Analysis of Ocean Thermal Energy Conversion (OTEC)

Potential using Closed-cycle System Simulation of 100 MW Capacity

in Bali Sea

Ismail Ali Hajar Aswad

1

, Nanda Annisa Okasari Yusal

2

, Haryo Dwito Armono

1

, Purwanto

2

,

Delyuzar Ilahude

3

, Liany Ayu Catherine

1

and Asfarur Ridwan

1

1

Faculty of Marine Technology, Sepuluh Nopember Institute of Technology, Surabaya, Indonesia

2

Faculty of Fisheries and Marine Sciences, Diponegoro University, Semarang, Indonesia

3

Marine Geological Research and Development Center, Bandung, Indonesia

Keywords: OTEC, Closed-cycle, Bali Sea.

Abstract: The Bali Sea is one of the body water that has OTEC potential because of its location in tropical region, thus

it has high sea surface temperatures. This research was conducted to examine temperature differences to run

the system and analyze the results of simulation of the closed-cycle OTEC system based on the simulation

results of Uehara and Ikegami (1990) as a basic reference in the installation of plants and obtain net power

produced by the cycle. The data used in this study is temperature in depth data per day during October

2008-June 2017 which downloaded from HYCOM website and vertical temperature data of CTD which is

the result of P3GL survey on 21 May 2017 -3 June 2017. Data processing was done by calculating the

differences in temperature of warm sea air on the surface and cold sea water at depth of 800 m by qualifying

the minimum difference requirement of 20

o

C. The results of temperature data processing yield the

difference in temperature minimum requirements of 20

o

C at all study area in the range of 21.895

o

C-24.7

o

C.

The parameter values in the closed cycle OTEC system obtained are the warm sea water (TWS) and cold

(TCS) temperatures of 28.4

o

C-30.36

o

C and 5.591

o

C-6.711

o

C; warm seawater pump power (PWS), cold

seawater pump power (PCS), and working fluid pump power (PWF) of 10.9596-11.521 MW, 16.0596-

16.621 MW, and 1.94-1.97 MW; and the heat transfer area in evaporator (AE), the heat transfer area in

condenser (AC), and total of heat transfer area (AT) of 0.737-1.7478 x105 m

2

, 0.9685-1.614 x105 m

2

, and

1.7058-3.3435 x105 m

2

. Net power potential of OTEC in Bali Sea has range between 70-71 MW with

maximum net power found at Point 2 of 71.041 MW with capacity of 100 MW and produce a cycle

efficiency of 0.41323 or 41.323%.

1 INTRODUCTION

Sunlight reaches the earth's surface 35-100 m (Avery

and Wu, 1994). The sea in the tropics absorbs the

sun continuously all the time causing sea surface

temperatures to vary to reach 27

o

C-29

o

C. The total

area of the world's tropical oceans totaling 60

million km

2

produces energy equivalent to 250

trillion fuels per yield (Nihous, 2005). Seas in

Indonesia with a total thermal potential of 2.5x10

23

Joules and an efficiency of 3%, can produce power

of 240,000 MW (Prabowo, 2012).

Sea Heat Energy Conversion (OTEC) is one of th

solutions in developing ocean energy by using

temperatures between the sea and the deep sea in the

tropics to produce electrical energy with a minimum

temperature difference of 20

o

C (Nihous, 2007).

Energy generated from sea heat is very suitable to be

applied in tropical regions such as Indonesia. If this

can be done effectively and on a large scale, OTEC

provides a renewable energy source that is needed to

complement various energy problems (Syamsuddin,

2015).

Various studies and OTEC studios that have

been carried out in Indonesia to date have been

carried out by Sinuhaji (2015) in the North Bali Sea

with the result of an increase in surface temperature

between 28-31°C with a difference of 24

o

C; Negara

and Koto (2016) in Karangkelong, North Sulawesi

with a potential of 100 kW; and Syamsuddin (2015)

at seven location points in Indonesia using World

Aswad, I., Yusal, N., Armono, H., Purwanto, ., Ilahude, D., Catherine, L. and Ridwan, A.

Analysis of Ocean Thermal Energy Conversion (OTEC) Potential using Closed-cycle System Simulation of 100 MW Capacity in Bali Sea.

DOI: 10.5220/0010046600130021

In Proceedings of the 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2019), pages 13-21

ISBN: 978-989-758-516-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

13

Ocean Atlas 2009. Previous research on the potential

of the OTEC in the Bali Sea is only theoretical and

must be further discussed to obtain the expected

results.

The goal of this research is to obtain minimum

temperature difference requirement of 20

o

C at seven

study points in the Bali Sea Waters, to obtain

minimum temperature difference requirement of

20

o

C at seven study points in the Bali Sea Waters

and to analyze the result of OTEC system simulation

closed cycle with 100MW power capacity.

2 SEA WATER TEMPERATURE

AND OTEC OVERVIEW

2.1 Vertical Distribution of Sea Water

Temperature

Solar thermal energy is absorbed by the surface

layer and penetrates the deeper sea. However, the

conduction process occurs so slowly that only a

small portion of the heat flowing in (Santos et al.,

2012). The temperature will decrease dramatically at

depths between 200-300 m to 1000 m. This

decreasing depth layer is known as a thermocline

that is thinner at low latitudes than at high latitudes.

At a depth of 300-1000 m, seawater does not change

in temperature and ranges from 0-3

o

C. It is

influenced by cold temperatures originating from the

mass of water from the poles then flowing into the

equatorial region (Santos et al., 2012) equatorial

region (Santos et al., 2012).

2.2 Ocean Thermal Energy Conversion

(OTEC)

It is a powerplant by utilizing the temperature

difference of seawater on the surface and the

temperature of the seawater where the ocean, which

covers two-thirds of the earth's surface area, receives

heat from solar radiation. This thermal energy can be

utilized by converting it into electrical energy with a

technology called Ocean Thermal Energy

Conversion (OTEC). A large amount of energy is

absorbed by the oceans in the form of heat that

comes from the sun's rays and magma located

beneath the seabed (Masutani and Takahashi, 2001).

2.3 OTEC System

The OTEC system is divided into three types,

namely open cycle, closed cycle, and hybrid cycle

(Aldale, 2017). The closed-cycle OTEC system is

more widely studied than other systems based on

various source literature. A closed-cycle requires a

turbine that is smaller than an open cycle (open-

cycle) and can increase the efficiency of the

electrical energy produced by the generator

(Masutani and Takahashi, 2001). This study will use

a closed-cycle OTEC system.

2.4 OTEC Power Calculation

The power generated from the turbine generator in

the OTEC system according to (Uehara and

Ikegami, 1990) is

𝑃

=𝑚

𝜂

𝜂

(

ℎ1 − ℎ2

)

(1)

Where

𝑃

: turbine generator power(𝑀𝑊)

𝑚

:

the mass flow rate of the working

fluid(𝑘𝑔/𝑠)

𝜂

: turbine efficiency = 0.85

𝜂

: generator efficiency

ℎ1 − ℎ2 :

a decrease in adiabatic heat between the

evaporator and the condenser

The net electrical power equation used is

𝑃

=𝑃

−

(

𝑃

+𝑃

+𝑃

)

(2)

Where

𝑃

: clean electric power (𝑀𝑊)

𝑃

: turbine generator power (𝑀𝑊)

𝑃

: warm sea flow pump power (𝑀𝑊)

𝑃

: cold sea water pump power (𝑀𝑊)

𝑃

: working fluid pump power (𝑀𝑊)

3 METHOD

The method used in this research is a quantitative

method. The first step is taking CTD temperature

data and collecting HYCOM temperature data by

using a data model downloaded from the website

http://ncss.hycom.Org/thredds /catalog.html with the

Net Common Data File (NetCDF) format which

used daily temperature data for 9 years (October

2008-June 2017) with a resolution of 1/12

o

and a

depth of 0-5500 m. The second step is the

processing of CTD temperature data and HYCOM

temperature data processing by using data

verification using the Root Mean Square Error

(RMSE) (Neill and Hashemi, 2018).

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

14

𝑹𝑴𝑺𝑬=

𝟏

𝐧

(

𝐒

𝐢

𝐎

𝐢

)

𝟐

𝐧

𝐢𝟏

(3)

Where

n : number of observation

O : observation value

Si

: predictive value

Formula parameters to determine the bias values

by Neill and Hashemi (2018), as follows:

𝑏𝑖𝑎𝑠=𝑆

̅

−𝑂

(4)

3.1 Calculation of Sea Water Pump

Power and Working Fluid

To calculate sea water pump power and working

fluid is used the formulation by Uehara and Ikegami

(1990) and it can be followed this step.

The power of warm seawater pump is calculated

by the formulation as follows

𝑷

𝑾𝑺

=

𝒎

𝑾𝒔

∆𝑯

𝑾𝑺

𝒈

𝜼

𝑾𝑺𝑷

(5)

Cold sea water pump power is calculated with

the following formulation:

𝑷

𝑪𝑺

=

𝒎

𝑪𝑺

∆𝑯

𝑪𝑺

𝒈

𝜼

𝑪𝑺𝑷

(6)

Power of the working fluid pump is calculated

by the formulation as follows:

𝑷

𝑾𝑭

=

𝒎

𝑾𝑭

∆𝑯

𝑾𝑭

𝒈

𝜼

𝑾𝑭𝑷

(7)

Where

P

WS

: warm sea flow pump power (MW)

P

CS

: Cold sea water pump power (MW)

P

WF

: working fluid pump power (MW)

m

W

s : Mass flow rate of warm sea water (t/s)

m

CS

: Cold sea water mass flow rate (t/s)

m

WF

: Working fluid mass flow rate (t/s)

η

WSP

: Warm water pump efficiency

η

CSP

: Cold water pump efficiency

η

WFP

: Efficiency of the working fluid pump

∆H

WS

: The total pressure difference in Warm

water pipes

∆H

CS

: The total pressure difference in the Cold

water pipe

∆H

WF

: The total pressure difference in the

working fluid pipe

g : acceleration of gravity (m/s

2

)

3.2 Calculation of Sea Water Pump

Power and Working Fluid

In this study, the A

T

value was obtained from the

interpolation between the temperature difference

value (ΔT) from the temperature data processing and

the AT value using Uehara and Ikegami (1990).

To determine the total heat transfer area, the

following equation can be used from Uehara and

Ikegami (1990):

𝐀

𝑻

=𝐀

𝑬

+𝐀

𝑪

(8)

On the evaporator, the heat transfer area is

calculated by the formula:

𝐀

𝑬

=

𝑸

𝑬

𝑼

𝑬

(∆𝑻

𝒎

)

𝑬

(9)

To find out the value of the heat transfer rate on

the evaporator, can use the formula:

𝑸

𝑬

=𝒎

𝑾𝑭

(

𝒉

𝟏

−𝒉

𝟒

)

(10)

In the condenser, the heat transfer area is

calculated by the formula:

𝐀

𝑪

=

𝑸

𝑪

𝑼

𝑪

(∆𝑻

𝒎

)

𝑪

(11)

To find out the value of the heat transfer rate in

the condenser, can use the formula:

𝑸

𝑪

=𝒎

𝑾𝑭

(

𝒉

𝟐

−𝒉

𝟑

)

(12)

Where

A

T

: The area of heat transfer in the evaporator

(m

2

)

A

E

: The area of heat transfer in the condenser

(m

2

)

A

C

: Total heat transfer area (m

2

)

Q

E

: Heat transfer rate to the evaporator

Q

C

: Heat transfer rate to the condensor

(∆T

m

)

E

: logarithmic mean temperature differences

(LTMD) pada evaporator

(∆T

m

)

C

: logarithmic mean temperature differences

(LTMD) pada kondensor

(h

1

-h

4

) and (h

2

-h

3

) : the enthalpy value matches the

Rankine cycle

3.3 Calculation of OTEC Net Power

and Rankine Cycle Efficiency

The net power of OTEC (P

NET

) can be calculated

using equation (2). The efficiency of the Rankine

cycle (ηRan) can be calculated by the equation

𝜼

𝑹𝒂𝒏

=

𝑷

𝑮

𝑸

𝑬

(13)

Analysis of Ocean Thermal Energy Conversion (OTEC) Potential using Closed-cycle System Simulation of 100 MW Capacity in Bali Sea

15

Where

η

Ran

: Rankine cycle efficiency

P

G

: Turbine generator power (MW)

Q

E

: Heat transfer rate to the evaporator

4 RESULT AND DISCUSSION

4.1 Verification of HYCOM and CTD

Temperature Data

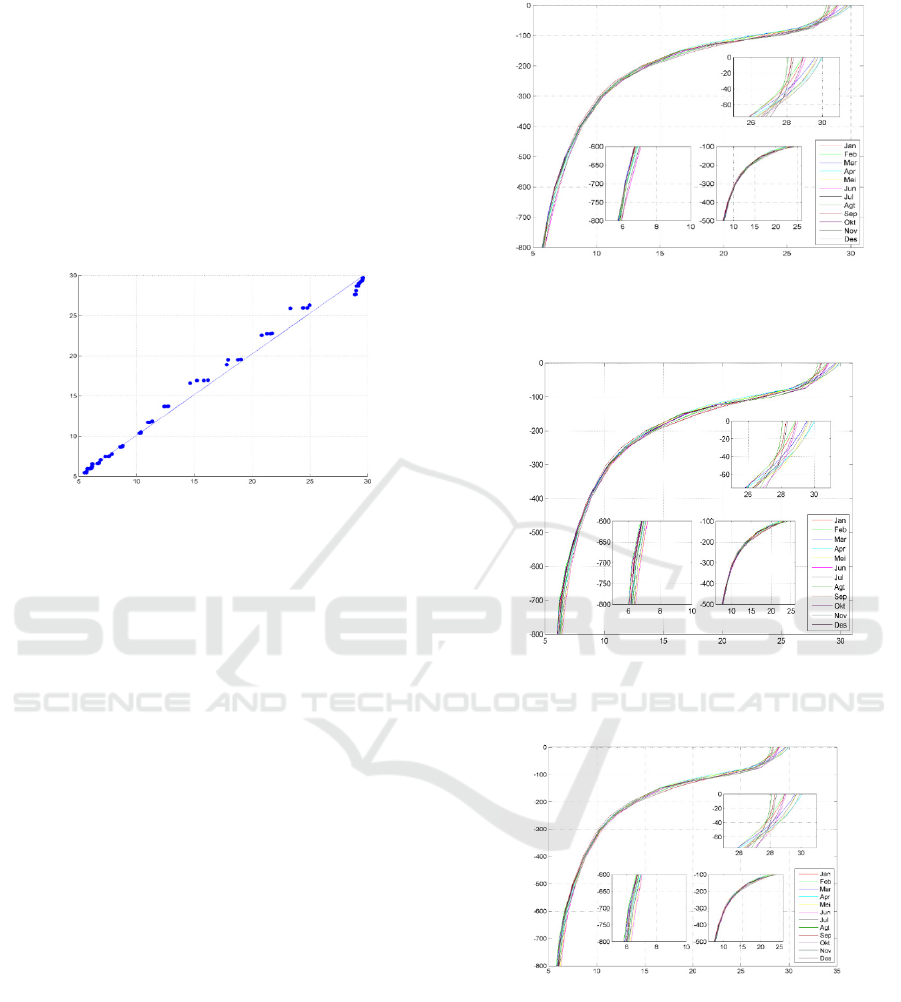

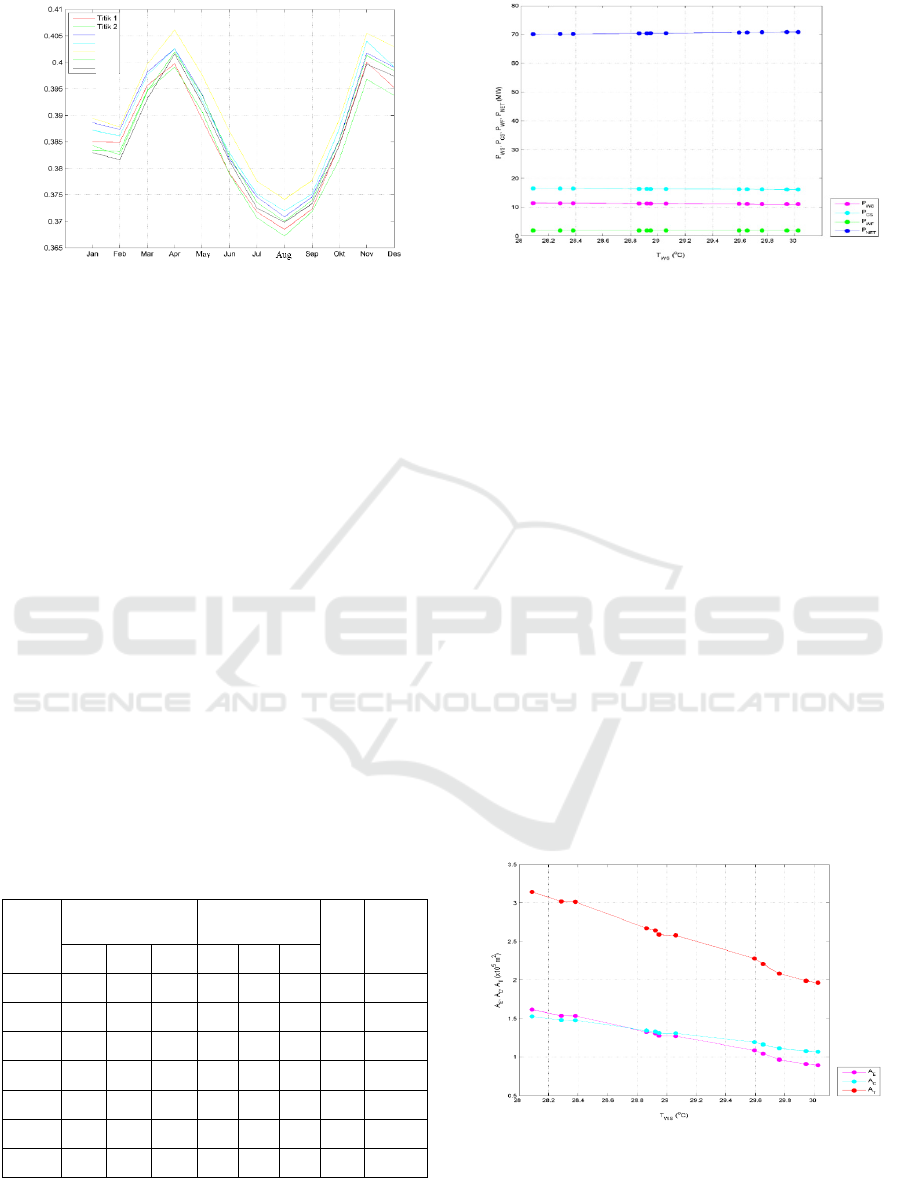

Figure 1: Distribution of Temperature Value to Depth

between HYCOM Data and C

TD

Data (Source: Data

Processing).

The error value obtained and the data distribution

graph below, then HYCOM has good data and is

considered capable of representing the temperature

conditions of the C

TD

collection.

4.2 Vertical Temperature Distribution

in the Bali Sea

The temperature of warm seawater at the surface

(T

WS

) and the temperature of cold seawater at depth

(T

CS

) are obtain to get the difference in temperature

(ΔT) between sea level and depth.

In general, temperatures that tend to be uniform

in the mixed layer (Figure 2-8) are caused by the

turbulence mechanism by wind and waves and heat

flux at sea level. Changes in temperature at the

surface of the sea and layers are mixed due to the

strength of the wind influenced by monsoons so that

the temperature at the surface of the sea and the

layers are mixed experiencing monthly variations.

Also, according to Atmadipoera and Hasanah

(2017), the temperature in the mixed layer shows

seasonal variability. The cause of this variability is

thought to be due to the influence of the mass

movement of water in the Java Sea and the Flores

Sea which partly entered the Lombok Strait.

Figure 2: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 1 (Source: Data Processing).

Figure 3: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 2 (Source: Data Processing).

Figure 4: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 3 (Source: Data Processing).

4.3 Difference in Surface and Depth

Temperature in the Bali Sea

From 2008 to 2017, the maximum temperature

difference value occurs in April at all points as

shown in Figure 12 with the average maximum

temperature difference of 23,998

o

C. From April to

Depth (m)

Temperature (

o

C)

Depth (m)

Temperature (

o

C)

Temperature (

o

C)

Depth (m)

Temperature (

o

C)

Temperature CTD (

o

C)

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

16

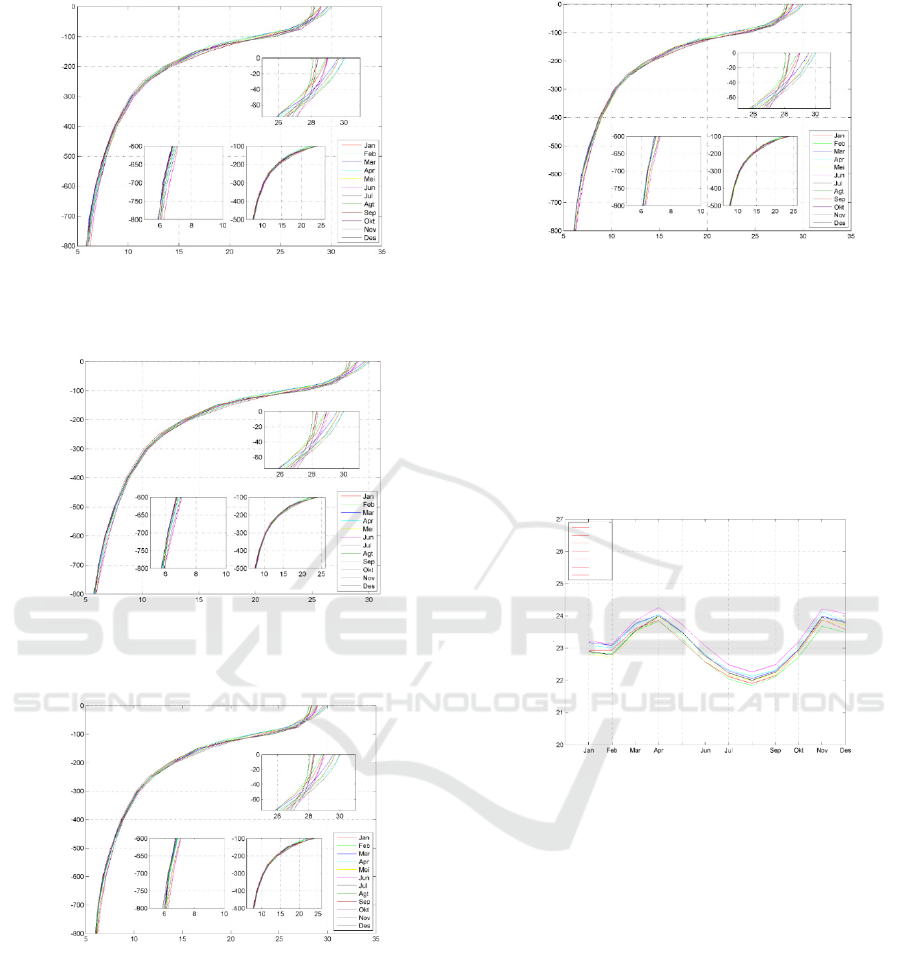

Figure 5: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 4 (Source: Data Processing).

Figure 6: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 5 (Source: Data Processing).

Figure 7: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 6 (Source: Data Processing).

August, the temperature difference decreased quite

dramatically at all points with an average decrease

of 1,975

o

C. The lowest temperature difference

occurred in August, with an average of 22,023

o

C.

Then, starting in August there was a significant

increase of 1,933

o

C at all points until November

with an average temperature difference of 23,956

o

C

for the month.

Figure 8: Temperature Vertical Distribution Plot of 2008 -

2017 at Point 7 (Source: Data Processing).

Bali Sea meets the potential OTEC requirements

of more than 20

o

C during October 2008-2017 with a

temperature difference ranging from 21.9

o

C to

24.5

o

C. However, this potential needs to be studied

further to get the true potential by determining the

net power value based on a closed-cycle system

simulation of 100 MW.

Figure 9: Average Monthly Temperature Difference in

2008-2017. (Source: Data Processing).

4.4 Closed Cycle System Simulation

4.4.1 Warm and Cold Water Temperature

Profiles

This shows that the temperature of cold seawater is

not affected by monsoons like warm seawater

temperatures. The almost uniform temperature is

caused by a large enough density in the deep sea so

that the mass of seawater is denser. The high density

is caused by layers in the deep sea not having a

direct influence from the wind, the intensity of

sunlight, precipitation and evaporation, and cloud

cover such as the temperature of warm seawater.

Depth (m)

Temperature (

o

C)

Depth (m)

Temperature (

o

C)

Depth (m)

Temperature (

o

C)

Temperature (

o

C)

Depth (m)

Month

Temperature (

o

C)

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

May

Aug

Analysis of Ocean Thermal Energy Conversion (OTEC) Potential using Closed-cycle System Simulation of 100 MW Capacity in Bali Sea

17

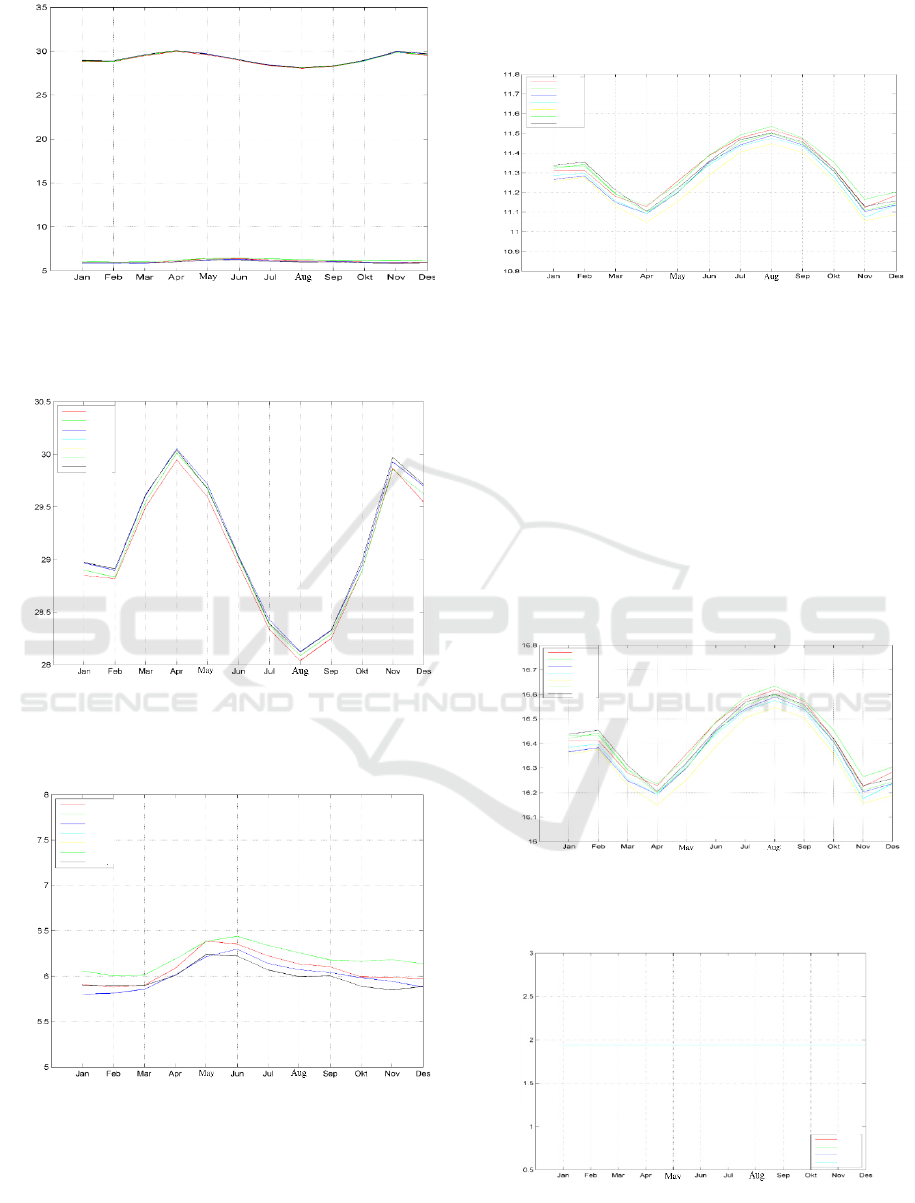

Figure 10: Variations in Surface Temperature Monthly

(T

WS

) and Temperature Depth (T

CS

) in 2008-2017 (Source:

Data Processing).

Figure 11: Monthly Variations of Warm Sea Water

Temperature on T

WS

2008-2017. (Source: Data

Processing).

Figure 12: Monthly Variations in Cold Sea Water

Temperature at Depths of 800 m (T

CS

) in 2008-2017

(Source: Data Processing).

4.4.2 Pump Power for Warm Water, Cold

Water and Working Fluid

Figure 13: Monthly Warm Water Pump Power (P

WS

) in

2008-2017 (Source: Data Processing).

Warm seawater pump power reached the highest rate

in August, which was an average of 11,495 MW.

Meanwhile, the lowest warm seawater pump power

occurred in April with an average value of 11.1

MW.

Coldwater pump power reached the highest rate

in August, which was an average of 16,595 MW.

Meanwhile, the lowest warm seawater pump power

occurred in April with an average value of 16.2

MW. Coldwater pump power is stable from year to

year with a range between 1.94-1.97 MW.

Figure 14: Monthly Cold Power Pump (P

CS

) 2008-2017

(Source: Data Processing).

Figure 15: Power of Monthly Working Fluid Pump (P

WF

)

in 2008-2017 (Source: Data Processing).

Month

Temperature (

o

C)

Temperature (

o

C)

M

o

n

t

h

Month

Water Pump Fluid Warm Water (MW)

Temperature (

o

C)

Month

Month

Month

Cold Power Pump (MW)

Fluid Pump

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

Point 1

Point 2

Point 3

Point 4

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

18

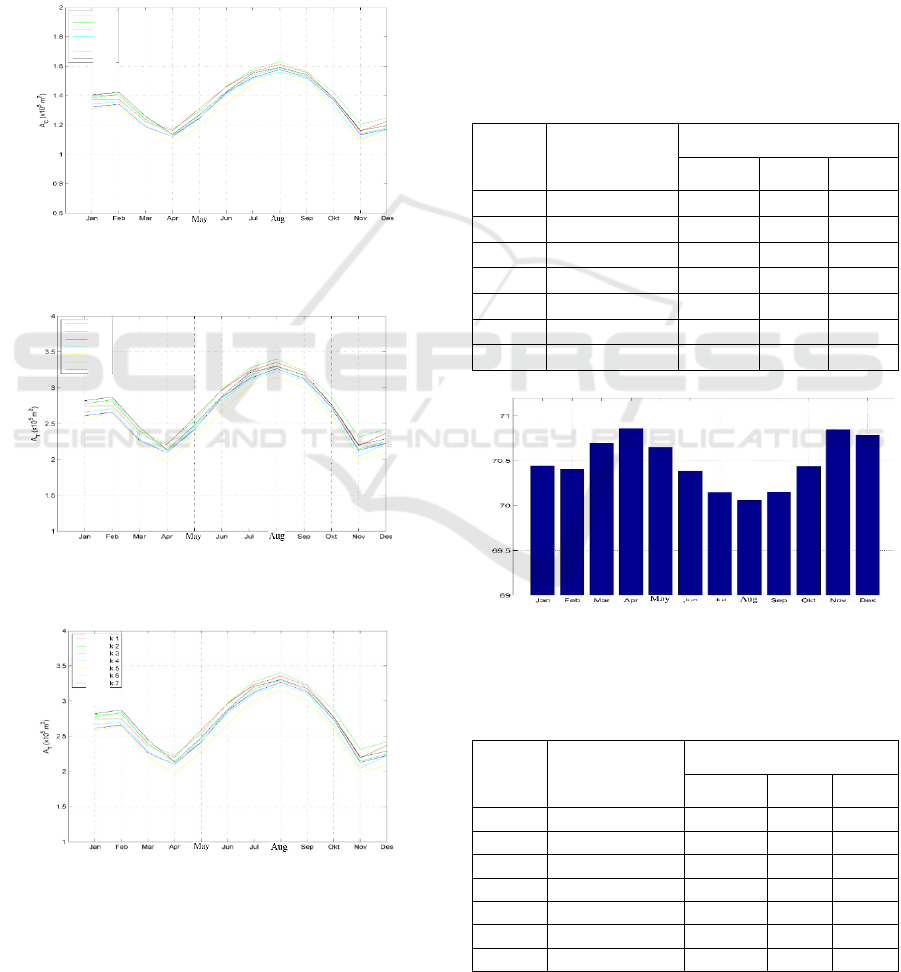

4.4.3 Heat Transfer Area

The heat transfer area in the evaporator reached the

highest number in August, which was an average of

1.70164x105m

2

. Meanwhile, the lowest heat transfer

area in the evaporator occurred in April with an

average value of 0.99052 x105m

2

.

The area of heat transfer in the condenser

reached the highest number in August, namely an

average of 1,58466 x105m

2

and the lowest in April

with an average value of 1.130330 x105m

2

.

Figure 16: Area of Heat Transfer in Monthly Evaporators

2008-2017 (Source: Data Processing).

Figure 17: Heat Transfer in Monthly Condenser (A

C

)

2008-2017 (Source: Data Processing).

Figure 18: Total Heat Transfer Area (A

T

) in 2008 -2017

(Source: Data Processing).

4.5 Calculation of OTEC Net Power

and Cycle Efficiency

The results of the OTEC net power estimation

results are listed in the table 1.

The highest net power for 9 years (Table 1.) was

achieved in April with an average net power of

70,759 MW and the lowest occurred in August with

an average net power of 69,969 MW. The maximum

cycle efficiency is 0.4061 at Point 5. The highest

cycle efficiency occurs in April with an average

maximum value of 0.402, while the lowest cycle

efficiency occurs in August with an average

minimum value of 0.3704.

Table 1: OTEC Clean Power at Study Point 2008-2017.

Location Temperature

Difference (

O

C)

Clean Power (MW)

Average Min Max

Point 1 22.969 70.348 69.922 70.711

Point 2 22.896 70.318 69.891 70.689

Point 3 23.140 70.416 69.981 70.775

Point 4 23.157 70.423 70.010 70.810

Point 5 23.327 70.491 70.064 70.863

Point 6 23.053 70.381 69.961 70.759

Point 7 22.990 70.356 69.956 70.750

Figure 19: Monthly Net Power in 2008-2017 at the

Potential Point (Source: Data Processing).

Table 2: Efficiency of the Rankine Cycle at the Study

Point in 2008-2017.

Location

Clean Power

Average (MW)

Efficiency

Average Min Max

Point 1 70.348 0.3855 0.3685 0.4000

Point 2 70.318 0.3843 0.3672 0.3992

Point 3 70.416 0.3882 0.3709 0.3026

Point 4 70.423 0.3885 0.3720 0.4040

Point 5 70.491 0.3912 0.3742 0.4061

Point 6 70.381 0.3868 0.3700 0.4020

Point 7 70.356 0.3858 0.3698 0.4016

Month

Month

Month

Clean Power (MW)

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

Month

Analysis of Ocean Thermal Energy Conversion (OTEC) Potential using Closed-cycle System Simulation of 100 MW Capacity in Bali Sea

19

Figure 20: Efficiency of Monthly Cycles in 2008-2017

(Source: Data Processing).

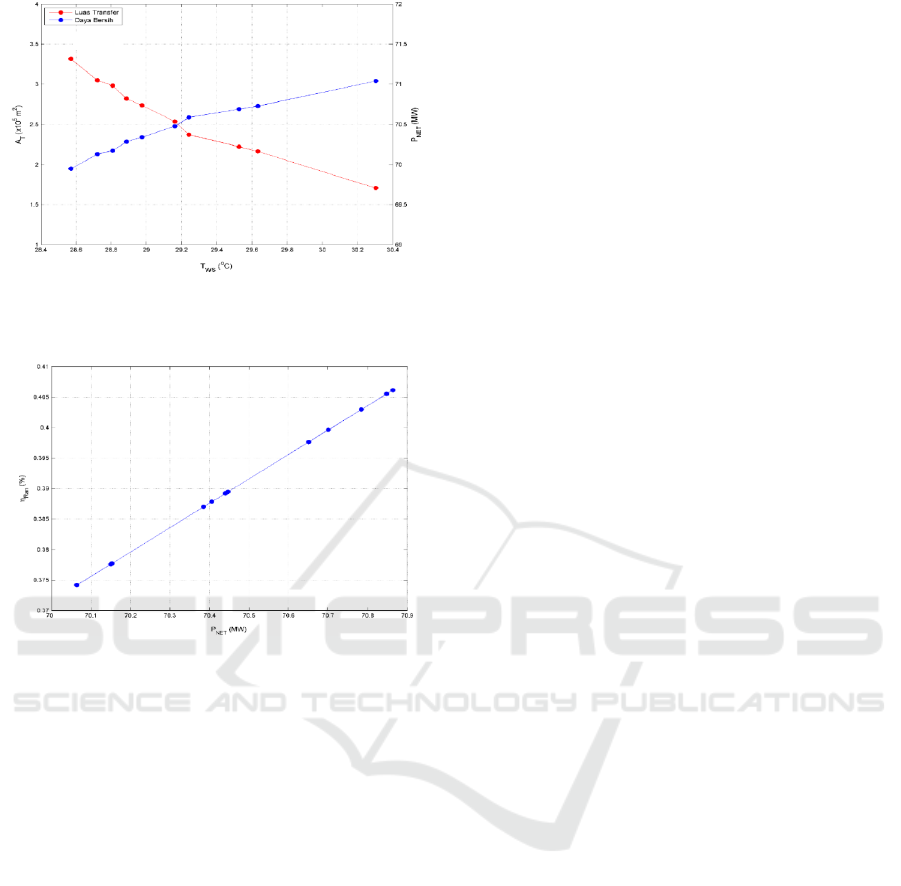

4.6 Discussion of Closed Cycle OTEC

System Simulation

The power of warm seawater pumps (P

WS

) and cold

seawater pump power (P

CS

) decreases but is not very

significant, while the power of the working fluid

pump (P

WF

) is stable against the increase in T

WS

.

Meanwhile, the net power (P

NET

) increased from

70.06 MW to 70.86 MW. P

NET

value is derived from

the remaining power generated by the turbine due to

be used to pump warm seawater, cold seawater, and

working fluid.

The heat transfer area in the evaporator (A

E

)

decreases from 1.61633x105m

2

to 0.89701x105m

2

.

Likewise, the area of heat transfer in the condenser

(A

C

) which also decreased from 1.53015 x105m

2

to

1.0705882x105m

2

. This decrease certainly affects

the value of the area of heat transfer on the

condenser (A

T

) which decreased from 3.14648

x105m

2

to 1.967596 x105m

2

Table 3: Simulation Parameter Value Based on 100 MW

Closed Cycle Simulation.

Location

Pump Power (MW)

Heat Transfer Area

(x10

5

m

2

)

Net

Power

(MW)

Cycle

Efficiency

(%)

P

WS

P

CS

P

WF

A

E

A

C

A

T

Point 1 11.306 16.406 1.94 1.361 1.367 2.728 70.348 0.3855

Point 2 11.321 16.421 1.941 1.387 1.384 2.771 70.318 0.3843

Point 3 11.272 16.372 1.951 1.300 1.328 2.628 70.416 0.3882

Point 4 11.269 16.369 1.951 1.293 1.324 2.617 70.423 0.3885

Point 5 11.235 16.335 1.94 1.232 1.285 2.517 70.491 0.3912

Point 6 11.289 16.389 1.951 1.331 1.348 2.679 70.381 0.3868

Point 7 11.302 16.402 1.95 1.354 1.362 2.716 70.256 0.3858

Figure 21: Relationship Between Pump Power (P

WS

, P

CS

,

P

WF

) and Clean Power (P

NET

) (Source: Data Processing).

Uehara and Ikegami (1990) stated that the cost of

the heat exchanger is one of the components that

most cuts the cost of generation, around 25-50% of

the total cost. Therefore, it is necessary to obtain the

minimum objective function value by increasing the

production of clean electric power and the heat

exchanger needed to optimize the area of heat

transfer can be suppressed.

The graph (Figure 24.) shows a linear

relationship between net power and cycle efficiency.

Increasing the value of net power will also increase

the value of cycle efficiency. To produce a

maximum electric power of 70.86 MW, the

efficiency of the issued Rankine cycle reaches a

maximum of 0.4061 or 40.61%. The efficiency of

the Rankine cycle comes from how efficient the

OTEC generator is in releasing power to pump

warm seawater (P

WS

), cold seawater (P

CS

), and

working fluid (P

WF

). Thus, the greater the net power

produced, the pump power produced must also be

greater and this will increase the value of the

Rankine cycle efficiency.

Figure 22: Relationship Between Heat Transfer Area in

Evaporator and Condenser (A

E

, A

C

) and Total Heat

Transfer Area (A

T

) (Source: Data Processing).

Month

Cycle Efficiency (%)

Point 1

Point 2

Point 3

Point 4

Point 5

Point 6

Point 7

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

20

Figure 23: Relationship Between Total Heat Transfer Area

(A

T

) and Clean Electricity Power (P

NET

) (Source: Data

Processing).

Figure 24. Relationship Between Clean Electric Power

(P

NET

) and Cycle Efficiency (ηRan) (Source: Data

Processing).

5 CONCLUSION

1. Minimum temperature difference requirement

of 20

o

C at seven study points in the Bali Sea

Waters was fulfilled during 2008-2017 with a

range between 21.9

o

C - 25.3

o

C.

2. Potential net electric power OTEC in the Bali

Sea has a range between 69.8-70.8 MW with a

maximum net power found at Point 5 of 70.86

MW with a capacity of 100 MW with cycle

efficiency of 0.4061 or 40.61%.

3. Based on the simulation of closed cycle OTEC,

the components that describe and support the

potential of OTEC are warm sea water

temperature (T

WS

) and cold water (T

CS

) of 28

o

C-

30

o

C and 5.7

o

C-6.4

o

C; warm sea water pump

power (P

WS

), cold sea water pump power (P

CS

),

and working fluid pump power (P

WF

) of 11,048-

11,543 MW, 16,148-16,634 MW, and 1.94-1.97

MW; heat transfer area on the evaporator (A

E

),

heat transfer area on the condenser (A

C

), and the

total heat transfer area (A

T

) of 0,897-1,772x105

m

2

, 1,07059-1,62968x105 m

2

, and 1,9676-

3.401794x105 m

2

.

REFERENCES

Aldale, Abdullah Mohammed. 2017. “Open Access Ocean

Thermal Energy Conversion (OTEC) American

Journal of Engineering Research (AJER).” (4):164–67.

Avery, W.H. and Chih Wu. 1994. Renewable Energy from

The Ocean: A Guide To OTEC. Oxford University

Press, Inc., New York, 446 p.

Masutani. and Takahashi. 2001. “Ocean Thermal Energy

Conversion (Otec).” 1(1997):1993–99.

Negara, Ridho Bela dan J. Koto. 2016. Potential of 100

kW of Ocean Thermal Energy Conversion in

Karangkelong, Sulawesi Utara, Indonesia.

International Journal of Environmental Research &

Clean Energy, 5 (1): 1-10

Neill, Simon P., Hashemi, M. Reza. 2018. Fundamentals

of Ocean Renewable Energy: Chapter 8-Ocean

Modelling for Resource Characterization.Academic

Press. Elsevier 1

st

Edition

Nihous, Gérard C. 2007. “A Preliminary Assessment of

Ocean Thermal Energy Conversion Resources.”

Journal of Energy Resources Technology,

Transactions of the ASME 129(1):10–17.

Prabowo, H. 2012. Atlas Potensi Energi Laut. J. M&E,

10(4): 65-71.

Santos, Fran, Moncho Gómez-Gesteira, Maite deCastro,

and Inés Álvarez. 2012. “Variability of Coastal and

Ocean Water Temperature in the Upper 700 m along

the Western Iberian Peninsula from 1975 to 2006.”

PLoS ONE 7(12):2–8.

Sinuhaji, A.R. 2015. Potential Ocean Thermal Energy

Conversion (OTEC) in Bali. KnE Energy, 1: 5-12.

Syamsuddin, Mega L., Adli Attamimi, Angga P. Nugraha,

and Syahrir Gibran. 2015. “OTEC Potential in The

Indonesian Seas.” Energy Procedia 65:215–22.

Uehara, Haruo dan Yasuyuki Ikegami. 1990. Optimization

of a Closed Cycle OTEC System. Journal of Solar

Energy Engineering, 112: 247-256.

Transfer Area

Clean Power

Analysis of Ocean Thermal Energy Conversion (OTEC) Potential using Closed-cycle System Simulation of 100 MW Capacity in Bali Sea

21