A Performance Analysis Study of a Single Slope Solar Still with

Integrating Fins and Nanofluid for Productivity Enhancement

H. Hafs, A. Zaaoumi, Z. Bouramdane, O. Ansari, A. Bah, M. Asbik

and M. Malha

1

Research Team in Thermal and Energy, ENSET, Mohammed V University Rabat, Morocco

o.ansari@um5s.net.ma, a.bah@um5s.net.ma, mohamed.asbik@um5.ac.ma, malha102@yahoo.fr

Keywords: Desalination, Solar Still, Nanofluid, Fins, Productivity.

Abstract: The present paper deals with the thermal performance of solar desalination system. The mean objective of

this work is to enhance the productivity of fresh water by integrating fins in basin liner and using Cu

2

O

nanoparticles in the base fluid, based on the experimental data (solar radiation and ambient temperature) (lat

34°00′47″ N, Rabat). A finite element based 3D mathematical model has been developed using COMSOL

Multiphysics 5.2a.the numerical results showed that the daily productivity increase by20% for the finned

basin liner with nanofluid (Brackish water/Cu

2

O) and by 12.6% for the finned basin liner with base fluid

compared to the conventional solar still.

1 INTRODUCTION

Solar desalination is one of various technologies

developed for water purification; it is an effective

and an ecological technology, but the low

productivity of freshwater is the mean and essential

problem to solve for solar stills.

A lot of research works are developed to

improve the productivity of solar stills desalination

systems. (Tiwari and Tiwari, 2007) highlighted the

effect of different parameters such as water depths

and ambient air velocities on the productivity of

solar still, in their others works (Sahota and

Tiwari,2016) studied impacts of different

concentrations of Al

2

O

3

nanoparticles on thermal

properties of the passive double slope solar still

(DSSS) with 35kg and 80kg of basefluid, Moreover,

they investigated the effect of three different

nanoparticles (Al

2

O

3

,TiO

2

and CuO)on the

performance of passive double slope solar still, this

study showed that the thermal energy efficiency was

higher for nanofluids compared to basefluid. Also,

incorporation of AL

2

O

3

nanoparticles in saline water

(Water/Al

2

O

3

) gives more productivity than others

nanofluids (Water/TiO

2

and Water/CuO). (Rabhi et

al, 2017) developed experimentally a modified

single basin solar still with pin fins absorber and

external condenser. It can be concluded from the

results that using solar still with pin fins enhance the

productivity of fresh water by 32.18% compared to

the conventional still. Other experimental work

highlighted graphite and copper oxide effects as new

nanoparticles on the still yield. Also different basin

water depths and different film cooling flow rates is

experimentally investigated. The obtained results

showed that the solar still productivity increase by

about 44.91% and 53.95% using the copper oxide

and graphite, respectively, compared with the

conventional solar still, however by adding the glass

cooling the daily efficiency is 47.80% and 57.60%

using copper oxide and graphite, respectively

(Sharshir et al, 2017).

(El Sebaii et al, 2009) studied experimentally

and numerically the performance of a single solar

still with PCM (Stearic Acid) during charging and

discharging periods. It was founded that the daily

productivity is doubled by using 3.3cm of PCM

compared to conventional solar still. Moreover, they

investigated the effect of fin configuration

parameters (El Sebaii et al, 2015) (El Sebaii and

El-

Naggar, 2017) such as numbers of fins, thickness and

height, also by using different materials (aluminum,

iron, copper, stainless steel).It was concluded that

productivity increase by 13.7% using seven fins with

a thickness and height of 0.001m and 0.04m

respectively.(Ansari et al, 2013) Conducted a

342

Hafs, H., Zaaoumi, A., Bouramdane, Z., Ansari, O., Bah, A., Asbik, M. and Malha, M.

A Performance Analysis Study of a Single Slope Solar Still withIntegrating Fins and Nanofluid for Productivity Enhancement.

DOI: 10.5220/0009773203420348

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 342-348

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

numerical study which highlighted the improvement

of passive solar still performances by using

separately three kinds of phase change materials

(Paraffine C18, Paraffin52–54, Paraffin wax) as a

storage medium. They reported that using heat

energy storage enhances both the productivity and

the efficiency of the distillation system.

Furthermore, this last research work was

undertaken by (Asbik et al, 2016) to determine the

exergy losses during the charging/discharging

periods. They deduced that the use of the latent heat

storage process allows the increasing of the water

productivity but it also reduces the exergy efficiency

of the system. For the same goals mentioned above.

(Ragupathy and Velraj, 2018

) Studied

experimentally the effect of floating absorbers acted

as storage material and bubble-wrap (BW) insulation

on the single slope solar still (SSSS).the results

showed that the daily productivity increase to

3.1l/m².day compared with 1.9 l/m².day for the

Conventional solar still. (Kabeel et al, 2011)

fabricated three solar still designed with a same

construction, the first one is a conventional type, the

second is a finned still and the third one is a

corrugated still. They compared the performance of

both stills with the conventional one, it was

concluded that integrating nineteen fins on the

bottom of solar still increase the amount of distillate

water by 40%; however an amount of 21% is

measured for a corrugated still.

The mean objective of this paper is enhancing

the rate of heat transfer between basin liner and

brackish water by integrating fins in the basin liner.

Moreover, improving the productivity by using

Cu

2

O nanoparticles in the base fluid (Brackish

Water).

2 MATERIALS AND METHODS

2.1 System Description

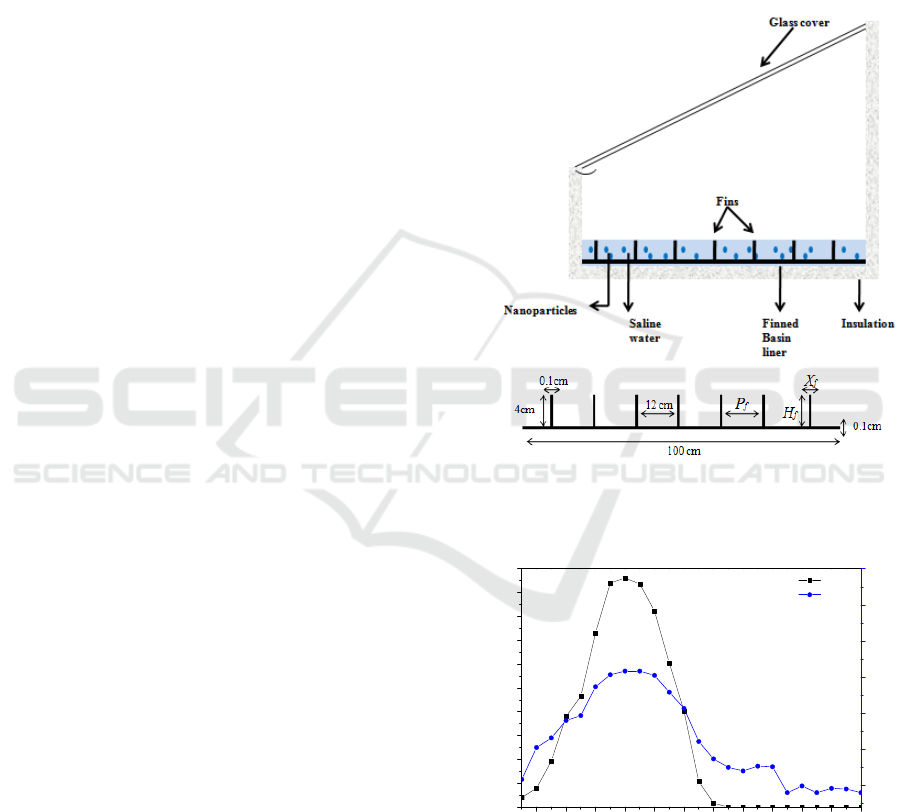

The geometry configuration used in this study is

shown in Figure.1. The single basin desalination

system is constructed with a basin area of 1m².Based

on the results of (El Sebaii et al, 2015). The absorber

plat is integrated with seven fins where the thickness

and the height are 0.001m, 0.04m respectively.

Cuprous oxide nanoparticles (Cu

2

O) have been

added to the saline water (40kg) to obtain a

nanofluid whose thermal and optical properties will

be enhanced (Table.1). The whole system is

insulated by the Foam layer (5cm of thickness) to

minimized heat losses between the system and

ambient area; also it is covered by a transparent

glass with a thickness of 3mm and inclination angle

of 34°. The solar still is south facing in order to have

a maximum solar radiation.

The weather data (ambient temperature and solar

radiation) were measured in the “Ecole Normale

Superieure de l’Enseignement Technique-ENSET”

localized at Rabat city (Morocco) whose

geographical coordinates are: Latitude: 34°00′47″

N, Longitude: 6°49′57″ W. On a typical day of

26/05/2018 (Figure.2).

Figure.1: A Schematic diagram of desalination system

with finned basin liner with nanofluid (Brackish

Water/Cu

2

O).

2 4 6 8 10 12 14 16 18 20 22 24

0

100

200

300

400

500

600

700

800

900

1000

G (t)

Ta (t)

Time(hr)

G(W/m²)

15

20

25

30

35

40

45

Ta,°C

26-05-2018

Figure.2: Hourly variation of solar radiation and ambient

temperature for 26-05-2018

A Performance Analysis Study of a Single Slope Solar Still withIntegrating Fins and Nanofluid for Productivity Enhancement

343

2.2 Numerical Model

In order to define the thermal energy process

through different components of the system, three

physical processes are simulated in this study: heat

transfer by conduction, convection and radiation.

2.2.1 Heat Transfer: Conduction

Heat transfer in solid region like glass, finned

absorber and insulated material is by conduction

only. The heat equation to solve is

.

.

.

,

,

,

Where T is the temperature,

, Cp and k are the

density, the specific heat and the thermal

conductivity of the material.

i: glass/finned absorber/insulation.

2.2.2 Heat Transfer: Convection

Heat transfer from finned basin liner to brackish

water happens by convection .In this case, the

energy equation between solid fluid interfaces is

defined as

.

.

.

T

2.2.3 Heat Transfer: Radiation in

Participating Media

The glass cover is exposed to solar radiation

intensity. Qr(t) is the heat flux radiation defined as

Where the solar absorption coefficient

(Table.2) and I (t) is the solar radiation intensity.

Table.1: Thermophysical properties of nanofluid (Brackish

Water/Cu

2

O).

Correlat

ions

Expressions

(Taylor

et al, 2013)

nf

=(1-

p

).

bf

+

p

.

p

(Taylor

et al, 2013)

Cp

nf

=[(1-

p

).Cp

bf

+

p

.Cp

p

]/(

bf

)

(Alawi

et al,2018)

k

nf

=k

bf

.[1+1.0112.

p

+2.4375.

p

.(47/d

p

)-0.0248.

p

.(k

p

/0.613)]

(Kabeel

et al, 2017)

µ

nf

=µ

bf

.(1+2.5

p

)

2.2.4 Boundaries Conditions

The governing equations of thermal model are

developed and written using the following initial and

boundary conditions:

Initially (t=0), all the domains of the system

are at constant temperature (T

ini

=288.95K).

The external surface of the desalination

system exchanged energy by convection with

the ambient area (Ta (t)).

.

.

Were T

ext

=Ta (t) and h is the heat

transfer coefficient.

No slip at the solid-liquid interfaces.

Water layer is supposed to be an isothermal

domain.

2.3 Mesh Generation

Free tetrahedral mesh has been used (Figure.3), to be

sure that smaller geometries are discretized with

232468 numbers of elements.

Figure.3: Meshed solar still desalination

geometry.

Table.2: Technical specifications and numerical constants

of the developed solar still (Sahota and Tiwari, 2016;

Ansari et al, 2013; Kabeel et al, 2017)

Thermal

Properties

value Numerical

constants

value

Glass

g

g

Cp

g

0.78(W/m

.K)

2800(kg/

x

g

x

b

x

ins

g

0.003(

m)

0.002(

m)

(2)

(3)

(4)

(1)

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

344

g

Water

bf

bf

Cp

bf

bf

Absorber

b

b

Cp

b

Cu

2

O

p

Cp

p

p

m

3

)

840(J/kg.°

C)

0.88

0.64(W/m

.K)

1000(kg/

m

3

)

4190(J/kg.

°C)

0.9

73(W/m.K

)

7897(kg/

m

3

)

452(J/kg.°

C)

6320

(kg/m

3

)

550

(J/kg.°C)

76.5

(W/m.K)

τ

g

Ag

w

b

bf

d

p

L

bf

0.05(

m)

0.05

0.09

1(m²)

0.05

0.9

0.469.10

-3

(N.s/m

2

)

20(nm)

2350(kJ/k

g.K)

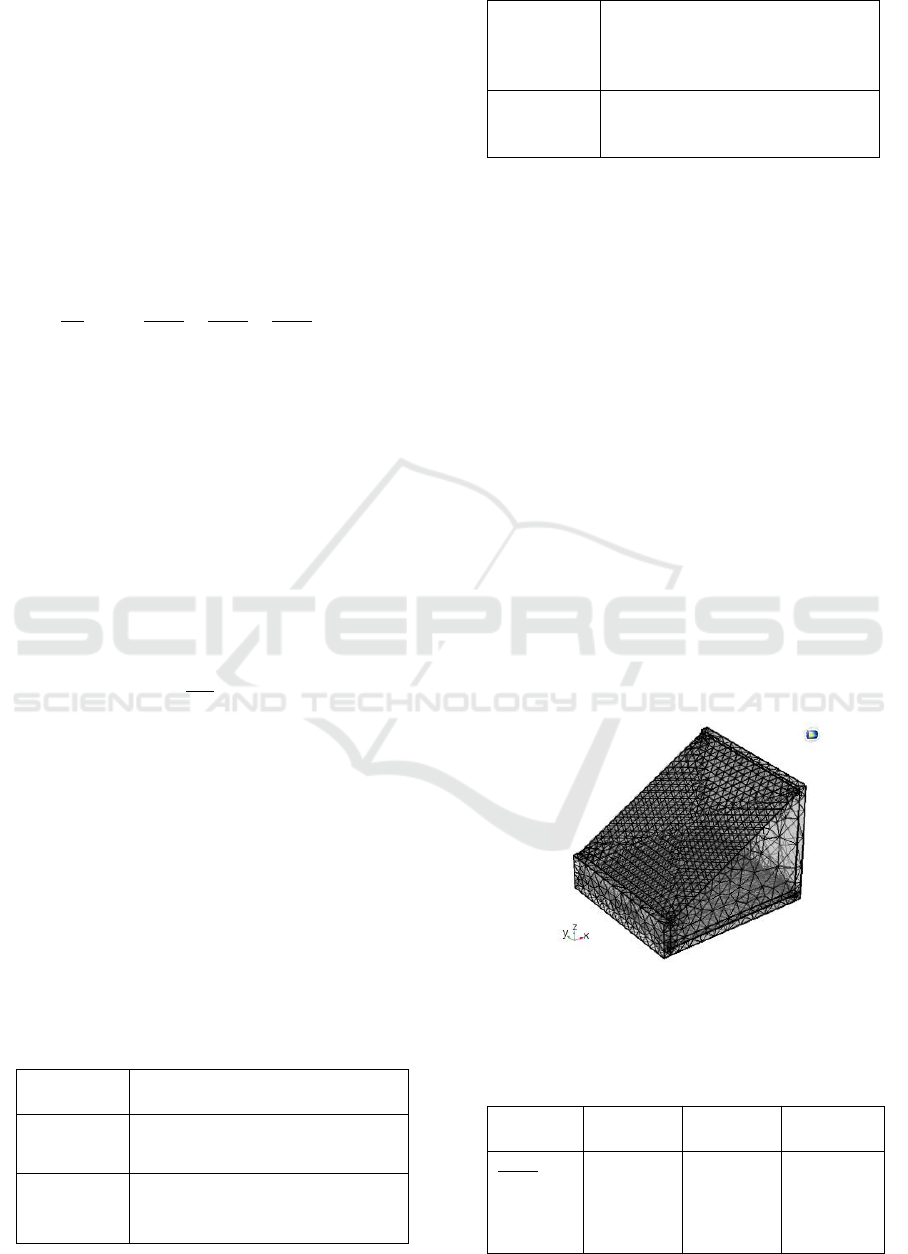

2.4 Validation Model

In order to validate the current model, a numerical

simulation has been carried out using COMSOL

Multiphysics and taking into account the initial and

boundaries conditions defined in section (2.2.4).

A comparison with experimental results of (El

Sebaii et al, 2015) has been done. It is clear from the

results of figure.4, that the current model showed

good agreement with those reported in the reference

(El Sebaii et al, 2015).

1234567891011121314

20

25

30

35

40

45

50

55

60

65

70

75

Experimental

Numerical Simulation

T

w

,°C

Time (hr)

06-08-2014

Figure.4: Experimental and numerical Hourly

temperature variation of brackish water

3 RESULTS AND DISCUSSION

Numerical simulations have been carried out for

modified solar still by using the nanofluid based on

cuprous oxide (Cu

2

O) nanoparticles with integrating

fins in the basin liner.

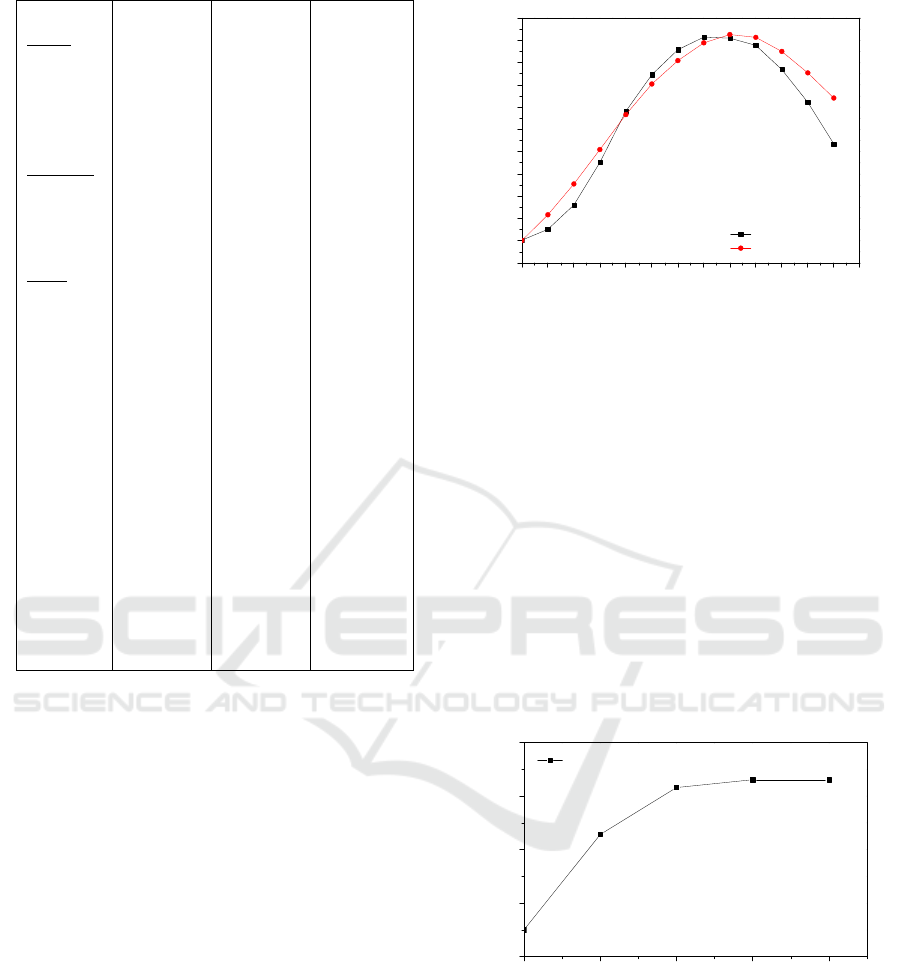

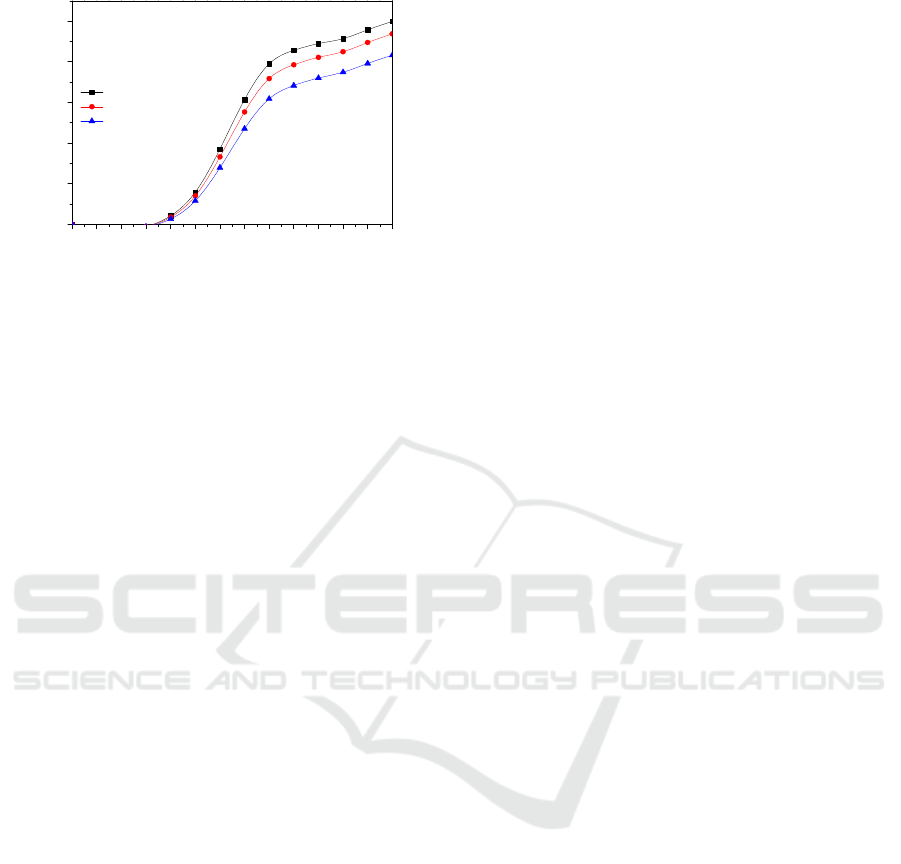

It can be observed from Figure.5 that the

maximum average temperature (T

nf

-T

bf

) of 4.6°C

occurred when using Cu

2

O concentration of

0.25%.thermal conductivity of nanofluid plays a

vital role in enhancing productivity of the system. It

is the most significant property. So, by applying this

conditions thermal properties of the system

enhanced.

0,10 0,15 0,20 0,25 0,30

3,0

3,5

4,0

4,5

5,0

Cu

2

O

(

T

nf

-T

bf

)

avg

, °C

Concentration, %

Figure.5: Average temperature variation between

nanofluid (Brackish water/Cu

2

O) and base fluid for

different concentration

Figure.6 highlights variations of temperature

during time for different components (finned basin

liner, nanofluid and glass cover). The solar radiation

absorbed by basin liner is transferred by convection

to the brackish water. It is generally observed that

the temperature of nanofluid increases with

A Performance Analysis Study of a Single Slope Solar Still withIntegrating Fins and Nanofluid for Productivity Enhancement

345

nanoparticles concentration (=0.25%) and by using

finned basin liner.

The viscosity correlation (see Table 1), as

known, is a function of volume fraction and

therefore the Nusselt number vary with this

parameter. Also, it had been inferred that the

nanofluid’s temperature increases due to the energy

received from finned basin liner and cuprous oxide

nanoparticles.

1234567891011121314

10

15

20

25

30

35

40

45

50

55

60

65

T

p

T

w

T

g

T,(°C)

Time(hr)

26-05-2018

m

w

= 40kg

np

= 0,25%

Figure.6: Hourly temperature variation for modified solar

still with integrating fins and nanofluid (Brackish

water/Cu

2

O)

1234567891011121314

0

5

10

15

20

25

30

With find and nanofluid

With fins

CS

h

evap

,(W/m².k)

Time (hr)

26-05-2018

m

w

=40kg

Figure.7: Evaporative heat transfer coefficient.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

0,0

0,1

0,2

0,3

0,4

0,5

0,6

with fins and nanofluid

with fins

CS

P

h

,(kg/m².hr)

Time(hr)

m

w

=40kg

26/05/2018

Figure.8: Variation of hourly freshwater productivity for

developed solar still and conventional solar still,

26-05-2018.

Three modes of heat transfers occurred between

base fluid and the bottom surface of the glass cover,

by radiation, convection and evaporation. Figure.7

illustrates a significant increase of h

evap

for finned

basin liner with nanofluid where the maximum value

is (29W/m².k), during the sunny period of the

specific day, compared to the conventional solar still

(h

evap

=26 W/m².k).

Besides, the hourly and daily productivity are

defined using the following equations (Ansari et al,

2013)

P

h

= (Q

e,f-g

.3600)/L

f

P

d

=

t

P

h

(t)

From the results of Figure.8, it has been found

that the hourly variations of the yield increase over

time as solar radiation increase. It is due to the

coefficient of evaporation enhanced by the effect of

nanofluid and fins compared to the conventional

solar still.

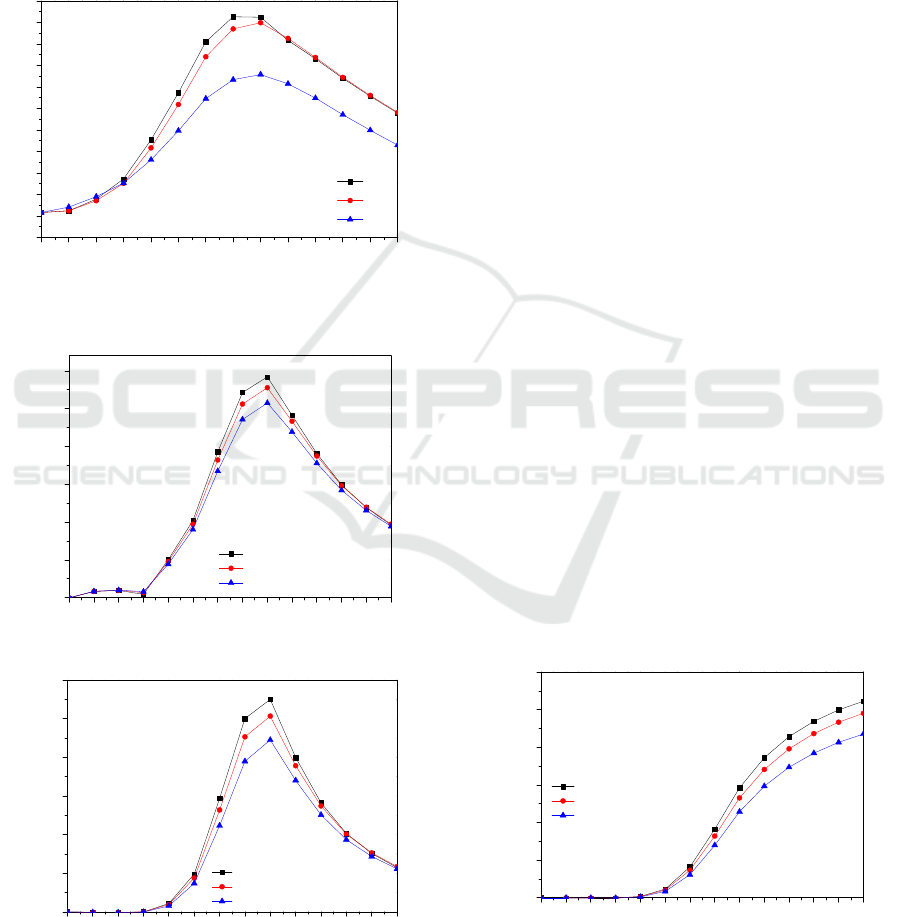

It has also obvious that the daily productivity of

the conventional solar still , the SSSS integrating

fins in the basin liner with nanofluid ,and the SSSS

with only integrating fins are 2.17 kg/m².day, 2.45

kg/m².day and 2.61 kg/m².day, respectively

(Figure.9). Moreover, the equation used to define the

overall thermal efficiency is:

= (L

f

.

t

P

h

(t))/A

g

.

t

G(t)

So, it is the report between evaporative heat flux

(Q

e,f-g

)and total solar radiation incident (G(t)).

Figure.10 illustrates these variations, where we show

the significant increase for the developed SSSS with

fins and nanofluid of 25% compared to 20% for the

single slope solar still (SSSS) without fins and

nanofluid.

1234567891011121314

0,0

0,5

1,0

1,5

2,0

2,5

3,0

With fins and nanofluid

With fins

CS

P

d

,(Kg/m²)

Time(hr)

26/05/2018

m

w

=40kg

Figure.9: Accumulated daily productivity on a typical day

of 26-05-2018

(7)

(5)

(6)

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

346

1234567891011121314

0,00

0,05

0,10

0,15

0,20

0,25

With fins and nanofluid

With fins

CS

Time(hr)

26/05/2018

m

w

=40kg

Figure.10: Overall thermal efficiency of developed solar

still with fins and nanofluid, only with fins and for the

conventional solar still

4 CONCLUSION

In this work, the effect of nanofuid based cuprous

oxide nanoparticles (Cu

2

O) with integrated fins has

been studied for the single slope solar still (SSSS)

under real climatic conditions of Rabat city

Morocco. Moreover, the physical processes

encountered in the heat transfer by conduction,

convection and radiation can be developed

numerically using COMSOL Multiphysics.

The results showed that the daily productivity

registered for modified SSSS with fins and nanofluid

(Brackish water/Cu

2

O), for modified SSSS only with

fins and for conventional solar still are 2.61

kg/m².day, 2.45kg/m².day and 2.17 kg/m².day

respectively.

NOMENCLATURE

A Surface Area, m²

Cp Specific heat, J/Kg. °K

h Heat transfer coefficient, W m

−2

K

−1

H

f

height of fins, m

G Incident solar power, W m

−2

L Latent heat, J/Kg

m Masse, Kg

P

h

Distillation mass flow rate, Kg/m².h

P

f

Distance between two fins, m

Q Heat flux, W/m²

T Temperature, °C

t Time, hour

X

f

Thickness of fins, m

GREEK LETTERS

Thermal conductivity, W/m. K

Viscosity, N.s/m

2

Density, Kg/m

3

Emissivity

Nanoparticles concentration

Absoptivity

Thermal expansion coefficient of nanoparticle, K

-1

SUBSCRIPTS

a Ambient

b, abs Absorber

bf Base fluid

d Daily

e Evaporation

g Glass

h Hourly

nf nanofluid

r Radiation

w Water

REFERENCES

A. K. Tiwari and G. N. Tiwari, “Thermal modeling based

on solar fraction and experimental study of the annual

and seasonal performance of a single slope passive

solar still: The effect of water depths,” Desalination,

vol. 207, no. 1–3, pp. 184–204, 2007.

L. Sahota and G. N. Tiwari, “ScienceDirect Effect of Al 2

O 3 nanoparticles on the performance of passive

double slope solar still,” Sol. ENERGY, vol. 130, pp.

260–272, 2016.

L. Sahota and G. N. Tiwari, “Effect of nano fl uids on the

performance of passive double slope solar still : A

comparative study using characteristic curve,”

Desalination, vol. 388, pp. 9–21, 2016.

K. Rabhi, R. Nciri, F. Nasri, C. Ali, and H. Ben Bacha,

“Experimental performance analysis of a modified

single-basin single-slope solar still with pin fins

absorber and condenser,” Desalination, vol. 416, no.

January, pp. 86–93, 2017.

S.W. Sharshir, Guilong Peng, Lirong Wu, Nuo Yang ,

F.A. Essa, A.H. Elsheikh, Showgi I.T. Mohamed, A.E.

Kabeel “Enhancing the solar still performance using

nanofluids and glass cover cooling: Experimental

study”, Applied Thermal Engineering, vol.113,

pp.684–693, 2017.

A. A. El-Sebaii, A. A. Al-Ghamdi, F. S. Al-Hazmi, and A.

S. Faidah, “Thermal performance of a single basin

solar still with PCM as a storage medium,” Appl.

Energy, vol. 86, no. 7–8, pp. 1187–1195, 2009.

A Performance Analysis Study of a Single Slope Solar Still withIntegrating Fins and Nanofluid for Productivity Enhancement

347

A.A. El-Sebaii, M.R.I. Ramadan, S. Aboul-Enein, M. El-

Naggar, “Effect of fi n con fi guration parameters on

single basin solar still performance,” Desalination,

vol. 365, pp. 15–24, 2015.

A.A. El-Sebaii, M. El-Naggar. Engineering, “Year round

performance and cost analysis of a finned single basin

solar still,” Appl. Therm. Eng., vol. 110, no. January,

pp. 787–794, 2017.

O. Ansari, M. Asbik, A. Bah, A. Arbaoui, and A. Khmou,

“Desalination of the brackish water using a passive

solar still with a heat energy storage system,”

Desalination, vol. 324, pp. 10–20, 2013.

M. Asbik, O. Ansari, A. Bah, N. Zari, A. Mimet, and H.

El-ghetany, “Exergy analysis of solar desalination still

combined with heat storage system using phase

change material ( PCM ),” Desalination, vol. 381, pp.

26–37, 2016.

P. Ragupathy and R. Velraj, “Productivity enhancement of

solar still by using porous absorber with bubble-wrap

insulation,” J. Clean. Prod., 2018.

Z. M. Omara, M. H. Hamed, and A. E. Kabeel,

“Performance of finned and corrugated absorbers solar

stills under Egyptian conditions,” Desalination, vol.

277, no. 1–3, pp. 281–287, 2011.

P. Taylor, “Experimental Heat Transfer : A Journal of

Thermal Energy Generation, Transport , Storage , and

Conversion HYDRODYNAMIC AND HEAT

TRANSFER STUDY OF DISPERSED FLUIDS

WITH SUBMICRON METALLIC OXIDE,” no.

January 2013, pp. 37–41.

O. A. Alawi, N. Azwadi, C. Sidik, H. Wei, T. Hao, and S.

N. Kazi, “International Journal of Heat and Mass

Transfer Thermal conductivity and viscosity models of

metallic oxides nanofluids,” Int. J. Heat Mass Transf.,

vol. 116, pp. 1314–1325, 2018.

A. E. Kabeel, Z. M. Omara, and F. A. Essa, “nanofluids

and external condenser,” J. Taiwan Inst. Chem. Eng.,

vol. 0, pp. 1–10, 2017.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

348