Comparison of Control Simulation on Cornstarch Dryer using

Mamdani and Sugeno Fuzzy Logic

Ulfah Mediaty Arief

1

, Dyah Nurani Setyaningsih

2

, Sugeng Purbawanto

1

, and Adi Setiawan

1

1

Electrical Engineering, Engineering Faculty, Universitas Negeri Semarang, Indonesia

2

Family Welfare Education, Engineering Faculty, Universitas Negeri Semarang, Indonesia

setiawanadi64@gmail.com

Keywords: Cornstarch, Dryer, Fuzzy Logic

Abstract: Corn is an important commodity for Indonesia. According to BPS data, Indonesia's maize production

increased by 2.81% annually. The abundance of corn productivity was making Techno Park Grobogan

innovated corn noodle. However, cornstarch is long dried and requires a lot of power to make its own loss in

this business. Fuzzy logic is one of the control algorithms that can streamline the working of the tool. The

weakness of previous researchs were using triangle membership function in the form. The purpose of this

study to applied a trapezoid-triangle membership function on the fuzzy logic simulation of Mamdani and

Sugeno method then comparing them in. The design of device to be simulated consists of input temperature

and humidity and the regulated output is heater, heat blower, and moisture blower. The simulation results

showed the Mamdani method is more efficient in using heat and power. While the mamdani method is

efficient in the dissemination of heat and time used.

1 INTRODUCTION

Several innovations to increase the selling value of

corn have been done. An innovation well developed

that is making corn noodles from Grobogan Techno

Park (Pusat Teknologi Agroteknologi. 2017). Corn

has the greatest carbohydrate content number 2 after

rice that is equal to 73,4% (Masniah and

Syamsuddin. 2013). Making corn noodle can not be

separated from the main ingredient that is corn flour.

The better the corn flour used is the better quality

corn noodles. The quality of corn flour based on

Indonesian National Standard (01-3727-1995) has a

smell, taste, and normal color with a maximum

water content of 10% (Badan Pengkajian and

Pengembangan Kebijakan Perdagang. 2016). Good

dried corn flour is used with moisture content of 14-

18% (Resmisari, 2014) (Wylis, et al. 2014). Good

flour is obtained through temperature and humidity

settings to avoid browning in the drying process.

Temperature required 50-55 ° C with 50% humidity

(Sacchetti, G., et al. 2004) (Ahmed, et. al. 2010).

This research purposed to simulate the efficient

control of efficient corn flour automatic control

system. In previous flour-drying innovations like,

cabinet dryer, rack dryer, and the latest is the rotary

dryer (Mentari, 2015). However, the control system

used has not been optimally consequently making

the drying time to be long, and the power used is

large. This research use fuzzy logic control method.

Fuzzy logic control has advantages over other

frequently used control methods such as

Proportional Integral Derivative (PID) and Artificial

Neural Network (ANN). Fuzzy control is more

robust than PID controllers, since fuzzy controls

cover a wider area of operation than a PID

controller. Fuzzy can worked with many disturbing

environments(Arief, et. al. 2015). The study was

conducted by comparing the simulation of Mamdani

fuzzy method with Sugeno method.

Fuzzy Logic Research is widely used in the field

of automatic control. Several studies on control

systems have developed fuzzy logic of temperature

and humidity in the dryer. Research conducted

(Benvenga, et al. 2010) showed good drying results

with a temperature of 54 ° C and humidity of 43%.

Arief, U., Setyaningsih, D., Purbawanto, S. and Setiawan, A.

Comparison of Control Simulation on Cornstarch Dryer using Mamdani and Sugeno Fuzzy Logic.

DOI: 10.5220/0009009602670272

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 267-272

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

267

Fuzzy logic has high experimental and predictive

values, so it is effective for designing and building a

control system on the dryer (Farzaneh, et al. 2016)

(Al-Mahasneh, et al. 2016). Other research got good

results after applying fuzzy logic to the dryer system

(Nugroho, et al. 2017) (Kumar, et. al., 2013)

(Mansor, H., et al. 2010). The research is still use the

triangle membership function. The model has its

weaknesses, namely the integral squared error is

quite high, as a result the time to reach the setpoint

is long enough (Suratno, et al. 2011).

This research was carried out innovation on

member function form and treatment of output

control on rule base. The member function used is

trapezoid-triangular. Member functions from one

input and another input also have the same form.

This study uses a combination of member function

forms between triangles and trapezoidal. The

combination of membership functions in the form of

a trapezoid and a triangle is the best form

combination (Barua, et al. 2007) (Coupland, 2007)

(Butt, et al. 2004) (Zhao, et al. 2002). The

combination of trapezoid and triangle gives fuzzy

variables with sharp input. This combination shows

the difference between the linguistic set points. The

combination expresses the signal measured by the

sensor properly

2 METHOD

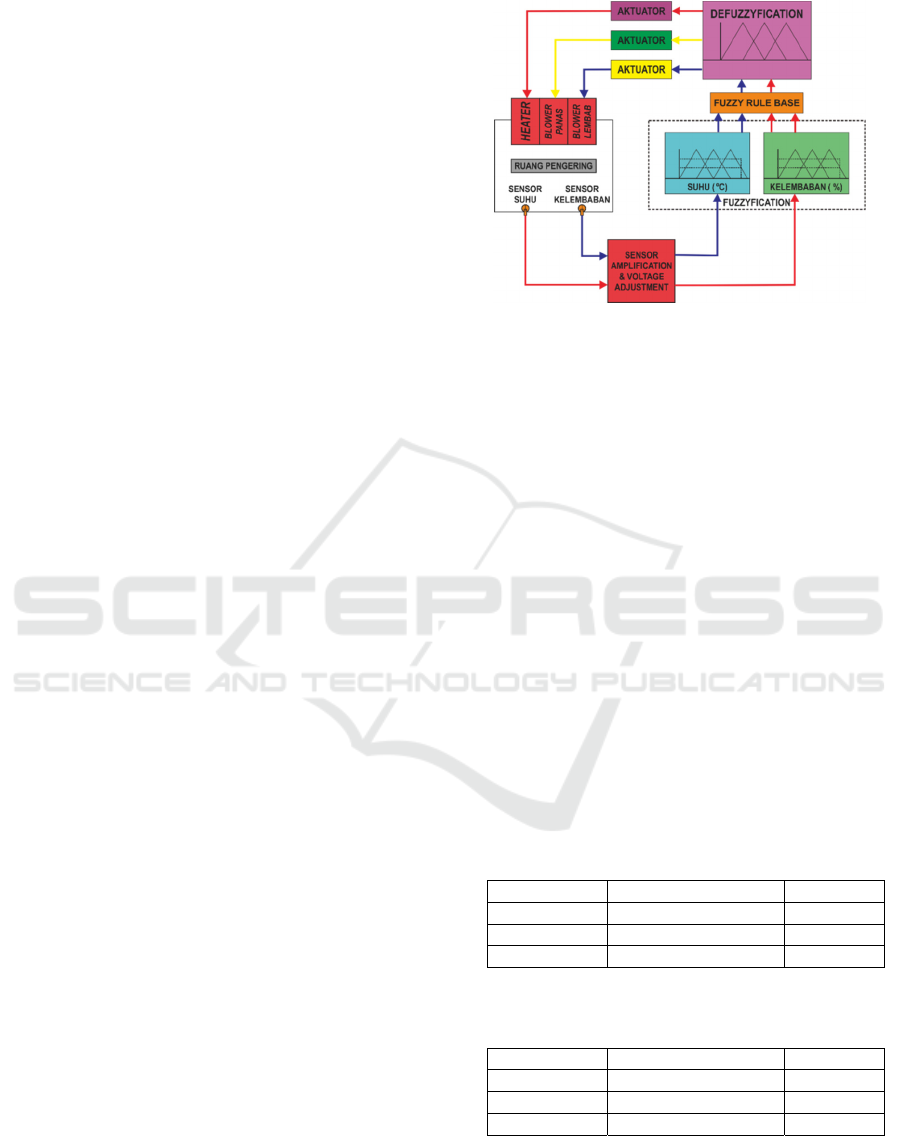

2.1 Basic Stucture of Product

The basic structure of the design of the device to be

simulated consists of heater, and 2 blowers with

fuzzy logic control. A good algorithm control is

created through an overview of the system to be

controlled. The system is designed with 2 inputs of

the DHT 22 sensor form temperature and humidity.

The DHT 22 sensor will detected the temperature

and humidity present in the drying chamber. The

input is processed by microcontoler Atmega328

using fuzzy logic. The output of a microcontroller is

a PWM signal to regulated the output of this system.

The heater in this scheme serves as a drying

temperature controller. The temperature in the space

will be propagated by the hot wind blower. While

the other blower serves to provide a moist air flow

from outside the dryer room.

Figure 1: Dryer Block diagram.

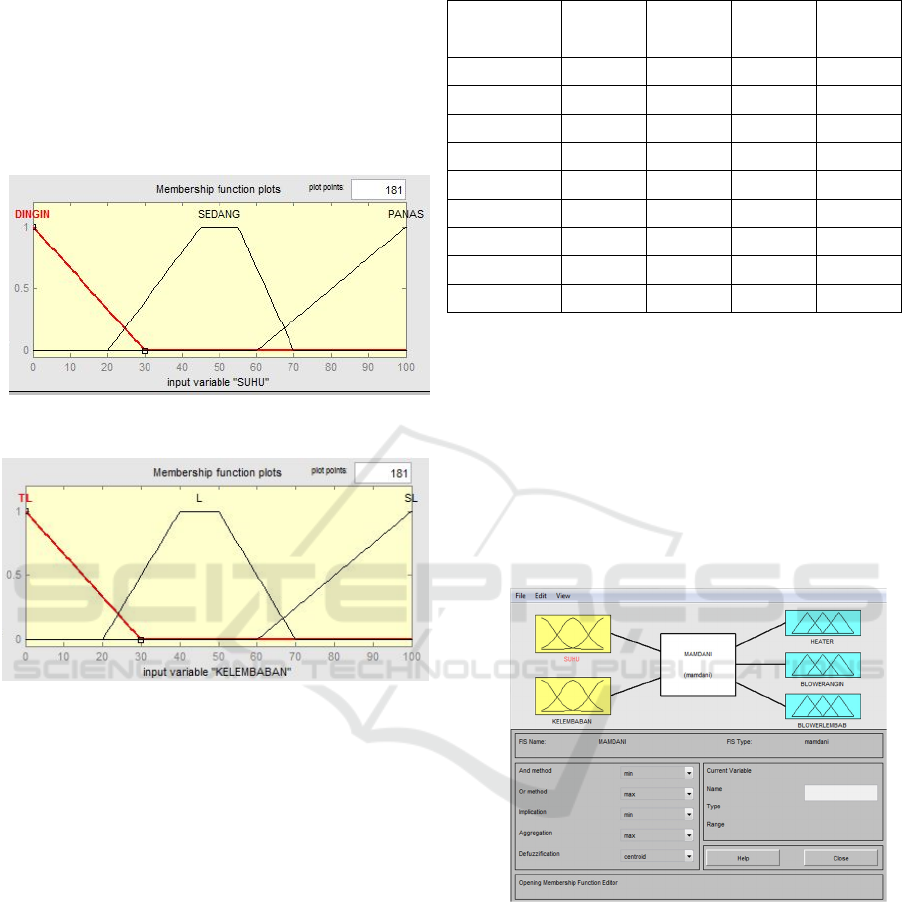

2.2 Design of Fuzzy Logic Algorithm

The test is performed by performing a

comparison analysis of fuzzy logic control

simulation of Mamdani and Sugeno method using

Matlab application. Fuzzy logic itself consists of 4

stages that is, Fuzzifier, Rules, Inference, dan

Deffuzifier (Khaur, et al. 2012) (Singhala, et al.

2014)(Chaudhari, et al 2014). The input of DHT22

sensor will be used to design the fuzzifier, inferences

engine, Rule Base, then in the defuzzifier to achieve

the quality and quantity on the machine used

(Abbas, et al 2011).. This work design using

trapezoidal membership function for input

temperature with a range of 0 ° C-100 ° C. While the

input humidity has a membership function in the

form of a triangle with a range of 0% -100%. Every

input is grouped into three conditions as in Table 1

for temperature and Table 2 for humidity.

Table 1: Temperature Membership Group

Specification Fuzzy Level

Index

0-30 Dingin

D

20-70 Sedang

S

60-100 Panas

P

Table 2: Moisture Membership Group

Specification Fuzzy Level

Index

0-30 Tidak Lembab

TL

20-70 Lembab

L

60-100 Sangat Lembab

SL

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

268

Each input variable has three membership

functions can be seen in Figure 2a and Figure 2b.

The temperature membership function consists of,

“dingin”, “sedang”, dan “panas”. As for the

membership function of humidity consists of, “tidak

lembab”, “lembab”, dan “sangat lembab”

(a)

(b)

Figure 2: Plot of Membership Function (a) The

Temperature Variable, (b) The Humidity Variable.

The input is then received by the machine

inference with the AND logic operator. After that,

input will processed microcontroller using fuzzy

logic rule base. The number of Rules Base of the

system can be searched by the formula m^n, with m

= the maximum number of members is 3. While n =

the number of inputs that is 2. So, the number of rule

base used a number of 9 rules. The details are as

follows:

Table 3: Rule Base Of Control Fuzzy Logic.

Tempera-

ture

Humi-

dity

Heater Blower

1

Blower

2

Dingin TL P K1 SP2

Dingin TL P K1 P2

Dingin TL P K1 K2

Sedang L H P1 SP2

Sedang L H P1 P2

Sedang L H P1 K2

Panas SL M SP1 SP2

Panas SL M SP1 P2

Panas SL M SP1 K2

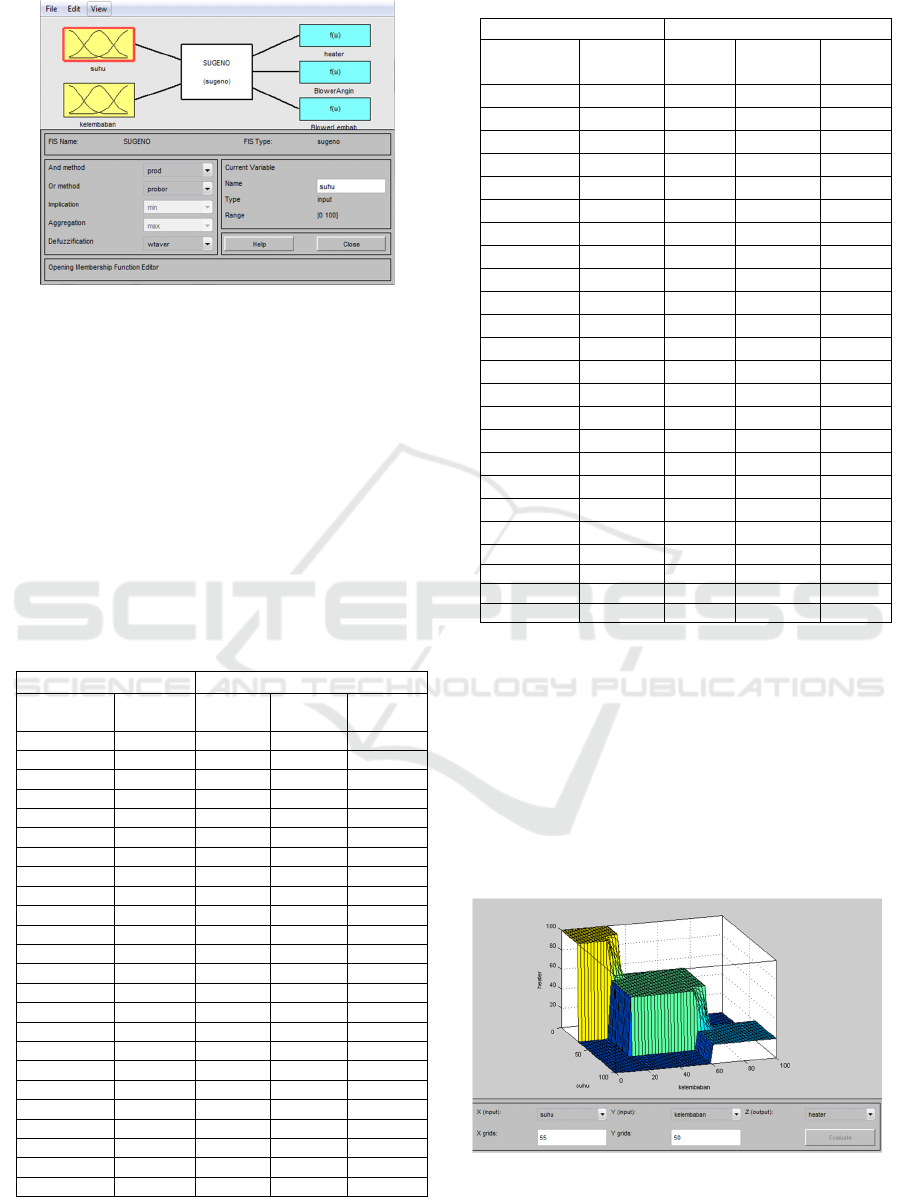

3 RESULT AND DISCUSSION

The result of simulation test is done using Matlab

(Matrix Laboratory) R2014a application. Matlab has

ability to simulate various mathematical

calculations. This test phase uses two methods of

fuzzy logic namely Mamdani, and Sugeno. The test

is done by setting the system input. Each method

will be compared to the simulation result.

(a)

Comparison of Control Simulation on Cornstarch Dryer using Mamdani and Sugeno Fuzzy Logic

269

(b)

Figure 3: Display Logic Fuzzy (A) Mamdani Method, (B)

Method Sugeno.

Each fuzzy method in this test will see the output

response generated. Each method is given input,

form member function, and same rule base. So, we

can see the difference of working system by them.

The defuzzification process of Mamdani method

using centroid method. While, Sugeno method using

wtaver method. After going through the

defuzzification stage will be known output

produced.

The following is the comparative test result:

Table 4: Simulation Result Of Mamdani Method.

Dry Room Fuzzy Output

Tempera-

ture

Humi-

dity

Heater Warm

Blower

Moist

Blower

35 30 55 20 24.7

35 40 55 20 24.5

35 50 55 20 24.5

35 60 55 20 24.7

40 30 55 20 24.7

40 40 55 20 24.5

40 50 55 20 24.5

40 60 55 20 24.7

45 30 55 20 24.7

45 40 55 20 24.5

45 50 55 20 24.5

45 60 55 20 24.7

50 30 55 20 24.7

50 40 55 20 24.5

50 50 55 20 24.5

50 60 55 20 24.7

55 30 55 20 24.7

55 40 55 20 24.5

55 50 55 20 24.5

55 60 55 20 24.7

60 30 55 20 24.7

60 40 55 20 24.6

60 50 55 20 24.6

60 60 55 20 24.7

Table 5: Simulation Result Of Sugeno Method.

Dry Room Fuzzy Output

Tempera-

ture

Humi-

dity

Heater Warm

Blower

Moist

Blower

35 30 60 30

30

35 40 60 30

30

35 50 60 30

30

35 60 60 30

30

40 30 60 30

30

40 40 60 30

30

40 50 60 30

30

40 60 60 30

30

45 30 60 30

30

45 40 60 30

30

45 50 60 30

30

45 60 60 30

30

50 30 60 30

30

50 40 60 30

30

50 50 60 30

30

50 60 60 30

30

55 30 60 30

30

55 40 60 30

30

55 50 60 30

30

55 60 60 30

30

60 30 60 30 30

60 40 60 30 30

60 50 60 30 30

60 60 60 30 30

Results from the simulation table obtained fuzzy

logic mamdani and sugeno method can keep the

output to still maintain the conditions specified. The

mamdani method can optimize the temperature of

heater and the power used is not large. However, it

takes quite a long time than the sugeno method.

While the sugeno method is able to use the heater

efficiently with high temperatures. Drying time is

relatively fast. But the power needed is great. The

difference will be more clear on the graphs produced

by each method.

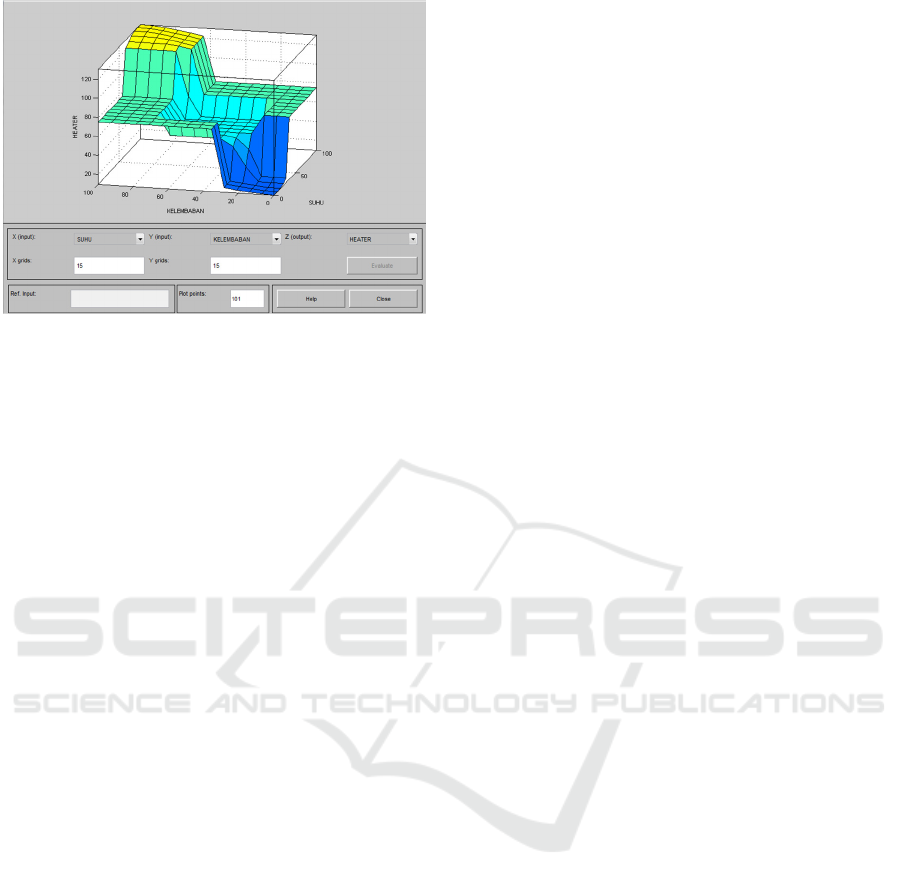

(a)

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

270

(b)

Figure 4: Graphic Result (a) Mamdani Method, (b)

Sugeno Method

Mamdani method commonly known as min-max

method. The antecedents of the mamdani method

have a minimum form, while the combined

consequences have the maximum shape. Every rules

in the mamdani method is implication (causal). In

addition, the rules set of mamdani method are also

independent of each other (Setiadji, 2009). Thus, in

the resulting graph shown input from temperature

and humidity is small then the heater will work

optimally to supply heat.

The sugeno method is a fuzzy inference method

with representation of IF-THEN-shaped rules. The

outputs generated at the rule base stages are

constants or linear equations (Syarif, 2016)

(Wachdani, 2010). Collection and correlation

between rules will shape the inferences. Then, in the

defuzzification stage will be searched the average

value (Kusumadewi,2010). The resulting output is

crisp.

4 CONCLUSIONS

The result of the simulation shows that there is no

significant difference. The mamdani method is

efficient in the use of electrical power with average

system workability. So, the drying time will be

slightly longer than sugeno method. While the

method sugeno able to make the system work in

incentives with the resulting power consequences

will be higher. Therefore, the use of fuzzy logic

control method mamdani or sugeno will be better if

adjusting the goals and desires to be achieved. If you

want fast time use the Sugeno method. But, if you

want to save power, it is better to choose mamdani

method.

REFERENCES

Pusat Teknologi Agroteknologi. 2017. Sosialisasi Produk

Mie Jagung Hasil Inovasi Techno Park Grobogan.

Diakses http://pta.bppt.go.id/2-uncategorised/31-

sosialisasi-produk-mie-jagung-hasil-inovasi-techno-

park-grobogan pada Jum’at, 11 Mei 2018 pukul 20.18

WIB.

Masniah and Syamsuddin. 2013. Pemanfaatan Jagung

dalam Pembuatan Aneka Macam Olahan untuk

Memperkuat Ketahanan Pangan. Makalah disajikan

dalam Seminar Nasional Serealia, Pusat Penelitian dan

Pengembangan Tanaman Pangan.

Badan Pengkajian and Pengembangan Kebijakan

Perdagang. 2016. Potret Jagung Indonesia: Menuju

Swasembada Tahun 2017. Blueprint : Kementerian

Perdagangan Republik Indonesia.

Resmisari, Asri. 2014. Tepung Jagung Komposit,

Pembuatan dan Pengolahannya. Makalah disajikan

dalam Seminar Nasional “Inovasi Teknologi Pertanian

Spesifik Lokasi”, Banjarbaru,.

Wylis, et al. 2014. Kajian Pembuatan Tepung Jagung

dengan Proses Pengolahan yang Berbeda. Makalah

disajikan dalam Seminar Nasional “Inovasi Teknologi

Pertanian Spesifik Lokasi”, Banjarbaru,

Sacchetti, G., et al. 2004. Effects of Extrusion

Temperature and Feed Composition on The

Functional, Physical and Sensory Properties of

Chestnut and Rice Flour-based Snack-like Products.

Food Research International Journal. Vol 37, pp 527-

534.

Ahmed, Maruf., Akter, Sorifa., Jong-Bang Eun. 2010.

Peeling, Drying Temperatures, and Sulphite-

Treatment Affect Physicochemical Properties and

Nutritional Quality of Sweet Potato Flour. Food

Chemistry Journal. Vol.121, pp 112-118.

Mentari, Dyan Dwi O. 2015. Prototipe Pengeringan

Biomassa Tipe Rotari (Uji Kinerja Rotary Dryer

Berdasarkan Efisiensi Termal Pengeringan Serbuk

Kayu untuk Pembuatan Biopelet). Skripsi Jurusan

Teknik Kimia. Politeknik Negeri Sriwijaya:

Palembang.

Arief, Ulfah M., and Setiyo Wahyono. 2015.

Pengendalian Suhu dan Humidity Pada Alat

Pengering Seledri Menggunakan Kontrol Fuzzy Logic.

Edu Elektrika Journal. Vol. 4, pp 21-26.

Benvenga, Marco A.C., et al. 2010. Application of

Simulated Annealing in Simulation and Optimization

of Drying Process of Zea Mays Malt. Journal of Eng.

Agríc. Vol.31, no.5.

Farzaneh, Vahid, et al. 2016. Modelling of The Selected

Physical Properties of The Fava Bean with Various

Moisture Contents Using Fuzzy Logic Design. Journal

of Food Process Engineering., Vol 40 (2)

Al-Mahasneh, Majdi, et al. 2016. Application of Hybrid

Neural Fuzzy System (ANFIS) in Food Processing and

Technology. Food Engineering Reviews. Vol.8, pp

351-366.

Nugroho, Fajar, et al.

2017. Analysis of Maizena Drying

System Using Temperature Control Based Fuzzy Logic

Comparison of Control Simulation on Cornstarch Dryer using Mamdani and Sugeno Fuzzy Logic

271

Methode. Engineering International Conference,

Indonesia:EIC

Kumar, Tarun D. and Yudhajit Das. 2013. Design of A

Room Temperature and Humidity Controller Using

Fuzzy Logic. American Journal of Engineering

Research (AJER). Vol.2, issue.11. pp.88-97.

Mansor, H., et al. 2010. Intelligent Control Of Grain

Drying Procces Using Fuzzy Logic Controller. Journal

of Food, Agriculture &Environment. Vol.8, pp 145-

149.

Suratno, et al. 2011. Pengaruh Perbedaan Tipe Fungsi

Keanggotaan

pada Pengendali Logika Fuzzy

Terhadap Tanggapan Waktu Sistem Orde Dua Secara

Umum. Skripsi.

Jurusan Teknik Elektro. Universitas

Diponegoro: Semarang.

Barua, Aditi, Lalitha Snigdha M., Olga Kosheleva. 2013.

Why Trapeziodal and Triangular Membership

Function Work So Well: Towards a Theoritical

Explanation. Journal of Uncertain Systems. Vol. 8 (3),

pp164-168.

Coupland, Simon and Robert John. 2007. Geometric Type-

1 and Type-2 Fuzzy Logic System. Journal of IEEE

Transactions on Fuzzy Systems. Vol. 15, No. 1., pp 3-

15

Butt, Casey B., Ashraful Hoque, M., and Azizur Rahman,

M. 2004. Simplified Fuzzy-Logic-Based MTPA Speed

Control of IPMSM Drive. Journal of IEEE

Transactions on Industry Applications. Vol. 40, No. 6.,

pp 1529 – 1535.

Zhao, Jin and Bose, Bimal K. 2002. Evaluation of

Membership Functions for Fuzzy Logic Controlled

Induction Motor Drive. Journal of IEEE.

Kaur, Arshdeep and Amrit Kaur. 2012. Comparisson of

Fuzzy Logic and Neuro Fuzzy Algorithms for Air

Conditioning System. International Journal of Soft

Computing and Engineering (IJSCE). Vol. 2, issues 1.,

pp 417-420

Singhala, P., D.N. Shah., and B. Patel. 2014. Temperature

Control Using Fuzzy Logic. International Journal of

Instrumentation and Control System (IJICS). Vol. 4,

No 1., pp 1-10

Chaudhari, Swati., and Patil, Manoj. 2014. Study and

Review of Fuzzy Inference System for Decision

Making and Control. American International Journal

of Research in Science, Technology, Engineering and

Mathematics. Vol.5, pp 88-92.

Abbas, M., Saleem Khan, M., Zafar, Fareeha. 2011.

Autonomous Room Air Cooler Using Fuzzy Logic

Control System. International Journal of Scientific

and Engineering Research. Vol.2, issue 5., pp 74-81

Setiadji. 2009. Himpunan & Logika Samar serta

Aplikasinya. Yogyakarta: Graha Ilmu.

Syarif, M. Irfan. 2016. Implementasi Logika Fuzzy

Inference System Metode Sugeno Pada Penentuan

Jumlah Produksi Sarung. Skripsi. Jurusan

Matematika. Universitas Negeri Semarang: Semarang.

Wachdani, R., Zainal Abidin, and M. Ainul Yaqin. 2010.

Aplikasi Fuzzy Infernce System (FIS) Metode Sugeno

dalam Menentukan Kebutuhan Energi dan Protein

Pada Balita. Matics Journal. Vol.4, No.2.

Kusumadewi, S. and Purnomo, H. 2010. Aplikasi Logika

Fuzzy untuk Pendukung Keputusan. Yogyakarta:

Graha Ilmu.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

272