Study and Analysis of the Thermal Impact on the Overall

Performance of the Proton Exchange Membrane Fuel Cell and Its

Management and the Exploitation of PEM Fuel Cells in a

Cogeneration System: Review

Z. Hbilate, S. Hamham, Y. Naimi, D. Takky

Electrochemistry Team, Laboratory of Physical Chemistry of Materials, Faculty of Sciences Ben M'sik, University of

Hassan II Casablanca, Morocco

Keywords: PEM fuel cell, thermal management, heat, Cogeneration, environment.

Abstract: With the huge interest in clean energy development and the sources of production, appeared the development

of fuel cell technology as a clean source of energy which generates electricity releasing only water and heat

and which responds the most to the climatic requirement to perpetuate our environment. Current research

aims to the development and improving the performance and improving the performance as well as reducing

the cost to compete with other current sources of polluting energies. A proton exchange membrane fuel cell

has a lot of enticing characteristics however, in parallel to these distinctive and advantages, has also various

constraint and a considerable challenge to its widespread commercialization. That we will have to overcome

them to make it profitable and accessible, whose one of those challenges that requires the most effort is the

thermal management technology that makes this increasingly complex. In this review we will focus on the

study of the thermal management of the heat released inside the PEM fuel cell during operation and to study

the thermal impact on the performance of PEMFCs. As well as the possibility to rationalize the thermal energy

produced using the combined use of heat and energy cogeneration to maximize the energy produced and

improves the overall efficiency of the energy system.

1 INTRODUCTION

The need for energy will continue to increase

more and more, mainly following the metaphors and

the development of the industrial field which

consumes a huge part of world energies, which the

largely part comes from fossil energies, presents a

huge challenge and creates adverse undesirable

environmental effects, emissions at the local level and

overall greenhouse gases GHGs, what makes the

search for other alternatives a task that persists to

preserve our environment. In this order of ideas

renewable and clean energies remains as the most

appropriate solution to preserve our environment,

since they have the lowest carbon footprint (Naimi, et

al., 2016)and they are not harmful (Panwar, et al.,

2011) (Alper & Oguz, 2016).Of which their major

problem is the availability at the time of need which

is almost impossible because depends on several

climatic factors (Balat, 2008) (Viswanathan, 2017).

But in parallel with the development of this

technology, it turns out that another technology that

is also very promising and even if it is not a primary

source but just a carrier of energy, its hydrogen

technology (Harris, 2011). This technology boils

down to converting the potential energy produced by

renewable energy sites into hydrogen using an

electrolyzer. This technology can be summarized in

the fact to transform the potential energy generated by

the sites of renewable energy into hydrogen using an

electrolyzer. We use thereafter the Hydrogen

produced as needed to produce electricity, unlike the

electricity produced by renewable energies which is

not always available and depends on environmental

factors.

In the manner of renewable energies, the field of

fuel cells also remains as a highly promotive domain

that can respond to climatic and environmental

requirements. There are different types of fuel cells

which differs by several characteristics (materials,

electrolyte, fuel, ...) in our study we are interested in

PEMFC, due to its many advantages, like it is not

pollutant, doesn’t have a corrosive effect and it offers

Hbilate, Z., Hamham, S., Naimi, Y. and Takky, D.

Study and Analysis of the Thermal Impact on the Overall Performance of the Proton Exchange Membrane Fuel Cell and Its Management and the Exploitation of PEM Fuel Cells in a

Cogeneration System: Review.

DOI: 10.5220/0009772501150124

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 115-124

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

115

the highest energy density among the others (Lamei,

2012) (Zhang Liyan, 2011) (Zhidong, et al., 2015)

(Authayanun, et al., 2015), its low operating

temperature between 60 and 80 (Song W, 2014)

(Yan Z Y, 2013), Its low weight and volume and its

immediacy start (fast-star).What makes PEM fuel

Cell a promising candidate. However, although the

huge progress of PEMFC technology; the

development of fuel cells is still limited and presents

a lot of the difficulties and intrinsic problems to

overcome, which leading to the deterioration of

PEMFCs and directly affecting the overall yield of

the cell. In this perspective the thermal problem that

boils down in the temperature distribution and the

thermal management inner the fuel cell is presented

as one of the critical elements for an optimal

operation of the PEMFC. Therefore, our review

focuses in analyzing and managing this crucial

element to ensure the balance, stability and efficiency

of the PEM fuel cell. As well as studying the

exploitation of the PEM fuel Cell in a system of

cogeneration and analyzing namely the contextual, of

the global art system status and the technological

environment. In this paper we present a complete

analysis to study and analyze the influence of

temperature on the performance of the fuel cell and

also tools for its good management of this

determining parameter, in order to increase the

efficiency of the Fuel cell.

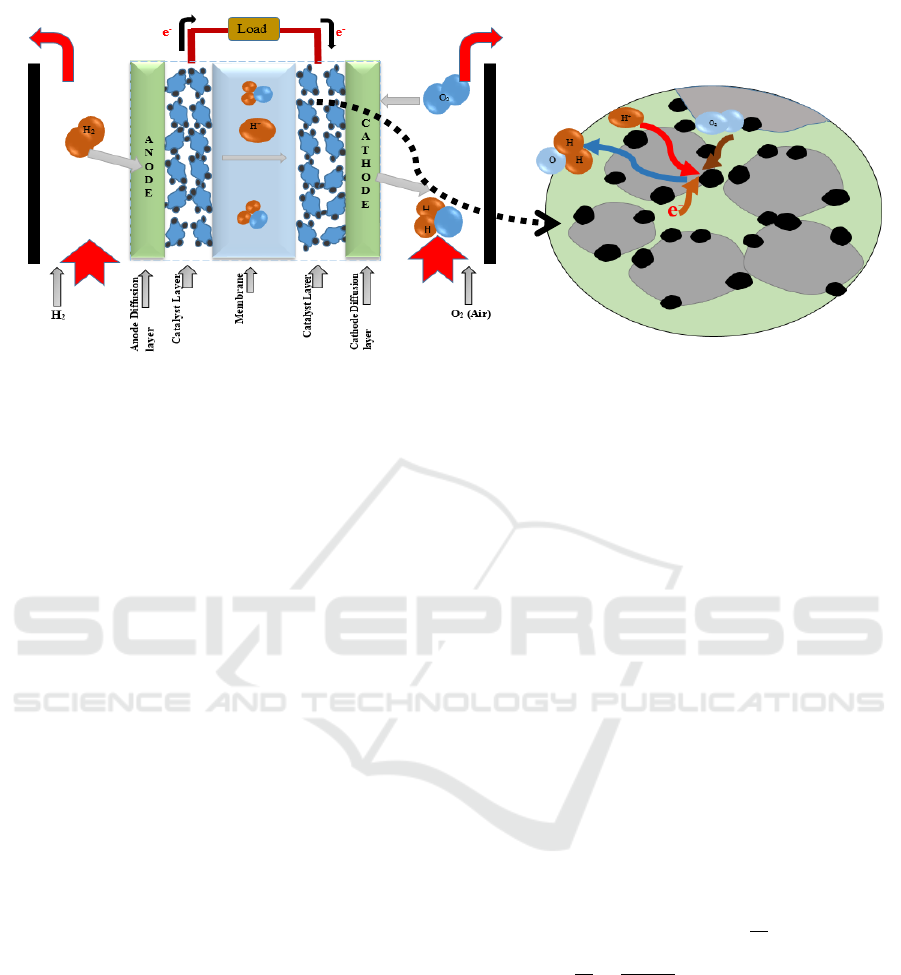

2 PRINCIPLE OF OPERATION OF

THE PEMFC

A fuel cell is an electrochemical device its

operating principle is to convert the chemical energy

stored in the fuel into electrical energy, the principle

of the fuel cell process can be described as the inverse

of the electrolysis of water. Indeed, this type of

battery can operate at room temperature and can

deliver a reasonable power for the intended

application. It is a controlled electrochemical

combustion of hydrogen and oxygen (Air) (Fig.1).

The only products of hydrogen decomposition and

oxygen reduction are water and heat formed as

secondary products with simultaneous generation of

electricity.

Both oxidation and reduction reactions (Eq.1)

(Eq.2) occur at the triple point areas which is located

at the interface between the electrolyte and electrode

with the presence of the catalyst (platinum) (Fig.1).

The only products of hydrogen decomposition and

oxygen reduction are water and heat formed as

secondary products with simultaneous generation of

electricity, according to the overall chemical reaction

(Eq.3).

Oxidation reaction:

→2

2

(1)

Reduction Reaction:

1

2

2

2

→

(2)

Overall reaction:

1

2

→

(3)

The theoretical potential delivered by a cell equal

to 1,23 and calculates by

≡

|

∆

|

(4)

E

th

: theoretical potential, ΔG: free enthalpy (Gibbs

energy of the reaction), F: Faraday constant.

To have a PEM fuel cell that generates a

significant amount of electricity must be assembled

several cells, in electrical series, which causes a lot of

difficulty in the management of the reaction products

during its operation of which the temperature increase

remain one of the important keys to the proper

functioning of the fuel cell that it has a decisive

impact, note that the thermal power produced is of the

same order of magnitude as the electrical power

(Alleau, Révision Octobre 2014). In this manuscript

we will study and detail the influence of the increase

of heat on the different components of the PEMFC.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

116

Figure 1: Schematic diagram of the operating principle and components of the membrane proton exchange fuel

cell (PEMFC) and the catalytic reaction at the electrode

3 THERMODYNAMIC AND

ELECTROCHEMICAL STUDY

The yield of PEM fuel cells generally does not

exceed 40% which implies the existence of a large

part of energy lost during the operation of the PEM

fuel cell and this mainly due to the electrochemical

reaction which is accompanied by several irreversible

losses. In practice, the existence of irreversible losses

will make the reactions exothermic. These losses are

actually, electricity transformed into heat.

These different types of losses that affects the

electrical efficiency and contribute to the increase of

dissipated energy as heat instead of electrical energy,

as the losses related to the transport of the different

reactant in the electrodes, the activation losses related

to reaction kinetics in the active layers, the losses

related to the transport of charges (Ohmic losses) in

the membrane (protons) and the electrodes (electrons)

which led to lowering the fuel cell yield.

The energy produced by the PEMFC specifically

comes from the thermodynamic energy that appeared

during the electrochemical reactions inside the cell.

Fundamentally, this energy comes from the

exothermic reaction of the water composition from H

2

and O

2

(Saeeda & Warkozekb, 2015) as in any

electrochemical component, only the free energy of

the reaction ΔG can be converted into electricity

(Eq.4), the maximum amount of electrical energy

produced in a PEM cell corresponds to the Gibbs free

energy.

ΔG = ΔH – TΔS (5)

ΔH: Enthalpy of the reaction, ΔS: The entropy of the

reaction. T: Operating temperature (K).

However, this energy is divided into two parts,

electrical and thermal energy, which the thermal

energy generated during operation exchanged with

the environment in the form of heat. The variation of

free enthalpy ΔG depends on the temperature, the

pressure, the conditions of the reaction and more

specifically reactants activities.

The Raising the temperature reduces voltage

losses, therefore a higher temperature led to a higher

cell voltage. However, an excessive local cell

temperature can cause dehydration of the membrane,

a contraction or even a rupture, which adversely

affects the proton conductivity which inversely

affects the course of the electrochemical reaction in

its turn. On the other hand, a low temperature is

unfavorable for the kinetics of the reaction, Because

it depends directly on the operating temperature, as

shows the Nernst equation of the reversible potential

which depends directly on pressure and temperature

(J. Bvumbe, et al., 2016) (Hosseinzadeh, et al., 2013)

(Ozbek, et al., 2013) (Yao, et al., 2004) (Pandiyan, et

al., 2008) (Authayanun, et al., 2015).

,

,

∆

ln

,

(6)

Pressure referential,

: hydrogen

pressure,

:oxygen pressure,

:pressure of H

2

O.

The internal thermal power produced during

operation of the cell defined as the difference

between, the chemical power released from the

reactants and the electrical power generated. The two

relations which follows, presents respectively the

chemical power (Eq.7) defined as the chemical

energy released by the hydrogen consumption and the

electric power (Eq.8)

Study and Analysis of the Thermal Impact on the Overall Performance of the Proton Exchange Membrane Fuel Cell and Its Management

and the Exploitation of PEM Fuel Cells in a Cogeneration System: Review

117

∆

∗

2

(7)

∗ (8)

The difference between the open circuit cell voltage

and the operating voltage, quantified as the amount of

energy dissipated as thermal power.

4 ENERGY AND THERMAL

PRODUCTION IN PEMFC AND

THE THERMAL DISTRIBUTION

IMPACT

4.1 Thermal Production and Joule Effect in

PEM Fuel Cell

The heat produced and released inside the stack

mainly due to the effect of the two terms one of which

is derived from the heat of the electrochemical

reactions as is already presented in the foregoing, and

the other of the Joule effect, due to the Ohmic

resistance of the components of the PEM fuel cell

assembly.

The joule effect in the membrane is caused by the

resistance to proton transfer and is reflected by a

volume heat source uniformly distributed in its

thickness, which is expressed by the following

relation:

(9)

: Overall resistance of the membrane.

A study conducted by (Pandiyan, et al., 2008) on

the thermal effect of the other components of the pile

show as a result of a difference of 10 of

temperature, it is properly clear that the thermal

resistance increases almost three times but on the

other side the current increases only by about 50%

which implies the existence of a high electrical

resistance in the components of the stack. It is clear

that the internal electrical resistance of the electrode

plays decisive role, Which decreases the current that

can be drawn from the PEM fuel cell for each increase

in unit temperature, which implies, in parallel with

the increase in electrical resistance an increase in the

effect, then more energy dissipated as heat, so the

characteristics of the electrodes materials have a

decisive role to decreasing the internal resistance. In

practice, the potential of a PEM cell is lower than the

theoretical potential due to internal losses in the fuel

cell (Haji, 2011). As we have already presented in the

foregoing part, the heat inside the fuel cell generates

mainly by the irreversibility of the electrochemical

reactions and the Ohmic resistance of the components

of the assembly of the stack (joule effect) (Pandiyan,

et al., 2008).The Heat also affects the distribution of

water by condensation and affects the gas diffusion

transport characteristics in multi-component by

thermo-capillary forces and thermal buoyancy

(Pandiyan, et al., 2008).

The overall yield of a PEMFC varies between

40% and 60% which implies the existence of a large

dissipation of chemical reaction energy which is

transformed into thermal energy that amount of

energy comparable to the electric energy. A study

(Alleau, Révision Octobre 2014)reported that the

thermal power to be removed is substantially the

same for a fuel cell (50% in heat and 50% in

electricity), Can go up to 100 kilowatts in automotive

applications (Kandlikar, et al., 2007) (Wen C.-Y.,

2011) (J. Bvumbe, et al., 2016). Another study

(Pandiyan, et al., 2008) has showed that the energy

produced inside of the cell comes out in the form of

thermal energy as much as electrical energy. For this

reason it is clear that for every decrease in operating

voltage we will have an increase in thermal output.

So, strictly speaking, for each temperature increase

we will have a decrease in current. On the other hand,

a study (Benmouiza & Cheknane, 2017) has clearly

demonstrated that a lower temperature directly affects

the performance of fuel cells and worsened the

voltage drop. In addition, it also shows that a high

temperature ensures rapid reaction that produces

more power. Furthermore, at higher temperatures, the

electrochemical reaction is faster, it increases the

water production in the cathode and better hydrates

the membrane, and thus the ionic resistance is

reduced.

The temperature clearly affects the performance

of the cell; generally adequate operating temperatures

are suitable for the efficiency of fuel cell. But in

parallel a high or low temperature can (Benmouiza &

Cheknane, 2017) amplify the degradation of PEM

fuel cell (J. Bvumbe, et al., 2016). As stated above a

study (Pandiyan, et al., 2008)also clearly stated that

the operating temperature has a decisive impact on

the kinetics of electrochemical reactions and its

distribution in the cell affects the performance. The

same work has shown that the ratio between the

electrical output power and the thermal output is

unitary. However, when the operating voltage of the

cell decreases, the ratio increases to 2 for an operating

voltage of 0.5 V. This shows that twice the energy

goes out as heat instead of the electrical output. This

also supports the studies presented previously.

Several studies have shown that the electrode

manufacturing process also has a very important role

in reducing the internal resistance of the cell in

addition to its components the effect of the electrical

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

118

and thermal resistance of a PEM fuel cell has been

evaluated (Pandiyan, et al., 2008)and has been

observed that the increase in thermal resistance is

three times and the current increases by 50% for a

temperature change of 10 .Confirming that the

internal resistance of the electrode increases by the

increase of the current density with respect to

temperature change. Then an adequate temperature

within the cell is highly useful for the improvement

of the kinetics of the electrochemical reaction and the

ion transport which gives the improvement of the

performances by means of the reduction of the

voltage losses. That’s why, it is necessary to handle

and control the heat produced inside the fuel cell. As

well as to manage well its distribution in the various

components of the PEM fuel cell.

4.2 Temperature Distribution in the PEM

Fuel Cell

The temperature distribution in PEM Fuel Cell is

recognized as an important factor for fuel cell

stability and efficiency. Because there is a generally

fractional relation between temperature and heat

diffusion in semi-solid systems such as fuel cell. To

avoid amplification of the deterioration of the fuel

cell, the lowering of its performance in general, as

well as the membrane in a specific way and make it

last. This is why we must think of eliminating the

excess heat produced, effectively to ensure good

thermal distribution inside. Part of this heat is

spontaneously dissipate either by convection and

radiation to the environment, or by unused reactants.

But this part remains nevertheless low by contribution

to the heat produced. As well as when the temperature

is high these evacuation modes are negligible, which

can be thought of dissipated by active cooling to

prevent overheating of the PEMFC. In this

perspective, several studies have studied the effect of

forced cooling. Who let’s think of the dissipated by

active cooling to avoid overheating of the PEMFC.

5 OVERALL THERMAL

MANAGEMENT OF THE SYSTEM

5.1 Adverse Thermal Effect on the

Membrane and Its Management

Concerning the membrane and its proper

functioning, we must clearly keep a good balance

between its temperature and its hydration which many

studies have investigated this point in the fuel cells.

From a theoretical point of view, a fuel cell involves

an exothermic reaction. Due to the different losses

that we have already described in advance, which

generates a fairly large amount of temperature which

heats all of the components, so beyond this point,

there is a surplus of heat that must be released towards

the outside of the component. And it will cool the

component in order to not destroy the membrane,

because the current membranes do not withstand

temperatures higher than 90 (Rallieres, 2011). So,

an improper thermal management will induce various

thermal problems. As dehydration of electrolyte as

well as the problem of overflow in the cathode, which

imposes more critical challenges on the PEMFC

operation.

On the one hand the cathode overflow

phenomenon has been the subject of many studies

(Lampinen & Fomino, 1997) (Eikerling, 2006) (Abd

Elhamid, et al., 2004) (Shimoi, et al., 2004) (Yu, et

al., 2006) (Zong, et al., 2006) (Kandlikar & Lu,

2009)which (Kandlikar & Lu, 2009)has exhibited that

the phenomenon of overflowing is strongly affected

by the distribution of temperature due to its

dominance of condensation / evaporation process in

the cathode. On the other hand, several causes have

been identified for the dehydration of PEMFC which

increases the proton conduction resistance. A

relatively low humidification, a high stoichiometric

ratio with either a high temperature or just a high

temperature can easily cause the membrane as a

subject of dehydration. An electroosmotic drag, a

displacement of the water molecules from the anode

to the cathode by a proton flow also leads to

dehydration. Like the other difficulties presented,

another thermal imposing problem is the non-uniform

temperature distribution in the membrane, which

exists both through the membrane (Maes & Lievens,

2007) (Lampinen & Fomino, 1997) (Eikerling, 2006)

(Berning & Djilali, 2003) (Gloaguen & Durand,

1997) (Kandlikar & Lu, 2009)and along the flow

length (Jordan, et al., 2000) (Kandlikar & Lu, 2009).

This non-uniformity of temperature, of the order of

many degrees, has a considerable impact on the water

content of the membrane and the uniformity of

current density (Meyers, et al., 2006) (Wilkinson &

Vanderleeden, 2003) (Kandlikar & Lu, 2009). But it

always remains a need to have an adequate

temperature to lead to an improvement of the kinetics

of the electrodes as well as the increase of the ionic

conductivity in the membrane and the electrodes thus

the improvement of power density (Ferng, et al.,

2003).A study (Odne, et al., 2014) showed that the

thermal conductivity in the membrane clearly

depends on the water content, and we will have a 50%

Study and Analysis of the Thermal Impact on the Overall Performance of the Proton Exchange Membrane Fuel Cell and Its Management

and the Exploitation of PEM Fuel Cells in a Cogeneration System: Review

119

increase in thermal conductivity when the catalytic

layer is fairly saturated. Thus an increase of 33%

temperature difference between the gas flow field

plates and the PEM fuel cell, with a catalytic layer

moderately moistened. A high proton conductivity

depends essentially on the water content of the

membrane (Ben-Attia, 2013). Nevertheless, we have

a great correlation between water content and thermal

conductivity in the membrane (Burheim, et al., 2010)

(Burheim, et al., 2011). The presence of water is

known by increasing the thermal conductivity of the

Porous Transport Layer (Burheim, et al., 2011)

(Wang & Gundevia, 2013) (Burheim, et al., 2013)and

the membrane of the PEM fuel cell (Burheim, et al.,

2010) (Khandelwal & Mench, 2006) (Odne, et al.,

2014). This problem is the subject of many works in

order to minimize a study of (Paul, et al., 2011)

presented that among the suggested measures is to

take in consideration the water content in the

materials of the membrane as well as the thickness of

the membrane, because more the membrane is thin

the water content and the conductivity of the protons

also fluctuate.

We realize that to have a good functioning of the

cell and have the best performance, we will have to

manage the amount of heat and the water content in

order to maintain the best operating conditions of the

membrane and ensure a balance between the water

and humidification rate, while keeping a necessary

amount of heat to satisfy the proper functioning.

5.2 Efficient Management and

Evacuation of the Thermal Power

Produced Inside the PEM Fuel Cell

System

Generally, as described above, in the fuel cell the

electric power supplied is almost the same as the

thermal power and must be evacuated to avoid

overheating hence the degradation of the components

of PEM fuel cell and especially the membrane. An

appropriate thermal management of the heat

generated inside the cell ensures a uniform

distribution in space and time in order to avoid high

temperature points in the cell generally and

specifically in the membrane, as well as to ensure a

higher electrical efficiency. Therefore the cooling

system must be efficient and ensure a proper coolant

circulation and provide a more uniform temperature

distribution in the stack of fuel cell (Ravishankar &

Arul Prakash, 2014)to optimize the system and

ensuring a high overall cell yield (Pandiyan, et al.,

2008). In the same vision a study carried out (Rojas,

et al., 2015)has showed that a good distribution of

water channels can homogenize the temperature

variation throughout the stack. So following the effect

of cooling by the distribution of water in the channels,

the temperature of the cells in a Stack is fairly similar

and that the greatest temperature difference is close to

the last plates (In the first cell, the temperature is

higher due to the lack of water channels between the

first side plate and the first cell. And that the last cell

of the series has a lower temperature, because of the

presence of water channel, and there is no production

of electricity between the last cells in the second side

plate). This study clearly stated that heat can be

dissipated in an effectively by this cooling system

achieve, this method has prevented overheating of the

cells to ensure the stability of operation and to

maintain the cell. But the effectiveness of this system

cells must be under operating conditions identical to

each other. What in reality is not feasible for different

reasons such as the location of the cell and channel

cooling and the general design of the fuel cell,

therefore a control system is strongly recommended

to ensure the efficiency in order to properly maintain

and control the uniform distribution of heat (Strahl, et

al., 2014) (J. Bvumbe, et al., 2016). Moreover, a

poorly designed cooling system accelerates the

general deterioration of the components of PEM fuel

cell, involving the lowering of the overall yield, that

means a good thermal management maintain the

overall system functionality and improves the overall

yield. In this context the study by (Alleau, Révision

Octobre 2014)proposed some measures in order to

successfully achieve heat evacuation, firstly one of

the essential is to ensure a circulation of a coolant in

the bipolar plates every 2 to 3 cells, then for a more

efficient heat evacuation, we can equip the bipolar

plates with the cooling fins to promote its cooling, put

a system of forced circulation of air to the outside, as

well as the injection of the air humidify with water at

the entrance of the PEMFC which will remove an

amount of heat by partial evaporation.

The system must be continually examined to

ensure the durability of the different functions of all

components by a control set. In addition to ensure

proper functionality of the membrane and have a

good protonic conduction, we will have to ensure

both a temperature distribution and an adequate

humidification, as well as appropriate drainage of the

water produced by the reaction during operation by

an air flow introduced to the cathode. This airflow

must be important for a better distribution of the

oxygen concentration and for the drainage of

produced water. One last point to have a good

performance and better performance in each cell of

the PEMFC we will have a supply of pure hydrogen

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

120

and oxygen in order to have optimal operation (Baek,

et al., 2011). A very high purity of gases is required,

because the membrane / electrode assembly is

extremely sensitive to all impurities in the water

(Varkaraki, et al., 2003) (Colliera, et al., 2006)

(RABIH, 2008).The more pure the reactants, the

more we will not have impurities which hinders the

reactions in both electrodes reaction, which implies

optimal functioning.

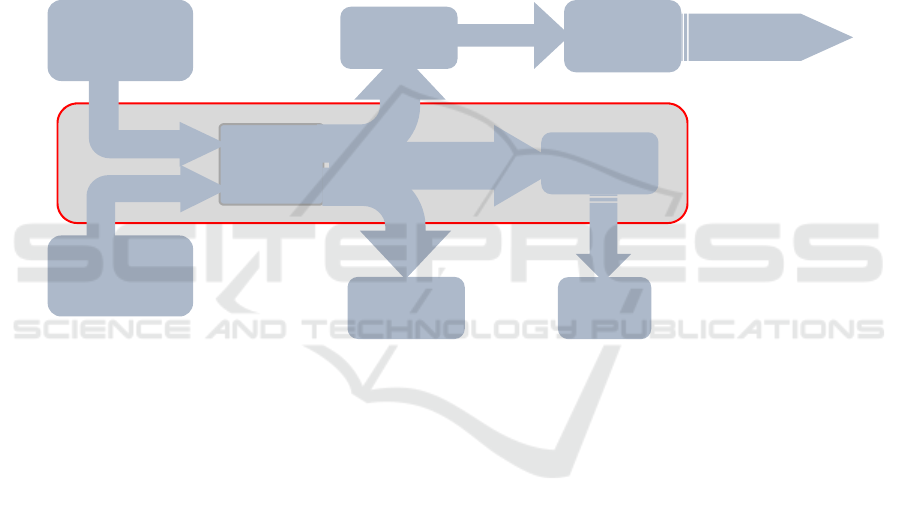

6 HEAT AND POWER

COMBINATION

(COGENERATION) (CHP)

The catalytic oxidation during operation of the

PEM fuel cell is an exothermic reaction, therefore this

oxidation generates a very significant amount of

energy as heat. Its temperature generally ranges from

60 to 80 ° C, that we must adapt it effectively to avoid

overheating the PEMFC. On other hand all the same

we need to keep an adequate temperature for the

system to ensure proper functioning. The figure

(Fig.3) shows the overall distribution of thermal

evacuation, while a part evacuated by the reagent of

overloading a second part by spontaneous heat

transfer, as well as a part is dissipated by vaporizing

some of the water produced and the remaining part of

heat requires an appropriate cooling system.

Figure 2: Fuel cells used in CHP application.

The temperature difference between the PEMFC

and the ambient temperature of the environment

constitutes a challenge for the design of a slight

cooling system that can work in a desirable manner

(Kandlikar & Lu, 2009) (Rogg, et al., 2003) (Islam, et

al., 2015). But although the principle of cooling is

simple, its implementation is a real industrial and

technological challenge. The production of the

electricity by PEM fuel cell always leads in parallel

to a heat generation. With an energy conversion

efficiency that tends to 55% (Islam, et al., 2015). This

implies the existence of a fairly large amount of

produced heat that is in the same order of the

electrical power (Barbir, et al., 2005) (Tekin, et al.,

2006). So in this case appear the interest of exploiting

the heat generated by the PEM fuel cell in a system of

cogeneration (combined heat and power CHP). The

technology of cogeneration manifests itself as a better

solution to avoid the energy dissipation, Whose the

overall interest of the use of the technical CHP is lies

in the possibility of reusing the heat generated in the

other applications combined heat and power (CHP)

(Fig.2).

In the case of PEM fuel cell, cogeneration is an

ideal way to use residual heat generated, during fuel

cell operation to improve its efficiency. The

cogeneration has a very efficient form of energy

conversion that can improve yields by over 90%. The

overall efficiency of cogeneration is the sum of net

electrical and thermal efficiency of cogeneration

systems operated.

Several researches carried out around this subject

which showed the interest of this technology, one of

them (Hubert, 2005) showed that the fuel cell

(PEMFC) is a promising technology not just an the

huge system of cogeneration but also mainly for

micro-Cogeneration (CHP).For several years, the

Hydrogen

Oxygen (Air)

System

boundary

PEM

Fuel Cell

DC Power

Converter

DC/AC

Heat

stora

g

e

Heating

Installation

CHP

AC

Powe

r

Heat

Supply

Exhaust

Gas

Study and Analysis of the Thermal Impact on the Overall Performance of the Proton Exchange Membrane Fuel Cell and Its Management

and the Exploitation of PEM Fuel Cells in a Cogeneration System: Review

121

research is moving towards this energy sector and

especially gas companies and Japanese industrial

groups are very active in research and development

on the use of PEMFCs for micro-cogeneration (Inaka

& Al, 2002) (Geiger & Cropper, 2003) (Hubert,

2005).In order to have a qualitative and quantitative

understanding of this type of system; many research

projects are carried out on PEMFC operated on

cogeneration in several European countries such as

Belgium and Germany (Pokojski, 2004) (Frey, et al.,

2004), these projects have been able to deliver good

electrical efficiencies that have been able to go up to

38% and 40% of thermal efficiency. Nevertheless, in

parallel with these progress different technical

complications and the high operating and

maintenance costs have occurred to limit its

exploitation. The cogeneration technology remains

unmatched in terms of efficiency and yield in this

power field. The study of (Hubert, 2005) has

exhibited that small stationary fuel cell systems

powered by natural gas and exploited in cogeneration

are at a phase of technological and commercial

development which suggests a close

commercialization if we manage to reduce its high

cost and stringent maintenance requirements which

prevent it from being widely marketed.

Figure 3: Sankey diagram of the energy distribution produced by the PEMFC (Islam, et al., 2015)

7 CONCLUSION

A large amount of thermal energy has been

retained in the stack, so it is necessary to evacuate this

energy to avoid excessive heating, which can lead to

many problems. In this manuscript we showed and

analyzed the influence of the heat produced inside the

PEM fuel cell and the tools for leading to the

dissipation of this thermal energy, to avoid

precipitous deterioration of the PEM fuel cell. As well

as s the possibility of exploiting it by cogeneration in

another system, in order to avoid losses and achieve

higher profits from the chemical energy wasted in the

form of thermal energy instead of electrical during

reaction. So the use of residual heat produced by

PEMFC that is normally rejected by conversion

systems. Cogeneration technology is one of the

promising solutions, having real potential to save

primary energy and improve overall yield. The main

reason for this potential is to save primary energy and

exploit the thermal energy instead of throwing it

away. Finally, we generally realize that the

improvement of the materials used, the optimization

of the overall operation and the knowledge of the

phenomena taking place in the heart of the pile, these

are the keys to better optimization for the system but

still require significant research efforts. This study

allowed us to have a good understanding on the

manipulation of the different parameters influencing

the thermal management during operation As well as

to understand what is happening inside the studied

environment. Although the operating principle of the

fuel cell is simple, its implementation remains a real

industrial and technological challenge.

Hydrogen

Excess Hydrogen

(5%)

Power (50%)

Heat (45%)

Heat removal by

extra reactants (2%)

Heat used by the FC

internally for water

evaporation (5%)

Heat removal by

cooling system

Heat removed by natural

convection from the

body of the FC if the

stack is water cooled

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

122

REFERENCES

Abd Elhamid, M., Mikhail, Y., Blunk, R. & Lisi, D., 2004.

Inexpensive dielectric coolant for fuel cell stacks. US

Patent 6,740,440, assigned to General Motors

Corporation.

Alleau, T., Révision Octobre 2014. Mémento de

l’Hydrogène la pile à combustible de type PEM, s.l.:

Fiche 5.2.2 Source: AFHYPAC.

Alper, . A. & Oguz, O., 2016. The role of renewable energy

consumption in economic growth: evidence from

asymmetric causality. Renew Sustain Energy Rev.

Authayanun, S., Im‐orb, K. & Arpornwichanop, A., 2015.

A review of the development of high temperature

proton exchange membrane fuel cells. Chinese journal

of catalysis, p. 473–483.

Baek, S., Yu, S., Nam, J. & Kim, C., 2011. A numerical

study on uniform cooling of large-scale PEMFCs with

different coolant flow field designs. Appl. Therm. Eng,

p. 1427–1434.

Balat, M., 2008. Potential importance of hydrogen as a

future solution to environmental and transportation

problems.. Int J Hydrogen Energy.

Barbir, F., Molter, T. & Dalton, L., 2005. Efficiency and

weight trade-off analysis of regenerative fuel cells as

energy storage for aerospace applications.. Int J

HydrogenEnergy.

Ben-Attia, H., 2013. Elaboration et caractérisation des

membranes à base de Nafion® / H3 et Nafion® / H1

pour les piles à combustible, France: Université de

Grenoble.

Benmouiza, K. & Cheknane, A., 2017. Analysis of proton

exchange membrane fuel cells voltage drops for

different operating parameters. International Journal of

Hydrogen Energy.

Berning, T. & Djilali, N., 2003. A 3D multiphase,

multicomponent model of the cathode and anode of

aPEM fuel cell. J. Electrochem. Soc. 150, p. A1589–

A1598.

Burheim, O. et al., 2013. Ageing and thermal conductivity

of porous transport layers used for PEM fuel cells. J

Power Sources.

Burheim, O. et al., 2011. Through-plane thermal

conductivity of PEMFC porous transport layers.

Journal Fuel Cell Sci Technol.

Burheim, O., Vie, P., Pharoah, J. & Kjelstrup, S., 2010. Ex-

situ measurements of through-plane thermal

conductivities in a polymer electrolyte fuel cell.. J

Power Sources.

Colliera, A. et al., 2006. Degradation of polymer electrolyte

membranes. International Journal of Hydrogen

Energy, pp. 1838-1854.

Eikerling, M., 2006. Water management in cathode catalyst

layers of PEM fuel cells: a structure-based model.

Journal Electrochem Soc 153.

Ferng, Y., Sun, C. & Su, A., 2003. Numerical simulation of

thermal–hydraulic characteristics in a proton exchange

membrane fuel cell. Internatonal journal of energy

research, Issue (DOI: 10.1002/er.891), p. 495–511.

Frey, H., Edel, M., Kessler, A. & Munch, W., 2004.

Stationary fuel cells at EnBW. Belfort, s.n.

Geiger, S. & Cropper, M., 2003. Fuel Cell Market Survey:

Small Stationary Applications. Fuel Cell Today.

Gloaguen, F. & Durand, R., 1997. Simulations of PEFC

cathodes: an effectiveness factor approach. Journal

Appl Electrochem, p. 1029–1035.

Haji, S., 2011. Analytical modeling of PEM fuel cell ieV

curve. Renew Energy.

Harris, A., 2011. Clean energy: resources, production and

developments. Nova Science Publishers.

Hosseinzadeh, E., Rokni, M., Rabbani, A. & Mortensen, H.,

2013. Thermal and water management of low

temperature Proton Exchange Membrane Fuel Cell in

fork-lift truck power system. Appl Energy, p. 434–444.

Hubert, C., 2005. Étude du fonctionnement et optimisation

de la conception d’un système pile à combustible PEM

exploité en cogénération dans le bâtiment, s.l.: École

Nationale Supérieure des Mines de Paris.

Inaka, H. & Al, 2002. The development of effective heat

and power use technology for residential in a PEFC co-

generation system. J. power sources, pp. vol. 106, p.

60-67.

Islam, M., Shabani, B., Rosengarten, G. & Andrews, J.,

2015. The potential of using nanofluids in PEM fuel

cell cooling systems: A review. Renewable and

Sustainable Energy Reviews, p. 523–539.

J. Bvumbe, T. et al., 2016. Review on management,

mechanisms and modelling of thermal processes in

PEMFC. Hydrogen and Fuel Cells, p. 1–20.

Jordan, L. et al., 2000. Effect of diffusion-layer morphology

on the performance of polymer electrolyte fuel cells

operating at atmospheric pressure. J. Appl.

Electrochem., p. 641–646.

Kandlikar, S. G. & Lu, Z., 2009. Thermal management

issues in a PEMFC stack – A brief review of current

status. Applied Thermal Engineering, p. 1276–1280.

Kandlikar, S. & Lu, Z., 2009. Fundamental research needs

in combined water and thermal management within a

proton exchange membrane fuel cell stack under

normal and cold startconditions. Journal Fuel Cell Sci

Technol.

Kandlikar, S., Lu, Z. & Trabold, T., 2007. Current Status

and Fundamental Research Needs In Thermal

Management within a PEMFC Stack. Edinburgh,

Scotland, s.n.

Khandelwal, M. & Mench, M., 2006. Direct measurement

of through plane thermal conductivity and contact

resistance in fuel cell materials. J Power Sources.

Lamei, X., 2012. Simulation and Optimization of Proton

Exchange Membrane Fuel Cell. Beijing: Beijing:

national defence industry press.

Lampinen, M. & Fomino, M., 1997. Analysis of free energy

and entropy changes for half-cell reactions. J.

Electrochem. Soc, p. 3537–3546.

Maes, . J.-P. & Lievens, S., 2007. Methods for fuel cell

coolant systems. U.S. Patent 7,201,982, assigned to

Texaco, Inc.,.

Meyers, . J.-P.et al., 2006. Evaporatively-cooled PEM fuel

cell stack and system. ECS Trans, p. 1207–1214.

Study and Analysis of the Thermal Impact on the Overall Performance of the Proton Exchange Membrane Fuel Cell and Its Management

and the Exploitation of PEM Fuel Cells in a Cogeneration System: Review

123

Naimi, Y., Saghir, M., Cherqaoui, A. & Chatre, B., 2016.

Récupération énergétique de la biomasse dans la région

de Rabat, Maroc. International Journal of Hydrogen

Energy.

Odne, S. et al., 2014. Study of thermal conductivity of PEM

fuel cell catalyst layers. international journal of

hydrogen energy, pp. 9397-9408.

Ozbek, M., Wang, S., Marx, M. & Soffker, D., 2013.

Modeling and control of a PEM fuel cell system: a

practical study based on experimental defined

component behavior. J Process Control.

Pandiyan, S., Jayakumar, K., Rajalakshmi, N. &

Dhathathreyan, K., 2008. Thermal and electrical energy

management in a PEMFC stack – An analytical

approach. International Journal of Heat and Mass

Transfer, p. 469–473.

Panwar, N., Kaushik, S. & Kothari, S., 2011. Role of

renewable energy sources in environmental protection..

Renew Sustain Energy Rev.

Paul, D., Fraser, . A. & Karan, K., 2011. Towards the

understanding of proton conduction mechanism in

{PEMFC} catalyst layer: conductivity of adsorbed

nafion films. Electrochemistry Communications.

Pokojski, M., 2004. Die erste 250 kW PEM Brennstoffzelle

in Europa -Betriebserfahrungen, s.l.: s.n.

RABIH, S., 2008. Contribution à la modélisation de

systèmes réversibles de types électrolyseur et pile à

hydrogène en vue de leur couplage aux générateurs

photovoltaïques, Toulouse: doctorats de l’université de

Toulouse l’institut national polytechnique .

Rallieres, O., 2011. Modélisation et caractérisation de

Piles A Combustible et Electrolyseurs PEM. Energie

_électrique, Toulouse: Institut National Polytechnique

INPT.

Ravishankar, S. & Arul Prakash, K., 2014. Numerical

studies on thermal performance of novel cooling plate

designs in polymer electrolyte membrane fuel cell

stacks. Appl Therm Eng, p. 239–251.

Rogg, S. et al., 2003. Cooling modules for vehicles with a

fuel cell drive. FuelCells.

Rojas, J. D., Kunusch, C., Ocampo-Martinez, C. & Puig,

V., 2015. Control-oriented thermal modeling

methodology for water-cooled PEM fuel cell based

systems. IEEE Transactions on Industrial Electronics,

pp. 5146-5154.

Saeeda, W. & Warkozekb, G., 2015. Modeling and

Analysis of Renewable PEM Fuel Cell System.

International Conference on Technologies and

Materials for Renewable Energy, Environment and

Sustainability, TMREES15, Energy Procedia 74, p. 87–

101.

Shimoi, R. et al., 2004. Visualization of the membrane

temperature field of a polymer electrolyte fuel cell.

Journal Energy Resour Technol, p. 258–261.

Song W, Y. H. M. S. Z. G. Y. B. L. L. J. L. N., 2014. Chin

J Catal.

Strahl, S. et al., 2014. Performance improvement by

temperature control of an open-cathode PEM fuel cell

system. Fuel Cells, p. 466–478.

Tekin, M., Hissel, D., Pera, M. & Kauffmann, J., 2006.

Energy consumption reduction of a PEM fuel cell

motor-compressor group than kstoefficient control

laws. J PowerSour, p. 57–63.

Varkaraki, E., Lymberopoulos, N. & Zachariou, A., 2003.

Hydrogen based emergency back-up system for

telecommunication applications. Journal of power

Sources, pp. 14-22.

Viswanathan, B., 2017. Chapter 9 e Hydrogen as an energy

carrier. Energy Sources.

Wang, Y. & Gundevia, M., 2013. Measurement of thermal

conductivity and heat pipe effect in hydrophilic and

hydrophobic carbon papers. International Journal Heat

Mass Transf, pp. 134-142.

Wen C.-Y., L. Y.-S. L. C.-H. L. T.-W., 2011. Thermal

management of a proton exchange membrane fuel cell

stack with pyrolytic graphite sheets and fans combined.

Int. J. Hydrogen Energy, p. 6082–6089..

Wilkinson, D. & Vanderleeden, O., 2003. Serpentine flow

field design, Handbook of Fuel Cells – Fundamentals,

Technology and Applications (Chapter 30), s.l.: Fuel

Cell Technology and Applications, vol. 3, John Wiley

and Sons, Ltd.

Yan Z Y, L. B. Y. D. J. M. J. X., 2013. Chin J Catal.

Yao, K. et al., 2004. A review of mathematical models for

hydrogen and direct methanol polymer electrolyte

membrane fuel cells. Fuel Cells.

Yu, H. et al., 2006. Hydrophilicity and hydrophobicity

study of catalyst layers in proton exchange membrane

fuel cells. Electrochim. Acta. 51, p. 1199–1207.

Zhang Liyan, Q. S., 2011. Modeling of the Fuel Cell

System Modeling and Optimization Control,. Beijing:

electronic industry press.

Zhidong, Q., Shengyuan, X., Liang, S. & Huijuan, B., 2015.

Dynamic Thermal Modeling of PEMFC based on

Fractional Order Theory. 27th Chinese Control and

Decision Conference (CCDC) 2015 IEEE, pp. 4069-

4072.

Zong, y., Zhou, B. & Sobiesiak, A., 2006. Water and

thermal management in a single PEM fuel cell with

non-uniform stack temperature. Journal Power Source,

p. 143–159.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

124