A Some of Paddy Cleaning Machine on Activity Free Float in

Activity- on –Arrow and Node Networks: Part II

S. Bangphan

1

and P.Bangphan

1

1

Department of Industrial Engineering, Faculty of Engineering, Rajamangala University of Technology Lanna

Keywords: Some paddy cleaning machine, activity, project management, activity on arrow (AOA) and activities on the

node (AON), total float, free float

Abstract: This research presents important guidelines for implementing the implementation process. Advantages and

disadvantages of the project implementation. Considering the project as a network, we use CPM techniques

to try to find the critical path of the network, and suggest the best way to supply and manufacture certain

machines. Under these constraints, critical paths that include certain project activities. Means the longest path

(Depending on the duration) of the project and any delays that will occur on this path will lead to delays in

the project. Therefore, critical path analysis is done using the PERT / CPM module. In the project schedule,

the total floats and free floats of activity show agility in scheduling. Activity time without affecting subsequent

activities.

1 INTRODUCTION

1.1 Total Float

Total float is what many of us are aware of, and is

commonly referred to as a float. Total float is the

amount of time an activity can be delayed without

delaying the project completion date. On a critical

path, the total float is zero. Total float is often known

as the slack. (https://pmstudycircle.com)

This research can calculate the total float by

subtracting the Early Start date of an activity from its

Late Start date (Late Start date – Early Start date), or

Early Finish date from its Late Finish date (Late

Finish date – Early Finish date).

(https://pmstudycircle.com)

1.2 Free Float

Now we come to free float. This is going to be a bit

different and might be new to you. Free float is the

amount of time an activity can be delayed without

delaying the Early Start of its successor activity.

We can calculate the free float by subtracting the

Early Finish date of the activity from the Early Start

date of next activity (ES of next Activity – EF of

current Activity).

Keep in mind that if two activities are converging

to a single activity, only one of these two activities

may have free float.

(https://pmstudycircle.com)

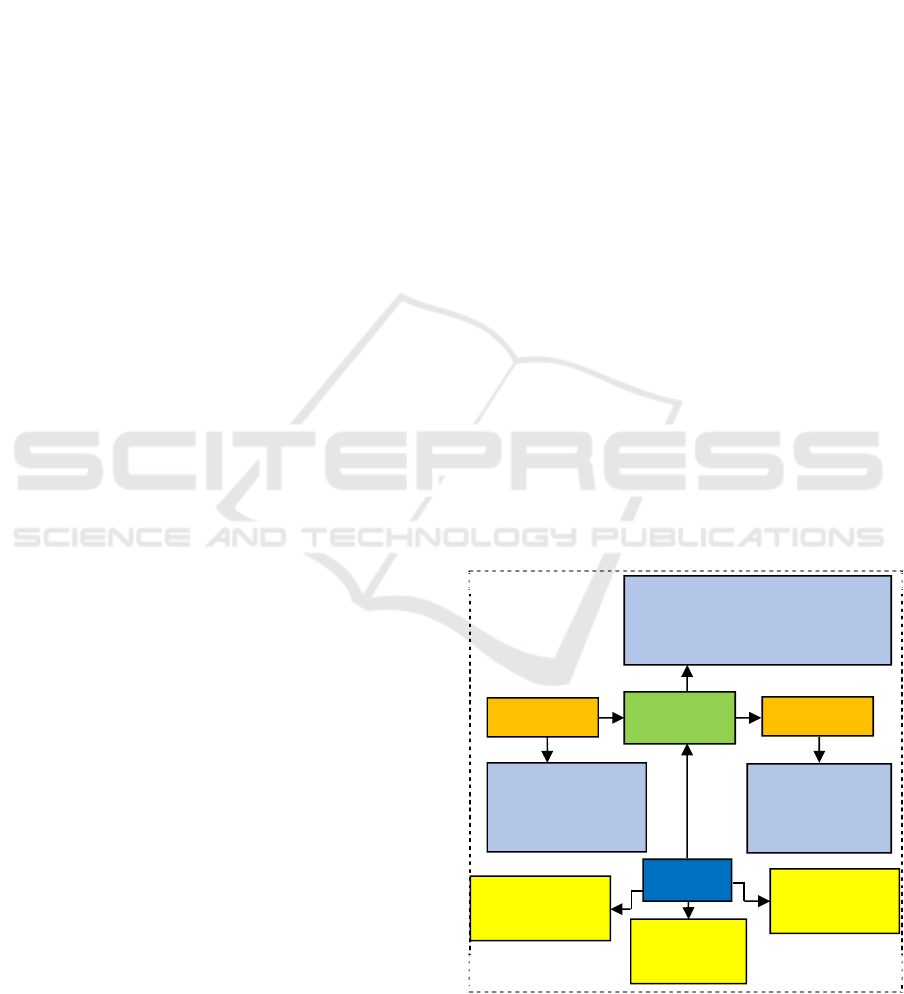

The Figure 1 below shown activity of network

analysis.

Figure 1: Network analysis.

Activity

Analysis

Results

-Relationships

-Duration

-Resource

-ES, EF, LS, LF, FF, TF

- Project Duration

-Critical Path / AOA, AON

-Reduce cost

-Reduce time

-Productivity

Float

Activity

Begin event

Activity

Duration

Activity

End Event

62

Bangphan, S. and Bangphan, P.

A Some of Paddy Cleaning Machine on Activity Free Float in Activity- on –Arrow and Node Networks: Part II.

DOI: 10.5220/0009771100620066

In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), pages 62-66

ISBN: 978-989-758-431-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1.3 Part I Research

Part I research has been conducted in the field of

planning, management and project control. The

project is a rice paddy cleaner of the project using a

network of activities (S. Bangphan, 2018).

This research has been funded by the University

for the Organic Business of 7 types of Organic Brown

Rice. The Network Analysis (CPM / PERT) has been

conducted and has provided the following answers:

• What are the important activities or tasks in the

project that could delay all projects if they are not

completed on time?

• Does the project meet deadlines or do not exceed

deadlines?

• If the project has to be completed earlier than

planned, what is the best way to do this in the least

possible way? (S. Bangphan, 2018)

• Table 1 shows the work breakdown structure and

Table 2 shows the details of the paddy cleaner.

Table 1: Work breakdown structure (W.B.S.) of paddy

cleaning machine.

Activity

code

Activity description

A Frame

B Install wheel base with wheel flange

C Install bearing sets and shaft

D

Install shaft combine with bearing

and pulleys

E Assembly kit one

F Hopper

G Control hopper sets

H Shaft support sets

I Flow controller

J Assembly kit two

K Sieve cleaning sets

L Made shaft of sieve cleaning

M Crankshaft

N Belts

O pulleys

P Assembly kit three

Q Top plate

R Down plate

S Adjust of belts

T Assembly kit four

U all assembly kit and adjust

Table 2: Description of activities paddy cleaning machine

(S. Bangphan, 2018).

Act

code

Activity

description

Immediate

predecessor

Estimate

d

duration

(Day)

Norma

l cost

(Dollar

)

A Frame - 5

115

B

Install

wheel base

with wheel

flange A 3

55

C

Install

bearing sets

and shaft A 2

125

D

Install shaft

combine

with

bearing

and pulleys A 2

135

E

Assembly

kit one B,C,D 3

120

F Hopper E 3

85

G

Control

hopper sets E 2

65

H

Shaft

support sets E 3

35

I

Flow

controller E 2

30

J

Assembly

kit two F,G,H,I 4

85

K

Sieve

cleaning

sets J 2

140

L

Made shaft

of sieve

cleaning J 3

110

M Crankshaft J 3

80

N Belts J 2

100

O pulleys J 2 120

P

Assembly

kit three K,L,M,N,O 3

135

Q Top plate P 1

120

R Down plate P 1

120

S

Adjust of

belts P 2

135

T

Assembly

kit four Q,R,S 4

100

U

all

assembly

kit and

adjust T 5

110

A Some of Paddy Cleaning Machine on Activity Free Float in Activity- on –Arrow and Node Networks: Part II

63

2 MATERIALS AND METHOD

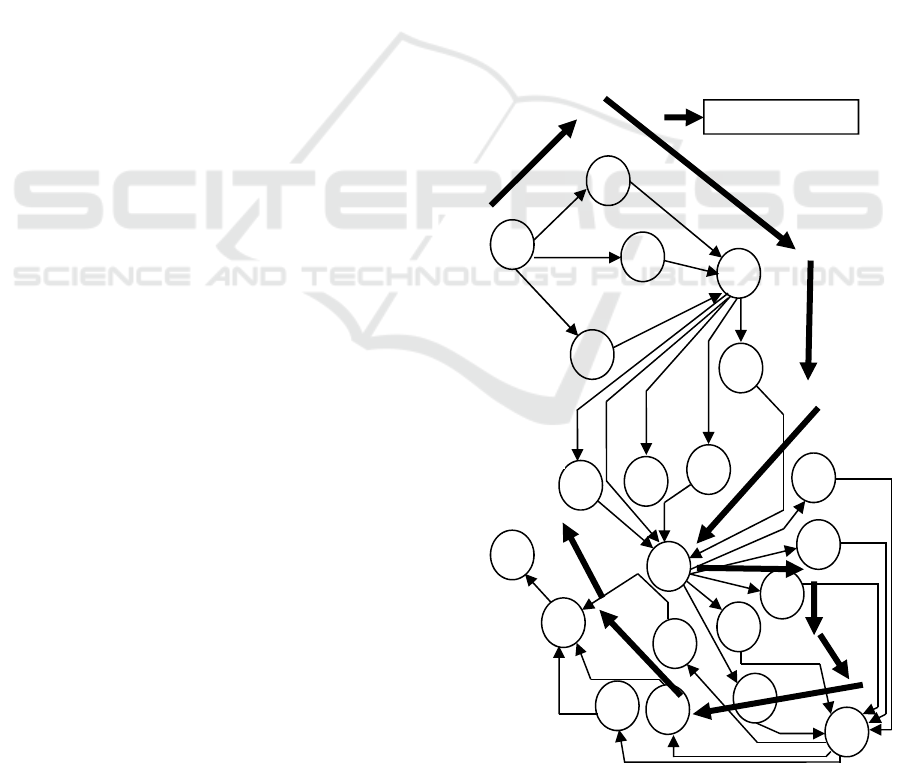

Consider the activity of the project using the

replacement of the AOA network, as shown in Figure

2. This is how the PERT / CPM identifies the critical

path. Each activity with a zero slack center is on an

critical path through the project network, such that

delays along this path will cause the project to delay.

Thus, the critical path is (S. Bangphan, 2018)

The starting and finishing times of each activity

without delay occurring anywhere in the project are

called the earliest start time and the earliest finish

time of activity. This time there are symbols (Scaat,

2009), (Surapong, 2013).

ES = earliest start time for a particular activity,

EF = earliest finish time for a particular activity,

D = (estimated) duration of the activity

Where

EF = ES + D (1)

The latest finish time has the corresponding

definition with respect to finishing the activity. In

symbols,

LS = latest start time for a particular activity,

LF = latest finish time for a particular activity,

Where

LS = LF - D (2)

The slack or total float for an activity is the

difference between its latest finish time and its

earliest finish time. In symbols,

Slack = LF – EF (3)

(Since LF - EF = LS - ES, either difference actually

can be used to calculate slack.)

ABEFJLMPSTU

= 5333433245 = 31 days

Project network has an important path and no plan

in the duplicate diagram. The corresponding AOA

and AON network displays are shown in Figures 2

and 3. The free and floating totals for some activities

are summarized in Table 3.

2.1 Float Calculations

In the Arrow activity network, the computer

calculates the data for both events at the end of the

arrow and the activity itself (arrows). As a result, a

variety of data sets are available to determine:

Free Float: This means all floats that can handle

the activity without affecting the float of the activity.

It can be calculated by subtracting the discount of the

main activity from the total float of the activity.

FF

i

j

= TF

i

j

– (slack of event j) (4)

The float is the maximum time that this activity

can cause a delay in completion before an activity

becomes an important activity, that is, the delay of the

project.

Free float indicates the value at which the

problem activity can be delayed beyond the

beginning, without affecting the fastest start.

2.2 Part II Research

Second Research, It is a study of floating time sums.

And free floating time. The research is part one. Is a

critical path.

.

Figure 2: Network diagram for activities paddy cleaning

machine (S. Bangphan, 2018).

A

5

B

C

D

F

E

2

2

3

3

2

G

3

H

3

I

2

4

J

N

2

L

2

K

3

M

3

O

2

P

3

R

2

S

1

Q

1

U

4

T

5

Critical Path

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

64

Figure 3: Diagram Node for constructs of paddy cleaning

machine (S. Bangphan, 2018).

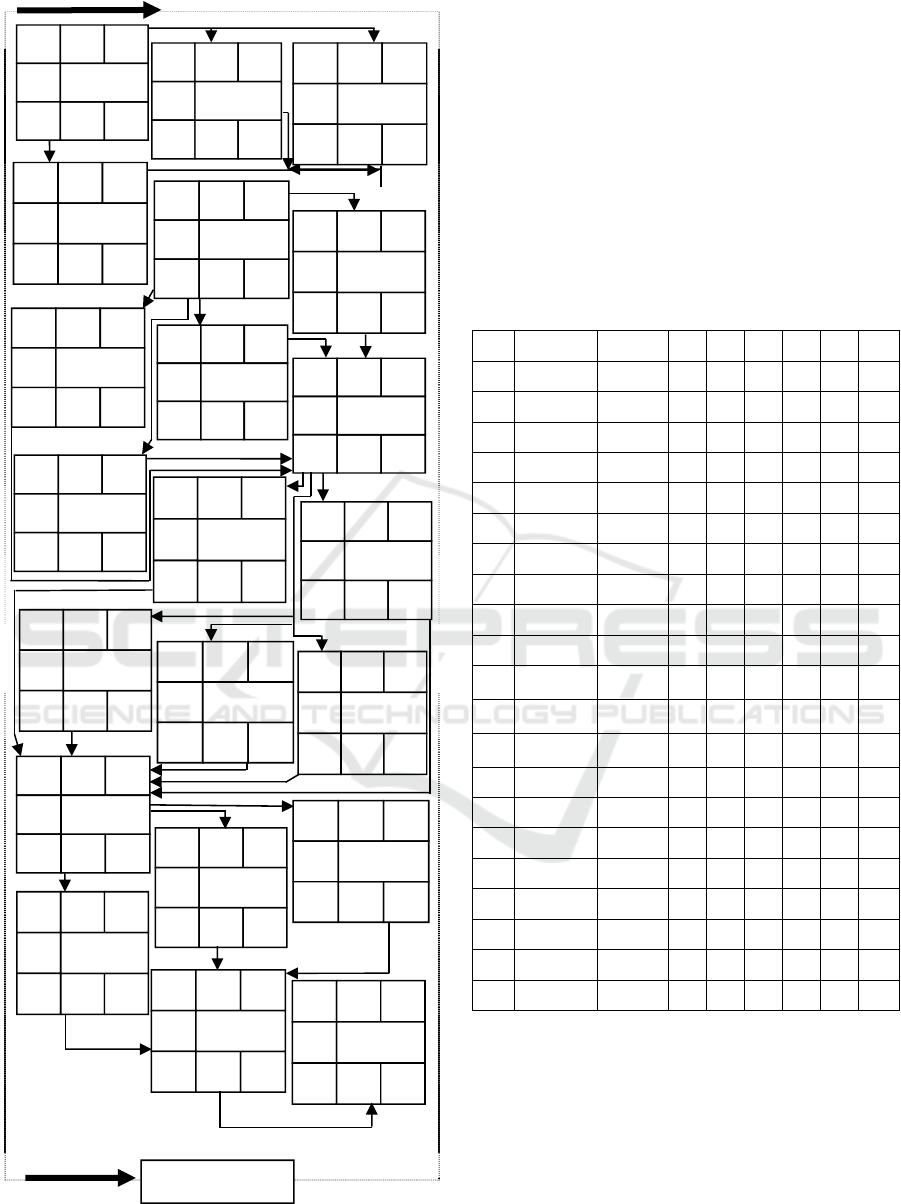

3 IMPLEMENTATION AND

RESULTS

Consider sample projects with AOA networks.

Shown in Figure 2. The project network has an

important path and no plans in the duplicate diagram.

The corresponding AON network representation is

shown in Figure 2. The use of (3), (4) free float for

some activities summarizes the final column in Table

3.

Table 3: Summary of free floats for some activities of the

activity network of project (S. Bangphan, 2018).

Act

Predecessor

s Duration ES EF LS LF SL

FF

A 0 5 0 5 0 5 0

0

B A 3 5 8 5 8 0

0

C A 2 5 7 6 8 1

1

D A 2 5 7 6 8 1

1

E B,C,D 3 8 11 8 11 0

0

F E 3 11 14 11 14 0

0

G E 2 11 13 12 14 1

1

H E 2 11 13 12 14 1

1

I E 2 11 13 12 14 1

1

J F,G,H,I 4 14 18 14 18 0

0

K J 2 18 20 19 21 1

1

L J 3 18 21 18 21 0

0

M J 3 18 21 18 21 0

0

N J 2 18 20 19 21 1

1

O J 2 18 20 19 21 1

1

P K,L,M,N,O 3 21 24 21 24 0

0

Q P 1 24 25 25 26 1

1

R P 1 24 25 25 26 1

0

S p 2 24 26 24 26 0

0

T Q,R,S 4 26 30 26 30 0

0

U T 5 30 35 30 35 0

0

Explanation: Consider activity B. The slack of head

event 5 is 8 – 8 = 0. Therefore, free float = 0 – 0 = 0.

Likewise slack of tail event A is 0 – 0 = 0. Therefore

independent float = 0.

Critical Path: ABEFJLMPSTU

5333433245= 31 days.

The data analysis in Table 3 can be seen as the

date of completion of the activity U. The last activity

of the project should be 35 days, which is equal to the

time it takes to complete the project.

5 B 8

0

5 3 8

Description

Critical path

11 I 13

1

12 2 14

Description

0 A 5

0

0 5 5

Description

5 C 7

1

6 2 8

Description

5 D 7

1

6 2 8

Description

8 E 11

0

8 3 11

Description

11 F 14

0

11 3 14

Description

11 G 13

1

12 2 14

Description

11 H 13

1

12 2 14

Description

14 J 18

0

14 4 18

Description

18 L 21

0

18 3 21

Description

18 M 21

0

18 3 21

Description

18 K 20

1

19 2 21

Description

18 O 20

1

19 2 21

Descript

18 N 20

1

19 2 21

Description

21 P 24

0

21 3 24

Description

24 S 26

0

24 2 26

Description

24 Q 25

1

25 1 26

Description

24 R 25

1

25 1 26

Description

30 U 35

0

30 5 35

Description

26 T 30

0

26 4 30

Description

A Some of Paddy Cleaning Machine on Activity Free Float in Activity- on –Arrow and Node Networks: Part II

65

3.1 Calculated Project Float

Team research requires a 44-day end date. Project

Float is the total length of time a project can be

delayed without delaying the project.

44 days – 35 days = 9 days.

The float may be deleted on a date determined by

the research team prior to the time specified in the

project schedule. Crashed projects need to be

removed or tracked quickly. Crashing is a technique

used to shorten the duration of a project by assigning

additional resources to the task and reducing the time

required for those tasks and details of the components

for the construction paddy cleaning.

4 CONCLUSIONS

This research presents a free float for AOA and AON

diagrams that assign activity to a specific column in a

network diagram, a schedule under a dependency

structure, by examining a selected group or activity

for each change.

May result or improve all the time estimated by

the PERT / CPM method to summarize the paddy

machine production project for 44 days. After

accelerating all the activities that constitute the

critical path, the total project completion time will be

35 days.

The results show that PERT / CPM techniques can

lead to improved time and cost of paddy mill

production projects and application to other industry

and university projects. Increasing number of projects

implemented and leading to increased

competitiveness.

The float of the project shows a decrease in

construction time of 9 days, because it can easily

handle data exchange and sequence planning.

ACKNOWLEDGEMENTS

Financial support “RMUTL Research grants for

agricultural research, such as cutting and packaging,

cold storage, processing and packaging. Research and

development of economic crops. Project Code AG2-

180307163528-60”: Rajamangala University of

Technology Lanna, Chiang Mai is gratefully

acknowledged.

.

REFERENCES

https://pmstudycircle.com/2013/03/total-float- versus-

free-float.

S, Bangphan., P, Bangphan., and S, Phanphet., 2018.

Application of production process for paddy cleaning

machine by using pert & cpm techniques

:case study, The 2018 International Conference

of Computer Science and Renewable Energies,

Ouarzazate, Morocco, 22-24 November 2018.

Scaat., [Internet]., 2009. [cited 2013 July 12]

www.scaat.in.th/Bachelor/new/1_2552/010.

Surapong Bangphan., 2013. Project Management

Engineering, teaching materials, translation and

collection, Chiangmai.

ICCSRE 2018 - International Conference of Computer Science and Renewable Energies

66