Bioethanol Production from Lindur Fruit (Burguiera Gymnorrhiza)

Strach with Variation of Inoculum Volume of

Zymomonas Mobilis

Hamdan Azhari

1

, Emma Zaidar Nasution

2*

and Rumondang Bulan Nasution

2

1

Postgraduate Chemistry Study Programme, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

2

Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

Keywords: Acid Hydrolysis, Bioethanol, Lindur Fruit, Strach, Zymomonas mobilis.

Abstract: Bioethanol is the fermentation product of hydrolyzed carbohydrates by using acids or enzymes. Commonly,

bioethanol uses fermented microbes, one of them is bacterium Zymomonas mobilis. Lindur ( Burguiera

gymnorrhiza ) is the fruit of one kind mangrove plant which are not fully utilized. One of the chemical content

of lindur Fruit is carbohydrate 23.53 %, it can be used for the production of bioethanol which uses

fermentation of carbohydrates. Isolation of starch which is one kind of carbohydrates from lindur fruit by

precipitation the starch using water. Pati will be hydrolyzed using HCl 20 % to obtain a solution of glucose

around 7.49 %. after that, fermentation carried out using a different variation of the number of inoculums (5,

10 and 15 % (v/v)). Bioethanol obtained from the fermentation process will be measured using Gas

Chromatography (GC ), density, acidity, and evaporation residue also tested. The result shows the highest

content of bioethanol is 43.75 %.

1 INTRODUCTION

Lindur fruit or Burguiera gymnorrhiza is the fruit of

one kind mangrove plant. This mangrove plant grows

a lot in tropical regions, especially Indonesia. These

plants grow in the coastal area, it aims to prevent

surface erosion by sea waves (abrasion)

Lindur fruit which is not fully utilized by many

people. This fruit has a carbohydrate content of

around 23.53 % (De, 2005). Carbohydrates are

natural polymers that are abundant in nature, one type

of carbohydrate is starch. Starch is a glucose

homopolymer with α-glycosidic bonds. Lindur starch

has an amylose content of about 31.56 % and an

amylopectin content of about 26.17 % (Jacoeb et al.,

2014). Starches consisting of glucose can be used for

bioethanol production.

Bioethanol can be produced using microbial help.

Zymomonas mobilis is a bacterium that can ferment

glucose and fructose (Gunasekaran and Chandra Raj,

1999) (Geeta, 2007). Bioethanol productivity

obtained from zymomoas mobilis is higher when

using the Entner-Duodoroff pathway (Obire, 2005)

(Tripetchkul S.Z.D Hilary, 1998). Zymomonas

mobilis is not harmful to humans and is often used as

a natural inoculum to make traditional alcoholic

drinks. Most of Zymomonas strains (90 %) can grow

at pH 3.5. But it does not grow at pH 3.05 or lower.

Because Zymomonas is rather thermolabile, the best

condition for Zymomonas mobilis growth is at

temperatures between 25

o

C and 30

o

C; 74 % of

strains grow at 38

o

C, but the growth will rarely occur

at 40

o

C.

Zymomonas mobilis has a tolerance to high

substrate and product concentrations. Some types of

Zymomonas can tolerate up to 30-40 % glucose and

13% (weight/volume) ethanol. This bacteria has a

high tolerance to ethanol among the other bacteria,

only the majority of bacterial growth is inhibited by

ethanol concentrations of 1-2 % (weight/volume). As

an explanation, the main protective function comes

from hopanoids, which are pentacyclic triterpenoids,

which are widely present in the Zymomonas mobilis

cell membrane. Most likely, amphiphilic substances,

such as sterols, stabilize Zymomonas mobilis cell

membranes against dissolving with ethanol (Yanase,

2014).

This research aimed to determine the content of

bioethanol produced from zymomonas mobilis

fermentation in starch from acid hydrolyzed.

Azhari, H., Zaidar Nasution, E. and Bulan Nasution, R.

Bioethanol Production from Lindur Fruit (Burguiera Gymnorrhiza) Strach with Variation of Inoculum Volume of Zymomonas Mobilis.

DOI: 10.5220/0010133100002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 47-52

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

47

2 METHODOLOGY

2.1 Preparation Lindur Fruit

The fruit obtained is then peeled and cleaned with

clear water, then cut into cubes and then put into a

bucket and soaked with 0.2 % Na

2

S

2

O

5

for 12 hours.

Then blend until smooth by adding aquadest 1:5

(weight/volume) then let stand for 24 hours.

Furthermore, starch is separated from the solution and

roasted at a temperature of 45

o

C for 24 hours.

2.2 Fourier Transforms Infrared

Spectroscopy

The starch was prepared into pulp. Pulp slurry was

examined in a thin film placed between flat plates of

salt. The test was carried out by pinning the resultant

film on the sample container. Then the film was

placed on a plate in the direction of infrared light. The

result will be recorded periodic paper in the form of a

flow curve of 4000-200 cm

-1

waves with intensity.

2.3 Starch Hydrolysis

10 g of starch obtained was then put into a 250 ml

glass beaker, and then added with 100 ml 25% HCl

and covered with alumanium foil. Then it was heated

at 80

o

C while stirring for 30 minutes. After that, it

was cools down, the hydrolyzate was adjusted to

neutral pH using 30 % NaOH.

2.4 Preparation YEPD Media (Yeast

Extract Pepton Dextrose)

The preparation of YEPD media is by dissolving 4 g

Yeast extract, 2 g KH

2

PO

4

(s)

, 3 g (NH

4

)

2

SO

4

(s)

, 1 g

MgSO

4

.7H

2

O

(s)

, 3.6 g Pepton and 2% Bacto agar

with 1000 ml Aquadest. Then heated on a hotplate

until it was clear yellow.

2.5 Zymomonas Mobilis Bacteria

Culture

Z. Mobilis bacterial culture is carried out in a sterile

place near or around a burning Bunsen fire so that

there are no contaminants that inhibit the growth of

Z. Mobilis bacteria. Culture was carried out by

inserting YEPD media into a petri dish, then 1 ose

was taken from isolate Z. mobilis and then etched on

a petri dish containing YEPD media. When the petri

dish was closed and wrapped in plastic wrap, it was

then incubated at 30

o

C for 24 hours.

2.6 Hydrolyzed Fermentation using

Inoculum Z. Mobilis

Fermentation using inoculum Z. Mobilis was done by

dissolving 4 g Yeast extract, 2 g KH

2

PO

4

(s)

, 3 g

(NH

4

)

2

SO

4

(s)

, 1 g MgSO

4

.7H

2

O

(s)

, 3.6 g Pepton and

2% agar Bacto with 1000 ml of hydrolyzate. Then

sterilized using an autoclave for 2 hours at 121

o

C.

After the hydrolyzate was cooled, 5 %, 10 % and 15

% inoculum Z. Mobilis was added. Then it was tightly

closed using alumanium foil and plastic wrap and put

in a shaker incubator for 21 hours at 30

o

C with 100

rpm speed.

2.7 Separation of Bioethanol from

Fermentation Solutions

500 ml fermentation solution was put into a 1000 ml

rotary evaporator flask then CaO was added to the

fermentation solution at a ratio of 1: 2 (g / ml) and

then in the rotary evaporator at 78

o

C for 1 hour. Then

the distillate obtained was test for ethanol qualitative.

Figure 1: Lindur Fruit.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

48

2.8 Bioethanol Density Test

Bioethanol density test was carried out using a

pycnometer, where the dry, clean and empty

pycnometers weighed, then filled with water/

aquadest, and then it was dried and cleaned.

Furthermore, weighed with an analytical balance to a

constant weight. The same step was done by using a

distillate (bioethanol).

Density (g∕ml)=(a-w)/(b-w)

a = weight of empty pycnometer + sample

b = weight of empty picnometer + water

w = weight of the empty pycnometer

2.9 Determination of Bioethanol

Content

Determination of obtained bioethanol content by

using bioethanol density conversion tables with

bioethanol content.

3 RESULTS AND DISCUSSIONS

3.1 Starch Isolation Results from

Lindur Fruit

Starch isolation from lindur fruit was carried out by

precipitating starch in water overnight, so that starch

from lindur fruit has a brownish white color. Starch is

a type of carbohydrate which is a glucose

homopolymer with α-glycosidic bonds and there are

many in all plants, one of which is fruit. Starch is in

the cortical tissue in the fruit which is located in the

xylem surrounded by phloem (Seknun, 2012) so that

by destroying the fruit will damage the cortical tissue

so that the starch of the fruit can be removed. Where

the physical properties of starch that can not dissolve

in aquadest it will precipitate starch at the bottom of

the solution because the molecular mass of starch is

heavier than the water molecules in the fruit juice.

3.2 Characterization using Fourier

Transforms Infrared Spectroscopy

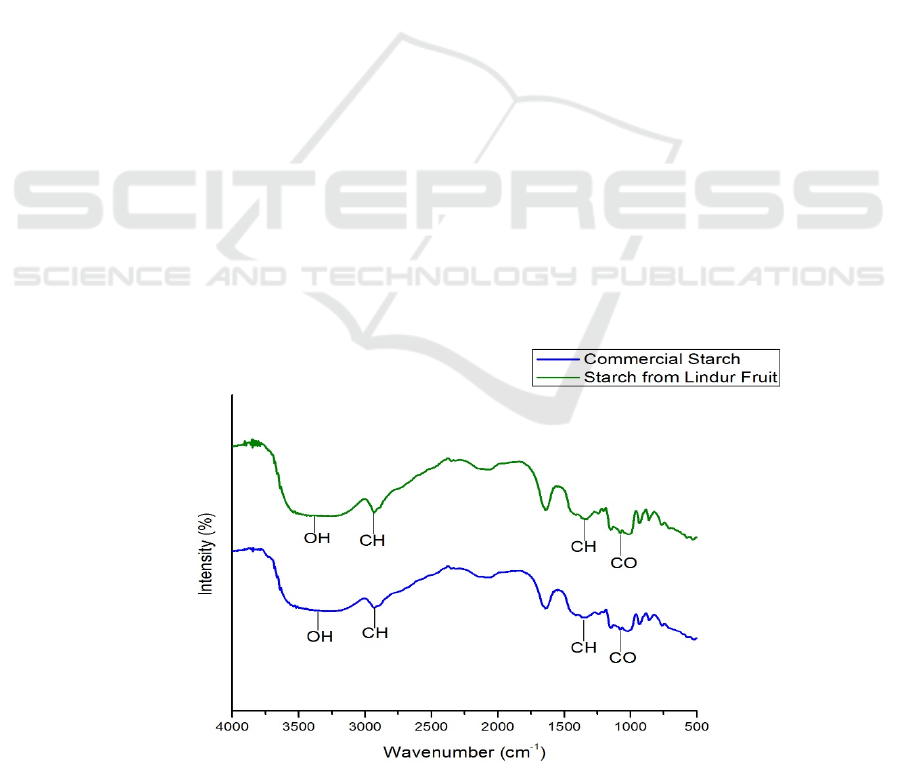

In the functional group analysis using FTIR for both

the spectrum of the fruit starch and commercial starch

showed that there was no significant difference

between the starch band of the fruit and the

commercial starch. It happened because both are

starches. From FTIR spectra, there are widening

bands in the absorption regions 3398 and 3286 cm

-1

which show the existence of OH stretch vibrations

from alcohol in the starch molecule, followed by the

CH stretch vibrations of the alkane chains in the

absorption area 2931 cm

-1

.(Estrada-León et al., 2016)

In addition, the vibrational peak was also seen in the

absorption area of 1145 cm

-1

which showed the

presence of C-O-C strain in the starch ring (Estrada-

León et al., 2016). Whereas the absorption area of

1338 and 1350 cm

-1

indicates the presence of C-H

groups (Wijaya et al., 2019).

Figure 2: Spectrum FT-IR of Commercial Starch and Starch from Lindur Fruit.

Bioethanol Production from Lindur Fruit (Burguiera Gymnorrhiza) Strach with Variation of Inoculum Volume of Zymomonas Mobilis

49

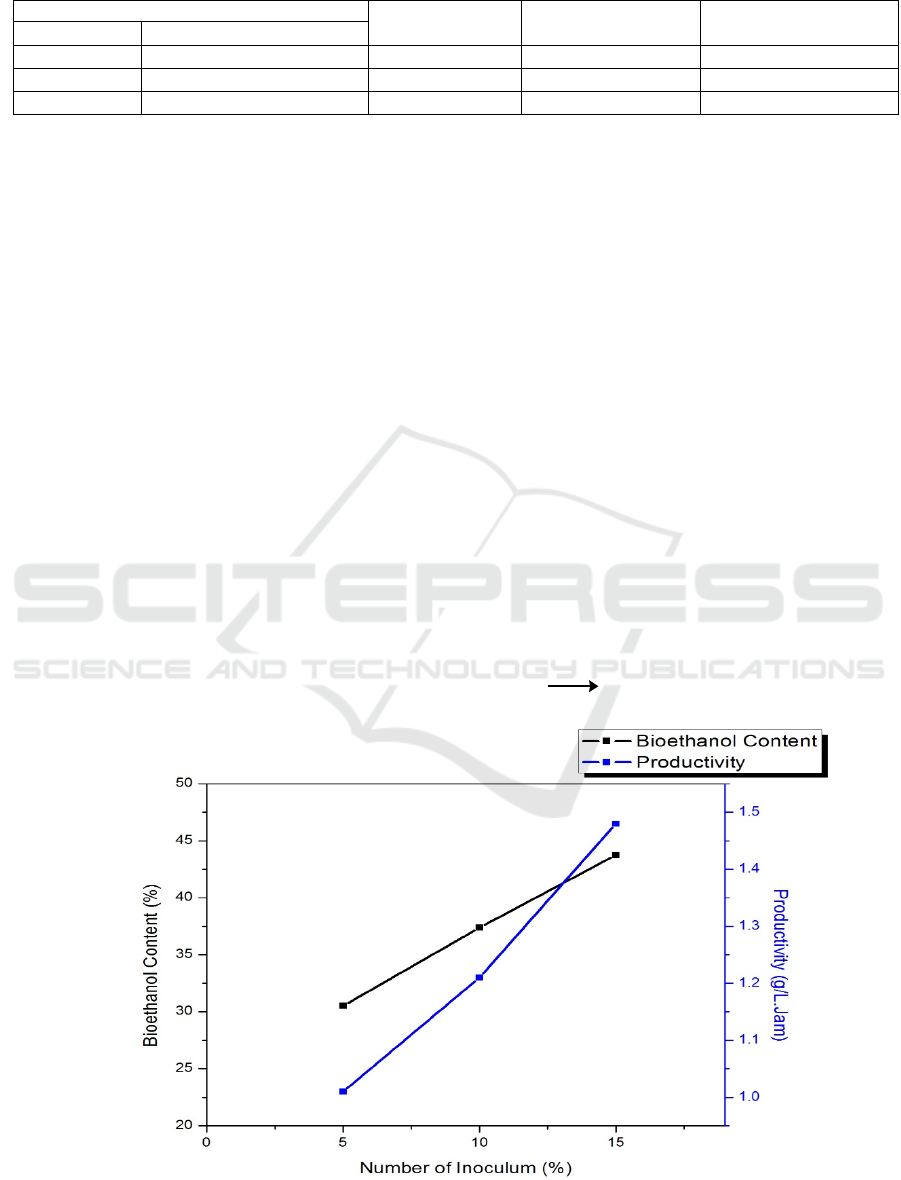

Table 1: Results of Starch Fermentation from Hydrolyzed Lindur Fruit.

Treatment

Yield (%)

Bioethanol

content (%)

Productivity (g / L.

Hours)

Starch (%) Inoculum Z. Mobilis (%)

10 5 8.8 30.53 1.01

10 10 8.6 37.38 1.21

10 15 9.0 43.75 1.48

3.3 Hydrolysis Starch by Acid

Hydrolysis of lindur fruit starch using 25 % HCl

solution and neutralization using 30 % NaOH

solution to obtain a glucose solution of about 7.5 %.

The hydrolysis of starch from the fruit yields 7.5 %

glucose from 10% starch content. The added acid can

hydrolyze because it can form hydroxonium ions

(H

3

O

+

) which are electrophilic so that they attack the

oxygen atom in the glycosidic α-1,4 bond and

hydrolyze the glucosidic bond. Then the electrons in

one of the carbon-oxygen bonds move to the oxygen

atom and produce an unstable high-energy

carbocation intermediary. Furthermore, intermediate

carbocation reacts with water, which leads to the

regeneration of hydroxyl groups (Hoover, 2000).

3.4 Fermented Hydrolyzed Starch

Results of fermentation of hydrolysis solution of

starch fruit will be distilled using a rotarievaporator

to separate the bioethanol obtained by boiling point

differences. The bioethanol content obtained will be

determined using gas chromatography (GC).

Zymomonas mobilis is widely used as a

fermentation bacterium, which converts glucose,

sucrose, and fructose into ethanol. Like Z. mobilis,

Saccharomyces cerevisiae naturally consumes hexose

sugar (for example, glucose, fructose).

The metabolism in Zymomonas is different from

the metabolism of Saccharomyces in which glucose

becomes pyruvate through the Enbden-Meyerhof-

Parnas (EMP) pathway; ethanol is then formed from

pyruvate. Instead, Zymomonas ferments sugar

through the ED pathway, forming pyruvate from

gluconate. As in Saccharomyces, the released

pyruvate is decarboxylation, producing acetaldehyde

and CO

2

, after which acetaldehyde is reduced to

produce ethanol.

When the formation of ATP through the EMP and

ED pathways was compared, it was found that EMP

produced 2 moles of ATP per mole of glucose,

whereas the ED pathway produced 1 mole of ATP per

mole of glucose. Thus, ATP cells result in less

glucose in Zymomonas metabolism than in yeast. The

equation describing molar fermentation is as follows:

1mol C

6

H

12

O

6

1,93 mol C

2

H

5

OH + 1,8 mol CO

2

+ 0,053 mol CH

3

CHOHCOOH

Figure 3: Fermentation Results Chart.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

50

Figure 4: Bioethanol Density Graph.

In table 1 above, it can be seen that the % yield

obtained from the distillation of fermentation

solutions using 10 % starch content ranges from ± 9

% with bioethanol content ranging from 30-40 %.

Whereas in Figure 3 can be seen in the variation

of the number of Zymomonas mobilis bacteria

inoculums there is an increase in the productivity of

bioethanol where in the starch variation of 10 % the

highest productivity is 1.48 g / L. Hours. This is in

accordance with (Fajrin, Amraini and Muria, 2008) ,

which with an increase in the number of inoculums

will increase the productivity or bioethanol content

produced, according to (Kusumaningati, Nurhatika

and Muhibuddin, 2013) with an increase in the

number of inoculums, it will increase its bioethanol

levels due to more microorganisms that can utilize

reducing sugars. According to (Prescott, 1981) there

are two factors that influence the occurrence of

increased bioethanol content, namely the number of

substrates (sugar) and the number of microbes.

3.5 Density Test

In Fig. 4 above it can be seen that the highest density

value on the variation of starch is 10 % and the

amount of inoculum is 5 % with a density of 0.9485

g / ml while the lowest density with an amount of

inoculum of 15 % is 0.9346 g / ml. This is due to the

imperfect distillation process so that bioethanol is still

mixed with water where the pure bioethanol content

has a density of 0.798 g / ml but the density value

obtained exceeds the density of pure bioethanol. So it

can be concluded that the density value has decreased

with the addition of the number of inoculum.

This decrease in density is due to the amount of

inoculum which can increase bioethanol levels or

productivity. High bioethanol content will have a low

density value. So it can be explained that the density

value of bioethanol is inversely proportional to the

bioethanol contentwhere the higher the bioethanol

content, the lower the density value.

4 CONCLUSIONS

Lindur fruit can produce starch that has a brownish

white color. Lindur fruit starch hydrolyzed using acid

produces a glucose solution of about 7.5 % with 10 %

starch content. Fermentation of hydrolysis solution of

lindur fruit starch showed productivity of 1.48 g /

L.Hours

REFERENCES

De, F. J. (2005) Ditemukan Buah Bakau Sebagai Makanan

Pokok. Available at: http://www.ebook.pangan.com.

Estrada-León, R. J. et al. (2016) The effect of isolation

method on properties of parota (Enterolobium

cyclocarpum) starch, Food Hydrocolloids. Elsevier

Ltd. doi: 10.1016/j.foodhyd.2016.01.008.

Fajrin, I., Amraini, S. Z. and Muria, S. R. (2008) ‘Pengaruh

Volume Inokulum pada Produksi Bioetanol dari

Limbah Kulit Nanas Menggunakan Zymomonas

Mobilis dengan Metode Solid State Fermentation ( SSF

) Ikhsan Fajrin , Said Zul Amraini *, Sri Rezeki Muria

Laboratorium Rekayasa Bioproses Jurusan Teknik

Kimia’, I, pp. 1–5.

Bioethanol Production from Lindur Fruit (Burguiera Gymnorrhiza) Strach with Variation of Inoculum Volume of Zymomonas Mobilis

51

Geeta, M. S. G. & G. S. (2007) ‘Effectivenes of Fungal

Pretreament of Agro Residues on Etanol Production by

Yeast and Zymomonas mobilis’, 2, pp. 301–304.

Gunasekaran, P. and Chandra Raj, K. (1999) ‘Ethanol

fermentation technology - Zymomonas mobilis’,

Current Science.

Hoover, R. (2000) ‘Acid-treated starches’, Food Reviews

International. doi: 10.1081/FRI-100100292.

Jacoeb, A. M. et al. (2014) ‘Pembuatan Edible Film Dari

Pati Buah Lindur Dengan Penambahan Gliserol Dan

Karaginan Edible Film from Lindur Fruit Starch with

Addition of Glycerol and Carrageenan’, Jphpi.

Kusumaningati, M. A., Nurhatika, S. and Muhibuddin, A.

(2013) ‘Potensi Kapang Aspergillus sp. dalam Proses

Hidrolisis untuk Produksi Etanol dari Sampah Sayur

dan Buah Pasar Wonokromo Surabaya’, Makalah Orasi

Ilmiah.

Obire, O. (2005) ‘Activity of Zymomonas species in palm-

sap obtained from three areas in Edo State, Nigeria.’, J.

Appl. Sci. Environ. Mgt.

Prescott, S. . (1981) Industrial Microbiology. New York:

Mc. Grow-Hill Book Co Ltd.

Seknun, N. (2012) ‘Pemanfaatan Tepung Buah Lindur (

Bruguiera Gymnorrhiza ) Dalam Pembuatan Dodol

Sebagai Upaya Peningkatan Nilai Tambah Oleh :

Niswani Seknun Departemen Teknologi Hasil

Perairan’, pp. 1–71.

Tripetchkul S.Z.D Hilary (1998) ‘strategies for improving

ethanol production using zymomonas mobilis’, Devel.

in Agricultural & Biological Chem, 2, pp. 41–55.

Wijaya, C. et al. (2019) ‘Isolation and characterization of

starch from Limnophila aromatica’, Heliyon. Elsevier

Ltd, 5(5), p. e01622. doi:

10.1016/j.heliyon.2019.e01622.

Yanase, H. (2014) ‘Zymomonas’, Encyclopedia of Food

Microbiology: Second Edition, 3, pp. 856–863. doi:

10.1016/B978-0-12-384730-0.00365-7.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

52