Synthesis of Semi Interpenetrating Polymer Network’s Hydrogel

from Bacterial Cellulose

Putri Rizky

1

, Tamrin

1

and Marpongahtun

1,2

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

2

Laboratorium Penelitian Terpadu, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Acrylic Acid, Bacterial Cellulose, Hydrogel, Interpenetrating Polymer Network, N,N’-

Methylenebisacrylamide.

Abstract: Semi interpenetrating polymer network’s (IPN) hydrogel from bacterial cellulose (BC) has been

successfully synthesized. This semi-IPN hydrogel was prepared from a suspension of BC in a solvent

system of PEG1000/NaOH in the presence of acrylic acid (AA) as monomer, potassium persulfate (KPS) as

initiator, and N,N’-methylenebisacrylamide (MBA) as crosslinker. The obtained semi-IPN hydrogel was

characterized using FT-IR and SEM, also its physical property was characterized, i.e. swelling degree and

crosslinked percentage. The swelling degree and crosslinked percentage showed the semi-IPN’s hydrogel

with the addition of 600 mg BC has the maximum value, 1338 and 46%, respectively. The FT-IR analysis

exhibited the crosslinked formation between AA and MBA with the presence of band at 1555 cm

-1

that

assigned as secondary aliphatic amine. The morphological analysis of semi-IPN’s hydrogel has a rough and

dense surface.

1 INTRODUCTION

Cellulose is an abundance natural polymer that

constructed by glucose as the monomer, and it can

be easily found as a component in the plants and

natural fibers, i.e. cotton and linen. Several bacteria

(e.g. Acetobacter xylinum) can produce cellulose

(exopolysaccharide) (Ross et al., 1991). Cellulose

that produced by microbe or bacteria is called as

bacteria cellulose which has similar chemical

properties with cellulose from plants (Czaja et al.,

2007). Cellulose and BC also constructed by glucose

unit that linked through 1,4-β--glycoside, this

resulted in the highest crystallinity degree of

cellulose and BC, and it cannot soluble in water and

other common solutions. The different between

these two celluloses is the fiber size. Generally, BC

has a nanosized fiber but in cellulose-plants, the

most common sized of fiber is micro-sized. The

other advantage of BC is mostly free from

impurities, i.e. pectin and lignin.

Cellulose is found in agricultural waste,

including 58% rice husk, 56.86% sago bark, corn

cob 44.9%, 40-45% hardwood, 38-49% softwood,

oil palm empty fruit bunches 36 - 42%, esparto 33-

38%, bagasse 32-44%, wheat straw 29-37%, rice

straw 28-36% and bamboo around 26-43% (Ito et

al., 2007).

Cellulose-based hydrogels can be obtained via

either physical or chemical stabilization of aqueous

solutions of cellulosics (Chang et al., 2008).

Additional natural and/or synthetic polymers might

be combined with cellulose to obtain composite

hydrogels with specific properties (Sarkar, 1979).

One polymeric material that currently famous for

multipurpose is hydrogel which can be synthesis

from natural and synthetic polymer, e.g. cellulose,

chitosan, alginate, etc. Hydrogel as the multipurpose

material has been utilized for medical, cosmetic,

wound healing, agriculture, etc. Hydrogel can be

synthesized through several techniques, one of them

is semi-IPN. This technique has a lot of advantages,

especially to the chemical and physical properties of

the obtained hydrogel. The objective of the current

study was to determine the physical properties of the

hydrogel and learn about its chemical structure

through FT-IR data also the morphological from

SEM images.

Hydrogels can be produced through the

Interpenetrating Polymer Network (IPN) technique.

Interpenetrating Polymer Network (IPN) is a

polymerization system that is made simultaneously

Rizky, P., Tamrin, . and Marpongahtun, .

Synthesis of Semi Interpenetrating Polymer Network’s Hydrogel from Bacterial Cellulose.

DOI: 10.5220/0010132800002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 37-41

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

37

and sequentially to produce overlapping networks.

IPN is made through crosslinked polymeric

materials that are synthesized by condensation,

addition or propagation using several monomers,

then the resulting polymer is polymerized and

crosslinked (Banerjeer et al., 2010).

The crosslinker used in this study is N, N′-

methylene bisacrylamide (MBA) which reacts with

carboxyl functional groups in the polymer chain to

form a polymer network. The ability of polymers to

absorb water is very dependent on the degree of

crosslinking (Garner et al., 1997).

Acrylic Acid (AA) is a type of hydrophilic

monomer which is the raw material for the

manufacture of acrylic polyacetylenes (PAA)

polymers. The chemical structure of the acrylic

acrylic (PAA) has ionizable -COOH group units.

This polymer chain can be crosslinked to the -OH

group. By progress in the development of research

and technology, in recent years research relating to

acrylic acid polymers (PAA) is being intensively

developed as a base material for new biomaterials

(Billmeyer, 1984).

The combination of biopolymers and synthetic

polymers will produce superior hydrogels. Cellulose

is one of the basic ingredients of hydrogel which is

widely used as a raw material for wound dressing,

inexpensive, biodegradable, and biocompatible

(Sannino et al., 2009). Cellulose can also be

produced by microorganisms, bacterial cellulose

(BC) which is purer than cellulose derived from

plants because it is free of lignin, hemicellulose, and

other biogenic products (Brown, 2007).

2 MATERIALS AND METHODS

2.1 Materials

The chemical in this study were analytical grade, i.e.

sodium hydroxide (Merck), acrylic acid (Sigma

Aldrich), N,N’-methylenebisacrylamide (Merck),

potassium persulfate (Merck), and Polyethylene

glycol 1000 (Merck). Bacteria cellulose in this study

was obtained by culturing A. xylinum in the coconut

water medium (Gea et al., 2011).

2.2 Synthesis of Semi-IPN’s Hydrogel

About 200 mg of bacteria cellulose powder was

suspended in 100 mL of distillate water that

contained PEG and NaOH 3:4. The suspension was

placed in freezer at -5

o

C for 24 h. The frozen

suspension was melted and homogenized using

magnetic stirrer at room temperature for 2 h, as the

result the transparent solution was obtained. About 5

mL of the transparent solution was reacted with 760

mg of AA, 40 mg of MBA, and 54 mg of KPS.

These mixtures were stirred at 60

o

C for 15 min until

all components was homogenous. At the end of

polymerization, the transparent hydrogel was

washed with distillate water until the neutral pH was

reached. The obtained hydrogel was dried in oven

and kept in desiccator. This procedure was repeated

for the other composition of BC (400 mg; 600 mg;

800 mg and 1000 mg).

2.3 Characterization

The obtained hydrogel was characterized using FT-

IR (Bruker Opus Alpha 7.5) and SEM (Quorum

Model Q150R ES). The physical property of

hydrogel also characterized, i.e. swelling degree and

crosslinked percentage.

Swelling degree

Five sample replications were dried in oven at

60

o

C until the constant weight was obtained. These

samples were soaked in water for 24 h. The swollen

samples were separated from the solvent and

weighed (S. K. Bajpai & Swarnkar, 2014),. The

swelling degree of these samples were determined

using the equation (1) below:

Rasio Swelling (%) = (W

s

-W

d

)/W

d

× 100% (1)

Where W

s

was the weight of swollen sample and W

d

was the weight of dried sample.

Crosslinked degree

Five sample replications were dried in oven at 60

o

C

until the constant weight was obtained. These

sample were soaked in chloroform for 24 h and then

dried at 60

o

C for 3 h. The dried hydrogel was

weighed (S. K. Bajpai & Swarnkar, 2014), and the

crosslinked degree was determined using the

equation (2) below:

Crosslinked degree (%) = W

a

/W

b

× 100 % (2)

where W

a

was the dried weight of hydrogel before

soaked in chloroform and W

b

dried weight of

hydrogel after soaked in chloroform.

3 RESULTS AND DISCUSSIONS

3.1 Synthesis of Semi-IPN’s Hydrogel

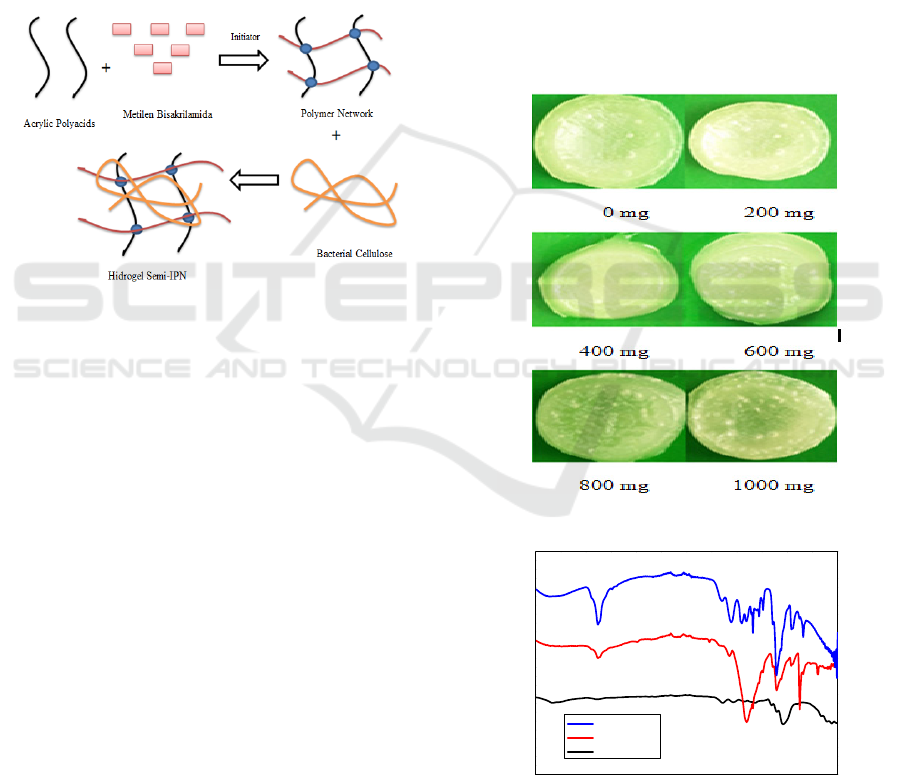

The semi-IPN’s hydrogel (Fig.2) was prepared from

BC in the combination of poly-AA. As in method,

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

38

this hydrogel was prepared by varying the mass of

BC. The obtained hydrogel was prepared using free

radical polymerization technique, the initiator was

KPS and the crosslinker was MBA. The obtained

semi-IPN’s hydrogel was reacted in the alkaline

condition by the using a solvent system of

PEG/NaOH.

The chemical structure of semi-IPN’s hydrogel

was constructed by the crosslinked poly-AA with

MBA (crosslinked network of poly-AA). In other

hand, the BC in the hydrogel system was overlapped

with the crosslinked network of poly-AA.

Illustration of making semi-IPN hydrogel and

hydrogel can be seen in Fig.1.

Figure 1: Illustration of Semi-IPN Hydrogel

Manufacturing.

3.2 Fourier Transform Infrared

Spectroscopy (FTIR) Analysis

FTIR spectra of BC, poly-AA, and semi-IPN’s

hydrogel can be seen in Fig.3.

In the FTIR spectrum of bacterial cellulose

(Figure 1), there is an absorption peak at 3336 cm

-1

indicating the

presence of hydroxyl (O-H)

stretching. Also, there is an absorption peak of 2891

cm

-1

indicating the presence of -C-H bonds. At the

peak of the absorption of 1424 cm

-1

is the vibration

vibrations of -CH

2

. There is also an absorption peak

of 1157 cm

-1

where the spectrum shows uptake of -

C-O groups originating from bonds between carbon

atoms and hydroxyl groups in bacterial cellulose

(Suo et al., 2007).

FT-IR spectra of poly-AA and semi-IPN showed

a similar band with the spectrum of BC, but only

different in their intensities. A significance different

can be observed near 1600-1650 cm

-1

that assigned

as secondary amine group of N,N’-

methylenebisacrylamide (MBA). Also, the most

dominant band of this kind of sample can be

observed at 3000-3600 cm

-1

that confirmed the

presence of hydroxyl group from BC and acrylic

acid. The presence of secondary amine also can be

observed near 715 – 874 cm

-1.

Based on Fig.3, the shape and absorption band of

600 mg semi-IPN semi-IPN hydrogel did not have a

significant difference with the infrared absorption of

the hydrogel blank. This proves that the cross-

linking process between AA monomers (forming

polyacrylic acid) and the MBA cross-linker has been

formed. The existence of SB is proven to be able to

provide a physical bonding effect characterized by

the formation of semi-IPN hydrogels without

changing the shape of the absorption band on the

hydrogel made. The description of functional groups

that were successfully observed by FTIR

spectrophotometer between hydrogel blanks and 600

mg semi-IPN hydrogels did not differ much only by

shifting wave numbers (Sannino et al., 2009).

Figure 2: The Obtained Semi-IPN’s Hydrogel.

3500 3000 2500 2000 1500 1000 500

Hidrogel 600 mg

Blanko

Bacterial Cellulose

Transmittance (%)

Wavenumber (cm

-1

)

Figure 3: FTIR spectra of (a) BC, (b) poly-AA, and (c)

semi-IPN with 600 mg of BC.

Synthesis of Semi Interpenetrating Polymer Network’s Hydrogel from Bacterial Cellulose

39

3.3 Scanning Electron Microscopy

(SEM) Analysis

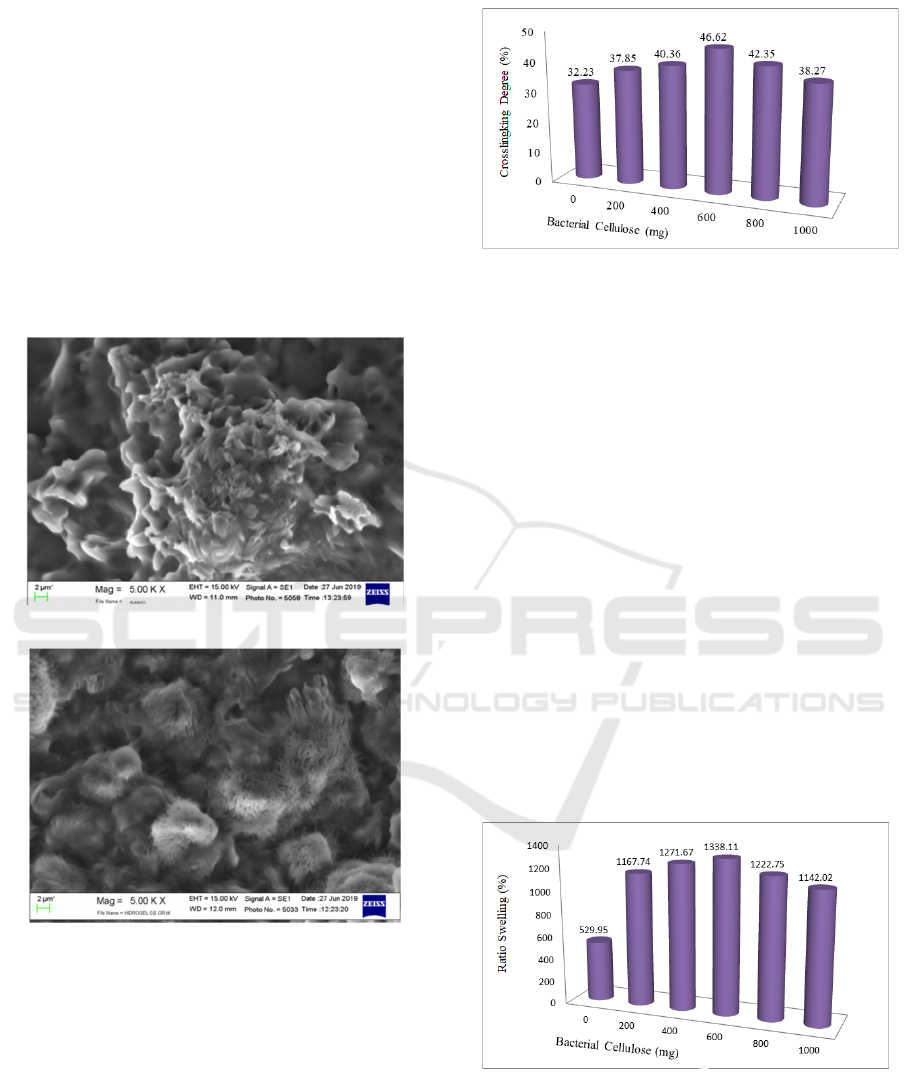

The morphological analysis using SEM was

performed to observe the surface characteristic of

the obtained semi-IPN’s hydrogel. Fig. 4 (a) the

obtained hydrogel poly-AA formed an agglomerate.

Hebeish et al. (2014) in his research explained that

the formation of agglomerate was twisting effect, an

indication of interaction. But a unique result was

found in Fig 4 (b), small pores were observed on the

hydrogel surface. The presence of this pores in the

semi-IPN’s hydrogel can enhance the diffusion and

swelling degree of hydrogel (Astrini et al., 2016).

a

b

Figure 4: The morphological of hydrogel (a) poly AA and

(b) semi-IPN.

3.4 Crosslinked Degree Analysis

The result of crosslinked degree is exhibited in Fig

5.

Figure 5: The crosslinked degree of semi-IPN’s hydrogel.

The crosslinked degree with the maximum is

observed in the addition of 600 mg of BC. This can

be assumed as the formation of a long polymer chain

and was linkage in the specific positions. But the

decrease of crosslinked degree observed in the

addition of 800 mg and 1000 mg of BC. This can be

assumed at this amount of BC the elasticity modulus

of semi-IPN was limited as the van der Waals and

hydrogen bonding interactions between BC and AA.

This decrease is caused by the occurrence of

equilibrium so that the addition of SB can reduce

mechanical properties due to irregular polymer

chains (Dragan et al., 2012).

3.5 Swelling Degree Analysis

The ability of hydrogel for absorbing water was

determined using swelling degree. Hydrogel can be

swelling, has a transparent and smooth surface, and

flexible (Okay & Sariisik, 2000). The swelling

degree of semi-IPN’s hydrogel can be seen in Fig.6.

Figure 6: Swelling Degree Of Semi-IPN’s Hydrogel.

Based on the Fig.5, the swelling degree increase

with the increase of BC in the hydrogel system. But

the value decrease when the addition of BC is more

than 0.6 g. For the first case, with the increase of BC

in the hydrogel system it will have a direct impact to

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

40

the number of hydroxyl group. The increase of this

hydroxyl group will influence the hydrophilicity of

hydrogel. But in the second case, the increase of

hydroxyl group may disturb the equilibrium of

water, as the impact the water diffusion become low

(S. K. Bajpai & Swarnkar, 2014). The other reason

of the decrease of swelling degree at the addition of

BC of 0.8 and 1.0 g can be caused the ratio between

MBA-poly AA and BC was not balanced. It can be

assumed, as the impact there are some of BC that

will not interact with MBA-poly AA through van

der Waals and hydrogen bonding interaction (A. K.

Bajpai & Giri, 2003).

4 CONCLUSIONS

Semi-IPN’s hydrogel has been successfully

synthesis using BC, AA and MBA through free

radical polymerization. The maximum value of

crosslink degree and swelling degree was found at

600 mg, with the value of 46,62% and 1338%,

respectively. The FT-IR spectra confirmed the

crosslinked of MBA to AA was found at 1555 cm

-1

.

The morphological surface of semi-IPN’s hydrogel

showed a rough and dense surface.

ACKNOWLEDGEMENTS

The authors thank the Polytechnic Industrial

Chemical Technology, Department of Chemistry,

Universitas Sumatera Utara, Medan for their support

in the use of laboratories, and do not forget my

supervisor who has provided the benefits of

guidance and advice in conducting this research.

REFERENCES

Astrini, N., Anah, L., & Haryono, A. (2016). Pengaruh

Metilen Bisakrilamid (MBA) pada Pembuatan

Superabsorben Hidrogel Berbasis Selulosa terhadap

Sifat Penyerapan Air. Jurnal Kimia Dan Kemasan,

38(1), 15–20.

Bajpai, A. K., & Giri, A. (2003). Water Sorption

Behaviour Of Highly Swelling (Carboxy

Methylcellulose-g-Polyacrylamide) Hydrogels And

Release Of Potassium Nitrate As Agrochemical.

Carbohydrate Polymers, 53(3), 271–279.

Bajpai, S. K., & Swarnkar, M. P. (2014). New Semi-IPN

Hydrogels Based On Cellulose For Biomedical

Application. Journal of Polymers, 2014, 1–12.

Banerjeer, S., Ray, S., Maiti, S., Sen, K., Bhattacharyya,

U., Kaity, S., & Ghosh, A. (2010). Interpenetrating

Polymer Network (IPN): A Novel Biomaterial.

International Journal of Applied Pharmaceutics, 2,

28–34.

Billmeyer, F. (1984). Textbook Of Polymer Science

(Third). John Wiley and Sons.

Brown, E. E. (2007). Bacterial cellulose/thermoplastic

polymer nanocomposites. Department of Chemical

Engineering, Washington State University.

Chang, C., Lue, A., & Zhang, L. (2008). Effects of

crosslinking methods on structure and Properties Of

Cellulose/PVA Hydrogels. Macromol. Chem. Phys.,

209(12), 1266–1273.

Czaja, W. K., Young, D. J., Kawecki, M., & Brown, R. M.

(2007). The future prospects of microbial cellulose in

biomedical applications. Biomacromolecules, 8(1), 1–

12.

Dragan, E. S., Perju, M. M., & Dinu, M. V. (2012).

Preparation and Characterization of IPN Composite

Hydrogels Based on Polyacrylamide and Chitosan and

Their Interaction with Ionic Dyes. Carbohydrate

Polymers, 88, 270–281.

Garner, C. M., Nething, M., & Nguyen, P. (1997).

Synthesis Of A Superabsorbent Polymer. J. Chem.

Educ., 74, 95–99.

Gea, S., Reynolds, C. T., Roohpour, N., Wirjosentono, B.,

Soykeabkaew, N., Bilotti, E., & Peijs, T. (2011).

Investigation Into The Structural , Morphological ,

Mechanical and Thermal Behaviour of Bacterial

Cellulose After A Two-Step Purification Process.

Bioresource Technology, 102(19), 9105–9110.

Hebeish, A., Farag, S., Sharaf, S., & Shaheen, T. I. (2014).

Thermal Responsive Hydrogels Based on Semi

Interpenetrating Network of Poly(NIPAm) and

Cellulose Nanowhiskers. Carbohydrate Polymers,

102, 159–166.

Ito, T., Yeo, Y., Highley, C. B., Bellas, E., Benitez, C. A.,

& Kohane, D. S. (2007). The prevention of peritoneal

adhesions by in situ cross-linking hydrogels of

hyaluronic acid and cellulose derivatives.

Biomaterials

, 28(6), 975–983.

Okay, O., & Sariisik, S. B. (2000). Swelling Behavior of

Poly (Acrylamide-co-Sodium Acrylate) Hydrogels in

Aqueous Salt Solutions: Theory Versus Experiments.

Eur. Polym. J., 36, 393–399.

Ross, P., Mayer, R., & Benziman, M. (1991). Cellulose

Biosynthesis and Function in Bacteria. Microbiol.

Rev., 5(1), 35–58.

Sannino, A., Demitri, C., & Madaghiele, M. (2009).

Biodegradable Cellulose-based Hydrogels: Design and

Applications. Materials (Basel), 2(2), 353–373.

Sarkar, N. (1979). Thermal gelation properties of methyl

and hydroxypropyl methylcellulose. J. Appl. Polym.

Sci., 24(4), 1073–1087.

Suo, A., Qian, J., Yao, Y., & Zhang, W. (2007). Synthesis

and Properties of Carboxymethyl Cellulose- graft-

Poly(acrylic acid-co-acrylamide) as a Novel Cellulose-

Based Superabsorbent. J. Appl. Polym. Sci., 103,

1382–1388.

Synthesis of Semi Interpenetrating Polymer Network’s Hydrogel from Bacterial Cellulose

41