A One Year Performance Evaluation of an Amorphous Grid

Connected PV System Facade Mounted at Bou-Ismail, Algeria

S. Berkane

1,2

, A. Mahrane

1

, M. Chikh

1

and M. Haddadi

2

1

Unité de Développement des Equipements Solaires /UDES Centre de Développement des Energies Renouvelables

/CDER,42415.W.Tipaza,Algérie

2

Laboratoire des Dispositifs de Communication et de Conversion Photovoltaïque LDCCP / École Nationale Polytechnique

d’Alger, El-Harrach, W.Alger.Algeria

Keywords: PV system, BAPV, Amorphous Silicon PV module, Outdoor performance

Abstract: This paper treats one year monitoring of a 2.4 kWp amorphous grid connected PV system facade mounted at

UDES’ site located at BouIsmaïl (latitude 36.66, longitude 2.71), Algeria, in a coastal zone of Mediterranean

Sea. The operational and meteorological data are collected between January 2016 and November 2016.

During the monitoring period, the PV system has generated about 850kWh with a daily average energy of

3.25 kWh/d. The daily average of the final yield, the performance ratio and the capacity factor are 1.35h/d,

0.57 and 6.29% respectively. The capture and system losses are 0.87h/d and 0.15h/d respectively.

1 INTRODUCTION

To satisfy the growing demand of electricity and

reduce the greenhouse gas emissions that lead to

global warming, Renewable Energies seems to be one

of the relevant solutions to be adopted.

As the residential sector is the largest consumer of

energy, about 40% of the total energy consumed in

the world (

A. Khuram Pervez et al.,2017), and as the

most of the buildings and houses are located in the

cities it appears that the Building Integrated

Photovoltaic (BIPV) and Building Added

Photovoltaic (BAPV) may represent a powerful

solution to meet the ever increasing demand by zero

energy and zero emissions buildings.

As the available areas to install the PV plant on the

roofs in the cities are very limited, the facades could

be used to increase at the same time the size of the PV

array and the production of electricity.

In order to explore the potential of the BAPV system

a 12.5 kWp photovoltaic pilot plant composed of six

photovoltaic arrays of different technologies which

are connected to the grid and integrated on the

conference room of the UDES Unit is investigated.

The crystalline PV modules are installed on the roof

while the thin film PV modules are mounted on the

facades. This choice is dictated by the fact that the last

modules are cheaper than the crystalline, and less

sensitive to temperature even if there are installed on

the walls. However, their efficiency is lower than that

of crystalline module but more stable in diffuse solar

radiations.

This paper treats the case of one of the six subsystems

composing the on grid PV platform namely the

amorphous silicon (a-Si) photovoltaic subsystem. At

first, a description of the a-Si PV system is given, then

the experimental results obtained during the test

period ranging from January 2016 to December 2016

are presented.

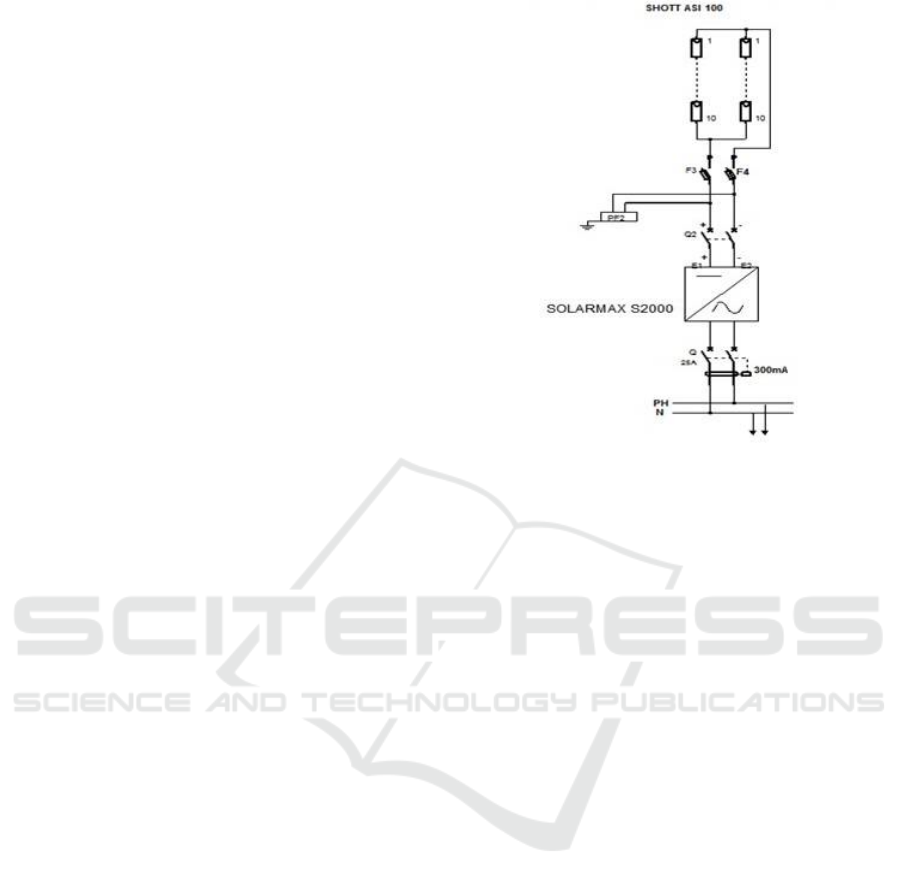

Figure 1: View of the 2.4 kWp amorphous Silicon

facade mounted PV plant

Berkane, S., Mahrane, A., chikh, M. and Haddadi, M.

A One Year Performance Evaluation of an Amorphous Grid Connected PV System Facade Mounted at Bou-Ismail, Algeria.

DOI: 10.5220/0009775003970404

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 397-404

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

397

Finally, the evaluation and analysis of the

performance of the a-Si PV plant is conducted for the

monitoring period.

2 SYSTEMS DESCRIPTION

2.1 PV System Description

The 12.5 kWp Multi technology solar PV plant grid

connected is located at UDES BouIsmaïl (latitude of

36°38, longitude of 2°41), and altitude of 13 m above

sea level, Algeria. It consists of six independent sub

system, each of them using one type of solar cells

technology (mono Si, poly Si, or thin films). The aim

of the study is to follow up the 2.4kWp amorphous

Silicon (a-Si) thin film PV plant mounted on the

facade of the conference room, Fig1. Its electrical and

technical properties are summarized in Table 1. This

PV plant is composed by 20 a-Si Schott modules

configured in two strings, each string consists of 10

modules in serial. The overall surface area of PV

plant system is 30m².The a-Si PV generator is

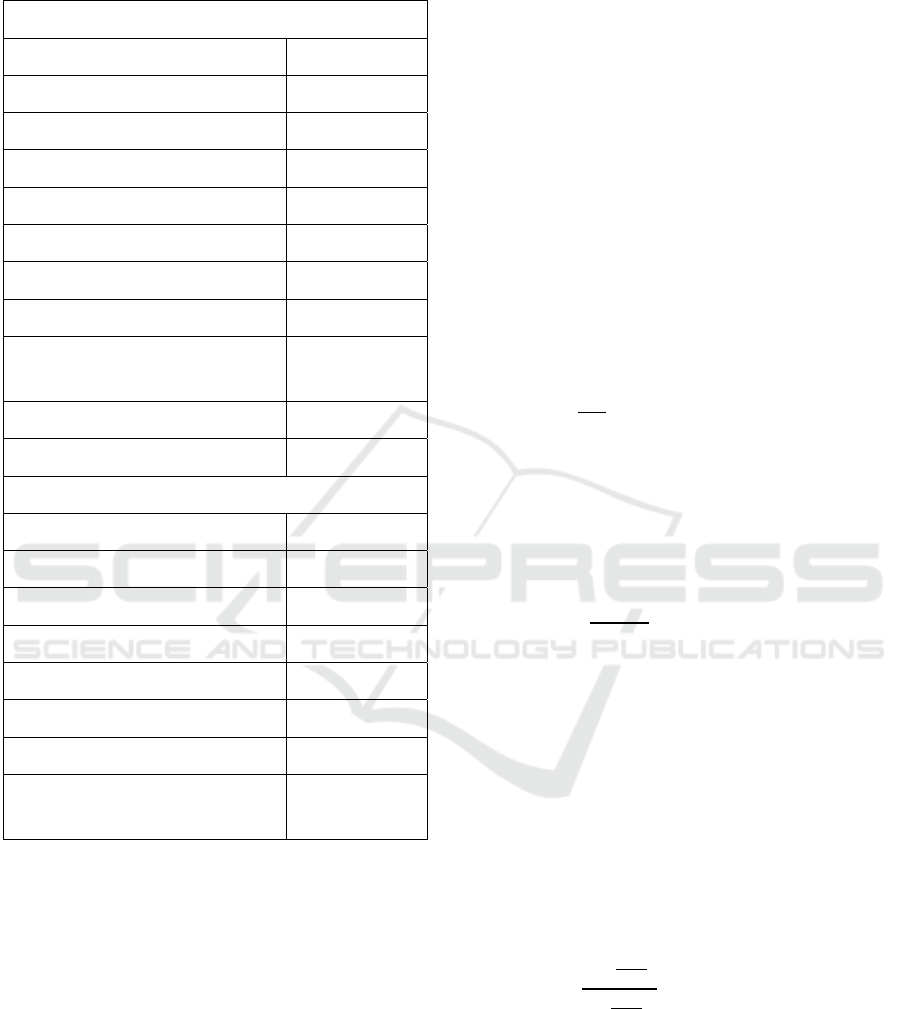

connected to the grid through a SOLARMAX

S2000inverter as shown in Fig 2.

2.2 Monitoring System Description

The PV system is fully monitored with Solarlog

300data logger. It is linked to the inverter through

RS485 cable. The recorded data provided by the

inverter are: the DC current and voltage, the AC

current and voltage and the DC and AC power. The

radiometric and metrological data are measured and

collected by a meteorological station installed at

UDES site, BouIsmaïl. The irradiance on vertical

plane used in this study is measured by a-Si reference

cell located in the same plane as the a-Si PV modules.

The data are recorded and saved at a pace of 5mn. The

monitoring system was designed to meet the standard

IEC 61724(

Chikh M et al.,2015).

Figure 2: Diagram of the 2.4kWp a-Sigrid connected

PV plant.

3 PERFORMANCE

PARAMETERS

The evaluation of the PV system performance is done

according to the performance parameters defined in

the IEC 61724 standard (IEC 61724,1998), and given

in the following:

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

398

Table 1: SCHOTT a-Si PVmodule and SOLARMAXS2000

inverter characteristics.

Module Specifications

Manufacturer SCHOTT

model ASI-100

Cell type a-Si/a-Si tandem

Nominal power P

max

[W] 100

Open circuit voltage V

oc

[V] 40.9

Short circuit curant I

cc

[A] 3.93

Voltage at maximum powerV

mpp

[V] 30.4

Curant at maximum power I

mpp

[A] 3.29

Efficiency ᶯ

m

[%]

6.9

Number of cell 72

Module surface A

m

[m²] 1.45

Inverter Specifications

Manufacturer SOLARMAX

model S2000

DC nominal voltage Vin[V] 600

DC power Pdc[w] 2000

DC voltage range Vdc[V] 100-550

AC nominal power Pac[VA] 1980

Nominal AC voltage Vac[V] 230/184-300

Efficiency ᶯ

ond

[%]

97

3.1 System Energy Output

The total daily E

(AC,d)

and monthly E

(DC,m)

,E

(AC,m)

energy generated by the PV system is given by

(

Sharma V, et al.,2013):

,

E

,

1

,

E

,

2

,

E

,

3

Where Nis the number of days in the month, E

(AC,t)

is

the instantaneous measured energy.

3.2 Inverter and System Efficiency

The instantaneous inverter efficiency is calculated as

(

Chikh M et al.,2015):

4

Where the P

dc

and, P

ac

are respectively the DC and

AC power.

The monthly system efficiency is calculated by

(

Chikh M et al.,2015):

,

.

.100

5

Where G

t

is the total in plane radiation (Wh/m²), and

A

m

the PV array area (m²).

3.3 Reference Yield(Yr)

The reference yield is the total in-plane solar

insolation H

t

(kW h/m²) divided by the array

reference irradiance (1 kW/m

2

) (Kymakis E, et al). This

parameter represents the equal number of hours at the

reference irradiance and is given by:

1

6

3.4 Array Yield (Ya)

The array yield Ya is defined as the energy output

from a PV array over a defined period (day, month or

A One Year Performance Evaluation of an Amorphous Grid Connected PV System Facade Mounted at Bou-Ismail, Algeria

399

year) divided by its rated power (

Sharma V, et

al.,2013) and is given by:

,

7

3.5 Final Yield (Yf)

The final yield is defined as the annual, monthly or

daily net AC energy output of the system divided by

the rated power of the installed PV array at standard

test conditions (STC) of 1 kW/m2solar irradiance and

25°C cell temperature. This is a representative figure

that enables comparison of similar solar PV power

plant in a specific geographic region. It is independent

on the type of mounting, vertical on a facade or

inclined on a roof and also on the location (

Tripathi B,

et al.,2014)

and is given by:

,

7

8

3.6 Performance Ratio (PR)

The Performance Ratio (PR) is a measure of the

quality of a PV plant that is independent of location.

Therefore, it is often described as a quality factor. The

(PR) is stated as percent rate and describes the

relationship between the actual and theoretical energy

outputs of the PV plant. It shows the proportion of the

energy that is actually available for export to the grid

after deduction of the energy loss (e.g. due to thermal

losses and conduction losses) and of energy

consumption for operation.

In real life, a value of 100 % cannot be achieved,

because unavoidable losses always arise with the

operation of the PV plant (e.g. thermal loss due to

heating of the PV modules). High-performance PV

plant scan however reach a performance ratio of up to

80 % (

SMA Solar Technology AG )The PR is given by:

9

3.7 Capacity Factor

The capacity factor (CF) is a means to present the

energy delivered by an electric power generating

system. If the system delivers the full rated power

continuously, its CF would be unity. The capacity

factor (CF) is defined as the ratio of the actual annual

energy output to the amount of energy that the solar

PV power plant could generate if it is operated at full

rate power (P

pv,rated

)for 24 h per day for a year (Tripathi

B, et al.,2014) and is given by:

24∗365

,

∗8760

10

3.8 Array Capture Losses

The array capture losses (Lc) are due to the PV array

losses and are given by (Ayompe L M, et al.,2010):

11

3.9 System Losses

The system losses (Ls) are induced by the inverter and

are given by (

Ayompe L M, et al.,2010):

4 RESULTS AND DISCUSSION

4.1 Meteorological Data

The total irradiation received on the PV

generator during the monitoring period is

833.55kWh/m². Figure 3 shows the evolution of the

monthly solar energy received by the array which

varies between 2.16 kWh/m².d recorded in January

2016 and 3.18 kWh/m².din September 2016. This

variation is predictable considering the sun's

trajectory relative to the PV field located in a vertical

plane. The maximum irradiation was reached during

the month of September which coincides with the

beginning of the fall and which is favorable for the

vertical inclinations.

Figure 3: Monthly average daily irradiation respectively on

the vertical plan of the PV array and on the optimal angle

for the site (36°).

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

400

It could be noticed that the PV array on the vertical

plane receives less solar irradiation than it could have

received if it is installed on an inclined plane with an

optimal angle of 36 ° for the site. The irradiation

losses were the highest in June (53.71%) and the

lowest in November (21.62%).

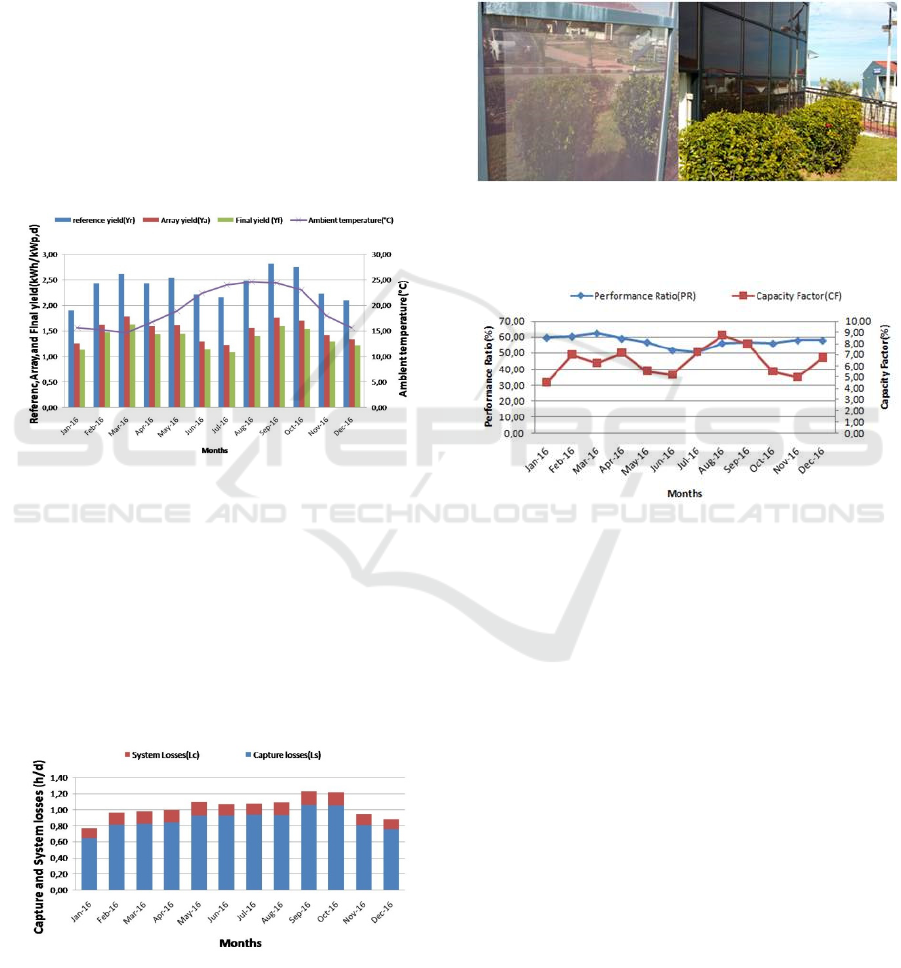

The ambient temperature of the site of BouIsmaïl

doesn’t exceed, the value 30 ° C all over the year and

this is due to the specific Mediterranean climate of the

location. The average monthly ambient temperature

and the back module temperature during the

monitoring period are shown in fig 4.

The average monthly ambient temperature varies

between 14.65 ° C in March and 24.63 ° C in August,

while the average monthly PV module temperature

varies between 19.5°C in February and 31°C in July.

Because of the fact that the temperature increase of

the amorphous modules is only 10°C, it can be

concluded that the influence of the temperature can

be considered negligible. This is due to the low value

of the temperature coefficient of the a-Si material.

Figure 4: Monthly average ambient temperature and

module temperature over the monitored period.

4.2 DC Power Input and Inverter

Efficiency

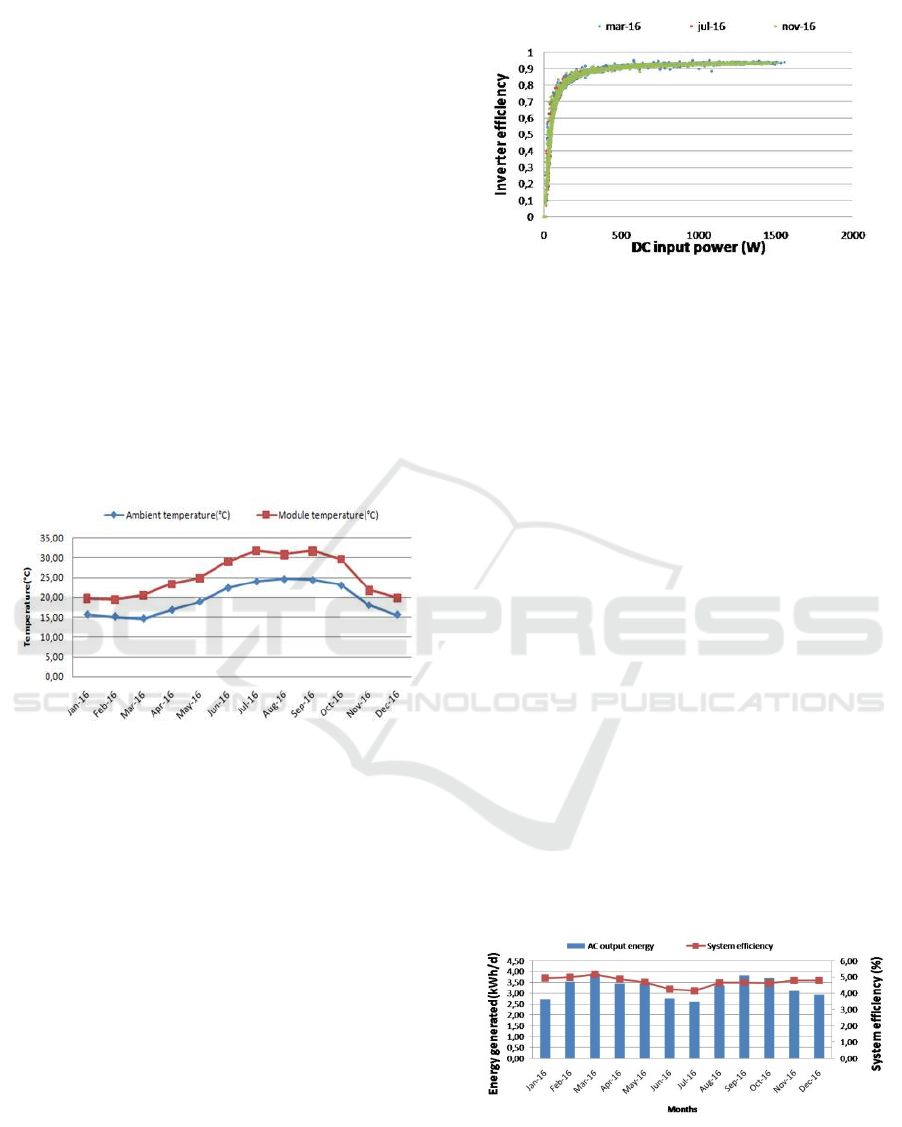

Figure 5 shows the variation of the inverter efficiency

with the DC power input for three months. It could be

noticed that the inverter operates with stability when

AC power input is greater than200W with an average

efficiency of 90.2%. When the DC power input is

under 200W, the efficiency decreases drastically due

to the fact that the DC voltage of the PV array is not

in the operating range of the inverter.

Figure 5: Inverter efficiency

4.3 Energy Output and PV System

Efficiency

The output energy and the efficiency of the PV

system are calculated using equations (2) and (3)

respectively. During 12 months the PV system has

produced about 850kWh, with an annual PV system

efficiency of 4.76% which is in the range efficiency

of the a-Si PV system. From the Figure 6, it could be

seen that the monthly output energy and the PV

system efficiency are mainly influenced by the solar

irradiation received on the vertical plane during each

month. Their values were comprised between

(2.60kWh/d and 4.68%) in July and (3.90kWh/d and

5.65%) in March respectively.

4.4 Reference Yield, Array Yield and

Final Yield

The reference yield (Yr), the array yield (Ya) and the

final yield (Yf) of the studied a-Si PV plant are given

in figure 7. It appears that the monthly values of

reference yield Yr ranged between1.9 kWh/kWp.d in

January and 2.82kWh/kWp.d in September.

Figure 6: Monthly average AC output energy and efficiency

of the a-Si PV system.

Ya varies between 1.28 kWh/kWp.d in July and 1.63

kWh/kWp.d in March and Yf varies between1.08

A One Year Performance Evaluation of an Amorphous Grid Connected PV System Facade Mounted at Bou-Ismail, Algeria

401

kWh/kWp.d in july and 1.59kWh/kWp.d in

September. As expected, it could be seen from Figure

7 that for the a-Si PV array the temperature variation

has less influence on the Yf than the irradiation.

4.5 Captures Losses and System Losses

Figure 8 shows the monthly average daily capture and

system losses through the monitoring period. The

capture losses (Lc) are very significant and vary

between 0.64 h/d in January and 1.06 h/d in

September. This is mainly due to two probable

reasons.

The first one, which is obvious, is related to the

vertical position of the PV plant which reduces hardly

the amount of solar irradiation received.

Figure 7: Monthly average daily system’s final yield

Yf,reference yield Yr and array yield Ya.

The second reason concerns the partial shading due to

the holder structure of the modules and the vegetation

(cf. Figure9).

However, the system losses are relatively low and

ranged from 0.12h/d in January to 0.17 h/d in May

and September, thanks to the good efficiency of the

inverter.

Figure 8: Monthly average capture and system losses

4.6 Performance Ratio and Capacity

Factor

Figure 10 shows the results of PR and CF. The results

showed that the PR varied between 0.51in July and

0.62 in March and it has an annual value of 0.57,

meanwhile the CF varies between 4.53 % in January

and 8.72 % in August with an annual value of 5.68%.

Figure 9: View of partial shading components around the

PV plant system

Figure 10: Performance Ratio and Capacity Factor of the a-

Si PV system.

The results of works published in the IEA report on

thin film systems show, that the performance of 14

thin PV systems installed on the facade have their PR

ranged between 0.61 and 0.84 with an average of 0.72

(

Lee H M, et al.,2016).

Compared to a-Si vertical PV installations appearing

in Table 2, the UDES a-Si PV system has a slightly

lower PR (0.57) compared to the (

Lee H M, et

al.,2016).and (Rustu E and Ali S,2013) facilities with a

PR of 0.69 and 0.74 respectively. This is due to the

reasons mentioned above namely the shading and the

orientation of the strings of the PV plant.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

402

Table 2: Performance comparison of different amorphous grid-connected PV systems in different locations.

Location Installationtype Cell type Capacity

(kWp)

PR System

efficiency

(%)

réf

South Korea vertical BIPV

South facing

a-Si thin film

(10%Transmittanc)

10.6 0.69 - (Lee H M, et

al.,2016).

Morocco Rooftopinclined a-Si/a-Si tandem 1.86 0.73 7.21 Amine H, et

al.,2017)

Turkey On twers (vertically

installed)

a-Si Single junction

10.24 0.74 5.58

(

Rustu E

and Ali

S,2013)

Turkey Onfacade (60tilted) a-Si Triple junction 30.15 0.81 5.99

(

Rustu E

and Ali

S,2013)

Algeria FacadeVertical

South facing

a-Si/a-Si tandem 2.4 0.57 4.76 Present Study

5 CONCLUSIONS

The 2.4 kWp amorphous Silicon grid connected PV

system facade mounted at BouIsmaîl, was monitored

between January 2016 and December 2016, in the

context of providing information on this type of

facility in order to see their potential for the BAPV

application. Its performances were evaluated and

presented in this paper, the main conclusions are as

follows:

As the system is mounted on the facade, the

losses of solar radiation are considered in

comparison with the radiation received at an

optimum inclination. Their values are 53%

maximum in summer and 19% in winter.

During the monitoring period the system

supplied 850 kWh to the grid. This

production is strongly related to the amount

of radiation received, while the influence of

the temperature is not noticeable.

The average annual reference yield is 1.36

kWh/kWp.d and it reaches the maximum

2.82 kWh/kWp.din fall (September) and 1.9

kWh/kWp.din spring (May).

Due to the poor design of the holder

structure of the modules, the shadows

caused by the obstacles in front of the PV

field and the vertical position of the PV field,

the capture losses are high(0.88h/d). In

contrast,the system losses are

negligible(.0.139h/d).

During the monitoring period the system

contributed to the decrease of the CO2

emissions by 510 kg (Lee H M, et al.,2016).

REFERENCES

Khuram Pervez A, Muhammad Waqar A, Anzar M, Anila

K, Muhammad Y, Bilal A, Ghulam Qadar C, Syed

Kashif H, 2017. Energy Consumption Forecasting for

University Sector Buildings, Energies, vol. 10, no. 10,

p. 1579.

Chikh M, Mahrane A, and Berkane S, 2015. Performance

Analysis of a Grid Connected Micro-morphous Silicon

PV Pilot Plant After Eight Months Monitoring, 3rd

International Renewable and Sustainable Energy

Conference (IRSEC), IRSEC.2015.7455113.

International Standard IEC 61724, 1998. Photovoltaic

system performance monitoring - guidelines for

measurement, data exchange, and analysis.

Sharma V, Kumar A, Sastry O S, and Chandel S S, 2013.

Performance assessment of different solar photovoltaic

technologies under similar outdoor conditions, Energy

58(2013) 511e518, July.

Kymakis E, Kalykakis S, and Papazoglou T M, 2019.

Performance analysis of a grid connected photovoltaic

park on the island of Crete, Energy Conversion and

Management 50 (2009) 433–438.

Tripathi B, Yadav P, Rathod S, and Kumar M, 2014.

Performance analysis and comparison of two silicon

material based photovoltaic technologies under actual

climatic conditions in Western India, Energy

Conversion and Management 80 (2014) 97–102,

February 2014.

SMA Solar Technology AG, Performance ratio Quality

factor for the PV plant, Technical Information.

Ayompe L M, Duffy A, McCormack S J, and Conlon M,

2010. Measured performance of a 1.72 kW rooftop grid

connected photovoltaic system in Ireland, Energy

Conversion and Management 52 (2011) 816–825.

A One Year Performance Evaluation of an Amorphous Grid Connected PV System Facade Mounted at Bou-Ismail, Algeria

403

Lee H M, Yoon J H, Kim S C, U. Shin U C, 2016.

Operational power performance of south-facing vertical

BIPV window system applied in office building, Solar

Energy.

Rustu E and Ali S, 2013. Monitoring the performance of

single and triple junction amorphous silicon modules in

two building integrated photovoltaic

(BIPV)installations, Applied Energy 109 154–162.

Amine H, Bouchaib H, Abderrazzak E, Mehdi K and

Abderraouf R, 2017. Performance Indicators for Grid-

Connected PV Systems: A Case Study in Casablanca,

Morocco. IOSR Journal of Electrical and Electronics

Engineering (IOSR-JEEE).

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

404