Characterization of Physical Properties and Morphological

Ruberized Asphalt Paving Blocks based on Bituminous Coal and

Concentrated Natural Rubber Latex

Riri Indah Nitami Harahap

1

, Tamrin

2*

and Darwin Yunus Nasution

2

1

Postgraduate Chemistry Study Programme, Universitas Sumatera Utara, Medan, Indonesia

2

Department of Chemistry, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Paving Block, Concentrated Natural Rubber Latex (CNRL), Bituminous Coal, Ruberized Asphalt,

Morphological.

Abstract: This research about the characterization physical properties and morphological ruberized asphalt paving block

using asphalt as a binder replacement and utilization of natural resources such as bituminous coal and natural

rubber latex concentrate (NRLC). This research aims to determine the optimum value of physical properties

and learn the effect of morphological control on the paving block that have been prepared. Morphological

control with varied the composition asphalt, bituminous coal, and natural rubber latex concentrate that mixed

using by an internal mixer with addition of aggregates and additive agents such as dicumyl peroxide as an

initiator and divinylbenzene as a crosslinker. After the mixing process, then the mixture on shaping/forming

process. The result of physical properties obtained optimum value at the variation of composition asphalt :

bituminous coal : natural rubber latex concentrate (70:25:5)(Paving Block E). The percentage of water

absorption is 0.85 % and compressive strenght is 154.23 Kgf (0.605 Mpa). At this optimum variation of

composition has been characterized the morphological using by Scanning Electron Microscopy (SEM) which

is the result of surface morphology showed the mixture compactly and most effective homogenity of the

mixture.

1 INTRODUCTION

Infrastructure is a benchmark for developing a

country. Infrastructure development in developing

countries like Indonesia is urgently needed. One of

them is infrastructure in the field of road pavement.

The road pavement material used is paving block.

Interest in the use of paving blocks because it can

be applied to many areas such as parking lots,

residential streets, home yards, parks, industrial areas,

and other open spaces. Increased use of paving blocks

due to paving blocks including environmentally

friendly construction, good water absorption ability,

faster installation, lower cost, diverse shades and

colors so as to increase aesthetic value (Hastuty et al.,

2018). Based on ([Standar Nasional Indonesia] SNI-

03-0691-1996, n.d.), the constituent components of

paving blocks are made from a mixture of portland

cement or other adhesives with aggregates using or

without the addition of other materials which do not

reduce the quality of paving blocks.

Research on paving blocks has been carried out

by adding or replacing components in paving blocks.

The use of rice husk ash and lime as a partial

substitution of cement, addition of coconut shell, use

of spent catalyst waste. However, the physical

properties produced on the ability of water absorption

do not meet the water absorption standards on paving

blocks. The chemical composition of the constituent

of paving blocks also influences the characteristics of

paving blocks, such as physical, mechanical, and

morphological characteristics. One of the efforts

made to improve these characteristics is polymer

modification.

Asphalt can also be used as a substitute for

cement. Asphalt contains a long hydrocarbon chain,

where the longer the hydrocarbon chain content will

affect its polarity, so that the paving block produced

physical properties on good water absorption ability,

the use of cold mild catalyst waste results in better

water absorption. The characteristics of binder

substitutes such as asphalt can be modified with other

polymer materials. Asphalt modification can also be

30

Indah Nitami Harahap, R., Tamrin, . and Yunus Nasution, D.

Characterization of Physical Properties and Morphological Ruberized Asphalt Paving Blocks based on Bituminous Coal and Concentrated Natural Rubber Latex.

DOI: 10.5220/0010132700002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 30-36

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

done by using natural binders (natural binders) such

as pine resin (Yuniarti, 2015).

Rubber plants have been supporting the

Indonesian economy, since a few decades ago, but the

performance of rubber is less than optimal. Indonesia

is one of the countries with the largest rubber

plantations in the world, but its productivity is still far

behind that of other natural rubber producing

countries. Natural rubber is an efficient polymer

added to asphalt. Asphalt modification has been done

by Kartika (2017) using fresh natural latex rubber.

Modification of asphalt has been carried out with

commercial liquid bitumen and (Kartika, 2017).

Bitumen can be classified into liquid bitumen and

solid bitumen. The source of solid bitumen is coal.

Coal is an option that needs to be developed as

much as possible, because coal is a natural resource

whose availability and distribution is very abundant

in Indonesia. One rank of coal is bitumen coal. The

rank of coal which is widely spread in Indonesia is

bitumen coal. Bitumen coal is an organic and

inorganic macromolecule. The chemical composition

of bitumen coal contains the main elements namely

C, H, O, N, S, P. Based on ([WCI] World Coal

Institute, 2005) data, coal quality depends on the

hydrocarbon group (Rajan et al., 2017). Bitumen has

been applied as adhesives, sealants, waterproof

agents, and binders on road pavement construction

materials (Zhu et al., 2014).

Modification of bitumen with other polymers is

the incorporation of polymers in bitumen by

mechanical mixing or chemical reaction. Fresh

natural latex with a combination of liquid bitumen

(Kartika, 2017) has an effect on increasing the

characteristics of asphalt. Fresh natural latex contains

60% water and 40% rubber (Suksup et al., 2017). The

water content also influences the characteristics of

paving blocks. To optimize the performance of

natural rubber can be done with concentration and

centrifugation to produce concentrated latex with

more rubber content that is 60% and reduce water

content to 40% (Suksup et al., 2017). In addition, the

performance of natural rubber can be improved by

chemical modification by grafting techniques using a

compatible agent such as a crosslinker such as divinyl

benzene (Ritonga et al., 2018). Thus, it can increase

the stability and density of asphalt mixes (NorFazira

et al., 2016).

In the mixture of asphalt with aggregate, bitumen,

concentrated latex will only occur physical bonds.

The use of dicumil peroxide (DCP) as an initiator and

divinyl benzene (DVB) as a crosslinker in the

mixture, the polymers used in asphalt, concentrated

latex or bitumen will be radical. This radicalism

encourages chemical bonds between concentrated

latex, asphalt, bitumen ie covalent bonds.

Based on the description, researcher interest in

research about the Characterization of Physical

Properties and Morphological Ruberized Asphalt

Paving Block Based on Bituminous Coal and

Concentrated Natural Rubber Latex (CNRL) with the

addition of dicumyl peroxide (DCP) initiators and

divinyl benzene crosslinker (DVB).

2 MATERIALS AND METHODS

2.1 Materials

Bituminous coal from PT. Amber and Coal Sumatra,

Asphalt from Iran Type Grade 60/70, Concentrated

latex from PT. Bridgestone Sumatera Rubber Estate,

Divinyl benzene (DVB) from Sigma-Aldrich,

Dikumil Peroxide (DCP) from Sigma-Aldrich,

Aggregate from Pebble Stone from CV. Setia Jaya,

Fine Sand Aggregate from CV. Setia Jaya

2.2 Preparation of Paving Blocks

5 ml of concentrated latex was put into a 50 ml glass

beaker and heated at 70 °C. Then put 70 ml of asphalt

into the beaker while heated. Then both of them were

mixed while being heated at 140 °C for 15 minutes,

then added 25 grams of solid bitumen while stirring.

The mixture was added 0.9 ml DVB and stirred for

10 minutes. 300 grams of sand and 50 grams of gravel

were added to the mixture while still stirring, then

added 0.9 grams of DCP while still stirring for 10

minutes under the same heating. The mixture is then

put into a cube mold. Then the molds are put into a

hydrolyc press which has been set at 140 °C for 30

minutes, then cooled to room temperature.

Table 1: Variation Asphalt, Bituminous Coal, and CNRL.

Paving

block

Asphalt

(mL)

Bituminous

Coal

(gram)

CNRL

(mL)

A 70 5 25

B 70 10 20

C 70 15 15

D 70 20 10

E 70 25 5

F 80 0 20

G 80 20 0

Characterization of Physical Properties and Morphological Ruberized Asphalt Paving Blocks based on Bituminous Coal and Concentrated

Natural Rubber Latex

31

2.3 Characterization

2.3.1 Water Absorption Test

Water absorption test to find out the amount of water

absorption by polymer asphalt that has been made

refer to ASTM C C140 / C140M-15 by weighing and

recording it as a dry mass (Mk). Then soak the sample

in water for 24 hours then lift the sample and the

surface is dried with a tissue, then weigh the sample

weight after soaking and recorded as a saturated mass

(Mj) and calculate the value of water absorption test

using equation:

% 𝑊𝐴 =

𝑀𝑗 − 𝑀𝑘

𝑀𝑘

𝑥 100 %

2.3.2 Compressive Strength Test

Analysis of mechanical properties by compressive

strength test The tool used in the compressive test is

GOTECH AI - 7000M with a capacity of 2000 Kg.f

and refers to ASTM D-790 / C-293, with a sample

testing procedure in the form of a cube with a 5 cm

side in accordance with ASTM C-348-2002 by

placing a sample placed on a compressive testing

machine. Loading is given until the test object

collapses, ie when the maximum load is working. The

maximum load is recorded as P max. Then calculate

the compressive strength test value using equation

then the value of the compressive strength test of

polymer asphalt can be determined by using the

equation :

𝑃=

𝑀𝑎𝑥 𝐿𝑜𝑎𝑑

𝐴𝑜

2.3.3 Surface Morphology Analysis by using

SEM

Scanning Electron Microscope (SEM) is used to

analyze the surface of an object (solid) to find out

topographic, morphological, and composition

information of a sample. The instrument used was

SEM Hitachi TM-3000 with SEM specifications

including a resolution of 1-10 nm. SEM analysis was

conducted at the Integrated Research and Testing

Laboratory, Universitas Sumatera Utara.

3 RESULTS AND DISCUSSIONS

3.1 Results and Analysis of Water

Absorption Test

Water absorption analysis is carried out to determine

the capacity of paving block material produced in

absorbing water. This analysis refers to ASTM C140

/ C140M-15. The test is done by immersing all

samples in water for 24 hours. This test is carried out

on samples with different component variations to

find out the percentage content of the combination

components in an ideal mixture. The relationship

between the percentage of water absorption with

variations in asphalt components, solid bitumen, and

concentrated latex is presented following Table 2 and

Figure 1.

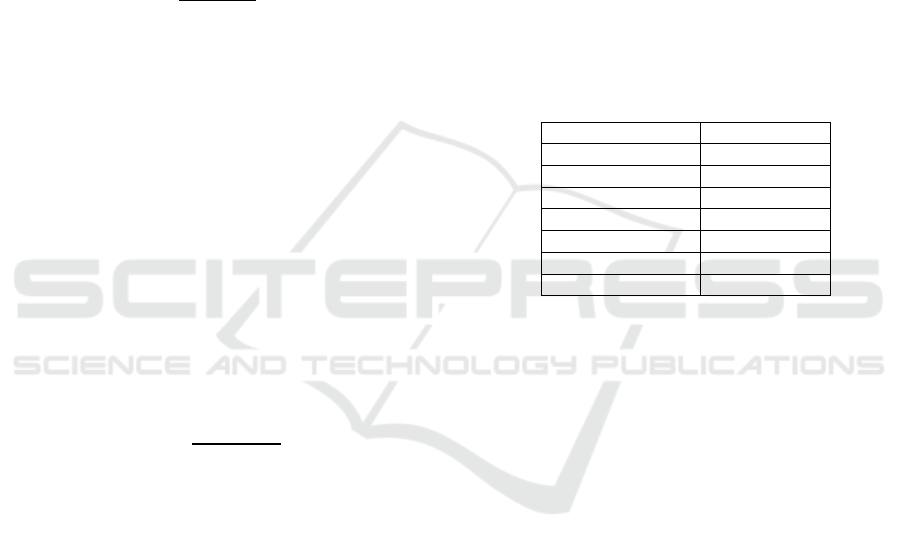

Table 2: Percentage water absorbtion paving block.

Pavin

g

Bloc

k

% WA

A1.56

B1.46

C1.27

D1.21

E0.85

F2.75

G2.30

In table 2 shows the minimum percentage of water

absorption value that is in samples with variations of

asphalt components: solid bitumen: concentrated

latex (70: 25: 5) which is 0.85%. It can also be seen

in the graph that with more levels of addition of solid

bitumen tends to reduce the value of water

absorption. This is because solid bitumens are

resistant to water (McNally, 2011). whereas in

samples without the addition of solid bitumen, a

higher water absorption value of 2.75% is produced.

This explains that the addition of solid bitumen to a

mixture of asphalt and concentrated latex can reduce

the percentage value of water absorption.

Inversely proportional to the increasing levels of

concentrated latex in a mixture of asphalt and solid

bitumen. Increased concentrated latex levels tend to

increase the ability of water absorption. In this

research, the percentage of absorption was 1.56% with

the addition of rubber at the most, 25%. The ability of

water absorption increases with increasing levels of

concentrated latex in the mixture (Kartika, 2017) so

that the water content of concentrated latex binds

water from the sample marinade. The minimum

percentage of water absorption in this study did not

differ significantly from the results reported by

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

32

Kartika (2017) using liquid bitumen, which is about

0.8%.

Based on this, variations with concentrated latex

levels will increase the mixing homogeneity to be less

effective. However, water absorption is increasing

without the addition of concentrated latex in the

material mixture which is 2.30%. This explains that

the added rubber content also affects the percentage

of water absorption.

The percentage of water absorption from paving

blocks produced meets the standards of SNI 03-0691-

1996. Based on this value, the resulting paving blocks

meet the quality requirements for all areas with a

maximum percent of each% WA, namely: 3% of the

road, 6% of the parking area, 8% of pedestrians, and

10% of parks and other uses.

3.2 Results and Analysis of

Compressive Strength Test

Compressive strength is the main mechanical

characteristic of road pavement material. This test

aims to determine the maximum compressive

strength characteristics that can be accepted by

paving block samples. This test refers to ASTM D790

/ C293. Compressive strength analysis has been

carried out on all samples using GOTECH AI-7000M

by giving a load of 20 KN or 2039.4 Kgf (1 KN = 101

Kgf). The results of the test are obtained in the form

of graphic output and max load data

Calculation of compressive strength value is

obtained from the price of P substituted into equation

3.2, so that the compressive strength value is obtained

in units of Kgf / mm2, then converted into units of

MPa (1 Kgf / mm2 = 9.81 MPa).

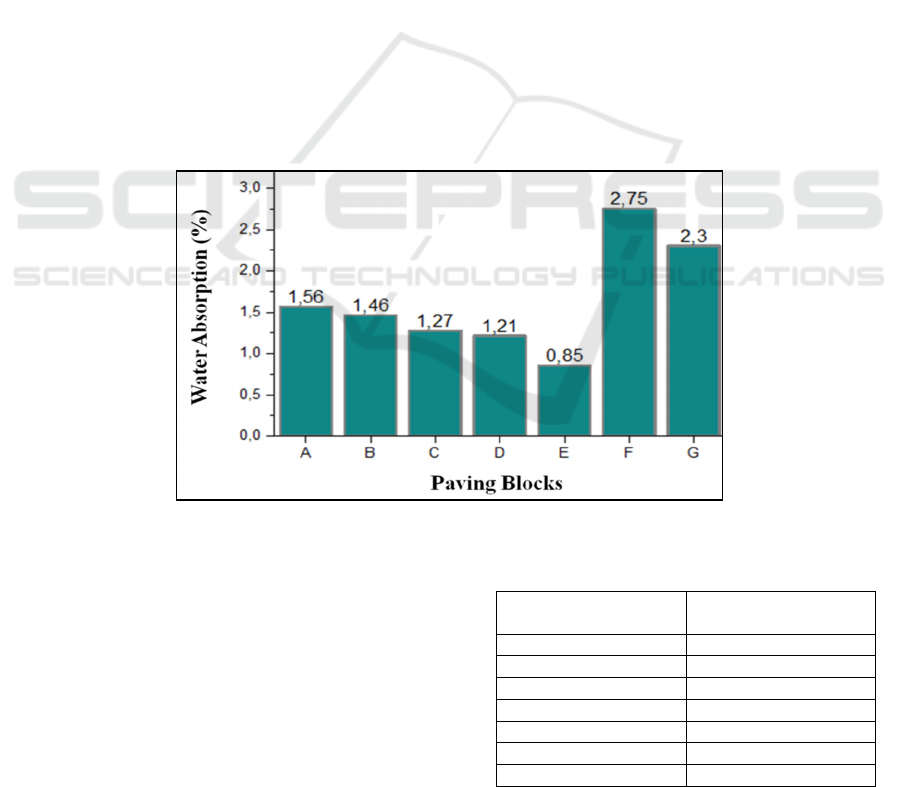

The variation of the ideal composition in the

paving block based on the compressive strength test

was obtained in the variation of the composition of

asphalt: solid bitumen: concentrated latex (70: 25: 5)

with a compressive strength value of 0.605 MPa. In

the mixture without the presence of solid bitumen, the

compressive strength value obtained is 0.085 MPa,

while without the addition of rubber the compressive

strength value of 0.103 MPa is obtained. Based on the

results of the data obtained, the addition of a

combination of concentrated latex and bitumen can

increase the strength of asphalt. Addition of polymer

materials around 2-6% is enough to improve the

quality of the asphalt mixture (Polacco & Berlincioni,

2005).

Figure 1: Percentage Value of Water Absorption for Asphalt, Bitumenous coal and Latex Variations.

The relationship between compressive strength

values and variations in the composition of asphalt

mixes: solid bitumen: concentrated latex is presented

in graphical form in the following Table 3 and Figure

2.

Based on the diagram in Figure 2. can be seen an

increase in compressive strength after the addition of

solid bitumen and concentrated latex. This shows that

in the asphalt mixing: solid bitumen: concentrated

latex (70: 25: 5), the dispersion of latex in the asphalt

and bitumen mixture is more homogeneous. The

more

addition of solid bitumen, which is as much as

Table 3: Compressive Strenght Value of Paving Block.

Paving Blocks

Compressive Strenght

(

MPa

)

A 0.180

B 0.222

C 0.299

D 0.452

E 0.605

F 0.085

G 0.103

Characterization of Physical Properties and Morphological Ruberized Asphalt Paving Blocks based on Bituminous Coal and Concentrated

Natural Rubber Latex

33

25%, shows an increase in compressive strength. This

works as a synergy with the addition of only 5% latex.

This is consistent with Azliandry (2011) reported,

where the highest mechanical properties were

obtained in asphalt mixtures with the addition of 5%

SIR 20 (95:5). This is because the dispersion of

rubber in asphalt is more homogeneous and the role

of rubber in the mixture slows the rate of permanent

deformation. DaSilva et al. (2015) also produced

paving blocks with cement binder and crumb rubber

obtained data on the addition of crumb rubber with

the least amount of content obtained the maximum

compressive strength in the resulting paving block. In

this variation crumb rubber is sufficient to be

distributed evenly throughout the matrix. Loading

strength is also distributed evenly, resulting in

increased compressive strength, but when there is no

addition of crumb rubber, the compressive strength

produced also tends to decrease. With increasing

levels of natural rubber in the mixture will reduce the

mechanical properties of the mixture. This is because

the elastomeric phase remains as dispersed particles,

also resulting in agglomeration and interaction of the

particles of rubber so that the stiffness in the mixture

will decrease (Ismail & Suryadiansyah, 2002).

In a mixture, the attachment of a molecule to the

rubber chain cannot prevent the rate of fracture

quickly against the applied pressure. Conversely, the

lower level of rubber tends to increase its mechanical

properties, because if a smaller size and more uniform

dispersion in the dispersed phase will contribute to

improving the mechanical properties of the mixture

(Ismail & Suryadiansyah, 2002).

The results obtained in this study are greater when

compared to studies conducted (Kartika, 2017),

where the mixture of asphalt and fresh latex using

liquid bitumen without crosslinkers. In addition to the

higher rubber content factor in concentrated latex

when compared with fresh latex, the thing that

influences this is the presence of a crosslinker will

limit the flow and mobility of the mixture which

allows the particles to reach higher pressures, when

the same will also give mechanical strength to the

particles (Ismail & Suryadiansyah, 2002). So that the

use of solid bitumen with concentrated latex using

crosslinkers is more effective.

Based on the results of the compressive strength

values obtained in the material with the optimum

combination between asphalt, solid bitumen, and

concentrated latex, it shows that the compressive

strength of the resulting paving blocks has not been

effective with the standard compressive strength

values based on SNI 03-0691-1996. When viewed

from its polarity, the components used such as

bitumen have an excellent combination of

compositions that are both adhesives and water

resistant (McNally, 2011) and concentrated latex

which are nonpolar but still contain 40% water

(Suksup et al., 2017) which when mixed will produce

a mixture that is misible or can be mixed but the

compatibility is less effective so that it will affect the

mechanical properties obtained (Ismail &

Suryadiansyah, 2002).

Figure 2: Graph of Compressive Values with Variations in

Asphalt, Solid Bitumen and Concentrated Latex Mixture.

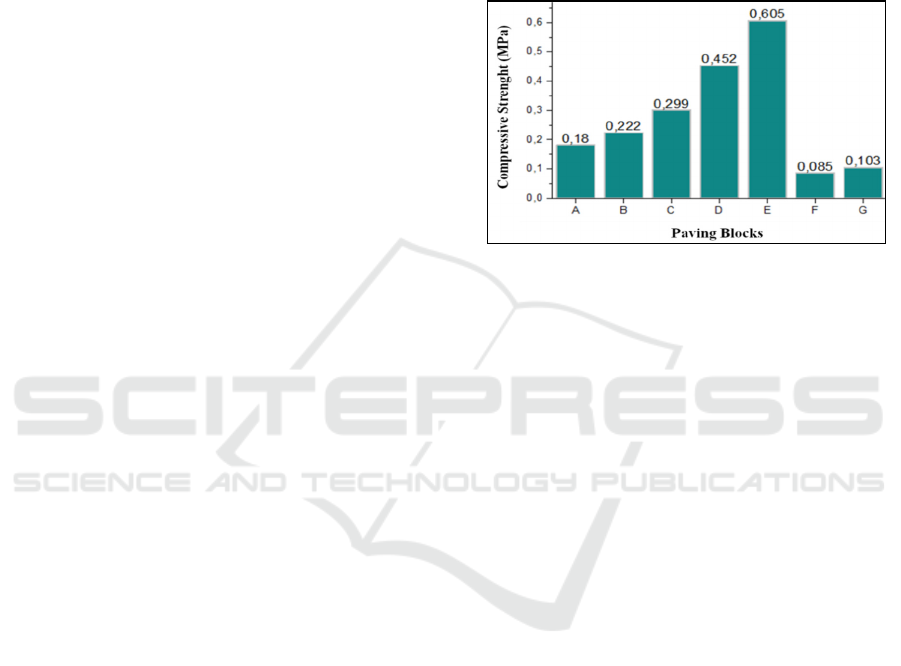

3.3 Results of Surface Morphology by

using SEM

In this study, an analysis using SEM was conducted

to determine the surface morphology of the resulting

paving block sample material. Objects that are

characterized are the results of asphalt mixing: solid

bitumen: concentrated latex with variations (70: 25:

5), (70: 5: 25), and control samples namely asphalt:

concentrated latex (80: 20) without the presence of

solid bitumen. SEM analysis is performed after

compressive strength testing. The results of the

characterization with SEM in the form of

micrographs. SEM analysis is carried out at

magnification 100 times which can be seen in the

figure 3.

The results of SEM micrographs show a

significant difference in surface morphology between

the mixture composition of the resulting paving block

material. Figure 3 a. is a control sample without the

addition of solid bitumen with a variation of asphalt:

concentrated latex (80: 20). In micrographs, it can be

seen that there are large piles which do not bind to

one another due to the lack of homogeneity from

mixing asphalt and concentrated latex. In all areas are

scattered small particles attached, which are small

particles which are aggregates of sand. This shows

that the sand aggregate is attached to asphalt and

concentrated latex.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

34

Figure 3 b. is a SEM micrograph of the sample

with the addition of solid bitumen with asphalt

variation: solid bitumen: concentrated latex (70: 5:

25). On the micrograph there is a very significant

difference with the micrograph in Figure 3 a, where

there are large piles that were previously not

homogeneous,

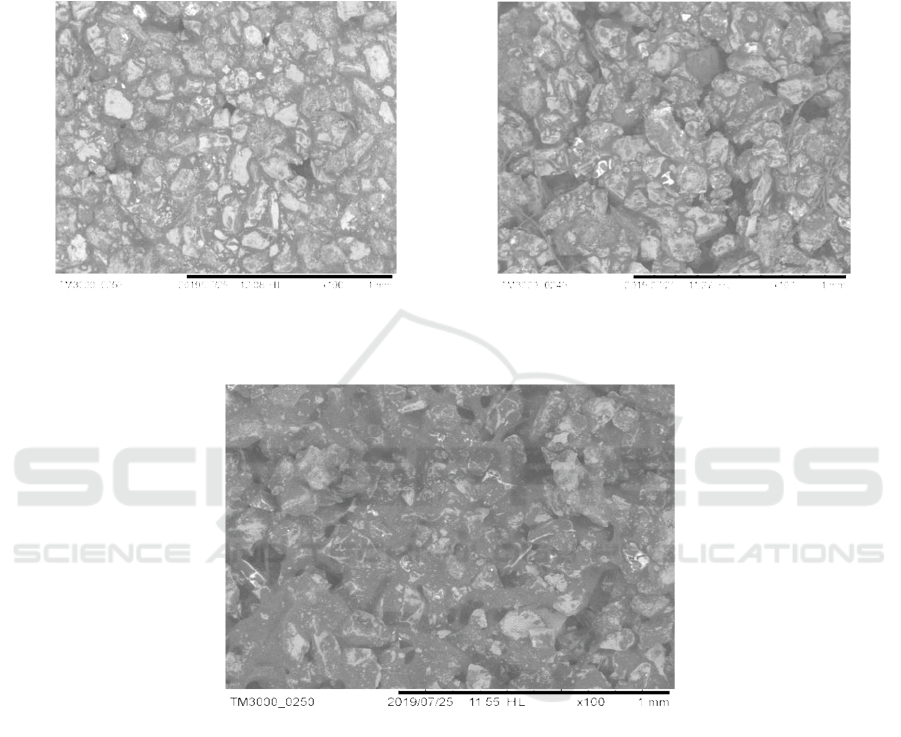

SEM micrograph in figure 4. is the result of a

sample with variations of asphalt: solid bitumen:

concentrated latex (70: 25: 5). Based on SEM

micrographs in this variation produce

(a)

(b)

Figure 3: Micrographs of SEM Analysis Results in Paving Blocks (a) Paving Block F (b) Paving Block A.

Figure 4: Micrographs of SEM Analysis Results in Paving Block E.

mixing with the most effective homogeneity between

one component with another component. Aggregates

which previously still look like in Figures 3 a and 3 b,

are no longer visible in Figure 4, where aggregates are

more bound to all components.

Surface structure density in asphalt variation:

solid bitumen: concentrated latex (70: 25: 5) is very

good compared to the structure density in Figures 3 a

and 3 b. The more even distribution of components in

micrographs indicates effective homogeneity

(Hardeli et al., 2018). This is due to the influence of

the addition of concentrated latex composition.

Addition of concentrated latex with less composition

results in a better surface structure compared to more

addition of concentrated latex composition, because

concentrated latex still contains water, so the

homogeneity of mixing concentrated latex with

bitumen and solid bitumen is less effective. Thus, the

dispersion of rubber in asphalt and with solid bitumen

is more homogeneous in this optimum variation,

binds to each other and plays a role in improving the

morphological properties of paving blocks with

asphalt as a binding.

Characterization of Physical Properties and Morphological Ruberized Asphalt Paving Blocks based on Bituminous Coal and Concentrated

Natural Rubber Latex

35

4 CONCLUSIONS

Based on the results of the research and discussion, it

can be concluded that: Paving blocks based on

polymeric materials can be made by mixing asphalt

as a substitute for binder and solid bitumen and

concentrated latex as an adhesive (adhesive) with the

addition of dicumyl peroxide as an initiator and

divinyl benzene as a crosslinker using sand and gravel

aggregates. Utilization of asphalt, solid bitumen, and

concentrated latex can improve the physical and

mechanical properties of the resulting paving block

with an optimum ratio of asphalt: solid bitumen:

concentrated latex (70: 25: 5) (Paving Block E).

Physical properties of the water absorbing capacity is

0.85%. The mechanical properties of compressive

strength are 0.605 MPa. Morphological

characteristics by using SEM show differences in

surface structure by comparison of the composition of

each component used. At the optimum ratio, mixing

is produced with the homogeneity of the most

effective surface structures.

ACKNOWLEDGEMENTS

The authors would like to thank to Mr. Prof. Dr.

Tamrin, M.Sc as advisor I and Mr. Dr. Darwin Yunus

Nasution, MS as advisor II in this research.

REFERENCES

[Standar Nasional Indonesia] SNI-03-0691-1996. (n.d.).

Persyaratan Mutu Bata Beton (Paving Block). Badan

Standarisasi Nasional.

[WCI] World Coal Institute. (2005). Sumber Daya Batu

Bara Tinjauan Lengkap Mengenai Batu Bara. World

Coal Institute.

Azliandry, H. (2011). Pemanfaatan Karet SIR-20 Sebagai

Bahan Aditif Dalam Pembuatan Aspal Polimer Dengan

Adanya Dikumil Peroksida Dan Divenil Benzena

Menggunakan Proses Ekstruksi. Universitas Sumatera

Utara.

DaSilva, F. M., Barbosa, L. A., Lintz, R. C., & Jacintho, A.

(2015). Investigation on the Properties of Concrete

Tactile Paving Blocks Made with Recycled Tire

Rubber. Construction and Building Materials, 91, 71–

79.

Hardeli, H., Sanjaya, H., Resikarnila, R., & Nitami, R.

(2018). Solar Cell Polymer Based Active Ingredients

PPV and PCBM. IOP Conference Series: Materials

Science and Engineering, 335, 1–8.

Hastuty, I. P., Sembiring, I. S., & Nursyamsi. (2018).

Comparison of Compressive Strength of Paving Block

with a Mixture of Sinabung Ash and Paving Block with

a Mixture of Lime. IOP Conf. Series: Materials Science

and Engineering, 309.

Ismail, H., & Suryadiansyah. (2002). Thermoplastic

elastomers based on polypropylene/natural rubber and

polypropylene/recycle rubber blends. Polymer Testing,

21(4), 389–395.

https://doi.org/https://doi.org/10.1016/S0142-

9418(01)00101-5

Kartika, Y. (2017). Modifikasi Resipren dan Bitumen dalam

Peningkatan Kekuatan Aspal. Universitas Sumatera

Utara.

McNally, T. (2011). Polymer Modified Bitumen. Properties

and Characterisation. Woodhead Publishing.

NorFazira, NorHidayah, Jaya, R. P., Aida, M., Zurairahetty,

N., & Mahmud, M. Z. H. (2016). An Overview On

Natural Rubber Application For Asphalt Modification.

International Journal of Agriculture, Forestry and

Plantation, 2, 212–218.

Polacco, G., & Berlincioni, S. (2005). Asphalt Modification

with Different PolyethyleneBased Polymer. European

Polymer Journal, 41, 2831.

Rajan, S., Sutton, M. A., Oseli, A., Emri, I., & Matta, F.

(2017). Linear Viscoelastic Creep Compliance and

Retardation Spectra Of Bitumen Impregnated

Fiberglass Mat And Polymer Modified Bitumen.

Construction and Building Materials, 155, 664–679.

https://doi.org/https://doi.org/10.1016/j.conbuildmat.2

017.08.030

Ritonga, A. H., Aritonang, B., & Zai, L. I. (2018).

Modifikasi Kopolimer Karet Alam Siklis Grafting

Asam Oleat Menggunakan Inisiator Benzoil Peroksida

dan Bahan Pengisi Bentonit-Cetil Trimetil Amonium

Bromida. Jurnal Kimia Mulawarman, 16(1), 42–48.

Suksup, R., Imkaew, C., & Smitthipong, W. (2017). Cream

concentrated latex for foam rubber products. IOP

Conference Series: Materials Science and Engineering

,

272.

Yuniarti, R. (2015). Modifikasi Aspal dengan Getah Pinus

dan Fly Ash untuk Menghasilkan Bio-Aspal. Jurnal

Sains Teknologi Dan Lingkungan, 1(2).

Zhu, J., Birgisson, B., & Kringos, N. (2014). Polymer

Modification of Bitumen: Advances and Challenges.

European Polymer Journal, 54(1), 18–38.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

36