Technical Analysis of PVC Pipe Materials for Hull Vessel

Wilma Amiruddin

and Hartono Yudo

Naval Architecture Department, Diponegoro University, Indonesia

Keywords: Strength, Vessel, PVC, Wooden.

Abstract: The use of PVC pipe material as a hull vessel can have a technical and economic influence when compared

to a wooden ship. This study aims to determine the difference in the longitudinal strength of the ship from

of both. It’s based on the maximum stress produced by referring to the BKI Class for Wooden Ship

Regulations. To see the technical benefits due to differences in the use of the material, treatment was given

by setting the same loading capacity (17 GT) for both ships as the dependent variable and the main

principles as the independent variable, PVC ship: Loa = 18.3 m, B = 4, 25 m, H = 0.75 m, T = 0.5 m and

Wooden Ship: Loa = 15 m, B = 5.2 m, H = 1.8 m, T = 1 m. Analysis results is the maximum stress of PVC

fishing boats (σ Deck = 9.714 N/mm2) have a greater than wooden fishing boat (σ Deck = 4.2817 N/mm2).

The difference in strength values can be used as a consideration in deciding the use of PVC material or

wood material.

1 INTRODUCTION

Bamboo rafts as early of the history of shipbuilding

or ships in modern times are now used for certain

conditions in the interior. Along with the

development of technology, in this case pipes made

of PVC (polyvinyl chloride) plastic have made PVC

pipe ships in Taiwan with the same principles as

bamboo rafts. The length of the ship ranges from 30-

40 feet. The ship is used by fishermen to catch fish,

with diesel engine drives. Figure 1 shows examples

of the shape of the pipe profile as intended.

Figure 1: PVC Pipe.

Polyvinyl chloride (PVC) is a pipe made of plastic

and several other vinyl combinations. It is a third-

order thermoplastic polymer in terms of the number

of uses in the world, after polyethylene and

polypropylene. In around the world, more than 50%

of PVC produced is used as construction material.

PVC is relatively inexpensive, durable, and easily

assembled. PVC can be made more elastic and

flexible by adding plasticizers.

In Indonesia traditional ships are generally made

from wood materials, likewise fishing vessels used

by most fishermen. The wood used has certain

requirements both physically (sufficient strength)

and durability (resistant to decay and from wood-

destroying animals). In addition, wood is also old

and long-sized. The problem that arises from the use

of this material is the reduced material stock and

increasingly expensive prices. The growing speed of

wood needed is relatively slow compared to the

consumption of wood material. Logging trees that

are still enough to meet these needs can damage the

environment.

A fishing vessel made from PVC pipe has been

built in a traditional shipyard in Pekalongan. The

construction of this ship is also an alternative to new

wood replacement materials. The use of this new

alternative material requires a research on its

feasibility, both technical and economic. The study

in this paper will provide an analysis of one of the

technical aspects, namely the strength of the length

of the ship.

The maximum flexural stress value obtained

from the use of PVC material as a hull material will

be compared to the strength requirements of wood

material commonly used as raw material for wood

Amiruddin, W. and Yudo, H.

Technical Analysis of PVC Pipe Materials for Hull Vessel.

DOI: 10.5220/0009341902050208

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 205-208

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

205

shipbuilding. The results of the strength analysis

from the use of PVC pipe material will be used as a

material for consideration in the design plan and

PVC shipbuilding in the shipyard.

2 METHOD

2.1 Longitudinal Strength

The purpose of the calculation of longitudinal

strength is to determine the stress experienced by the

ship's body as a unit in the longitudinal direction. It

is caused by the condition where the weight of the

ship at a point along the vessel is not supported by

buoyancy to the same size. If the difference in

longitudinal spread between gravity and

compressive force is greater, the load that works on

the ship is also greater. The longitudinal spread of

the weight of the vessel is determined by the load

state, while the spread of the upward pressure force

is determined by the shape of the submerged part of

the ship and the wave conditions. Generally, the

calculation of longitudinal strength is made based on

the static balance between gravity and buoyancy.

The longitudinal flexure of the vessel is shown in

Figure 2, and the cross section modulus expression

is shown in Figure 3. Based on the description

above, the amount of flexural stress (σ) can be

calculated extending with the concept of technical

mechanics in general, as follows (Eyres, 2001) :

σ=M/I.y (1)

Z=I/y (2)

σ=M/Z (3)

which :

M = longitudinal bending moment.

y = the distance of a point to the neutral axis.

I = moment of inertia cross section of the neutral

axis.

Z = cross section modulus.

Figure 2: Longitudinal bending and vertical force in calm

water conditions (Eyres, 2001).

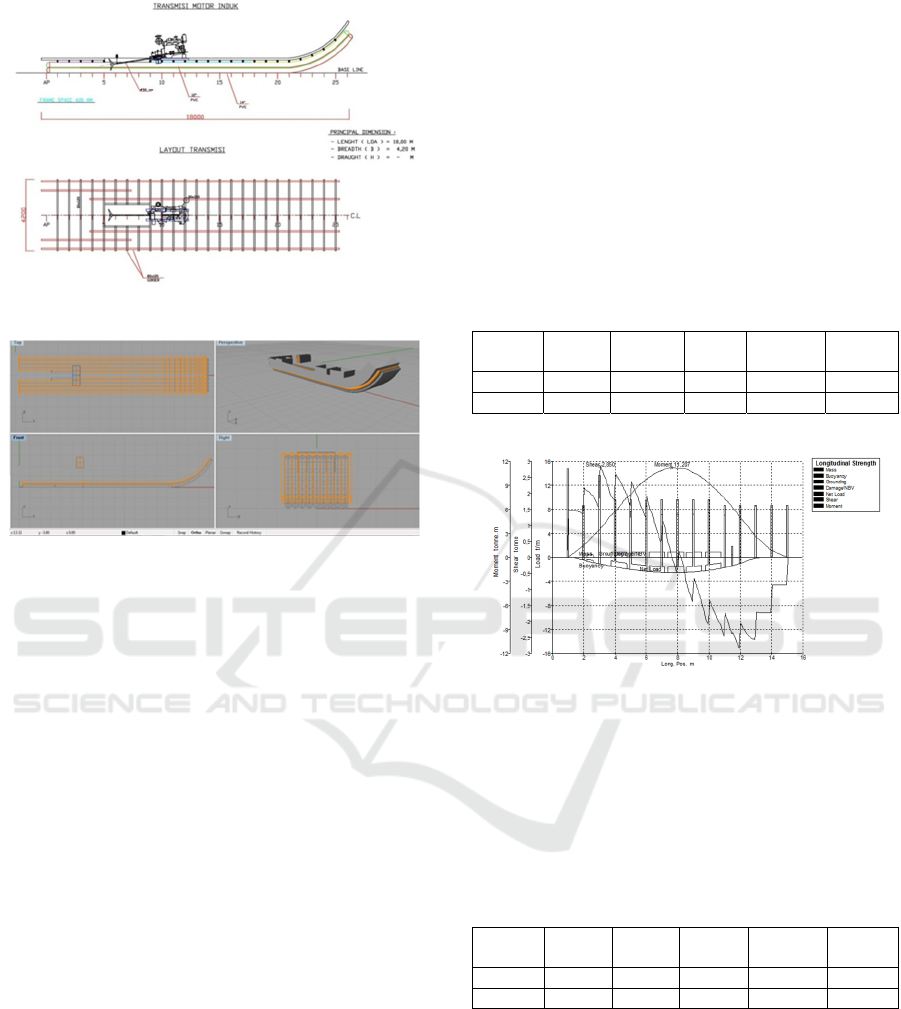

3 PRINCIPLE DIMENSION AND

MODELLING

Traditional fishing boats are built not based on

complete design drawings and technical

specifications. Direct measurement is needed in the

field to get the ship's hull form. Modelling in

Rhinoceros 4.0 Software is done to get the shape of

the ship, after the principle dimension of the ship has

been obtained. The calculation of traditional vessels

with wood material is needed as a comparison to the

results of bending stress analysis of ships with PVC

pipe material.

Principle Dimension of Fishing Vessel with Wooden

Material :

Length (Loa) : 15 m

Breadth (Boa) : 5.2 m

Height (H) : 1.8 m

Depth (T) : 1 m

Long Keel : 11 m

Width Keel : 0.5 m

Thick Keel : 0.5 m

GT : 17 ton

Figure 3: Modelling Traditional Fishing Vessel.

Principle Dimension of Fishing Vessel with PVC

Material:

Length (Loa) : 18.3 m

Breadth (Boa) : 4.5 m

Height (H) : 0.75 m

Depth (T) : 0.5 m

GT : 17 ton

Pipe Diameter : 14 inch (10 units) and 12 inch

(9 units)

Long Pipe : 18.3 m

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

206

Figure 4: Construction Profile of PVC Ship.

Figure 5: Modelling Traditional Fishing Vessel.

4 RESULTS AND DISCUSSION

One of the things that needs to be done with every

application of new material for construction needs is

to look at the safety factor. The safety factor is

needed as a guarantee of safety when construction

has received its maximum load when operated. The

safety factor in question can be measured from the

stress value (σ) that appears. The results of a

construction engineering after the stress value has

been analyzed, can be compared with the material

stress value in question and can also be compared to

the specific values of the other materials. The results

of the analysis will be useful as a basis for deciding

to use a particular type of material.

In connection with the use of wood material for

the construction of a ship's body, it is known that

several types of wood are compatible with certain

parts of the ship. These parts can require different

terms of strength and durability. There are five class

classifications that are related to their density values.

The best classification is at the density value ≥. 0,9

with absolute bending value ≥ 1100 kg / cm2 and the

lowest classification is at density value ≤ 0.3

absolute bending value 360 kg / cm2. Whereas the

best and lowest classification for firm press on the

criteria of the same density value as absolute

strength is ≥ 650 kg / cm2 (best) and ≤ 215 kg / cm2

(lowest) (anonymous, 1996). In its application to a

construction, it must be noted that the stress arising

must not be greater than 40% of the bending stress

of the material and 30% of the tensile stress

(anonymous, 2013).

The results of the calculation of bending stress

on wood-material vessels can be seen in Table 1 and

Figure 6. Based on the criteria set by BKI, the

results of calculations for both the stresses occurring

on the deck and the bottom are relatively safe.

Table 1: Calculation of Bending Voltage for Lengthening

Wooden Ships.

Wooden

Ship

M

(Ton.m)

Ina

(cm

4

)

Y

(cm)

W

(cm

3

)

σ

(kg/cm

2

)

Dec

k

11.207 4043067 157.62 25650.68 43.282

Bottom 11.207 4043067 22.38 180657.4 6.079

Note : H = 180 cm Y(na) = 22,38 cm

Figure 6: Strength chart extends wood-based ships.

The results of the calculation of bending stress

on wood-material vessels can be seen in Table 2 and

Figure 7. Based on the criteria set by BKI, the

results of calculations for both the stresses that occur

on the deck and on the bottom are relatively safe.

Table 2: Calculation of Bending Stress Lengthening PVC

Ships.

Wooden

Ship

M

(Ton.m)

Ina

(cm

4

)

Y

(cm)

W

(cm

3

)

σ

(kg/cm

2

)

Dec

k

8.762 534118 14.58 8839.52 97.14

Bottom 8.762 534118 14.58 36643.52 23.43

Note : H = 75 cm Y(na) = 14,58 cm

Technical Analysis of PVC Pipe Materials for Hull Vessel

207

Figure 7: Chart of Longitudinal Strength of PVC Ship.

If the two results of the calculation of bending stress

from the two types of ships are compared, then the

bending stress of the PVC vessel has a greater value,

or in other words the wooden material vessel has

better strength than the PVC vessel. The difference

is caused by different loading factors carried by each

ship with a factor of different size of profile section

(modulus). The difference in the distribution of

loading causes a difference in moments, as well as

the influence of its layout. The difference in cross

section modulus is due to differences in construction

systems and profile sizes. All of these factors will

determine the value of the longitudinal bending

stress.

Incompatibility in the size of the construction

profile on traditional ships which are generally wood

material is very possible. This is because the

manufacture of the wooden ship is based on

knowledge obtained from generation to generation,

without detailed calculations and design drawings.

A study has been carried out on wooden ships from

the fishing vessel in Gresik. Based on the BKI

reference, several measures of construction that are

appropriate and not appropriate are obtained. This

discrepancy results in a difference in stress values.

The stress that occurs in the construction of fishing

vessel in the field is greater than the stress that

occurs in the construction of fishing vessel, the

calculation of BKI, such as the tension that occurs

on the deck beam, keel, and bow height. While the

tension in ivory and wrangles is smaller than the

BKI calculation stress (Rachman et.al, 2012). Yudo

H & Yoshikawa (2015) were obtained the maximum

bending moment for pipe under bending load shown

in equation:

Mmax= 0.52MCR1 = 0.314πErt2 (4)

So, by entering the pipe data will be obtained the

maximum moment that can be received by the PVC

Ship.

Mmax = ( 7,01.105 + 5,4.105) N m

= 1,241.106 Nm

The maximum moment we get from PVC pipe data

is D = 14 "as many as 10 pieces and D = 12" as

many as 9 pieces with pipe thickness each t = 10

mm.

For maximum moments in hogging and sagging

conditions of PVC ships, the maximum moment that

occurs is equal to 8.8.104 Nm. So the safety factor is

14.

5 CONCLUSION

The results of longitudinal bending stress analysis

that occur from the use of two different materials,

namely wood and PVC material, as a shipboard

material, are obtained:

a. Referring to the strong standard size of

materials from BKI, all stresses arising from

calculation results are below the material stress

value set by BKI..

b. The longitudinal bending stress resulting from

the calculation shows the stress of the PVC

vessel is greater than the stress that arises on

the wooden ship, thus the wooden vessel has a

better level of security than PVC ships.

c. PVC pipes can be used as ship hulls, by

arranging pipes. Lengthening strength depends

on how many pipes are arranged on the hull

REFERENCES

Anonymous, 1996, Buku Peraturan Klasifikasi dan

Konstruksi Kapal Laut (Peraturan Kapal Kayu), Biro

Klasifikasi Indonesia, Jakarta.

Anonymous, 2013, Rules for Small Vessels up to 24 m,

BKI Vol VII , Jakarta.

Eyres, DJ. 2001, Ship Construction, Butterworth

Heinemann, Oxford.

Rachman, M. Abdur. Misbah Nurul, Wartono Mahardjo,

2012, Kesesuaian Ukuran Konstruksi Kapal Kayu

Nelayan Di Pelabuhan Nelayan (Pn) Gresik

Menggunakan Aturan Biro Klasifikasi Indonesia

(BKI), JURNAL TEKNIK POMITS Vol. 1, No. 1, 1-

4

Yudo H & Yoshikawa, 2015, Buckling phenomenon for

straight and curved pipe under pure bending , Journal

of Marine Science and Technology, Vol 20, Issue 1,

pp 94–103.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

208