Heat Recovery Technology Applications for the Desulfurization

Process of Phosphgypsum

M. Alla

a*

, M. L. El Hafyani

a

, S. Zouggar

a

, E. K. Gharibi

b

a

Laboratory of Electrical Engineering and Maintenance, Higher School of Technology,

University Mohammed First Oujda, Morocco

b

Laboratory of Solid Minerals and Analytical Chemistry, Faculty of Sciences,

Mohammed First University, Oujda, Morocco

Keywords: ORC, Phosphogypsum, desulfurization, SO2, waste heat, Enthalpy H.

Abstract: The Organic Rankine Cycle (ORC) is a very important technology for converting the deadly heat from

which it is desired to produce mechanical power at low or medium temperatures to produce electricity.

This paper presents existing applications and of desulfurization of phosphogypsum (PG). Provided the

interest to recover waste heat rejected by thermal devices and industrial processes continue to grow, and

favorable legislative conditions are adopted, waste heat recovery organic Rankine cycle systems in the near

future will experience a rapid growth at very low temperature. In this study the energy released by the

phosphogypsum desulfurization system on the ORC machine will be applied to produce the electricity.

1 INTRODUCTION

As the human population grows, it becomes

increasingly dependent on energy; the increasing

consumption of fossil fuels has led to more and more

environmental problems such as global warming,

ozone depletion and atmospheric pollution.

Furthermore, along with the fast development of

industry, energy shortages and blackouts have

appeared more and more frequently all over the

world. Due to all these reasons, utilizing low-grade

waste heat for energy production has attracted more

and more attention for its potential in reducing the

fossil fuel consumption. Thus, an excess of heat is

generated during many stages of the production and

processing of an energy intensive system. Thus, the

development of cogeneration capable of recovering

and converting and fatal heat into electrical energy,

this technology is one of the main pathways to a

high-efficiency, low-temperature energy future.

These technologies have been known for the

production of electricity, applied in many forms

ranging from domestic applications to industrial

applications in order to combine heat and electricity,

including various Stirling, thermoacoustic and

thermofluidic heat engines.

For a very important efficiency, it is necessary

that the heat occurs at the lowest possible

temperature. This is best achieved by generating

energy in combined cycle mode. Commercial

combined cycles generally use a gas turbine. These

heavy-duty gas turbines with higher output

temperatures, and also are technically and

economically viable for combined cycle

applications. There are five main focus points when

optimizing an ORC: the heat source type, the

selection of the working fluid, the hardware

components, the control strategy and the component

layout and sizing. The heat source can be waste heat,

solar energy, geothermal heat or biomass

combustion.

1.1 Organic Rankine Cycle Applications

1.1.1 Binary Geothermal Power Plants

Geothermal energy refers to both the science that

studies the internal thermal phenomena of the

terrestrial globe and the technology that aims to

exploit it. By extension, geothermal energy also

36

Alla, M., El Hafyani, M., Zouggar, S. and Gharibi, E.

Heat Recovery Technology Applications for the Desulfurization Process of Phosphgypsum.

DOI: 10.5220/0009774800360041

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 36-41

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

sometimes refers to geothermal energy from the

energy of the Earth that is converted into heat.

To capture geothermal energy, a fluid is

circulated in the depths of the Earth. This fluid can

be that of a natural captive hot water sheet, or water

injected under pressure to fracture a hot and

impervious rock. In both cases, the fluid warms up

and goes back loaded with calories (thermal energy).

These calories are used directly or partially

converted into electricity, allowing some locations to

be more suitable for geothermal applications than

others represent by figure 1:

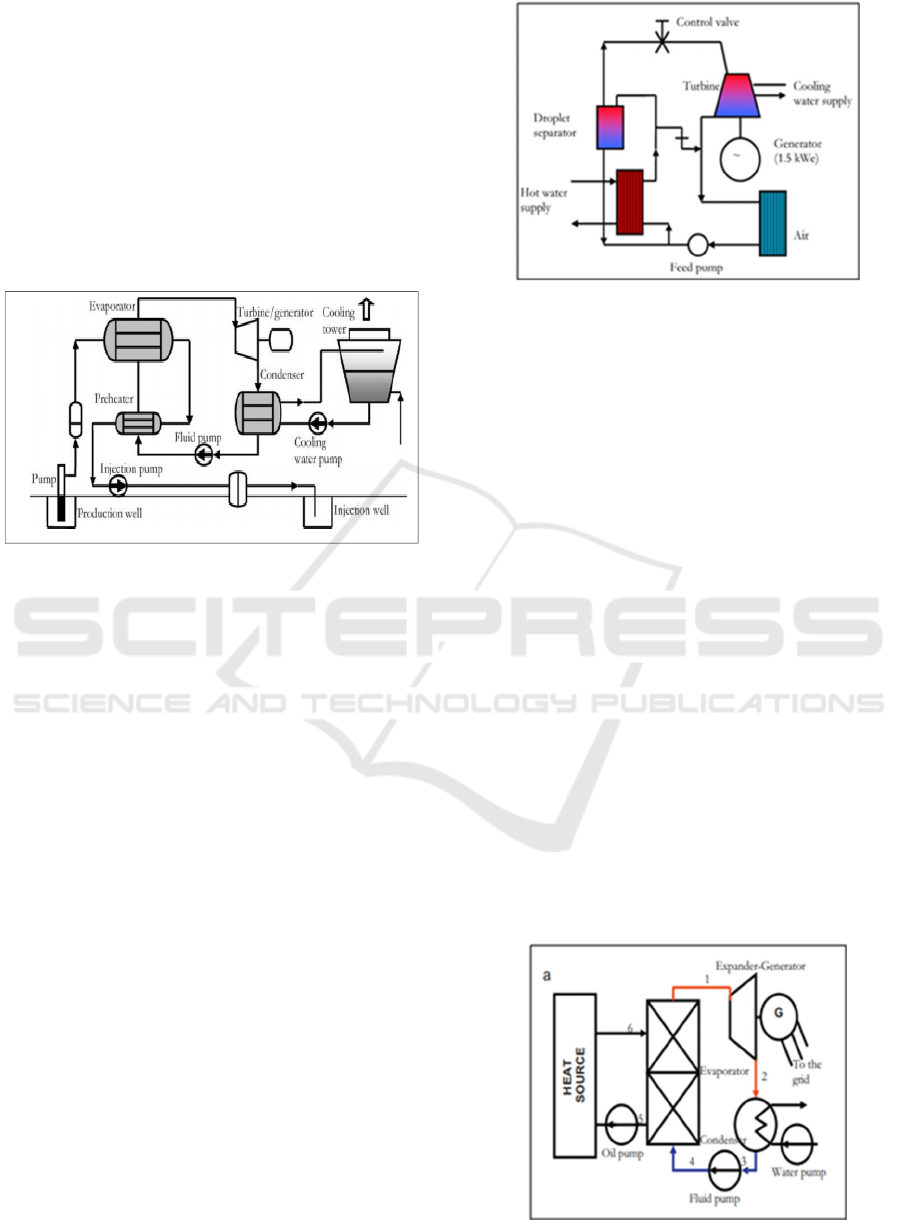

Figure 1: Flow diagram for a binary geothermal power

plant.

1.1.2 Solar Thermal Power Systems

Several factors increase the market potential of

power plants: the need for distributed power systems

in remote areas, the need for sustainable power for

the economic growth of developing countries and

also for producing clean electricity with the help of

renewable energy sources. Rankine cycle modular

organic solar power plants operate on the same

principle as conventional systems but use an organic

fluid instead of steam. The advantages of these

systems are as follows:

Low temperature operation (<300 ° C): low

temperature solar collectors and ORC modules

that can work well in regions of low solar

radiation intensity, such as sub-Saharan regions

African.

Modularity: it is possible to build large solar

ORC plants of several MW of power by

combining on the same site a large number of

ORC modules. Compressed air diaphragm pump

and a radial flow.

Turbine (65.000 rpm) coupled to a high speed

alternator (Fig. 2).

Figure 2: A micro-organic Rankine power system

1.2 Organic Rankine Cycles (ORCs) in

Waste Heat Recovery Application

Waste heat is the unused heat generated during a

combustion process or any other chemical

reaction/thermal process and, then directly

exhausted to the environment. Industrial energy

intensive processes as well as thermal engines and

mechanical equipment’s produce large amounts of

such waste heat . Exhausts discharged do not only

contain high exergy value but also large quantities of

pollutants: carbon dioxide (CO

2

), nitrogen oxides

(NO) and surlphur oxides (SO

x

) responsible of high

level concentration of atmospheric greenhouse gases

and of the global warming. Some developed

countries in view of cutting off their harmful gas

emissions while decreasing their energy imports in

the meantime have evaluated their waste heat

recovery potential. A study conducted within the

eight largest manufacturing sectors in Canada

showed up to 70% energy input lost . According to a

report published by the US Department of Energy

(DOE) in 2008, the industrial sector alone accounts

for about one third of the total energy consumed in

the country and contributes in the same proportion to

greenhouse gas emissions.

Figure 3: Flow diagram for a waste heat

Heat Recovery Technology Applications for the Desulfurization Process of Phosphgypsum

37

2 DESULFURIZATION PROCESS

OF PHOSPHOGYPSUM

The development of the fertilizer industry leads to

the production of more and more phosphoric acid

(more than 93% is CaSO

4

.2H

2

O) by treating natural

phosphates with sulfuric acid, this industry releases

significant amounts of phosphogypsum (PG), Solid

phosphogypsum waste often contains substances that

are directly hazardous or may become hazardous

during storage. Large quantities are produced world-

wide and it is estimated that by the year 2000 up to

280 million tones will be produced annually (in

Morocco 8 million tons per year).

2.1 Experimental Procedure

Phosphogypsum (PG) is placed in a reaction

chamber, attacked with concentrated hydrochloric

acid at boiling temperature. Varying amounts of

metallic iron are added to the phosphogypsum prior

to the etching step. After having dissolved almost all

the solid, we filtered cold and kept both the

insoluble residue and the solution. The gas released

from the reaction chamber is bubbled through

solutions that retain the Sulphur dioxide (SO

2

) gas.

The phosphogypsum reacts in the hydrochloric

medium in the presence of iron and the product

formed is SO

2

gas can be presented by the following

reaction [8]:

CaSO

4

. 2H

2

O + 4HCl + Fe Ca

2+

+ 4Cl

-

+ Fe

+2

+

4H

2

O + SO

2

(g) (Reaction 1)

Amounts of 400 g of the raw PG are placed in a

reaction chamber, attacked with concentrated

hydrochloric acid under boiling temperature.

Variable amounts of the metallic iron are added to

the PG before the attack step. After dissolving nearly

all of solid, we filtered out cold and we kept both the

insoluble residue and solution. After, the attack

solution was analyzed and the escaped gas was

recovered and assayed. The analytical techniques

used are X-ray diffraction 6000 SHIMADZU to

characterize structure of initial

and solid residues after attack. The PG

decomposition with a strong HCl acid (varying acid

/ solid / metal ratios) at the boiling point is carried

out in a reaction chamber partially insulated from

atmospheric pressure. The gas released from the

reaction chamber is bubbled through solutions that

keep SO

2

in the form of gas. SO2 gas which is

released from the reaction chamber by bubbling into

a solution of H

2

O

2

. Titration of excess H

2

O

2

by a

strong oxidant, KMnO

4

, indirectly gives the amount

of SO

2

released.

The table 1 gives the values of the

thermodynamic quantities calculated in function of

the temperature.

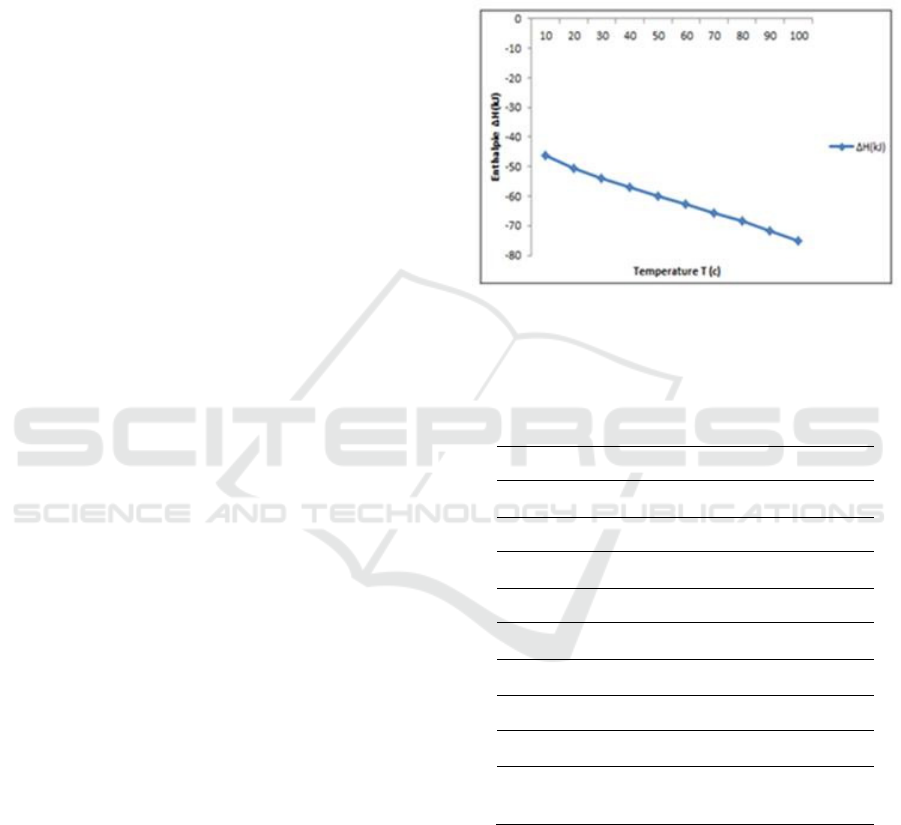

The evolution of the enthalpy in function of the

temperature is given by the figure 4.

Figure 4: Enthalpies of reaction 1 calculated at different

temperatures

Table 1: Thermodynamic parameters of Reaction 1

T

(°C )

∆H

(kJ)

∆S

(J/K)

∆G

(kJ)

Lo

g

K

10 -46.225 166.395 -93.340 17.221

20 -50.587 151.244 -94.924 16.915

30 -54.041 139.654 -96.377 16.608

40 -57.069 129.822 -97.723 16.302

50 -59.944 120.786 -98.976 16.000

60 -62.752 112.228 -100.140 15.702

70 -65.579 103.867 -101.221 15.409

80 -68.546 95.347 -102.217 15.120

90 -71.708 86.519 -103.127 14.835

100 -75.129 77.227 -103.946 14.552

As shown as in Fig. 1 Enthalpy increases linearly

as a function of temperature, which implies that our

system of desulfurization of phosphogypsum is

exothermic, which requires the valorization of this

fatal thermal energy to protect the environment.

2.2 Mathematical Model

Energy and energy analyzes based on the first and

second laws of thermodynamics are evaluated for

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

38

different organic working fluids under different

working conditions.

For the sake of simplicity, the internal

irreversibility and the pressure drops in the

evaporator, the estimation of the thermodynamic

properties of the condenser and the pipes will be

neglected. And each component is considered a

constant and stable flow system. Introduce the

equations to perform the thermodynamic

comparative analysis.

Evaporator/Vapor Generator

∆S = ∆Q/T (1)

Q = m

.

(h

in

t – h

out

) (2)

Turbine

W = m

r

.

(h

int

–h

g

) (3)

V

int

= m

r

*v

int

(4)

V

out

= m

r

*v

out

(5)

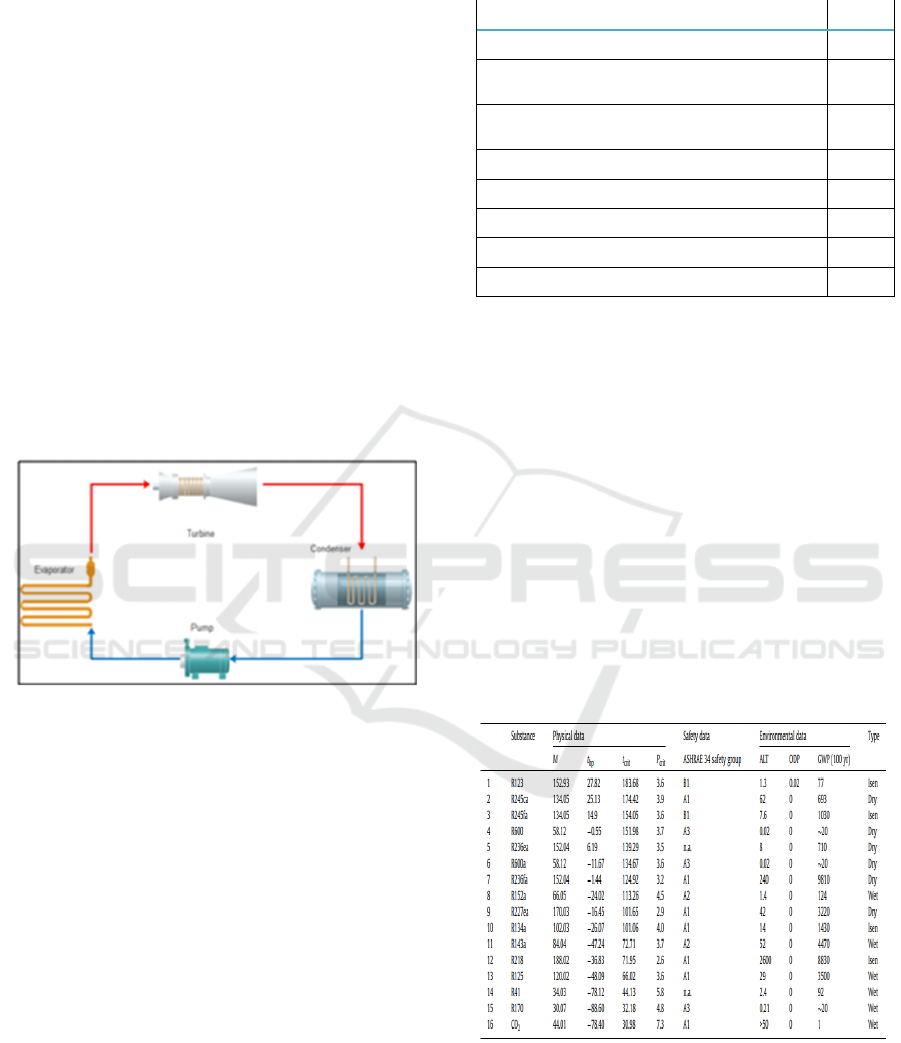

Figure 5: Schematic diagram of an ORC system

2.3 Choice of the Working Fluids

It is clear that, in order to calculate the ORC system

performance, a relevant number of parameters are to

be set. The inlet temperature of the heat source and

sink, the pinch temperature difference and flow rate

of the heat source were assumed in Table 2. The

flow rate of the heat sink is calculated to fulfill the

cooling needs. Saturated vapor was assumed at the

turbine inlet in subcritical ORC system. The basic

assumptions for the plant components are also listed

in Table2.

Table 2: Assumptions for heat source and sink and power

plant components.

The temperature of the thermal water, °C

90

The temperature of the cooling water, °C

20

The pinch temperature difference in both heat

exchangers, °C

5

The mass flow rate of the geothermal water,

kg/s

1

Isentropic efficiencies for the turbine

0.9

Isentropic efficiencies for the pump

0.75

Generator efficiency

0.96

Water pump efficiency

0.75

Turbine outlet quality

0.8

According to the temperature-entropy diagrams,

fluids show three different types of slope on their

saturation vapor curves and can be categorized into

three groups: (1) dry fluids have positive slope, (2)

wet fluids have negative slope, (3) isentropic fluids

have nearly vertical saturated vapor curves. The wet

fluids are generally not adequate for subcritical ORC

systems because they become saturated once they go

through a large enthalpy drop after producing power

in the turbine, and the condensate of the fluids

imposes a threat of damage to the turbine. The dry

and isentropic fluids can prevent the above

disadvantage [10]. Table 3 lists some properties of

the working fluids considered here.

Table 3: Basic thermodynamic and environmental

properties of the selected fluids [10]

Heat Recovery Technology Applications for the Desulfurization Process of Phosphgypsum

39

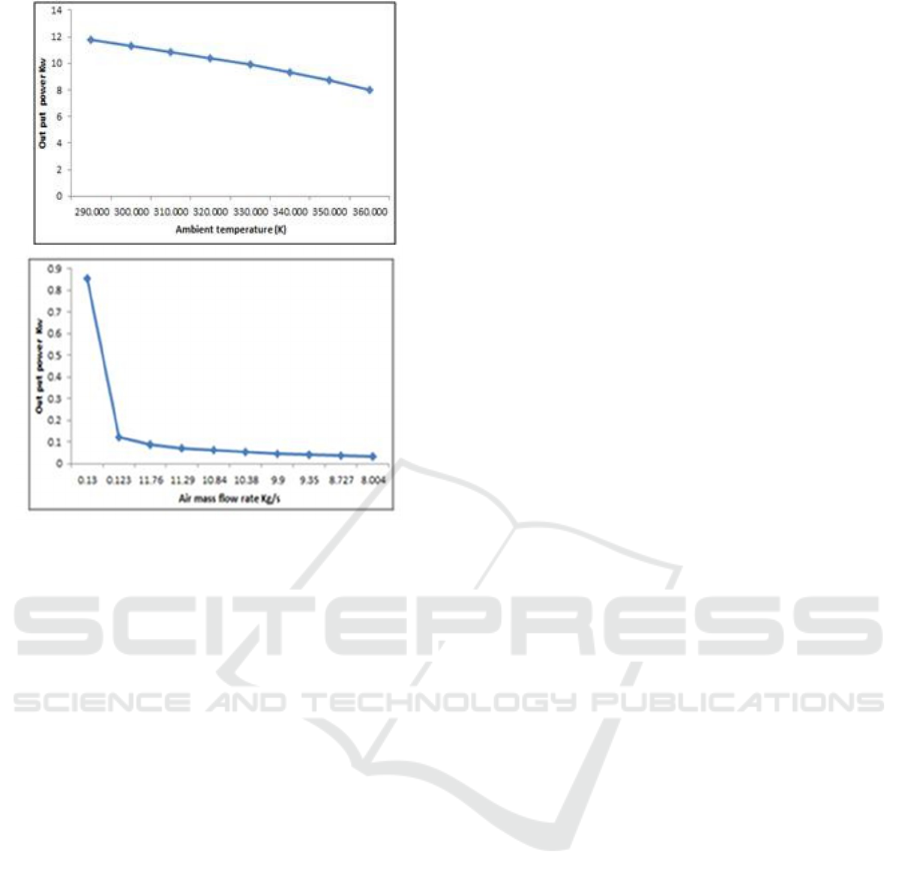

Figure 6: System output net power versus each input

Parameter (a) air mass flow rate (kg/s) and

(b) ambient temperature (K).

As shown as in Fig. 6a and b, the system output

net power increases evidently and linearly with the

increase of exhaust flow rate and temperature. In

other words, using the exhaust heat as much as

possible and the higher grade of heat source will

improve the system output net power according to

the calculations obtained, the energy produced by

the desulphurization system of phosphogypsum

(PG); the energy released by waste heat is 0.2 Mw <

waste heat < 200Mw so we apply our system to the

Rankine cycle.

3 CONCLUSION

The storage and management of a huge amount of

PG presents a serious problem on the environment,

so the objective of this work is to valorize the

thermal energy released by the desulfurization

system of the PG to produce electricity by applying

the cycle from Rankine.

REFERENCES

M. Canut, Belo Horizonte, Universidade Federal de Minas

Gerais, 2006.

C. A. Gregory, D. Saylak. W. B. Ledbetter, TRR Journal,

998, pp 47-52 (1984).

Bartow, FIPR Publication, 01, pp 124-119 (1996).

P. R Ernani, M. S. Ribeiro, C. Bayer, Sci. Agric., 58:825-

831, 2001.

P. A. Bellingieri, E.G. Bertin, L. Z. Mays, Científica, 31

pp 81- 89 (2003).

P. Bhawan, E.A. Nagar - Delhi: Central Pollution Control

Board, 2012.

G.A. Fattah, M.S. Altouq, A.A. Shamsaldien, Life Sci.,

13(3) (2016) 65-78.

S. Oumnih, E. K. Gharibi, E. B. Yousfi, N. Bekkouch, K.

El Hammouti, JMES, 2017 Volume 8, Issue 1, Page

338-344.

Chen H et al. A review of thermodynamic cycles and

working fluids for the conversion of low-grade heat.

Renew Sustain Energy Rev 2010. doi:10.1016/

j.rser.2010.07.00

Calm JM, Hourahan GC. Refrigerant data summary. Eng

Syst 2001;18(11):74–88.

Badr O, O’Callaghan PW, et al. Performances of Rankine

cycle engines as functions of their expanders’

efficiencies. Appl Energ 1984;18(1):15–27.

Badr O, O’Callaghan PW, et al. Rankine cycle systems for

harnessing power from low-grade energy sources.

Appl Energ 1990;36:263–92.

Lee KM, Kuo SF, Chien ML, et al. Parameters analysis on

organic Rankine cycle energy recovery system. Energ

Convers Manage 1988;28(2):129–36.

Lee MJ, Tien DL, Shao CT. Thermophysical capability of

ozone-safe working fluids for an organic Rankine

cycle system. Heat Recov Syst CHP 1993;13(7):409–

18.

Hung Tzu-Chen. Waste heat recovery of organic Rankine

cycle using dry fluids. Energ Convers Manage

2001;42:539–53.

Hung TC, Shai TY, Wang SK. A review of organic

Rankine cycles (ORCs) for the recovery of low-grade

waste heat. Energy 1997;22(7):661–7.

Liu BT, Chien KH, Wang CC. Effect of working fluids on

organic Rankine cycle for waste heat recovery. Energy

2004;29:1207–17.

Kribus A, Zaibel R, Carey D, et al. A solar-driven

combined cycle power plant. Sol Energy

1998;62(2):121–9.

Angelino G, Invernizzi C. Cyclic methylsiloxanes as

working fluids for space power cycles. J Sol Energ

Eng 1993;115:130–7.

Moustafa S, Hoefler W, El-Mansy H, et al. Deign

specifications and application of a 100 kWth

cogeneration solar power plant. Sol Energy

1984;32(2):263–9.

Gianfranco Angelino, Piero Colonna di Paliano. Organic

Rankine cycles (ORCs) for energy recovery from

molten carbonate fuel cells. American Institute of

Aeronautics and Astronautics; 2000. p. 2–11.

Ingwald Obernberger, Peter Thonhofer, Erwin

Reisenhofer. Description and evaluation of the new

1000 kWel organic Rankine cycle process integrated

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

40

in the biomass CHP plant in Lienz, Austria. Euroheat

Power 2002;10:1–17.

Weidao Shen, Zimin Jiang, Jungeng Tong.

Thermodynamics engineering. 3rd ed. China: Higher

Education Publishing Company; 2000.

Shilie Weng. Combustion turbine. China: Mechanical

Industry Publishing Company; 1989.

REFPROP Version 6.01, NIST Standard Reference

Database 23, the Secretary of Commerce, America;

1998.

Modelica Association. Specification, Tutorials [EB/OL],

http://

www.modelica.org/.

Dynasim AB, Dynamic Modeling Laboratory [EB/OL],

http://

www.dymola.com/.

Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.;

Papadakis, G. Low-grade heat conversion into power

usingorganic Rankine cycles – A review of various

applications. Renew. Sustain. Energy Rev. 2011, 15,

3963–3679. [CrossRef]

Bronicki, L. Short review of the long history of ORC

power systems. In Proceedings of the ORC2013,

Rotterdam, The Netherlands, 7–8 October 2013

Crook, A.W. Profiting from Low-Grade Heat; Institution

of Electrical Engineers: Stevenage, Hertfordshire,

1994.

Siemens. Fact Sheet: Organic Rankine Cycle. Available

online:

http://www.energy.siemens.com/nl/pool/

hq/power-generation/steam-turbines/orc

technology/Siemens_FactSheet-ORC-Module.pdf

(accessed on 1 May 2016).

Turboden. Organic Rankine Cycle Technology. Available

online: http://www.turboden.eu/en/public/

downloads/200-300%20kW.pdf (accessed on 5 April

2016).

Uusitalo, A.; Honkatukia, J.; Backman, J.; Nyyssönen, S.

Experimental study on charge air heat utilization of

large-scale reciprocating engines by means of organic

Rankine cycle. Appl. Therm. Eng. 2015, 89, 209–219.

[CrossRef]

MIROM. Verbrandingsinstallatie: enkele cijfers. Available

online: http://www.mirom.be/verbranding_

cijfers.html (accessed on 1 May 2017).

David, G.; Michel, F.; Sanchez, L. Waste Heat Recovery

Projects Using Organic Rankine Cycle Technology—

Examples of Biogas Engines and Steel Mills

Applications; World Engineers Convention: Geneva,

Switzerland, 2011.

Fernández, F.J.; Prieto, M.M.; Suárez, I. Thermodynamic

analysis of high-temperature regenerative organic

Rankine cycles using siloxanes as working fluids.

Energy 2011, 36, 5239–5249. [CrossRef]

Bao, J.; Zhao, L. A review of working fluid and expander

selections for organic Rankine cycle. Renew. Sustain.

Energy Rev. 2013, 24, 325–342. [CrossRef]

Stijepovica, M.Z.; Linke, P.; Papadopoulos, A.I.; Grujic,

A.S. On the role of working fluid properties in

Organic Rankine Cycle performance. Appl. Therm.

Eng. 2012, 36, 406–413. [CrossRef]

Maraver, D.; Royo, J.; Lemort, V.; Quoilin, S. Systematic

optimization of subcritical and transcritical organic

Rankine cycles (ORCs) constrained by technical

parameters in multiple applications. Appl. Energy

2014, 117, 11–29. [CrossRef]

Lecompte, S.; Huisseune, H.; van den Broek, M.; De

Paepe, M. Methodical thermodynamic analysis and

regression models of organic Rankine cycle

architectures for waste heat recovery. Energy 2016,

87, 60–76. [CrossRef]

Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and

pseudo-pure fluid thermophysical property evaluation

and the open-source thermophysical property library

CoolProp. Ind. Eng. Chem. Res. 2014, 53, 2498–2508.

[CrossRef] [PubMed]

Pacheco, J.E.; Showalter, S.K.; Kolb, W.J. Development

of a molten-salt thermocline thermal storage system

for parabolic trough plants. J. Sol. Energy Eng. 2002,

124, 153–159. [CrossRef]

Gamal A., Majida Sultan A. et AltafAbdulla S.,Life Sci.,

13(3) (2016) 65-78,

SfarFelfoul H., Clastres P. , Ben Ouezdou M., Carles-

Gibergues A. Proceedings of InternationalSymposium

on Environmental Pollution Control and Waste

Management 7-10 January 2002, Tunis (EPCOWM

(2002) 510-520.

Seidel G., Huckauf H., Starck J., Kerchove P. and

Chassard A., Technologie des ciments, chaux, plâtre

Ed. SEPTIMAZ-Paris, (1980)

Azimi G., Papangelakis V.G. and Dutrizac J.E., Fluid.

Phase Equilibr., 260 (2007) 300–315;

Daligand, Daniel. Plâtre. Ed. Techniques Ingénieur,

(2002).

Cooper J., Lombardi R., Boardman D. and Carliell-

Marquet C., Resour. Conserv. Recy.,57 (2011) 78–86,

Walan P., Davidsson S., Johansson S., Höök M., Resour.

Conserv. Recy.,93 (2014) 178–187,

Tayibi H, Choura M , A. Lopez F., J. Alguacil F., Lopez-

Delgado A., J. Environ. Manage., 90 (2009)

2377–2386,

Becker, P. (1989). Phosphates and phosphoric acid: raw

materials, technology, and economics of the wet

process. Revised and expanded (Vol. 6). Marcel

Dekker, Inc. ISBN :0824779762.

El Cadi A., Fakih Lanjri A., Lalilti A., Chouaibi N.,

Asskali A., Khaddor M.,J. Mater. Environ. Sci. 5 (S1)

(2014) 2223-2229, ISSN: 2028-2508,

Aliedeh M. A., and Jarrah A. N., Sixth Jordanian

International Chemical Engineering Conference,

Amman, Jordan (2012),

Hou Y., MA L., Zhang J. and Ning P.,Journal of

Kunming University of Science and Technology,

35(3), (2010),

Zhu Miao, Hairui Yang, Yuxin Wu, Hai Zhang, and Xuyi

Zhang., Ind. Eng. Chem. Res., 51(15) (2012)

5419-5423,

Guidelines for Management and Handling of

Phosphogypsum Generated from Phosphoric Acid

Plants. Central pollution control board, Delhi

India(2014).

Xie L. G., Ma L. P., Dai Q. X., Mao Y. Zhang H, and Ma

J.,Adv. Mat. Res.,726-731 (2013) 331-339

Heat Recovery Technology Applications for the Desulfurization Process of Phosphgypsum

41