Optimation of Asphalt Bituminous Coal and Resiprene Composition

to Improving the Physical Properties and Morphological

of Paving Block

Fitri Ikova Marantika, Riri Indah Nitami Harahap, Tamrin and Darwin Yunus Nasution

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Paving Block, Bituminous Coal, Resiprene, Asphalt, Physical Properties.

Abstract: The research has been done about the preparation of paving block with varied of composition Asphalt,

Bituminous Coal, and Resiprene. Which asphalt is used as a binder replacement. This research aims to

determine the optimum value of material produced to improving physical and morphological properties.

Paving block are prepared by mixing asphalt, bituminous coal, resiprene and DCP (Dicumil Peroxide) as an

inisiator and DVB (Divinil Benzene) as a crosslinker. Mixing using an internal mixer with the addition of

aggregates and then shaping/forming process. The results of characterization obtained optimum value of

physical properties at the variation of asphalt : bituminous coal : resiprene (70 : 5 : 25). The results of

morphological characterization using by SEM (Scanning Electron Microscopy) show that the mixture with

the most optimum physical properties is the most homogeneous. Maximum compressive strength value

5.885 Mpa and water absorption value 0.90%.

1 INTRODUCTION

The development of science and technology has an

influence on progress in all fields, one of which is in

the field of development. Where the rapid

development of development will affect the smooth

running of community activities. One of the

developments that influences the smoothness of

community activities is the construction of road

violence. One of the materials for road violence is

paving blocks. Paving block is defined as a

composition of building materials made from a

mixture of Portland cement or similar hydraulic

adhesives, water and aggregates with or without

other added ingredients that do not reduce the

quality of the paving blocks (SNI 03-0691-1996).

Paving blocks are one of the elements of building

materials that are widely used as a coating of road

pavement. Generally used for yard pavement,

parking lots or for environmental roads. Paving

blocks must meet the quality of building materials

that will be used as road pavement coatings. One of

the quality characteristics that paving blocks must

have is compressive strength. The quality of paving

blocks will be better if it has a higher compressive

strength (Murdiyoto, 2011) .

Research on paving blocks has been carried out

by adding or replacing constituent components in

paving blocks. One of them is the use of red brick as

a substitute for cement (Wikana & Gulo, 2012) and

the addition of coconut shell ash.

Asphalt can also be used as a substitute for

cement. Asphalt mixing in the paving block is done

so that the interaction occurs. Asphalt is used

because it contains hydrocarbons. Utilization of

asphalt waste from cold milling as added material

for making paving.

The results obtained show that a good mixture of

paving with the addition of asphalt cold milling

results of 35% produces a compressive strength of

11.11 MPa, and an average water absorption of

4.5174. The yield of compressive strength with the

addition of 35% bitumen is greater than that required

by SNI 03-0691-1996, which is 10 MPa (Karnanta,

2014).

Over time and the influence of weather changes

can cause physical damage from paving blocks.

Therefore it is necessary to improve the physical

properties of paving blocks where physical

properties are influenced by mechanical and

morphological properties.

24

Ikova Marantika, F., Indah Nitami Harahap, R., Tamrin, . and Yunus Nasution, D.

Optimation of Asphalt Bituminous Coal and Resiprene Composition to Improving the Physical Properties and Morphological of Paving Block.

DOI: 10.5220/0010132600002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 24-29

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

As for those that can affect the physical

properties of paving blocks, namely modification

using polymeric materials such as polyethylene, the

addition of polyethylene affects the compressive

strength yield where the compressive strength

produced is increasing because polyethylene has

high crystallinity and high tensile strength between

molecules and also polyethylene has a porous

structure so that it can reduce water absorption in

paving blocks (Hambali et al., 2013).

Modification of paving blocks using crumb

rubber as an aggregate to produce tactile paving

blocks. The addition of crumb rubber has an effect

on the yield of compressive strength and better

abrasion resistance (Silva et al., 2015).

In addition, the material used for the

modification of paving blocks is bitumen. Bitumen

is a low-cost thermoplastic material that is widely

used in roofing, road and pavement applications.

Has a unique combination of perfect waterproof and

adhesive properties that have been used effectively

for more than 5000 years. However, bitumen has

weak mechanical properties which are easily brittle

in cold conditions and can quickly soften and thaw

in hot conditions. One method used to strengthen

bitumen is mixing it with polymeric materials

(McNally, 2011).

Bitumen modified with GMA-g-LDPE has better

rutting properties at high temperatures and melting.

Crack resistance at low temperatures compared with

bitumen modified with LDPE results obtained are

lower (Li et al., 2007). Modification of bitumen by

using asphalt can increase water absorption,

compressive strength and morphology of road

pavement materials. The bitumen used is liquid

bitumen (Marantika, 2017).

Making polymer asphalt by using SIR-20 rubber

as an additive in the presence of DCP and DVB

using the extrusion process can improve its

characterization (Azliandry, 2011).

As for the cyclic rubber is reciprocator.

Resiprene is a cyclic rubber resin from natural

rubber that has a high solution viscosity, made like

granular solids. The recipient can act as an adhesive

in a material (Bukit, 2011). Mixing recipients and

bitumen gives a better effect on the improvement of

mechanical properties of the resulting pavement

layers and better morphological properties

(Marantika, 2017).

Chemical modification on rubber needs to be

done, this is because if the mixture consists only of

asphalt, rubber, and aggregates then only physical

bonding occurs. Chemical modification in rubber

can be done by cluster grafting techniques. Grafting

technique is one method that is simple, easy, and has

been done a lot. The use of dicumil peroxide (DCP)

initiator with divinyl benzene (DVB) crosslinker on

asphalt and rubber mixture will encourage chemical

bond between asphalt, rubber and aggregate.

This is because both the rubber polymer and

asphalt will be radical (Ritonga et al., 2018).

Based on the description above, the writer wants

to do research on Optimization of Asphalt

Bituminous Coal and Resiprene Composition to

Improve the Physical Properties and Morphological

of Paving Block.

2 RESEARCH METHODS

2.1 Material

Bituminous coal from PT. Amber and Coal Sumatra,

Asphalt from Iran Type Grade 60/70, Resiprene

from Resiprene 35 Factory, Toluent, Divinylbenzene

(DVB) from Sigma-Aldrich, Dikumil Peroxide

(DCP) from Sigma-Aldrich, Aggregate from Pebble

Stone from CV. Setia Jaya, Fine Sand Aggregate

from CV. Faithful Jaya.

2.2 Process of Making Paving Blocks

A total of 5 grams of recipient was put into the

erlenmeyer and dissolved with toluene while heated

and stirred with a magnetic stirer. Then put asphalt

into the glass beaker while heated. Then both of

them were mixed while being heated at 140

0

C for

15 minutes, then added 25 grams of bituminous coal

while stirring. The mixture was added 0.9 ml DVB

and stirred for 10 minutes. 300 grams of sand and 50

grams of gravel were added to the mixture while still

stirring, then added 0.9 grams of dcp while still

stirring for 10 minutes under the same heating. The

mixture is then put into a cube mold. Then the molds

are put into a hydrolytic press which has been set at

140

0

C for 30 minutes, then cooled to room

temperature.

Table 1: variations of asphalt, bituminous coal and

resiprene.

Asphalt

(mL)

Bituminous

coal (gram)

Resiprene

(gram)

70 20 10

70 15 15

70 10 20

70 5 25

70 0 20

80 20 0

Optimation of Asphalt Bituminous Coal and Resiprene Composition to Improving the Physical Properties and Morphological of Paving

Block

25

2.3 Water Absorption Test

Water absorption test refers to the SNI-03-0691

standard with the following procedure: the tested

sample is immersed in water for 24 hours and then

dried. To calculate the absorption value of water

with the following formula:

𝑊𝐴

𝑀

𝑀

𝑀

100%

(2.1)

with:

𝑊𝐴 water absorption

𝑀

dry sample mass

𝑀

saturated mass of water

(Butar-butar, 2009)

2.4 Compressive Strength Test

Compressive strength testing refers to ASTM D7901

/ C293, carried out with the AL-7000M GOTECH

apparatus by giving a load of 20 kN or 2039.4 Kgf,

with the following procedure: the tested sample is

placed on a compressive strength testing machine.

Loading is done slowly until the test specimen is

destroyed, ie when the maximum load is working.

The maximum load is recorded as Pmax.

Compressive strength test is calculated using the

following formula:

𝑃

𝐹

𝐴

(2.2)

with:

𝑃 compressive strength, N / m

2

𝐹 maximum force of the press, N

𝐴 cross-sectional area stressed, m

2

(Butar-butar, 2009)

2.5 Scanning Electron Microscopy

(SEM) Test

The test is carried out on the sample surface with the

following procedure: the sample is coated with gold

mixed with palladium in a pressure chamber (vacum

evavorator), then irradiated with secondary electron

beam and bounced electrons which can be detected

by scientor detectors which are amplified with an

electrical circuit that causes the cathode ray tube

(CRT).

The results of the shooting are done after

selecting a particular part of the object (sample) and

enlarged until a good and clear photo is obtained.

3 RESULTS AND DISCUSSION

3.1 Water Absorption Analysis

A water absorption test has been carried out by

immersing the sample for 24 hours on all types of

sample variation, where the test results are

substituted into equation 2.1. In order to obtain the

percentage of absorption shown in tabular form as

below.

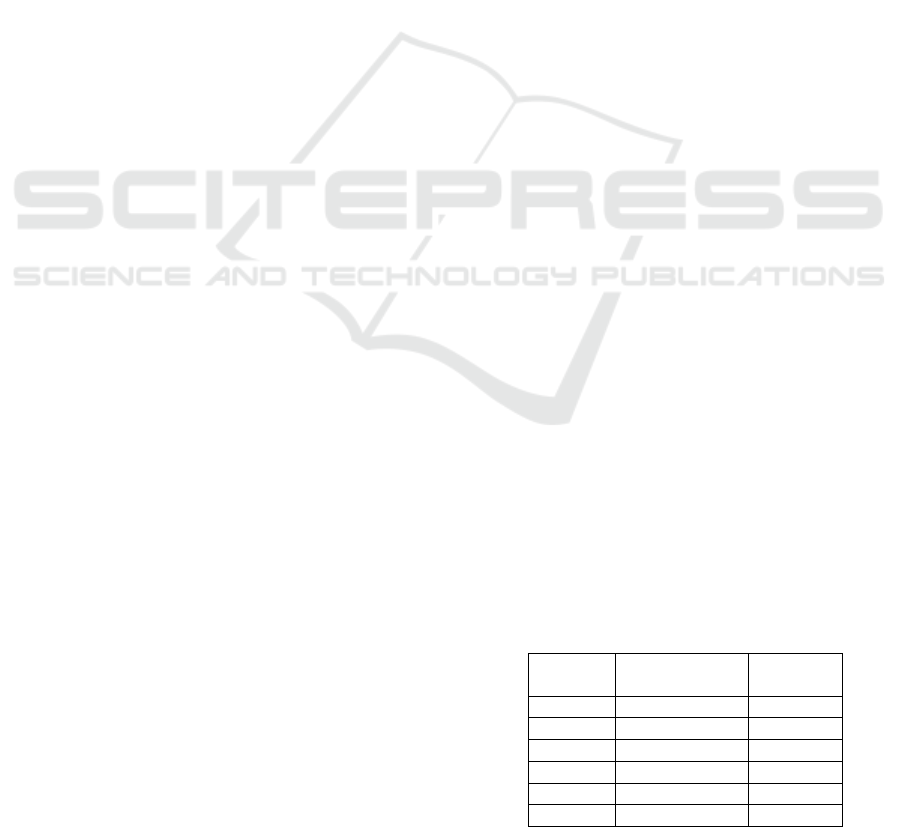

From the Table 2, it can be seen the relationship

between the percentage of water absorption with

variations of asphalt, bituminous coal and resiprene

displayed in graphical form.

Table 2: Water Absorption Values for Asphalt, Bituminous Coal, and Resiprene Variations.

NO

Variation

DCP

(Dicumil

Peroxide)

(gram)

DVB

(Divinil

Benzene)

(mL)

Specimen

Mass

(gram)

Difference

WA

(%)

Asphalt:BP:Resiprene

(mL:gram:gram)

Mk Mj

1 70:25:5 0.9

0.9

272.76 277.55 4.79 1.75

2 70:20:10

0.9 0.9

276.15 280.47 4.32 1.56

3 70:15:15

0.9 0.9

276.88 280.44 3.56 1.28

4 70:10:20

0.9 0.9

273.69 276.96 3.72 1.19

5 70:5:25

0.9 0.9

271.16 273.62 2.46 0.90

6 80:0:20

0.9 0.9

272.15 280.16 8.01 2.94

7 80:20:0

0.9 0.9

273.07 279.34 6.27 2.29

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

26

Figure 1: Relationship between Water Absorption Value and Asphalt, Bituminous, and Resiprene.

The results are continued in graphical form, it

shows a decrease which shows that with increasing

resiprene, the water absorption in the sample will

decrease, where the recipient serves as waterproof in

the paving block sample. And also with the addition

of bituminous coal also reduces the value of water

absorption, this is because bituminous is resistant to

water (McNally, 2011).

In the initial weighing ratio of 70: 25: 5 the

mixture of asphalt, bituminous coal and resiprene

with the addition of DCP and DVB is 272.76 grams

but after soaking for 24 hours the weight obtained is

277.55 grams there is a difference of 4.79 grams or

absorption sample water at 1.75%. At a ratio of 70:

5: 25 asphalt mixture, bituminous and resiprene

with the addition of DCP and DVB initial weight of

271.16 grams and weight after immersion of 273.62

grams there is a difference of 2.46 or a water

absorption capacity of 0.90%.

According to SNI 03-0691-1996 paving block

water absorption there are 4 qualities namely quality

A used for roads has an average water absorption of

max 3%, quality B used for parking lots has an

average water absorption of max 6%, quality C is

used for pedestrians have an average water

absorption of max 8%, and quality D is used for

parks and other users have an average water

absorption of max 10%.

This shows that all samples that have been tested

with water absorption have met the requirements

according to the Indonesian National Standard.

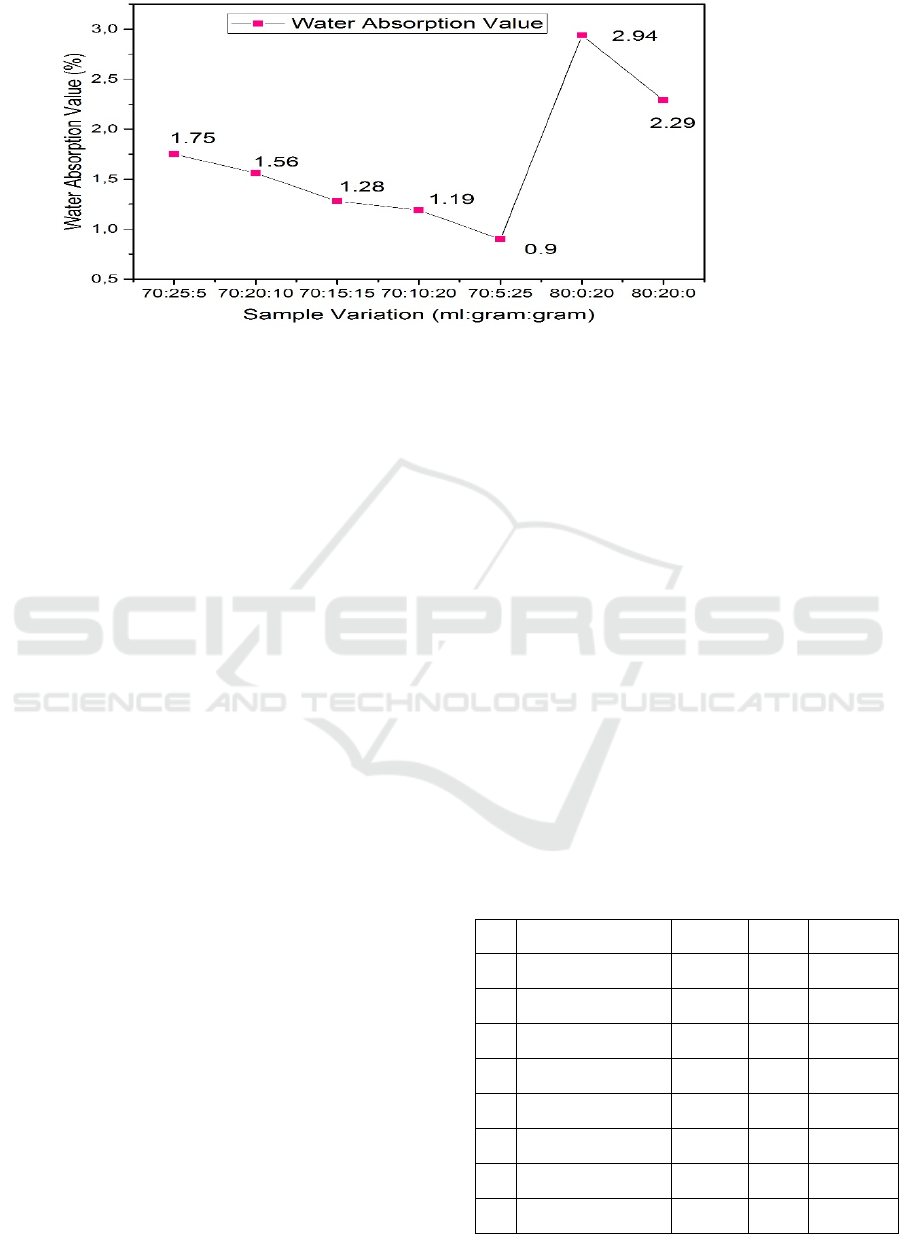

3.2 Compressive Strength Analysis

Compressive strength testing has been carried out on

all samples by giving a load of 2000 Kgf and a speed

of 10 mm / min. The test results are displayed in

tabular and graphical form. The results of

compressive strength measurements from the Paving

Block shown in the table shows that with the

increase in percent recipients added, the compressive

strength values tend to increase.

Where the optimum variation in the mixture of

asphalt, solid bitumen, and recipient with the

addition of DCP and DVB 70: 5: 25 with a strong

stress value of 5.885 MPa. From the sample

variations, the optimum combination of ingredients

in the paving block is obtained. As for the Asphalt,

Bituminous coal, without the addition of resiprenet,

the compressive strength value of 0.103 MPa.

Based on the graph, it can be seen that the

increasing number of resiprene shows an increase in

compressive strength, but after the recipient is not

added to the paving block mixture, a decrease in

compressive strength occurs. In this case it is clear

that the addition of polymer materials around 2-6%

is enough to improve the quality of the asphalt

mixture (Palacco & Berlincioni, 2005).

Table 3: Compressive strength Value of Asphalt,

Bituminous Coal and Resiprene.

No Variation

As

p

halt:BP:Resi

p

rene

P A Compressive

Stren

g

th

(mL:gram:gram) (Kg) (mm

2

) (Mpa)

1 70:25:5 68.078 25000 0.267

2 70:20:10 435.559

25000

1.709

3 70:15:15 800.171

25000

3.139

4 70:10:20 864.328

25000

3.391

5 70:5:25 1499.891

25000

5.885

6 80:0:20 26.165

25000

0.574

7 80:20:0 146.313

25000

0.103

Optimation of Asphalt Bituminous Coal and Resiprene Composition to Improving the Physical Properties and Morphological of Paving

Block

27

Figure 2: Compressive Strenght Grafic.

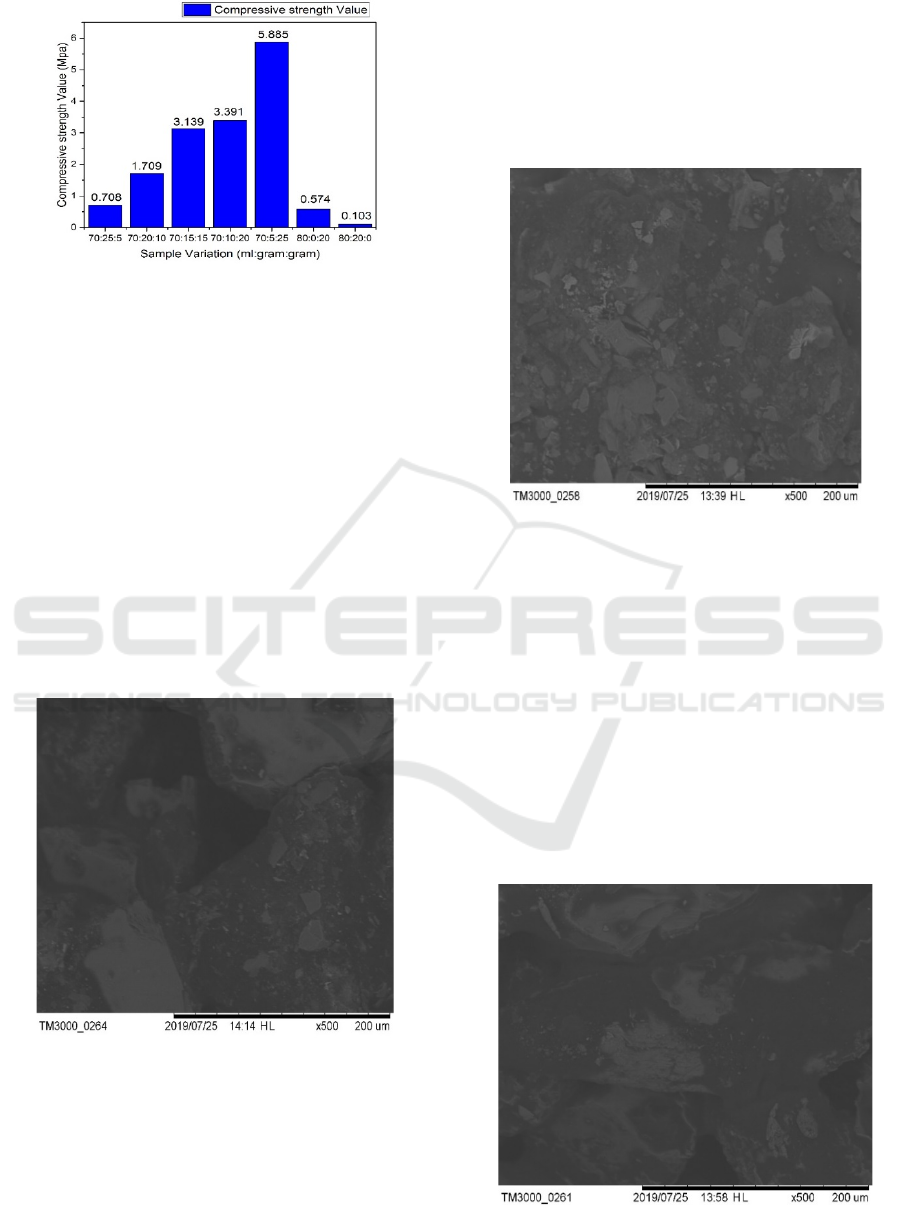

3.3 Scanning Electron Microscopy

Analysis

SEM analysis is one type of microscope that is able

to produce high resolution from the image of a

sample surface. The results of the SEM analysis can

provide information about the shape and surface

changes of the material being tested. Therefore the

resulting image has qualitative characteristics in two

dimensions because it uses electrons instead of light

waves and is useful for determining the surface

structure of a sample. Testing with SEM was carried

out to determine the surface structure of the sample

and was carried out on a mixture of asphalt, solid

bitumen and recipient. Tests carried out at

magnification 500 times.

Figure 3: SEM Photo Results of Bituminous coal Asphalt,

and Resiprene Mixture 80: 0: 20.

The SEM results shown in Figure 3 are the

results of SEM photographs on the surface between

the composition of the mixture of paving block

material from a mixture of asphalt, bituminous coal,

and resiprene with a ratio of 80: 20: 0 and the

addition of DCP and DVB with a magnification of

500 times. Based on SEM micrographs in this

variation show a lack of homogeneity from asphalt

mixing and reciprocity. This is indicated by the

existence of large piles that are not attached to each

other and also there is a small pile that is an

aggregate, where the aggregate looks more attached

to the recipient components.

Figure 4: Results of SEM Photos of Asphalt, Bitumen,

and Resiprene Mixtures 70: 25: 5.

The SEM results shown in Figure 4 are the

results of SEM micrographs of a mixture of asphalt,

solid bitumen, and resiprene with a ratio of 70:25: 5

and the addition of DCP and DVB at 500 times

magnification. In this variation the asphalt

component, dense bitumen and resiprene appear to

be sticking together.

This shows the difference from the results of

previous micrographs that are not mutually attached.

There are small collisions that are evenly distributed,

this shows the aggregate has been attached to the

components of asphalt, bituminous coal and

resiprene evenly.

Figure 5: Result of SEM photo of Asphalt, Bituminous

Coal, and Reciprene Mixtures 70 : 5 : 25.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

28

The SEM shown in Figure 5 is the results of

SEM micrographs from a mixture of asphalt,

bituminous coal, and resipren in a ratio of 70: 5: 25

and the addition of DCP and DVB at 500 times

magnification. The magnitude of the rubber content

also affects the homogeneity of the paving block

sample, where in this variation 25% rubber is added.

Based on the results of SEM migrographs in

Figure 5 show that homogeneity in Figure 5 is more

effective than in Figure 4. In this variation also no

visible small piles which are aggregates as seen in

Figures 3 and 4. This indicates that the aggregate has

been mixed into all components, both asphalt,

bituminous coal, and resiprene.

4 CONCLUSIONS

Utilization of asphalt, bituminous coal, and recipient

can improve the physical and morphological

characteristics of the paving blocks produced with

the optimum ratio of asphalt, solid bitumen and

resiprene (70: 5: 25). The physical properties of the

water absorption capacity of the samples produced

the best water absorption of 0.90% and mechanical

properties at the optimum compressive strength of

5.885 MPa.

Morphological characteristics of the

characteristics of SEM (Scanning Electron

Microscopy) test showed a difference in surface

structure by comparison of the composition of the

material used. Where the mixing results with

homogeneity of the most effective structures at the

optimum ratio.

ACKNOWLEDGEMENTS

Author would like express a gratitude to the head of

Material and Polymer riset University Sumatera

Utara.

REFERENCES

Azliandry, H. (2011). Pemanfaatan Karet SIR-20 Sebagai

Bahan Aditif Dalam Pembuatan Aspal Polimer Dengan

Adanya Dikumil Peroksida Dan Divenil Benzena

Menggunakan Proses Ekstruksi. Universitas Sumatera

Utara.

Bukit, N. (2011). Pengolahan Zeolit Alam sebagai bahan

Pengisi Nano Komposit Polipropilena dan Karet alam

SIR-20 dengan Kompatibilisher Anhidrida Maleat-

Grafted-Polipropilena. Universitas Sumatera Utara.

Butar-butar, N. (2009). Pembuatan dan Karakterisasi

Aspal Beton Berbasis Dreg dan Grit. Universitas

Sumatera Utara.

Hambali, M., Lesmania, I., & Midkasna, A. (2013).

Pengaruh Komposisi Kimia Bahan Penyusun Paving

Block Terhadap Kuat Tekan dan Daya Serap Airnya.

Jurnal Teknik Kimia, 4(19), 14–21.

Karnanta, S. P. (2014). Pemanfaatan Limbah Apal Hasil

Cold Milling Sebagai Bahan Tambah Pembuatan

Paving. Universitas Muhammadiyah Surakarta.

Li, J., Yuxia, Z., & Yuzhen, Z. (2007). The Research of

GMA-g-LDPE Modified Qinhuangdao Bitumen.

Construction and Building Materials, 22, 1067–1073.

Marantika, F. I. (2017). Modifikasi Resipren dan Bitumen

Dalam Peningkatan Kekuatan Aspal. Universitas

Sumatera Utara.

McNally, T. (2011). Polymer Modified Bitumen.

Properties and Characterisation. Woodhead Publishing.

Murdiyoto, R. A. (2011). Pemanfaatan Limbah Botol

Plastik Jenis PET (POLY ETHYLENE

TEREPHTHALATE) untuk Agregat Kasar Pembuatan

Paving Block. Universitas Indonesia.

Palacco, G., & Berlincioni, S. (2005). Asphalt

Modification with Different Polyethylene-Based

Polymer. European Polymer Journal, 41.

Ritonga, A. H., Aritonang, B., & Zai, L. I. (2018).

Modifikasi Kopolimer Karet Alam Siklis Grafting

Asam Oleat Menggunakan Inisiator Benzoil Peroksida

dan Bahan Pengisi Bentonit-Cetil Trimetil Amonium

Bromida. Jurnal Kimia Mulawarman, 16(1), 42–48.

Silva, F. M., Barbosa, L. A. G., Lintz, R. C. C., &

Jacintho, A. E. (2015). Investigation on The Properties

of Concrete Tactile Paving Blocks Made with

Recycled Tire Rubber. Construction and Building

Materials, 91, 71–79.

Wikana, I., & Gulo, D. (2012). Pengaruh Penambahan

Tumbukan Batu Bata Merah dan Pengurangan Semen

Terhadap Kuat Tekan Serta Keausan Paving Block.

Majalah Ilmiah UKRIM, 63–73.

Optimation of Asphalt Bituminous Coal and Resiprene Composition to Improving the Physical Properties and Morphological of Paving

Block

29