Computational Fluid Dynamic Simulation of Clearance Effect and

Velocity in Liquid Mixing System

Bayu Triwibowo

1

, Astrilia Damayanti

1

, Anwaruddin Hisyam

2

,

Dessy Ratna Puspita

1

, Dwiana Asmara

Putri

1

1

Department of Chemical Engineering,Universitas Negeri Semarang,Semarang, Indonesia

KampusUNNES Sekaran Gunungpati, Semarang 50229, Indonesia

2

Faculty of Chemical and Natural Resources Engineering, Universiti Malaysia Pahang, Lebuhraya Tun Razak,

26300, Kuantan, Pahang Darul Makmur, Malaysia

Keywords: Stirred Tank , CFD, MRF, LES, axial pressure.

Abstract: Stirred tank is one of the most important process-support tools in the industrial world, either in the food,

pharmaceutical, oil or gas industries. The stirring process in a stirred tank involves miscible liquid stirring,

gas dispersion or immiscible liquid into the liquid phase, suspension of solid particles, heat and mass

transfer and chemical reactions. This research aims to study the characteristic of the stirring process by

simulating the stir-equipped tank with water fluid that will be validated by experimentation that has been

done. The stirring process is done by simulating computational fluid dynamics (CFD) using multiple

reference frame (MRF) simulation method, modeling large eddy simulation (LES) flow turbulence and

stirring speed variable. The stages in the simulation of the stirring process include pre-process, solving and

post process. The simulation results have been validated by experiments conducted by Ivan Fort et al. The

erosion at the bottom of the tank is predicted by observing the axial pressure distribution shown by the

observation point..

1 INTRODUCTION

Stirred tanks are widely used for mixing of two

miscible fluids in the chemical, food and process

industries (Zadghaffari et al, 2008). In the various

applications, stirred tanks are required to fulfill

several needs like suspension of solid particles,

dispersion of gases into liquids, heat and mass

transfer, etc.

Agitation of solid-liquid system will caused

erosion in apparatus wall stirred tank. Erosion on

solid-liquid system have been studied by researcher

such as CFD simulation and experimental analysis

of erosion in a slurry tank test rig (Azimian and

Bart, 2013) dan Slurry Erosion in Complex Flows :

Experiment and CFD (Graham, Lester & Wu, 2009).

Azimian et al (2013) have reported that hydro-

erosion occurs in practice in two ways, one is the

erosion by cavitations of liquid and on the other

hand is the erosion by solid particles entrained in

liquid flow known as slurry erosion.

Erosion rate is generally considered as the main

function of influence particle rate, velocity and

impact angle, so that the distribution of erosion rate

depend on those factor. If the erosion is not equally

distributed may cause tools damages. The uniform

distribution will be achieved if the characteristic of

erosion rate for geometrical agitated tank

modification has known as a basic of engineering

technology (Graham et al, 2009). The rate of erosion

distribution can be determined from erosion model,

which can be a very useful tool for prediction..

Computational modeling has always been

presented as an option for the hydrodynamic

analysis of such systems as it is far inexpensive and

enables the study of detailed description of

multiphase flow. CFD modelling, however, can only

be applied after proper validation (Wadnerkar et al.,

430

Triwibowo, B., Damayanti, A., Hisyam, A., Puspita, D. and Putri, D.

Computational Fluid Dynamic Simulation of Clearance Effect and Velocity in Liquid Mixing System.

DOI: 10.5220/0009012604300434

In Proceedings of the 7th Engineering Inter national Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 430-434

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2012). Therefore, CFD can be used to achieve

characteristic of axial pressure distribution at stirred

tank wall to predict the erosion rate. In an attempt to

find a suitable computation technique for the

hydrodynamics simulations, Fradette et al. (2007)

assessed the accuracy of Shear-Induced Migration

Model (SIMM) to capture the particle suspending

phenomenon and particle migration in solid-liquid.

Fort et al (2009) studied about the distribution of the

local dynamic axial pressures along the flat bottom

of a pilot plant cylindrical mixing vessel equipped

with four radial baffles and stirred with a four 45°

pitched blade impeller pumping downwards. A set

of pressure transducers is located along the whole

radius of the flat bottom between two adjacent

baffles. The radial distribution of the dynamic

pressures indicated by the pressure transducers will

be determined in dependence on the impeller off-

bottom clearance and the impeller speed.

2 EXPERIMENTAL METHOD

This research simulated mixing of liquid system in

stirred tank conducted from an experiment by Fort et

al. (2009) with pitched blade turbine. Simulations

carried out by ANSYS academic license which the

method uses Large Eddy Simulation (LES) and

Multiple Reference Frames (MRF) to describe

turbulence flow in a stirred tank

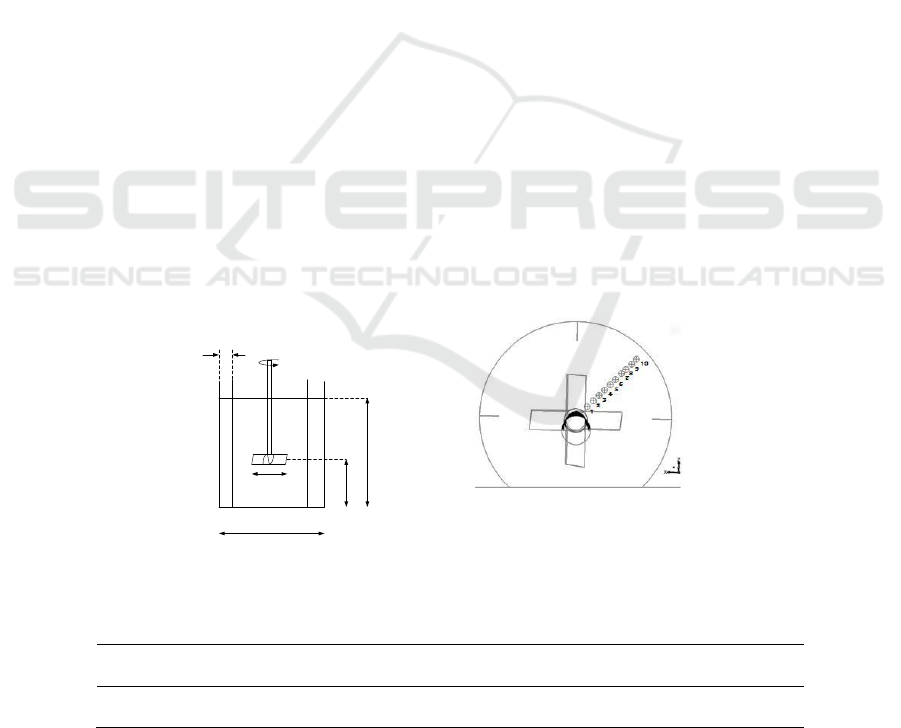

The experiment uses a stirred tank fullgrid 3-D

(360

o

) to get a flow pattern that approaches the

actual conditions. The mixing simulation were

conducted in a flat bottomed cylinder stirred vessel

with inner diameter T= 0.49 m, agitated by a 4-blade

45

o

pitched blade turbine (PBT) of diameter

D=(2/5)T. This vessel is equipped with four radial

baffles (b = 0.1 T), as illustrated in Figure 1 and

Table 1. The height of liquid was set at H=T and

impeller off-bottom clearance were T/4 and T/3 with

rotational speed 284 and 412 rpm. Materials used in

the simulation of liquid system is water with room

temperature. In this research to observe the axial

pressure distribution at the bottom of the stirred

tank, 10 observation points need to be made, as

illustrated in Figure 2. The figure is adapted from

Fort et al (2009) with configuration and point

distance shown in Table 2.

(a) (b)

Figure 1: (a) Configuration Tank, (b) Bottom View of Observation Point.

Table 1: Configuration Tank.

Tank

Diameter

Impeller

Diameter

Baffle

(B

w

)

Liquid Height (H)

Lebar

blade (W

b

)

Tinggi

hub

0.49 m

0.5 T

0.1 T

H=T

0.1 T

0.11 T

D

Bw

C

H

T

Computational Fluid Dynamic Simulation of Clearance Effect and Velocity in Liquid Mixing System

431

Table 2: Distance of Each Point in Bottom Vesel.

3 RESULT AND DISCUSSION

Flow Pattern

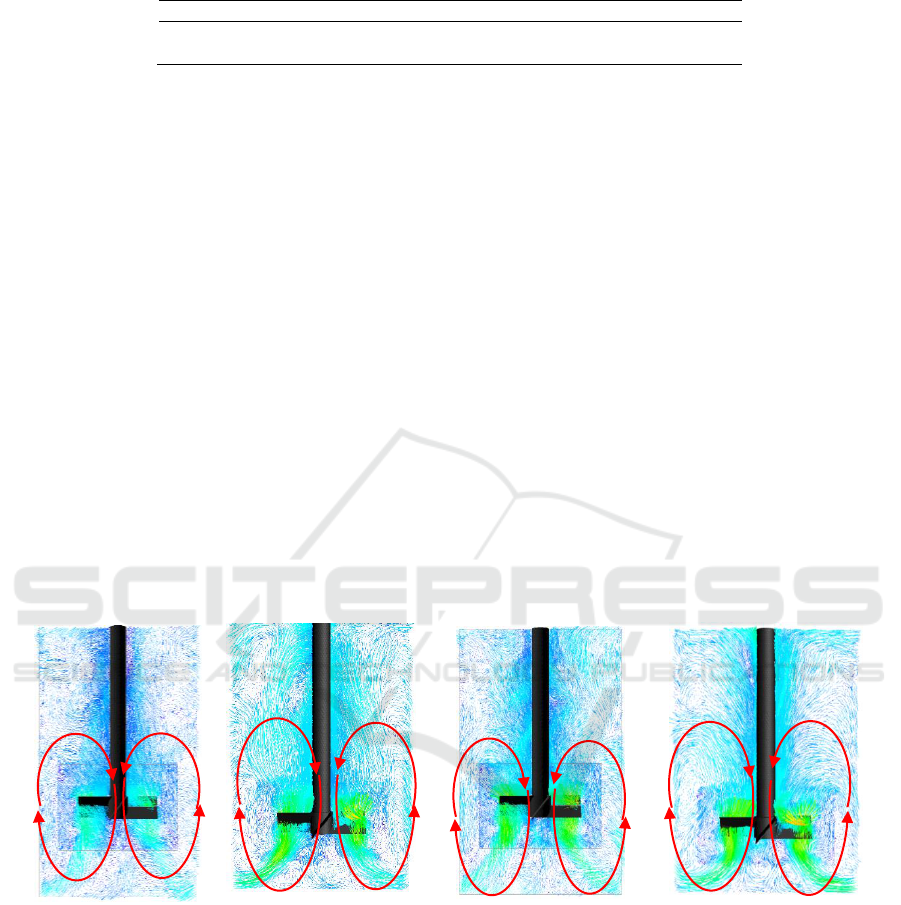

Flow patterns distribution in a stirred tank are very

important to know the circulation flow during the

mixing process which will leads to an impact on

mixing optimization. Observation of the flow pattern

distribution is done by observing the flow direction

that occurs during the mixing process produced by

impeller. Simulated vector plots of the flow

produced by the PBT using MFR and LES models

are presented in Figures 3. Figure 2. shows the

velocity vector due to flow turbulence that occurs

during the mixing process because of the friction

between the fluid and the tank wall. Variation of

rotational speed affects the vector velocity produced.

The high rotational speed and the longer mixing

time would increase turbulance flow.

Based on Figure 2 also shows that the flow

pattern generated from the simulation is in

accordance with the flow pattern of the literature

(Wallas, 1990). However, for hydrodynamic fluid

with various of Clearance has slightly different flow

pattern (Mukhaimin et al., 2016). Clearance of T/4

can reach a maximum speed in the area of the tank

that makes liquid easier to elevate from the bottom

of the tank than T/3.

Axial Pressure Distribution

At the beginning, it is necessary to check the validity

of the CFD code and the numerical method

performed. In order to achieve the objective, we

refer to the experimental work presented by Fort et

al. [2].With the same geometry (i.e. a baffled

cylindrical vessel with a flat bottom), variations of

the axial pressure along the vessel bottom are

predicted and presented on Figure 3 and Figure 4.

For purpose of validation, simulation results have

been compared to experimental data for different

clearance and rotational speed in the tank that shown

below.

(a) (b) (c) (d)

Figure 2: Flow Pattern (a) 284 rpm at Clearance T/3 (b) 284 rpm at Clearance T/4 (c) 412 rpm at Clearance T/3 (d) 412

rpm at Clearance T/4.

Point

1

2

3

4

5

6

7

8

9

10

Distanc

e (cm)

4

6.2

8.2

10.2

12.2

14

16.2

17.7

19.7

21.5

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

432

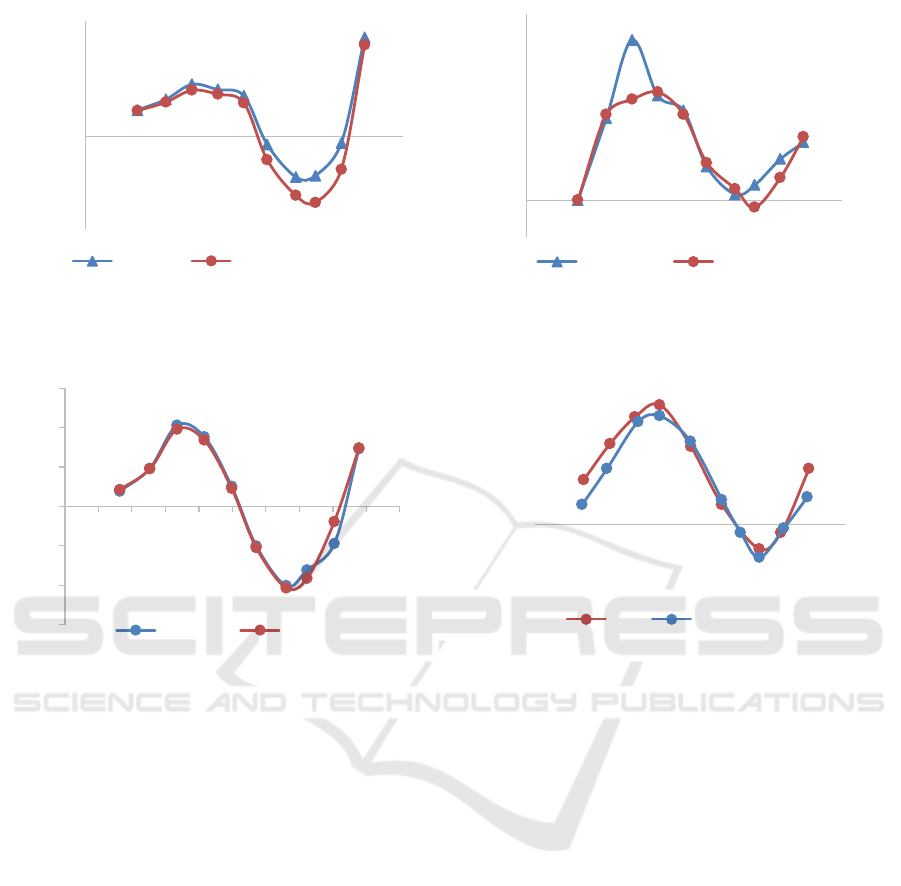

(a) (b)

Figure 3: Data Axial Pressure Distribution at Clearance T/3 (a) Simulation Data (b) Experimental Data.

(a) (b)

Figure 4: Data Axial Pressure Distribution at Clearance T/4 (a) Simualtion Data (b) Experimental Data.

Figure 3. shows data of axial pressure

distribution at clearance T/3, the simulation data

showed that at R 0.57 to 0.8 axial pressure to Y

negative axis direction in both impeller speed, where

point at Y negative axis direction indicates an

erosion. At impeller speed 412 rpm given axial

pressure to Y negative axis direction bigger than

impeller speed 284 rpm. Meanwhile, the experiment

data shows that at impeller speed 284 rpm doesn’t

show any axial pressure to Y negative axis direction

but have trend close to y negative axis direction

between R 0.6 to 0.7, but impeller speed 412 rpm

showed one point to Y negative axis direction at R

0.7. Based on the results, by increasing the impeller

rotational, the speed of the turbulence flow and axial

pressure distribution increases.

Figure 4. shows data of axial pressure

distribution at clearance T/4 for simulation and

experiment data. Simulation data shows that both

impeller have 4 point at R 0.57 to 0.8 where axial

pressure distribution to Y negative axis direction and

experimental data shows 3 point at R 0.6 to 0.8 of

axial pressure distribution to y negative axis

direction. Those point to Y negative axis direction

shows that axial pressure distribution suppress to the

vessel bottom and indicate erosion point. Triwibowo

et al (2017) showed its all caused turbulence flow at

stirred tank of static pressure in wall tank have

sthocastic direction.

Based on Figure 3 and Figure 4, axial pressure

distribution data of simulation data and experimental

data shows good agreement. Meanwhile, trend

simulation data of axial pressure distribution at

clearance T/4 result is much more similar to the

experimental data rather than clearance T/3. The

difference values between simulation data and

experiment data result motivated us to improve the

utilizations of CFD model. Some factors that were

assumed in present calculation must be corrected in

future study include time step size, number of

iterations etc.

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Pax

R

284 rpm 412 rpm

-0.01

0

0.01

0.02

0.03

0.04

0.05

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Pax

R

284 rpm 412 rpm

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Pax

R

412 rpm 284 rpm

-0.03

-0.01

0.01

0.03

0.05

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Pax

R

284 412

Computational Fluid Dynamic Simulation of Clearance Effect and Velocity in Liquid Mixing System

433

4 CONCLUSION

The models of simulation using MRF and LES used

in the present CFD simulation demonstrated an

alternative method for experimental method. The

effect of clearance showed that clearance T/4 can

reach a maximum speed which allow the liquid to

elevate much more easier from the bottom of the

tank, compare to T/3. Besides that, simulation data

of axial pressure distribution at clerance T/4 closer

to experiment data. Reasonable agreement between

experimental and simulation results was obtained.

The satisfactory comparisons indicate the potential

usefulness of this CFD approach as a computational

tool for designing stirred tank.

REFERENCES

Azimian, M & Bart, H., 2013. “CFD Simulation and

Experimental Analysis of Erosion in a Slurry

Tank Test”, EPJ Web of Conferences, Vol. 45,

pp. 1-8.

Fort, I., Hasal, P., Apglianti, A., & F. Magelli.

2009. “Axial Force at the Vessel Bottom

Induced by Axial Impellers”. Acta Polytechnica.

Vol. 48, No. 4, pp. 45-50.

Fradette, L., Thome, G, Tanguy, P.A., & Takenaka,

K.., 2007. “Power and Mixing Time Study

Involving a Maxblend Impeller with Viscous

Newtonian and Non-Newtonian Fluids”. Journal

of Chemical Engineering Research and Design,

Vol. 85, pp. 1514-1523.

Graham, L.J.W., Lester, D., & Wu, J., 2009. “Slurry

Erosion in Complex Flows: Experiment and

CFD. Seventh International Conference on CFD

in the Minerals and Process Industries CSIRO,

Melbourne, Australia 9-11 December 2009.

Triwibowo, B, Megawati, Puspita, D.R., & Putri, D.

A., 2017. “Simulasi Distribusi Shear Stress pada

Dasar Tangki Sistem Pengadukan Berbasis

Computational Fluid Dynamics (CFD)”. Jurnal

Kompetensi Teknik, Vol 9, pp. 20-28.

Wadnerkar, D., Utikar, R., Tade, M., and Pareek, V.

2012. “Simulation of solid-liquid flow in stirred

tanks at high solid loading, in Solnordal, C.B. et

al (ed), Ninth International Conference on CFD

in the Minerals and Process Industries, Dec 10-

12 2012, pp. 1-7. CSIRO, Melbourne: CSIRO.

Zadghaffari, R., Moghaddas, J.S., Ahmadlouydarab,

M., & Revstedt, J., 2009. “A mixing study in a

double-Rushton stirred tank”. Computers &

Chemical Engineering, Vol. 33, Issue 7, pp.

1240-1246.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

434