Characterization and Modification of Chitosan-reduced Graphene

Oxide Composite Films for Electrochemical Sensor

Rosnani Harahap

1*

, Irwana Nainggolan

1

and Zul Alfian

1

1

Department of Chemistry, Faculty of Mathematics and Sciences, University of Sumatera Utara, Medan, Indonesia

Keywords: Characterization, Chitosan, Electrochemical, Reduced Graphene Oxide, Sensor.

Abstract: Chitosan-reduced graphene oxide composite film was succesfully fabricated by electrodeposition method for

electrochemical sensor. In this regard, we have prepared chitosan-reduced graphene oxide composites using

a simple methodology, where chitosan-reduced graphene oxide composite can coat on the surface of screen-

printed copper electrode via a simple electrodeposition method. In this work, the characterization of the

composite film was intensively investigated by XRD and FT-IR method. The results of the XRD represented

reduced graphene oxide structure in 2θ, appeared at 26.61° with interlayer spacing was about 3.347Å. The

characterization of FT-IR confirmed the successful rGO presence in matrix polymer of chitosan.

1 INTRODUCTION

Electrochemical analysis is a quantitative or

qualitative analysis method based on the electrical

properties of a solution of the analyzed substance in

an electrochemical cell (Hendayana, 1994).

The electrochemical method is the most common

method in various fields of application, in particular

electrochemical sensors and biosensors developed for

pharmaceutical, food, agriculture and environmental

analysis because they have many advantages, such as

high sensitivity, cheap and easy to operate the tool

and quick response (Beitollahi et al., 2009), (Gajdar

et al., 2016) dan (Mazloum-Ardakani et al., 2011).

There are several advantages of electrochemical

sensors because electrodes can sense material present

in a sample without damaging the system with low

detection limits and high specificity. The active

sensing material on the electrode must act as a

catalyst and catalyze the chemical and biochemical

compound reaction in order to obtain a signal for

production. The combination of biosensors and

electrochemical sensors leads to a new type of sensor

called electrochemical biosensors, which applies

electrochemical methods to the construction and

work of biosensors (Kumar & Zou, 2005).

An electrochemical cell generally consists of three

types of electrodes, namely the working electrode, the

reference electrode, and the counter electrode. The

material used for the manufacture of electrochemical

cells must be able to be used over a wide temperature

range, stable form, resistant to solutions, organic

solvents and reagents, durable, and most importantly

is made of transparent material, so that the solution

and the electrodes can be observed (Sawyer, 1995).

Ideal working electrodes are electrodes that have a

reproducible surface area and low background

current.

(Vyskocil & Barek, 2009) have been determinated

of metronidazole based on electrochemical sensors

has many advantages ranging from high sensitivity,

low cost and easy to use and is widely used in

different fields, especially in analytical chemistry.

The growing importance of polymer-coated

nanomaterials from biological polymer sources has

brought chitosan to the fore, especially because of its

biological properties, which have been used in many

engineering and biological fields (Jayakumar et al.,

2010)

Chitosan is a biopolymer that has recognized

properties such as biodegradability and

biocompatibility (Muzzarelli, 2010). Due to its

biocompatibility, hydrophilicity, non-toxicity, good

mechanical stability, cost-effectiveness and

availability of reactive functional groups for chemical

modifications, chitosan has also been brought into

sharp focus as a suitable matrix (Kaur et al., 2019).

Over the past few years, chitosan-based sensor

materials have been widely developed, including in

conduction polymers, metal nanoparticles, and

oxidizing agents (Yang et al., 2010).

20

Harahap, R., Nainggolan, I. and Alfian, Z.

Characterization and Modification of Chitosan-reduced Graphene Oxide Composite Films for Electrochemical Sensor.

DOI: 10.5220/0010132500002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 20-23

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Polymer composites have now developed into one

of the largest groups in material science and offer

significant potential for the production of advanced

materials in a wide variety of applications (G. Singh

et al., 2012). Once nanofillers are distributed on a

molecular scale within a polymer matrix, chemical

bonding interacts with the matrix. These chemical

functionalities have been found to be a practicable

and effective way to improve the dispersion of

graphene materials and the interfacial bonding

between graphene and the polymer matrix (Verdejo

et al., 2008). GO has been reported to be well

dispersed in the chitosan matrix on a molecular scale

because of interactions between the chitosan matrix

and the GO sheets (Yang et al., 2010).

In recent years, many electrochemical techniques

have used electrocatalysts, one of which is graphene.

Graphene is a hexagonal lattice that has a single atom

and has many researchers' attention because of its

new mechanical and electronic features (Ramanathan

et al., 2008). Graphene has unique electrical,

mechanical, and optical properties that researchers

around the world use to create advanced electronic

materials including transparent conductors and

ultrafast transistors (R. Singh et al., 2019). Due to its

extraordinary properties, this novel nanomaterial has

great potential in electrochemical sensor.

Several individuals such as (Muralidharan et al.,

2016) have investigated reduced chitosan graphene

oxide film, stating that it is clear from studies on

mechanical properties that the tensile strength and

module of chitosan composites have improved

drastically with the incorporation of rGO as a filler

reinforcement. The added graphene increases the

chitosan voltage strength from 39.7 MPa to 69.5 MPa.

Based on the description above, the researchers

were interested in conducting a study of chitosan-

graphene oxide reduced modification for

electrochemical sensor.

2 EXPERIMENTAL

2.1 Materials

Chitosan and reduced graphene oxide (RGO) was

obtained from Sigma Aldrich, Co., 3050 Spruce

Street St. Louis, MO 63103 USA 314-771-5765 with

82% deacetylation degree and molecular weight of

190,000-310,000 Da using the viscometer method.

All chemicals have a standard analytical level and are

used when received. Solvents and electrolyte

solutions are prepared using double distilled water

(DD) without further purification.

2.2 Fabrication of Chitosan/rGO

Composite Flm Modified

Screen-printed Copper Electrode

To achieve a mirror-like coating on the electrode, the

bare screen-printed copper electrode surface

(diameter = 5 mm) was washed by polishing with

0.05 μm alumina, and then ultrasonically with

distilled water.

Chitosan solution was prepared by dissolving 1 g

of chitosan powder in 100 mL of 1.0% (v/v) acetic

acid solution. Then, the chitosan solution was stirred

for 24 h and refrigerated at 4°C (Baccarin et al.,

2017). Reduced graphene oxide (rGO) has been

prepared in different concentration (50, 100, 150, 200

and 500 ppm) and has been distributed into 100 mL

of double distilled water.

2.3 Characterization Method

Electrodes were characterized using

Potentiostat/Galvanostat Electrochemical

Workstation Corrtest with model CS-350. X-ray

diffraction (XRD) were observed with a Shimadzu

XRD-6100 to analyze the crystallinity of graphene

oxide reduction. The Fourier Transform Infrared (FT

IR) spectra were performed using Shimadzu Pestige

21 for chitosan and chitosan / rGO.

3 RESULTS

3.1 Preparation of Chitosan-Reduced

Graphene Oxide (rGO) Electrodes

Preparation of chitosan/rGO electrodes was carried

out in several stages, namely stiring, sonication and

fabrication. Chitosan was made with a concentration

of 1% using 1% acetic acid solvent, while reduced

graphene oxide (rGO) under the Sigma Aldrich brand

was dissolved using aquabides and made with several

variations of 50, 100, 150, 200 and 250 ppm.

The reduced graphene oxide (rGO) has been

added to the chitosan solution for 2 h under stirring at

room temperature and sonicated to ensure

homogeneous solution for 30 min. Fabrication of

reduced chitosan-graphene oxide sensors was carried

out using the electrodeposition method. The

electrodes are then applied to the electrochemical cell

as a working electrode.

Characterization and Modification of Chitosan-reduced Graphene Oxide Composite Films for Electrochemical Sensor

21

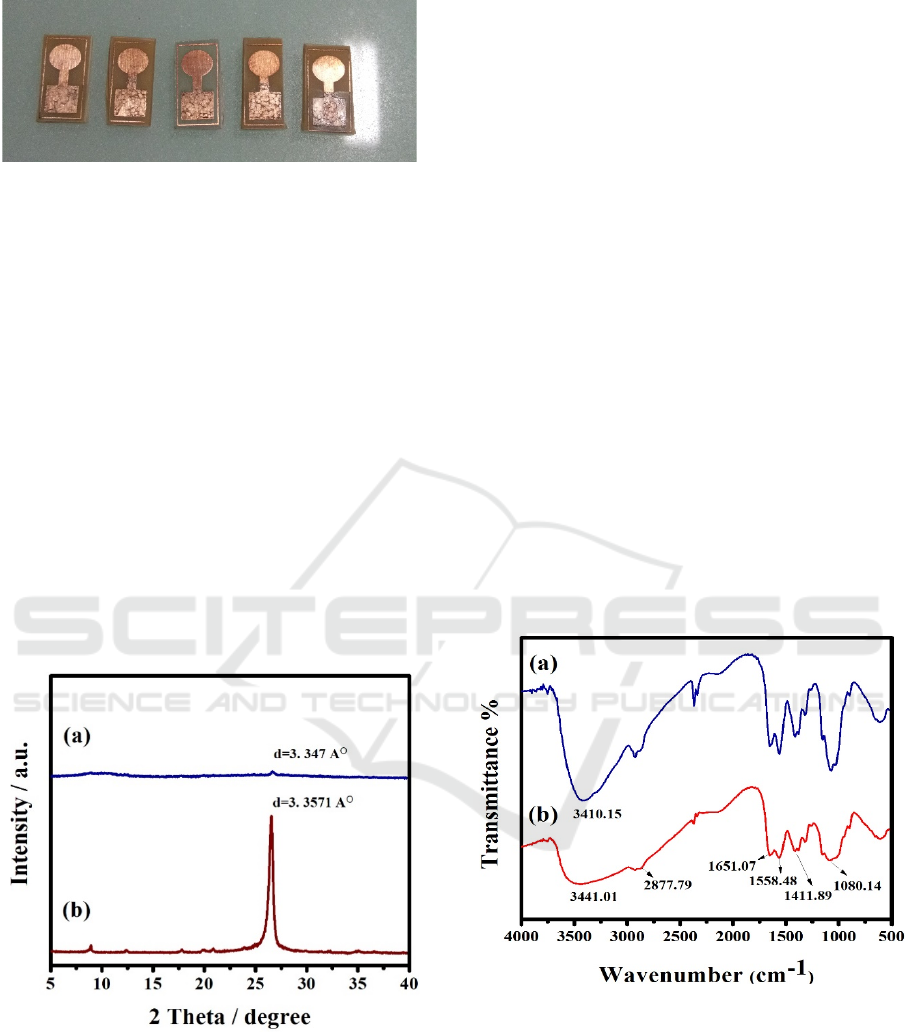

Figure 1: Chitosan/rGO Composite Film.

3.2 Characterization of Graphite and

rGO by X-ray Diffraction (XRD)

The composite film structure was further investigated

with X-ray diffraction (XRD). The typical peaks of

graphite (Fig.2b) observed at 26.53° with a d- spacing

3.3571 Å (Fig.2b). This is in accordance with

previous literature (Sandhya et al., 2018). The sharp

peak produced by graphite shows high crystallinity.

In Fig.1a, the XRD patterns of rGO shows the sharp

peak disappeared and move to higher 2θ angles at

26.61° with a d-spacing of 3.347 Å (Ali Umar et al.,

2013).

Due to the covalently bound oxygen atoms and the

displacement of sp3 hybridized carbon atoms above

and below the original graphene film, rGO films are

thicker than graphite films (Hassan et al., 2009). It has

been confirmed from the XRD patterns that the rGO

has been completely reduced.

Figure 2: XRD patterns of (a) rGO and (b) graphite.

3.3 Characterization of Chitosan and

Chitosan/rGO

Chitosan and rGO can be mixed well and forming a

homogeneously aqueous solution, and at room

temperature stable. And then, chitosan /rGO was cast

into substrates, and the films formed. Fig. 3 described

the chitosan and chitosan / rGO FT-IR spectra.

The chitosan spectrum (Fig.3a), the characteristic

hydroxyl group of OH peaks appeared at 3410.15 cm

-

1

and the absorption spectrum acquired at 1651.07 cm

-

1

and 1558.48 cm

-1

correspond to stretching vibration

of carboxylic group C=O of -NHCO- and the N-H

bending vibration of –NH

2

group (Yang, 2010).

Characteristic of CH

3

and C-H functional groups are

the bands at 1411.89 cm

-1

and 2877.79 cm

-1

. And

chitosan/rGO film, its spectrum shows a combination

of characteristics which includes the absorption peak

at 3441.01 cm

-1

(Fig.3b), assigned to extend NH

2

(amine) vibration group.

In the FT-IR peak of chitosan/rGO, The C-O

stretching chitosan intensity vibration is found to

have faded due to the interaction of chitosan and rGO.

Meanwhile, the intensities of C=C stretching

vibration peak at 1558.48 cm

-1

and the presence of

chitosan-derived N-H bonding. Deformation peak of

N-H from chitosan at 1411.89 cm

-1

. All these result

confirm that rGO presence on the chitosan polymer

matrix. And in the composite films, the chemical

structure of chitosan barely changes with the

increasing content of rGO, indicating that there was

primarily physical interaction but scarcely a chemical

reaction between chitosan and rGO.

Figure 3: FT-IR spectra of (a) chitosan and (b)

chitosan/rGO.

4 CONCLUSION

Fabrication of the chitosan-reduced graphene oxide

(rGO) in screen-printed copper electrode modified

was successfully by electrodeposition method and

was used for electrochemical sensor. The

characterizations of XRD confirmed the successful

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

22

formation of rGO. Furthermore, the spectra of FT-IR

also indicated rGO presence on the chitosan polymer

matrix composite film.

REFERENCES

Ali Umar, M. I., Yap, C. C., Awang, R., Hj Jumali, M. H.,

Mat Salleh, M., & Yahaya, M. (2013). Characterization

of multilayer graphene prepared from short-time

processed graphite oxide flake. Journal of Materials

Science: Materials in Electronics.

https://doi.org/10.1007/s10854-012-0920-5

Baccarin, M., Santos, F. A., Vicentini, F. C., Zucolotto, V.,

Janegitz, B. C., & Fatibello-Filho, O. (2017).

Electrochemical sensor based on reduced graphene

oxide/carbon black/chitosan composite for the

simultaneous determination of dopamine and

paracetamol concentrations in urine samples. Journal of

Electroanalytical Chemistry.

https://doi.org/10.1016/j.jelechem.2017.06.052

Beitollahi, H., Mazloum Ardakani, M., Naeimi, H., &

Ganjipour, B. (2009). Electrochemical characterization

of 2, 2?-[1, 2-ethanediylbis (nitriloethylidyne)]-bis-

hydroquinone-carbon nanotube paste electrode and its

application to simultaneous voltammetric

determination of ascorbic acid and uric acid. Journal of

Solid State Electrochemistry, 13(3), 353–363.

https://doi.org/10.1007/s10008-008-0553-z

Gajdar, J., Horakova, E., Barek, J., Fischer, J., & Vyskocil,

V. (2016). Recent Applications of Mercury Electrodes

for Monitoring of Pesticides: A Critical Review. In

Electroanalysis.

https://doi.org/10.1002/elan.201600239

Hassan, H. M. A., Abdelsayed, V., Khder, A. E. R. S.,

Abouzeid, K. M., Terner, J., El-Shall, M. S., Al-

Resayes, S. I., & El-Azhary, A. A. (2009). Microwave

synthesis of graphene sheets supporting metal

nanocrystals in aqueous and organic media. Journal of

Materials Chemistry. https://doi.org/10.1039/b906253j

Hendayana. (1994). Kimia Analitik Instrumen. IKIP.

Jayakumar, R., Menon, D., Manzoor, K., Nair, S. V., &

Tamura, H. (2010). Biomedical applications of chitin

and chitosan based nanomaterials - A short review. In

Carbohydrate Polymers.

https://doi.org/10.1016/j.carbpol.2010.04.074

Kaur, N., Bharti, A., Batra, S., Rana, S., Rana, S., Bhalla,

A., & Prabhakar, N. (2019). An electrochemical

aptasensor based on graphene doped chitosan

nanocomposites for determination of Ochratoxin A.

Microchemical Journal.

https://doi.org/10.1016/j.microc.2018.08.064

Kumar, S., & Zou, S. (2005). Electrooxidation of carbon

monoxide on gold nanoparticle ensemble electrodes:

Effects of particle coverage. Journal of Physical

Chemistry B. https://doi.org/10.1021/jp051981a

Mazloum-Ardakani, M., Beitollahi, H., Amini, M. K.,

Mirjalili, B. F., & Mirkhalaf, F. (2011). Simultaneous

determination of epinephrine and uric acid at a gold

electrode modified by a 2-(2,3-dihydroxy phenyl)-1, 3-

dithiane self-assembled monolayer. Journal of

Electroanalytical Chemistry, 651(2), 243–249.

https://doi.org/10.1016/j.jelechem.2010.09.020

Muralidharan, M. N., Shinu, K. P., & Seema, A. (2016).

Optically triggered actuation in chitosan/reduced

graphene oxide nanocomposites. Carbohydrate

Polymers, 144, 115–121.

https://doi.org/10.1016/j.carbpol.2016.02.047

Muzzarelli, R. A. A. (2010). Chitins and chitosans as

immunoadjuvants and non-allergenic drug carriers. In

Marine Drugs. https://doi.org/10.3390/md8020292

Ramanathan, T., Abdala, A. A., Stankovich, S., Dikin, D.

A., Herrera-Alonso, M., Piner, R. D., Adamson, D. H.,

Schniepp, H. C., Chen, X., Ruoff, R. S., Nguyen, S. T.,

Aksay, I. A., Prud’Homme, R. K., & Brinson, L. C.

(2008). Functionalized graphene sheets for polymer

nanocomposites. Nature Nanotechnology.

https://doi.org/10.1038/nnano.2008.96

Sandhya, P. K., Jose, J., Sreekala, M. S., Padmanabhan, M.,

Kalarikkal, N., & Thomas, S. (2018). Reduced

graphene oxide and ZnO decorated graphene for

biomedical applications. Ceramics International.

https://doi.org/10.1016/j.ceramint.2018.05.143

Sawyer, D. . et al. (1995). Experimental Electrochemistry

for Chemist (2nd editio). Wiley.

https://www.wiley.com/en-

id/Electrochemistry+for+Chemists,+2nd+Edition-p-

9780471594680

Singh, G., Choudhary, A., Haranath, D., Joshi, A. G.,

Singh, N., Singh, S., & Pasricha, R. (2012). ZnO

decorated luminescent graphene as a potential gas

sensor at room temperature. Carbon.

https://doi.org/10.1016/j.carbon.2011.08.050

Singh, R., Sansare, S., & Shidhaye, S. (2019). Biomedical

application of graphenes. In Biomedical Applications of

Nanoparticles. https://doi.org/10.1016/b978-0-12-

816506-5.00007-3

Verdejo, R., Barroso-Bujans, F., Rodriguez-Perez, M. A.,

De Saja, J. A., & Lopez-Manchado, M. A. (2008).

Functionalized graphene sheet filled silicone foam

nanocomposites. Journal of Materials Chemistry,

18(19), 2221–2226. https://doi.org/10.1039/b718289a

Vyskočil, V., & Barek, J. (2009). Mercury electrodes-

possibilities and limitations in environmental

electroanalysis. Critical Reviews in Analytical

Chemistry.

https://doi.org/10.1080/10408340903011820

Yang, Z., Peng, H., Wang, W., & Liu, T. (2010).

Crystallization behavior of poly(ε-

caprolactone)/layered double hydroxide

nanocomposites. Journal of Applied Polymer Science,

116(5), 2658–2667. https://doi.org/10.1002/app

Characterization and Modification of Chitosan-reduced Graphene Oxide Composite Films for Electrochemical Sensor

23