Nonlinear Model of the Hydraulic Automatic Gauge Control System:

Conrollability Analysis and Observability

Abdelmajid Akil, Mourad Zegrari, Abdelwahed Touati and Nabila Rabbah

Laboratory of Structural Engineering, Intelligent Systems and Electrical Energy

ENSAM, Department of Electrical Engineering – Hassan II University Casablanca, Morocco

Keywords: rollingmill; roll gap; nonlinearmodel; elastic deformation; Automatic gauge control

Abstract: In the reversible cold rolling mill, it is critical to control the gauge or thickness of the cold-rolled steel strip

for end-user requirements. To obtain a high precision in the output thickness of the strip, the automatic

control system of the gauge is used. As one of the most important functions of the basic mill automation,

there is the hydraulic roll gap controlsystem (HRGCS) which is the inner loop of the Hydraulic Automatic

Gauge Control (HAGC).In order to improve the control performance of the strip mill, a theoretical nonlinear

mathematical model of the complex HAGC has been established in this paper for a reversible cold rolling

system.The new nonlinear model of the HAGC will be used to develop nonlinear control strategies to

address the different control problems encountered.

1 INTRODUCTION

Nowadays, steel strips of various thicknesses are

vitally important products in the iron and steel

industry and are widely used in aeronautics,

household appliances, car manufacturing, machines

and many other areas.

The accuracy of the web thickness and flatness

control is directly dependent on the performance of

the web winding system (WWS) studied and

controlled by nonlinear controllers presented in

(akil, 2017), (akil, 2018a) and(akil, 2018b), the

Automatic Gauge Control (AGC) and Automatic

Flatness Control System (AFC) (John, 2010). In

particular, the Hydraulic AGC System is one of the

key techniques of modern mills to determine the

quality of the web based on Hydraulic Roll gap

controlsystem (HRGCS).

The HRGCS is an important part of the AGC

system by pressing the position adjustment of work

rolls in order to get a precision of the thickness and

flatness of the web (Soszy´nski, 2012), (Kim, 2013)

and(Hoshino, 1997). Therefore, the good dynamic

characteristics of the HRGCS are very important for

the AGC system (Zhang, 2012a).

The HRGCS is a typical of machine, electrical,

hydraulic integrated system for complete control of

the complex system. In nowadays, more and more

scholars have devoted themselves to the study of

hydraulic gap control (Zhou, 2007) and (Zhang,

2012b).

The cold rolling process has been taken as a

research topic for many decades, and currently some

theories are able to provide a valuable and detailed

description of the roll gap (Grimble, 1978). First

Siebel and von Karman (von Khmh, 1925),(Siebel,

1925) began studies on the subject; their analysis

introduced the vertical segments concept of

homogeneous compression of the sheet during

rolling. Another fundamental supposition was the

occurrence of a neutral plane in the length of the

contact arc (Freshwater, 1996).

The models proposed by (Sims ,1945),(Bland

and Ford ,1948) and (Nascimento, 2016) have

solved analytically the problem by avoiding most

numerical integrations, unlike the Orowan model

(Orowan, 1943) which is much more complex and

requires more of calculations. However, the

simplifications of Bland and Ford led to a sacrifice

of precision (Alexander, 1971).

In order to analyze and optimize the AGC, a

precise model of the HRGCS is required first.

Numerous studies on the control of the HRGCS in

Akil, A., Zegrari, M., Touati, A. and Rabbah, N.

Nonlinear Model of the Hydraulic Automatic Gauge Control System: Conrollability Analysis and Observability.

DOI: 10.5220/0009771303070316

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 307-316

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

307

modeling and simulation have been carried out (Liu,

2012) and (Sun, 2014).Sun (Sun, 2015) established a

mathematical model of the HRGCS that was used to

design a controller with a predictive control theory.

In (Sun, 2014), the mathematical model of the

HRGCS was established by adopting the mechanism

modeling method and the model was dynamically

simulated and analyze

d considering the nonlinear and saturation

characteristics. However, it is difficult to determine

the important parameters in the theoretical model

with the mechanism analysis method. Moreover, real

conditions play an important role in the decision on

parameters (Ren, 2014), (Li, 2006) and (Dyja,

1996).

In order to adjust the parameters of the change of

gap of the rolling mill, the authors carried out a

number of experiments where they studied the

rolling of the web with different correction

parameters in each stand (Petryakov, 2011); (Galkin,

2011) and (Khramshin, 2010). The parameters were

selected empirically and passed to the controller of

the automatic process control system.

Based on the nonlinear equations of the elastic

and plastic deformation of the web and work roll,

and the rolling force, a nonlinear model of the

HAGC for reversible cold rolling mill was

developed in this paper.

The rest of the article is organized as follows:

section 2 presents a description of the rolling

process, Basic theories of the cold rolling mill

introduced in Section 3, The model of the HAGC is

established in Section 4 and the Simulation Results

and Discussion in Section 5. Finally, the conclusion

is given in section 6.

2 DESCRIPTION OF THE

ROLLING PROCESS

Rolling is a manufacturing process by plastic

deformation. In this method, the metal web

undergoes a reduction in thickness by crushing

between the two work rollers rotating in two

opposite directions. While the larger diameter

backup rolls (support rollers) serve to support the

work rolls to prevent them from bending too much.

The rotary motion of the work rolls exerts a

compressive force to continually decrease the initial

thickness of the web by passing several times in the

same rolling stand for the reversible single-roll mill.

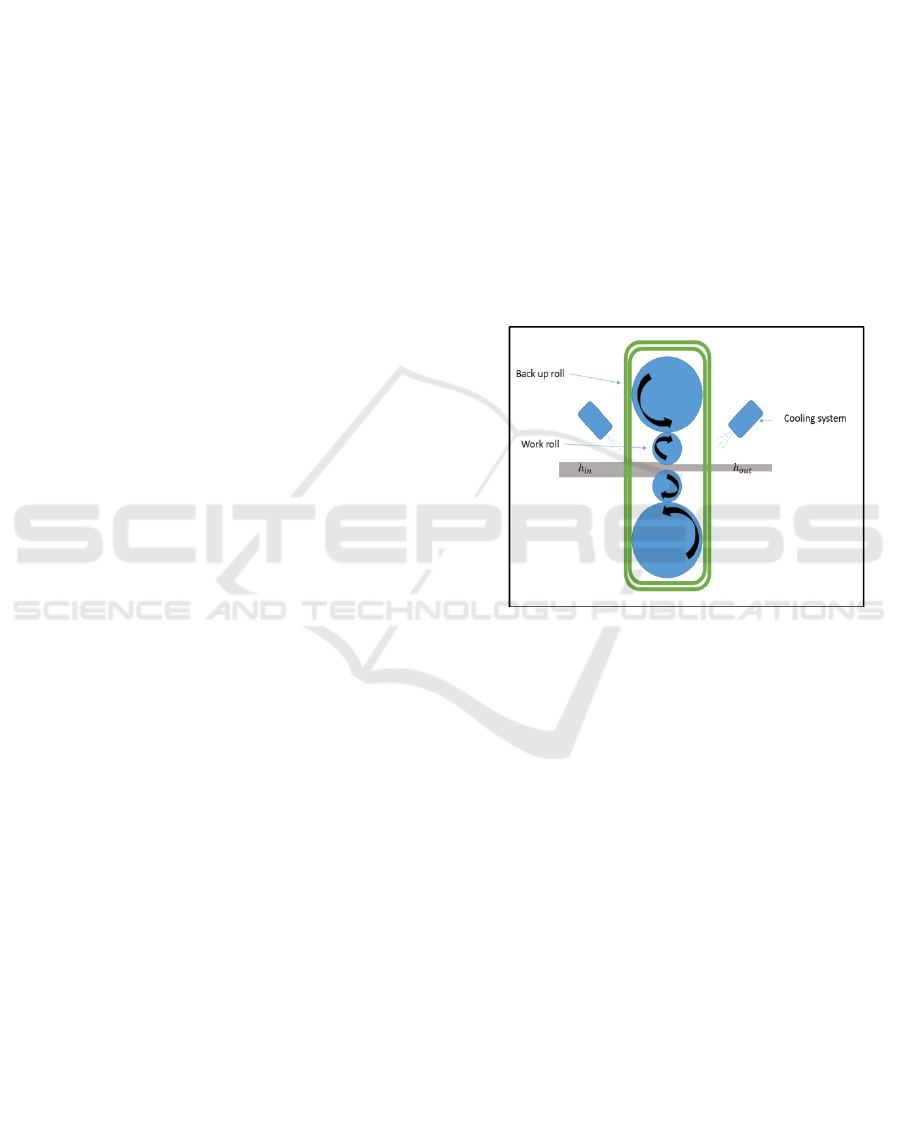

A rolling mill cage is composed of:

A pair of cylinders called "work roll"

between which the material is elongated.

The working cylinders are made of

rectified cast iron;

Another pair of cylinders called "backup

roll" (a cylinder on each side of the pair of

work rolls) to reduce the deformation of the

work rolls.

Two metal columns holding the cylinders

together (one column on each side).

Figure 1 illustrates the rolling process where a

web is engaged between the two rolls rotating in

opposite direction. The thickness

web must be

able to engage between the rollers where it is

deformed in compression to stand at a thickness

corresponding to the adjustment of the clearance

between the rolls.

Figure 1: rolling Principle

The necessary compressive force is applied to

the bearings of the backup rollers by hydraulic

cylinders or by a screw arrangement driven by an

electric motor. The thickness of the rolled web is

mainly determined by the gap between two work

rolls which is initially set by a pass line adjusting

mechanism. The actual position control is performed

by the exact and fast acting hydraulic control system

called Hydraulic automatic gauge control (HAGC).

3 BASIC THEORIES OF THE

COLD ROLLING MILL

3.1 Control System of the HAGC

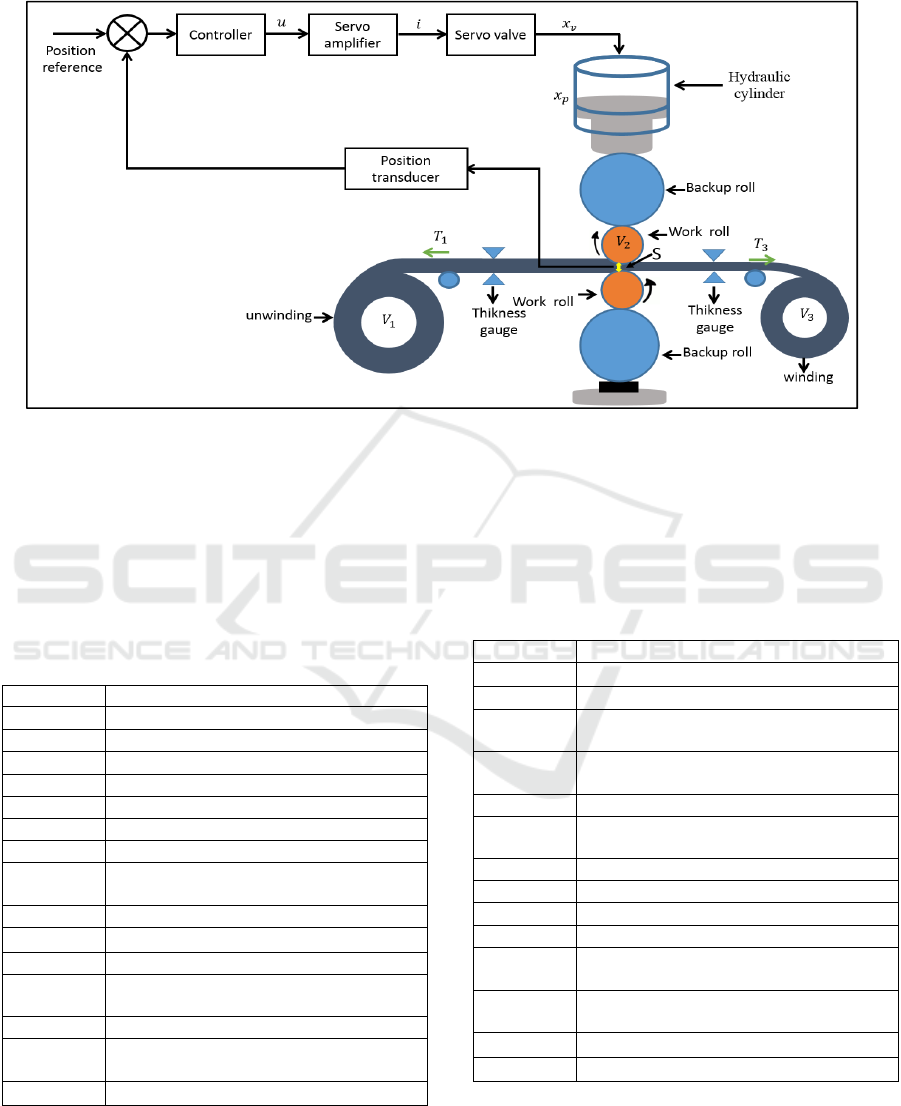

The structure of the HAGC is shown in figure 2. The

system is typically composed of thickness gauge,

position sensors, position controller, servoamplifier,

electrohydraulic servo valve, and hydraulic cylinder

components.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

308

Figure 2: Basic configuration of HAGC

The position control system of hydraulic roll gap

is constructed by the following process: the position

difference is obtained by comparing the position

reference and the actual position, and the difference

is transmitted to the position controller; take the

controller output values as servoamplifier input

values; the amplified current signal is transferred to

the degree of opening of the electrohydraulic servo

valve; Finally, the hydraulic oil passes the servo

valve by alternately driving the movement of the

actuator (Zhanget al, 2009 , Wang, 2011 , Lv, 2007

and Andrew and Rui , 2000).

3.2 Symbols

Table 1: Symbol description

Symbol Parameter

the spool valve position

Servo amplifier gain

The associated time constants.

servo valve input current

Servo valve flux

the flow coefficient of the valve port

Servo valve natural frequency

and

the inlet and outlet pressure of the servo

valve respectively

the oil density

the active area of the cylinder piston

the total leakage coefficient

The oil pocket volume of the hydraulic

cylinder

the bulk modulus of elasticity

the equivalent total mass of moving parts

of the upper roller system

the viscosity coefficient of cylinder

the elastic stiffness coefficient of load

the cylinder piston displacement

Other load force acting on the piston

the plastic stiffness coefficient of the

rolled piece

and

are the input and output thickness of the

rolled piece respectively

T The constant delay time.

the unknown force including the

coulomb friction force

the rolling load

the mill modulus

the roll gap

Unloaded roll gap

and

the magnitude and period of thickness

deviation respectively

vin the entry strip is passed through the roll

stand with the velocity

Time constant of hydraulic servo

constants specified

Nonlinear Model of the Hydraulic Automatic Gauge Control System: Conrollability Analysis and Observability

309

3.3 Basic Theoretical Equations

3.3.1 Servo Valve Torque Motor Equation

The servovalve used in this paper has a critical

center (zero overlap). Its orifices are supposed

symmetrical and matched. The internal leakage of

the servo valve are neglected. The servo valve treats

the current as the input and displacement of the

valve core

as the output.

The dynamic movement of the servovalve spool is

described by the following dynamic equation:

1

3.3.2 Servo Valve Flow Equation

The flow equation of the servo valve is a typical

nonlinear loop. The outflow equation of the

servovalve is:

2

In order to satisfy the Lipschitz condition to

guarantee the existence and uniqueness of the

solution to (2) for all initial conditions, the non-

differentiable sign function is approximated by the

continuously differentiable sigmoid function defined

as:

1

1

;0

By doing so, the system described by (1)

becomes differentiable and allows the use of the

feedback linearization approach

2

1

²

;0

lim

→

2

1

²

0

Furthermore, the use of the sigmoid function is

required to ensure that the feedback linearization

conditions on the Lie derivatives of the system

dynamics are satisfied [4]. When≫1, the sigmoid

function behaves like the sign function and the

model best approximates the real electrohydraulic

system.

The outflow equation of the servovalve became:

3

3.3.3 Hydraulic Flow Equation

The flow from servo valve into the cylinder, besides

driving the piston movement, can be used to

compensate various cylinder leaks and liquid

compressed volume, etc. The continuous flow

equation of the cylinder can be expressed as

4

4

3.3.4 Hydraulic Cylinder Load Force

Balance Equation

The output rolling force of the cylinder keeps

balance with the inertia force of the moving parts,

viscous damping force, elastic load force and other

load force. The dynamic equation can be written as

5

The

is other load force acting on the piston.

And

can be expressed by

3.3.5 Elastic Deformation of the Mill and

Spring Equation

Cold rolling is a processing method by passing the

metal strip between two rolls (work rolls), rotating in

opposite directions. Due to this rotational movement

and the compression generated by the cylinders

(deformation force P), there is a continuous

reduction of the initial thickness by plastic

deformation of the metal.

The simplified thickness model normally uses

the equation gaugemeter (BISRA) or spring equation

to derive the thickness of the strip. It is based on the

relationship between the position of the roll gap, the

gap of the work rolls and the thickness of the web.

A linear approximation of the grinding stretching

characteristic is used to estimate the thickness at the

exit of a cage as by the model "BISRA" or

"gaugemeter" (Zhanget al, 2015):

Σ

6

Where Σis the compensation including thickness

compensation, e eccentricity compensation and

thermal compensation.

Figure 3: Equation gaugmeter

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

310

In the gaugemeter equation (see Figure 3)

is

the amount of the mill stretch when a roll separating

force is applied. The output thickness is therefore

equal to the position of the unloaded gap plus the

stretch.When the entry strip is passed through the

roll stand with the velocity

, the disturbance ∆

is expressed as:

∆

sin

2

Where

and

are the magnitude and period of

thickness deviation respectively (Hwang et al,

1996).

There exists time delay between the output

thickness

and the thickness detected by the

thickness gauge, and it is a pure delay loop

Where is the constant delay time.

3.3.6 Dynamic Equation of the Roll Gap

The rolling model at each stand consists of the

dynamics of the roll gap and rolling direction, which

are described below.

The roll gap S is assumed to be controlled by a

local feedback loop of a hydraulic servo and is

governed by the following equation (OZAKIet al,

2012):

,

0

7

Where

denotes the command input, and

and

are constants specified by the local feedback

loop. The local feedback adjusts the roll gap S so

that h

g

(S, h) coincides with the command input

.The function

,

is defined in terms of the

thickness h i and roll gap S i as

1

Which represents the thickness modified by the

tuning parameter k (0 < k < 1).

The dynamics of the roll gap S i is governed by

1

1

0

Σ

8

3.3.7 Rolling Force Model

The mill model generates the roll force, exit strip

thickness, entry strip velocity, and exit strip velocity

using the roll gap, roll velocity, entry strip thickness,

and the other factors. The roll force and the exit strip

thickness are derived from Bland-Ford model (Bland

et al., 1948 and Ford and Bland, 1951) and the

gauge-meter equation respectively. The roll force

can be expressed as:

,

,…

9

4 NON-LINEAR GLOBAL MODEL

OF THE HAGC

4.1 Non-linear Model of the HAGC

The mathematical model of the HAGC can be

described by the system of equations including

nonlinear dynamic equations presented previously

by posing

,

,

,

4

,

5

and

6

as state variables:

1

1

1

Σ

1

4

1

Σ

Nonlinear Model of the Hydraulic Automatic Gauge Control System: Conrollability Analysis and Observability

311

The state vector is

,

,

,

,

,

and control

.

The model of the HAGC presented in the above

equation is nonlinear because of the sigmoid and

square root functions. In this state representation,

only the state variables are expressed as a function

of time. However, hydraulic and mechanical

parameters also vary during the operation of the

HRGCS.

4.2 Controllability Analysis of HAGC

The controllable canonical form is to represent the

dynamics of the system by a differential equation

relating the output variable to the control variable

HAGC. The state variable to be controlled and its

successive time derivatives represent new HAGC

state variables. The number of successive time

derivatives is determined by the number of

successive derivations performed on the output

variable in order to obtain the control variable.

Nonlinear controllable canonical form are

constructed from non-linear state representation of

the HAGC. This direct relationship between the

input variable and the state variable to enslave

enables us to develop our control laws. Consider the

non-linear state representation of the HAGC in the

space where y (t) represents the output variable

described below:

2

Σ

0

0

0

0

0

Or in compact form,

3

,

,

,

Where

is the n-dimensional state vector,

is the control input and

is the output.

Definition 1: the Lie derivative (Slotine et Li, 1991,

p. 229): Let :

→ be a smooth scalar function,

and :

→

be a smooth vector field on

,

then the Lie derivative of h with respect to is a

scalar function defined by

Definition 2: relative Degree (Khalil, 2002, p.

510): The nonlinear system describe by (sys 1) is

said to have relative degree ,1 , in a

region

⊂ if

,

0, 1,2,…,

2 ;

,

0 for all ∈

.

Thus, by successively deriving the position y (t),

we find:

,

10

,

1

1

Σ11

,

1

Σ

12

,

Σ

1

13

,

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

312

Σ

14

,

,

15

with

,

,

,

with

,

,

,

and

,

;

;

;

;

;

;

;

;

;

;

;

;

;

and

The expression

,

0 if and only if

. According to the standard design of the

electro-hydraulic servo systems explained by Merritt

(1967), the pressure across the hydraulic actuator

verifies

. Thus, the control signal

appears when the output is derived 6 times.Since the

system is of the sixteenth order (six state variables),

there is no internal dynamics. The nonlinear state

representation in canonical and controllable form

becomes:

,

,

16

With

,

,

,

,

,

and

,

∑

,

With the new selected state variables such

as

,

,

,

,

and

.

The mathematical representation of equation (16)

has the previous state variables because the system

is non-linear. For the design of the exact

linearization controller, the controllable canonical

form of equation (16) is used.

Nonlinear Model of the Hydraulic Automatic Gauge Control System: Conrollability Analysis and Observability

313

4.3 HAGC Observability

The problem of designing an observer for a

nonlinear system has been widely studied. Many

different approaches have been considered to design

observers. However, the observability property of

the system must be verified before to design an

observer.

It is well-known that the observability of a

nonlinear system can be lost under some conditions.

Now, we recall the conditions for checking that a

nonlinear system is observable (Hermann, 1977).

For the system (sys3), let us define the vector of

output derivatives, H (x), as follows:

.

.

.

.

.

.

17

and the Observability matrix, O (x), as:

.

.

.

18

where

represents the i-th Lie derivative of h

(x) in the f vector field direction. In addition, let us

suppose the following condition:

Condition 1: The system (sys3) is globally

observable, in the sense that the observability rank

condition

19

is fulfilled for all x∈R

.

Remark 1. In the following, the observability

property is studied for the case of the HRGCS. Then,

from Condition 1 and by considering

the

output of system (17).Then,

6

Thus system (17) is weakly observable.

5 SIMULATION RESULTS AND

DISCUSSION

The hydraulic system of the roll gap that we

modeled is simulated using the MATLAB

SIMULINK software and the simulation is

performed over 40 seconds. Figure 4 shows the time

performance obtained for HAGC to study that a step

is applied. The HRGCS index response shows a

significant overshoot and stabilizes after 20 s.

The hydraulic HAGC is very uncertain, so it should

really be used by control algorithms with strong

robustness.

6 CONCLUSIONS

In this paper, a dynamic nonlinear mathematical

model of the HRGCS of the reversible cold rolling

mill is developed primarily from the first principles

governing mechanical and electrical components,

associated with the theory of rolling for make the

resulting model fit for decision-making and control

analysis.

The dynamic mathematical model developed

can be used to analyze and design futurement

nonlinear order to fully control the various reversible

cold rolling mill systems thus contributing to

improving the final product quality broadband mills.

REFERENCES

Akil, A., Zegrari, M., Rabbah, N., 2017. Nonlinear control

of the web winding system by backstepping with

integral action. 1-5. 10.1109/EITech.2017.8255223.

Akil, A., Zegrari, M., Rabbah, N., 2018a. Nonlinear

Control of the Web Winding System by Adaptive

Backstepping. SSRN Electronic Journal.

10.2139/ssrn.3185341.

Akil, A., Zegrari, M., Rabbah, N., 2018b. Robust adaptive

backstepping control for web winding system of

reversible cold rolling mil. International Conference

on Control, Automation and Diagnosis (ICCAD),

Marrakech, Morocco, 2018, pp. 1-6. doi:

10.1109/CADIAG.2018.8751298.

John, P., Nichols, S., S., Marwan, A., S., 2010. A new

strategy for optimal control of continuous tandem cold

Figure 4: step response of HAGC

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

314

metal rolling [J]. IEEE Transactions on Industry

Application, 46(2): 703−711.

Soszy´nski, W., Studnicka, A., 2012. A review of

contemporary solutions for cold rolling that allow

quality improvement. Journal of Achievements in

Materials and Manufacturing Engineering. vol. 55, no.

2, pp. 810-816.

Kim, Y. D., Kim, C. W., Le, S. J., Park, H. C., 2013.

Dynamic modeling and numerical analysis of a cold

rolling mill [J]. International Journal of Precision

Engineering and Manufacturing. 14(3): 407−413.

Hoshino, I., Meakawa, Y., Fujimoto, T., 1997. Observer

based multivariable control of the aluminum cold

tandem mill [J]. Automatica,24(6): 741−754.

Zhang, H., Sun, J., Zhang, D., Li, X. , 2012.

Compensation method to improve dynamics of

hydraulic gap control system. 24th Chinese Control

and Decision Conference (CCDC), 1536–1541.

Zhou, M., Tian, Y., Gao, W., Yang, Z., 2007. High

precise control method for a new type of piezoelectric

electro-hydraulic servo valve [J]. Journal of Central

South University of Technology. 14(6): 832−837.

Zhang, J., et al., 2012. PID neural network control of

hydraulic roll gap control system. Proc. IEEE

International Conference on Measurement Information

and Control (MIC), vol. 2, pp. 791-795,

Grimble, M. J., Fuller, M. A., Bryant, G. F., 1978. A

noncircular arc roll force model for cold rolling.

International Journal for Numerical Methods in

Engineering. v. 12, p. 643-663.

Von Khmh, T. 1925 Zeitschriftaug. Math. u. Mech., vol.

5, p. 139.

Siebel, E. 1925 Stahl und Eisen, vol. 45, p. 1563.

Freshwater, I. J., 1996. Simplified theories of flat rolling I.

The calculation of roll pressure, roll force and roll

torque. International Journal of Mechanical Sciences,

v. 38, n.6, p. 633-648.

Sims, R.B., 1954. The Calculation of Roll Force and

Torque in Hot Rolling Mills. Proc. Inst. Mech. Eng.,

168, 191–200.

Bland, D.R.; Ford, H., 1948. The calculation of roll force

and torque in cold strip rolling with tensions. Proc.

Inst. Mech. Eng., 159, 144–163.

Nascimento, H. L. F., Shigaki, Y., Santos, S. C., Hubinger,

A. Z. ,Landre Júnior, J. , 2016. A Study of the Rolling

Load Calculation Models for Flat Cold Rolling

Process. In: XXXVII Iberian Latin American congress

on Computationak Methods in Engineering

Orowan, E., 1943. The calculation of roll pressure in hot

and cold flat rolling, Proceedings of the Institution of

Mechanical Engineers, 150 (1), 140-167.

Alexander, J. M., 1971. On the Theory of Rolling.

Proceedings of the Royal Society of London. Series A,

Mathematical and Physical Sciences (1934-1990), v.

326, n. 1567, p. 535-563.

Liu, G., Di, H., Zhou, C., LI, H., Liu, J., 2012. Tension

and thickness control strategy analysis of two stands

reversible cold rolling mill [J]. Journal of Iron and

Steel Research, 19(10): 20−25.

Sun, J., Zhang, D., Li, X., Zhang, J., Du, D., 2010. Smith

prediction monitor AGC system based on fuzzy self-

tuning PID control [J]. Journal of Iron and Steel

Research International,17(2): 22−26.

Sun, J., Chen, S., Han, H., Chen, X., Chen, Q., Zhang, D.,

2015. Identification and optimization for hydraulic roll

gap control in strip rolling mill [J]. Journal of Central

South University, 22(6): 2183–2191.

Sun, J., Peng, Y., Liu, H., 2014. Dynamic characteristics

of cold rolling mill and strip based on flatness and

thickness control in rolling process [J]. Journal of

Central South University, 21(2): 567−576.

Ren, Y., Ruan, J., Jia, W., 2014. Output waveform

analysis of an electro-hydraulic vibrator controlled by

the multiple valves [J]. Chinese Journal of Mechanical

Engineering, 27(1): 186−197.

Li, M., Liu, H., Wang, X., Yin, F., Bian, X., Zhang, L.,

TONG, C., 2006. Key techniques of automatic gauge

control and profile control for aluminium strip and foil

[J]. Transactions of Nonferrous Metals Society of

China, 16(3): 1595−1599.

Dyja, H., Markowski, J., Stoinski, D., 1996. Asymmetry

of the roll gap as a factor improving work of the

hydraulic gauge control in the plate rolling mill [J].

Journal of Materials Processing Technology, 60(3):

73−80.

Petryakov, S.A., 2011. Automatic thickness control

system for a broadband hot rolling mill /. Petryakov,

S.А, Khramshin, V.R., // Electric drive,

electrotechnology and electrical equipment of

enterprises: Sat. sci. tr. III Vseros. scientific-techn.

Conf. with the international. participation. - Ufa:

Publishing house "Churagul". - P. 263-268.

Galkin, V.V., Petryakov, S.A., Karandayev, A.S.,

Khramshin, V.R. , 2011 .Automatic correction of the

thickness of the head section of the strip in the

hydraulic system of automatic regulation of the

thickness of a broadband hot rolling mill.

IzvestiyaVuzov. Electromechanics. -No. 4. - P. 46-50.

Khramshin, V.R., Automatic correction of strip thickness

during rolling on a wide-band rolling mill / V.R.

Khramshin, S.A. Petryakov // Tinchurin Readings:

Mater. doc. V-th Intern. Mol. scientific-techn. Conf. -

Kazan: KGEU, 2010. - P. 65-66.

Zhang, W., Wang, Y., Sun, M., 2009. Modeling and

simulation of electric hydraulic servo valve control

system for hydraulic bending roll system [J]. China

Mechanical Engineering, 20(3): 345−348 (in Chinese).

Wang, Ch., 2011. Hydraulic control system [M]. Beijing:

China Machine Press, (in Chinese)

Lv, Y., 2007. Modeling in frequency domain for valve

controlled asymmetric hydraulic cylinders [J]. Chinese

Journal of Mechanical Engineering, 43(9): 122−126.

(in Chinese)

Andrew, A., Rui, L. , 2000. Amplified approach to force

control for electro-hydraulic systems [J]. Control

Engineering Practice, 8: 1347−1356.

Zhang, F., Zhang, Y., Hou, J., Wang, B., 2015. Thickness

control strategies of plate rolling mill. International

Nonlinear Model of the Hydraulic Automatic Gauge Control System: Conrollability Analysis and Observability

315

Journal of Innovative Computing, Information and

Control, vol. 11, no. 4, pp. 1227-1237.

Hwang, G., Ahn, H. S., Kim, D. H., Yoon, T. W., Oh,

S.R., Kim, K. B., 1996. Design of a Robust Thickness

Controller for a Single-Stand Cold Rolling Mill,”

IEEE Proceedings of the International Conference on

Control Applications, Dearborn, pp. 468-473.

Kohei O., Toshiyuki O., Kenji F., Akira K., and Makishi

N., 2012. Nonlinear Receding Horizon Control of

Thickness and Tension in a Tandem Cold Mill with a

Variable Rolling Speed. ISIJ International, Vol. 52

(2012), No. 1, pp. 87–95

Ford, H. and D. R. Bland., 1951. Cold Rolling with Strip

Tension,” J. Iron Steel Inst., 5, pp. 57.

Khalil, Hassan K. 2002. Nonlinear Systems (3rd Ed.).

Coll. « Upper saddle River, NJ ». New Jersey:

Prentice Hall, 750 p.

Hermann, R., and Krener, A. "Nonlinear controllability

and observability," in IEEE Transactions on

Automatic Control, vol. 22, no. 5, pp. 728-740,

October 1977.doi: 10.1109/TAC.1977.1101601

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

316