white. The results of Saba Banana Hump starch

can be seen in Figure 1

Figure 1: Results of Isolation of Starch from Saba

Banana Hump.

Starch isolation aims to be hydrolyzed into sugar.

The sample as a source of starch used is banana

weevil. From 1000 grams of Saba Banana Hump

obtained 157 grams of starch banana weights that are

milky white. Then a qualitative test was carried out

on the starch that had been obtained using iodine

solution. Iodine test is used to detect the presence of

starch.

The iodine test is carried out by means of a starch

sample inserted into the test board, adding one drop

of aqueous iodine solution (Widyaningsih, Kartika

and Tri Nurhayati, 2012). Then mixed evenly. Test

positive iodine for starch with the appearance of blue

after adding iodine to the sample. Starch that binds to

iodine will produce a blue color and this property can

be used to analyze the presence of starch. This is

caused by the structure of the spiral starch molecule

so that it will bind to the iodine molecule and form a

blue color (Winarno, 2004).

Figure 2: Qualitative Test of Saba Banana Hump.

3.2 Analysis of Saba Banana Hump

Starch using FT-IR Spectroscopy

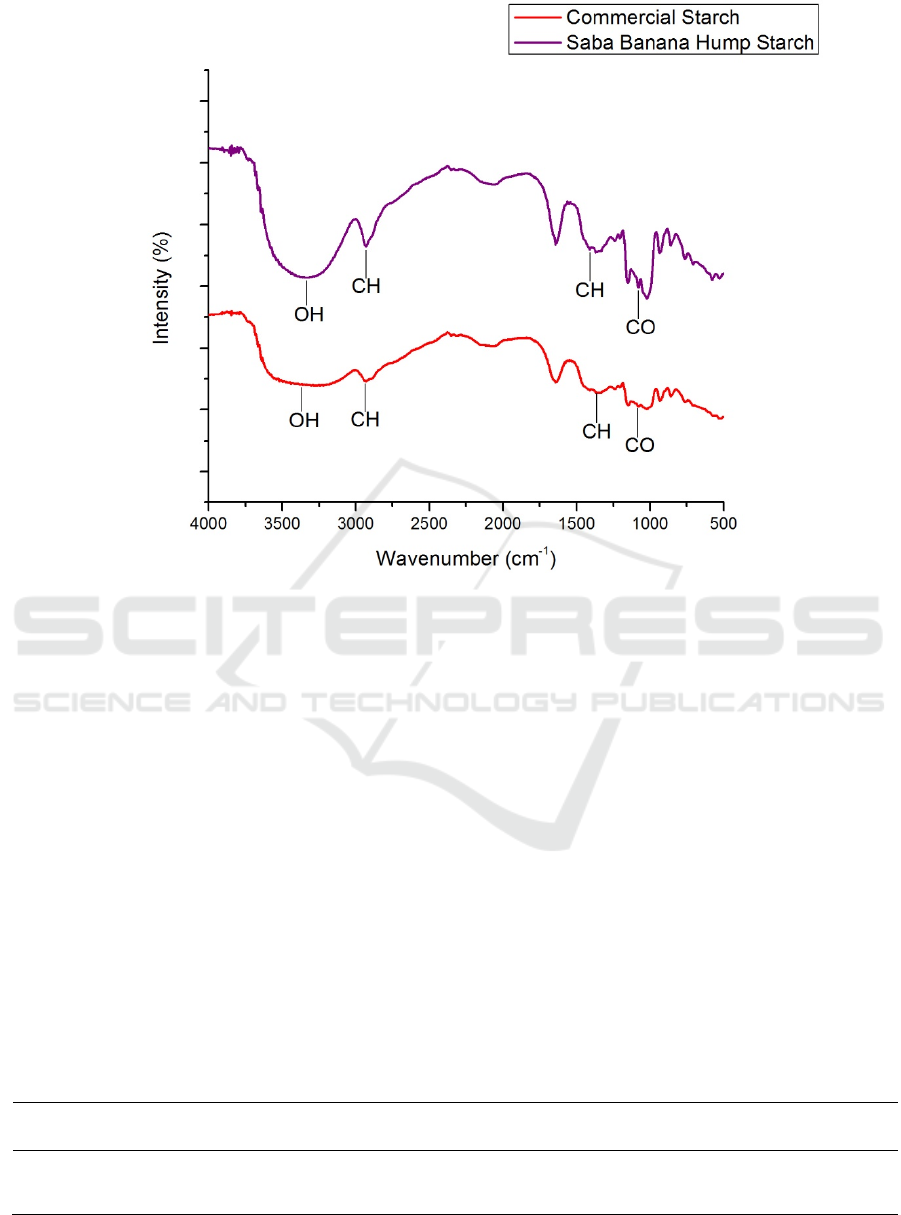

Functional group analysis in Saba Banana Hump

starch and commercial starch using FT-IR

spectrocopy showed almost the same wave number

and spectrum shape. Spectrum results and wave

numbers can be seen in Figure 3.

Observed at a glance, the FT-IR spectra pattern of

saba banana hump starch and commercial starch

above shows the number and location of peaks that

are relatively the same. Thus it can be interpreted that

the results of insulation are starches.

From FT-IR spectra of saba banana hump starch

and commercial starch, each absorption peak at wave

numbers 3336 cm

-1

and 3286 cm

-1

is associated as OH

strain vibrations of alcohol in starch molecules,

followed by absorption peaks at wave numbers of

2931 cm

-1

is associated as the CH stretch vibration of

the alkane chain. Whereas absorption at wave number

1639 cm

-1

is associated as O-H (H

2

O), then

absorption at wave numbers 1408 cm

-1

and 1350 cm

-

1

indicates the presence of C-H groups (Wijaya et al.,

2019). In addition, uptake at wave numbers of 1149

cm

-1

and 1145 cm

-1

is associated as vibrational strain

of C-O-C in the starch ring (Leon, 2016).

The Effect of Inoculum Volume on Bioethanol Production from Saba Banana Hump (Musa Paradisiacal. L) Starch by Zymomonas Mobilis

using Immobilization Technique

55

Figure 3: Results of FT-IR Spectrum of Saba Banana Hump Starch and Commercial Starch.

3.3 Starch Hydrolysis

Hydrolysis of 20 gram saba banana starch using 25%

HCl solution and 30% NaOH produced 14.01%

glucose solution. Hydrolysis of saba banana starch

using 25% HCl solution at 90°C produces glucose

solution. The purpose of hydrolysis is to break down

carbohydrates into simple sugars so that they can be

used in the fermentation process. In this research, HCl

acid is used as a catalyst in the hydrolysis process.

HCl catalysts produce higher glucose when compared

with H

2

SO

4

catalysts. This is due to H

2

SO

4

being

combustible while HCl is not so that the use of HCl

catalyst is more optimal in producing reducing

sugars. The acid produces H

+

ions and binds with H

2

O

to form H

3

O

+

will break the gilosidic bonds in

amylose and amylopectin to form simple monomers

(Balat, Balat and Öz, 2008).

3.4 Cell Immobilization Process

The process of immobilization of zymomonas

mobilis bacteria is to add a bacterial inoculum into the

nutrient media with variations in the bacterial

inoculum 5%, 10%, and 15%. After the next

incubation process 4% alginate solution will be added

in a ratio of 1:1 to a 2% CaCl solution which results

in a compact and round solid beads. Various studies

have shown that calcium alginate protects culture cell

immobilization better by increasing bacterial

resistance than without immobilization (Anal and

Singh, 2007). Alginates can form gels (egg-box

formations), films, manic (beads), pellets,

microparticles, and nanoparticles (Natalia, 2015).

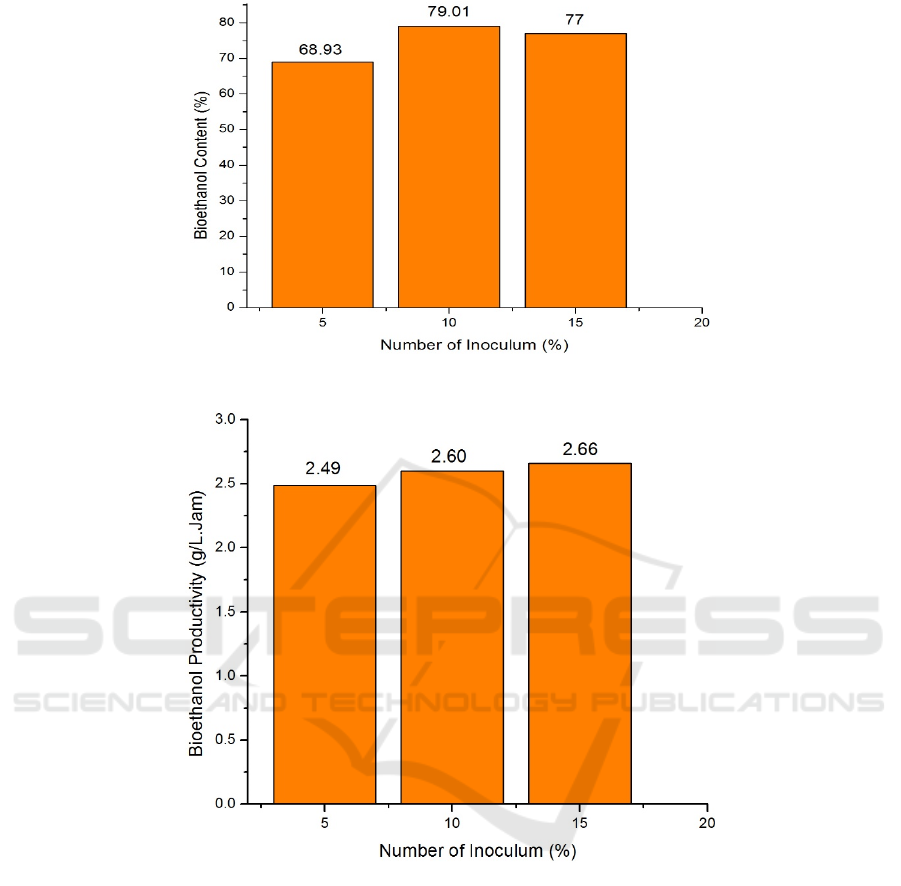

Table 1: Bioethanol results from the fermentation of Saba banana hump starch.

No Zymomonas mobilis Inoculum (%) Bioethanol Content (%) Productivity (g/L.Hours)

1 5 68.93 2.49

2 10 79.01 2.60

3 15 77 2.66

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

56

Figure 4: Graph of Bioethanol Levels.

Figure 5: Graph of Bioethanol Productivity.

3.5 Fermented Banana Starch Results

Kepok Banana

The fermentation process is carried out using an

immobilized Zymomonas Mobilis inoculum. Where

with the treatment of variation inoculum Zymomonas

Mobilis as much as 5%, 10%, and 15%. Furthermore,

the separation of bioethanol from the fermentation

solution using a rotary evaporator. Then the

fermentation results are tested using Gas

Chromatography. In the variation of zymomonas

mobilis inoculum as much as 5%, 10%, and 15%, the

results were fluactative yield. The results of

bioethanol can be seen in table 1.

From Figure 4 the diagram of the effect of

inoculum volume on bioethanol levels can be

explained that at 5% inocolum volume of bioethanol

produced is 68.93%, whereas an increase in

bioethanol levels in 10% inoculum volume with a

duration of 79.01%. However, there was a decrease in

levels of bioethanol at 15% inoculum volume

treatment by 77%. Hisreidi, (2016) said the higher

inoculum volume indicates that more and more

populations of Zymomonas mobilis bacteria are

fermenting and as a result the higher levels of

bioethanol produced (Hisreidi, 2016).

Figure 5 is a diagram of bioethanol productivity

with Zymomonas Mobilis inoculum variations of 5%,

The Effect of Inoculum Volume on Bioethanol Production from Saba Banana Hump (Musa Paradisiacal. L) Starch by Zymomonas Mobilis

using Immobilization Technique

57

10%, and 15%. Bioethanol productivity in

zymomonas mobilis inoculum variation of 5%, 10%,

and 15% showed increased results, namely 2.49%,

2.6%, and 2.66%. The highest results were obtained

in the zymomonas mobilis inoculum variation 15%

by 2.66%, while the lowest results were obtained in

the zymomonas mobilis inoculum variation 5% by

2.49%. It can be concluded that the higher the level

of bioethanol, the higher the value of bioethanol

productivity

4 CONCLUSIONS

Saba banana hump can produce starch that has a white

color. Starch from kepok banana weevil hydrolyzed

using acid to produce glucose as much as 14.01%

with 20 grams of starch content. The highest

bioethanol content is 79.01% and the highest

productivity that obtain was 2.66 g/L.Hours.

REFERENCES

Anal, A. K. and Singh, H. (2007) ‘Recent advances in

microencapsulation of probiotics for industrial

applications and targeted delivery’, Trends in Food

Science and Technology, pp. 240–251. doi:

10.1016/j.tifs.2007.01.004.

Atwell, W.A., Hood, L., Lineback, D., Varriano-Morston,

E., Zobel, H. (1988) ‘The terminology and

methodology associated with basic starch phenomena’,

Cereal Food World, 33, pp. 306–311.

Balat, M., Balat, H. and Öz, C. (2008) ‘Progress in

bioethanol processing’, Progress in Energy and

Combustion Science, pp. 551–573. doi:

10.1016/j.pecs.2007.11.001.

Geeta, M. S. G. & G. S. (2007) ‘Effectivenes of Fungal

Pretreament of Agro Residues on Etanol Production by

Yeast and Zymomonas mobilis’, 2, pp. 301–304.

Gunasekaran, P. and Chandra Raj, K. (1999) ‘Ethanol

fermentation technology - Zymomonas mobilis’,

Current Science.

Hisreidi (2016) Pengaruh Volume Inokulum Pada Produksi

Bioetanol Dari Kulit Pisang Kepok Kuning (Musa

paradisiaca L. var. Kepok Kuning) Menggunakan

Zymomonas mobilis Dengan Metode Solid State

Fermentation (SSF). Universitas Sanata Dharma.

Kusumaningati, M. A., Nurhatika, S. and Muhibuddin, A.

(2013) ‘Potensi Kapang Aspergillus sp. dalam Proses

Hidrolisis untuk Produksi Etanol dari Sampah Sayur

dan Buah Pasar Wonokromo Surabaya’, Makalah Orasi

Ilmiah.

Leon (2016) AC SC, Food Hydrocolloids. Elsevier Ltd. doi:

10.1016/j.foodhyd.2016.01.008.

Lin, Y. and Tanaka, S. (2006) ‘Ethanol fermentation from

biomass resources: Current state and prospects’,

Applied Microbiology and Biotechnology, pp. 627–642.

doi: 10.1007/s00253-005-0229-x.

Natalia, S. . (2015) Viabilitas enkapsulasi sinbiotik isolat

BAL dengan berbagai bahan enkapsulasi selama masa

simpan dan simulasi asam lambung. Universitas

Sumatera Utara.

Pacifico, C., Wu, W. and Fraley, M. (2001) ‘Sensitive

substance encapsulation’, US Patent 6,251,478, 1(12),

pp. 1–8.

Rodrigues, A. and Emeje, M. (2012) ‘Recent applications

of starch derivatives in nanodrug delivery’,

Carbohydrate Polymers, pp. 987–994. doi:

10.1016/j.carbpol.2011.09.044.

Setiadji, S. et al. (2017) ‘Alternatif Pembuatan Biodiesel

Melalui Transesterifikasi Minyak Castor (Ricinus

communis) Menggunakan Katalis Campuran Cangkang

Telur Ayam dan Kaolin’, Jurnal Kimia VALENSI, 3(1),

pp. 1–10. doi: 10.15408/jkv.v3i1.4778.

Widyaningsih, S., Kartika, D. and Tri Nurhayati, Y. (2012)

‘PENGARUH PENAMBAHAN SORBITOL DAN

KALSIUM KARBONAT TERHADAP

KARAKTERISTIK DAN SIFAT BIODEGRADASI

FILM DARI PATI KULIT PISANG’, Molekul, 7(1), p.

69. doi: 10.20884/1.jm.2012.7.1.108.

Wijaya, C. et al. (2019) ‘Heliyon Isolation and

characterization of starch from Limnophila aromatica’,

Heliyon. Elsevier Ltd, 5(October 2018), p. e01622. doi:

10.1016/j.heliyon.2019.e01622.

Winarno, F. G. (2004) Kimia Pangan dan Gizi

. Jakarta: PT.

Gramedia.

Wu, W., Roe, W. and Gimino, V. (2000) ‘Low melt

encapsulation with high laurate canola oil’, US Patent

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

58