Rooftop Photovoltaic System for Microgrid Design in State

Polytechnic of Ujung Pandang

Ashar AR

1,2

, Yusri Syam Akil

2

and Yusran

2

1

Politeknik Negeri Ujung Pandang

2

Hasanuddin University

Keywords: Microgrid;PV panel; green campus; State Polytechnic of Ujung Pandang

Abstract: Renewable energy sources are promised alternative energy to reduce using thermal power generation which

emitted emission gas. Solar energy is a good alternative choice for power generation in tropical country

such as Indonesia because of the geographical condition and a good duration time of sunlight every year.

The implementation of solar energy for campus electrical installation as a microgrid system to bring out the

idea of “green campus” is proposed in this paper. This microgrid system is design based on the potential of

solar energy sources and the load characteristics at the electrical engineering department building campus 2

State Polytechnic of Ujung Pandang in South Sulawesi, Indonesia. Maximum consumed energy per day in

this building during weekdays is 380 kWh. Therefore, PV panels power capacity is 108 kWp and the

number of installed PV for this system is 360 PV panels with battery capacity 10000 Ah. Based on the area

of the rooftop, needed space for installing the PV panel is 54% of the total wide area.

1 INTRODUCTION

Nowadays, looking for friendly resources of energy

becomes a big issues in all countries. The drawback

of conventional fossil fuel energy that emitted

hazardous emission gas alert people to care the

negative affect to human being and environment.

Therefore, the sources of conventional energy are

limited and some countries such Indonesia have

moved to the renewable energy sources. The big

challenge of using the renewable energy is the low

efficiency, reliability and its high initial cost.

Photovoltaic (PV) energy is one of the important

sources of renewable energy. In the recent decade,

PV has been a competitive energy source. The

efficiency of PV modules has been increased

significantly and now it is reaching 40% by the use

of new technologies (Tahri et al., 2018). Power

quality is also improved (Yusran et al., 2013).This

made the PV system become an essential system in

worldwide electrical power production.

Electrification ratio of Indonesia on December

2017 is around 95.35%, it is better than the

government target of 92.75% and electric ratio for

south Sulawesi is 99.12%. However, majority of the

power generation are thermal power plants.

Therefore, to reduce the dependency to fossil

sources, the government has set the target 23% from

the total used energy from renewable energy till

2025. Based on Electricity Supply Business Plan

(RUPTL) from PLN as utility company from

Indonesia, the target of solar power is 1047 MWp

and the realisation of solar power generation till

2018 is 94.42 MWp (ESDM, 2018). Therefore, there

are still a big challenge to fulfil the target of the

solar power generation. Campus as an educational

institution and research has a chance to build a solar

power generation in a microgrid system and there

are still small number of campus in Indonesia

provide electrical energy from renewable energy

sources. In campus, space is limited, so placement of

PV panels is usually only possible on the rooftops.

Various parameters have to be considered when

installing solar panel depend on the shape of

buildings’ roofs and regarding the received solar

irradiance. Some of the more important considered

parameters in solar potential estimation are

geographic location, surface topography and

shadowing effects from surrounding (Yuan et al.,

2016). PV power output has a strong correlation

with ambient temperature and irradiation of the

240

AR, A., Akil, Y. and Yusran, .

Rooftop Photovoltaic System for Microgrid Design in State Polytechnic of Ujung Pandang.

DOI: 10.5220/0009009202400245

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 240-245

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

sunlight so the intermittency of PV power supply

can threaten microgrid integrity (Ho et al., 2013).

Studies on microgridsare generally classified into

two groups: system design and operation planning.

System design involves the selection and sizing of

the distributed energy resources, minimum

investment cost and environmental issues. The

optimal design is very important to maintain the

reliability of the system. Selection and sizing is

related with load characteristic, operation and

maintenance cost and weather conditions (Hirsch et

al., 2018). The optimal sizing is between peak load

satisfaction and minimalized investment cost.

Microgrid operation planning includes the

management of a microgrid (Sahoo et al., 2015).

Considering the role of campus as an education

and research institution, campus can be a role model

to apply renewable energy sources in microgrid

system for its electricity demand. So, the purpose of

this research is as preliminary study for microgrid

installation on the rooftop electrical department

buildings. Number of PV panels, sizing of battery

and used area for PV panel placement on the

buildings’ roof are considered in this study.

The rest of this paper is organized as: location and

solar potential in section 2 followed by investigating

the campus load characteristic in section 3. Section 4

presents the result and discussion then conclusion

are drawn in section 5.

2 METHODOLOGY

2.1 Location And Potential

Buildings of Electrical Engineering Department,

Campus 2 of state Polytechnic of Ujung Pandang are

located in Moncongloe, Maros Regency, South

Sulawesi. The buildings location is at 5°08’40.9”S,

119°31’24.3”E. There are 4 main buildings in

Electrical Engineering Department; 1). Theatre

Building 2). Laboratory Building 3). Administration

Building and 4). Classroom Building. Those are

figured out in figure 2. The shape models of these

buildings are a little bit different. Theatre buildings

is half round. It is clearly shown in number 1 of

Figure 1. The roof shape is combination of concrete

deck roof and hipped roof. The roof shape of

building number 2,3 and 4 are shed model. From the

left side, theatre and laboratory buildings can be

shown in Figure 2. Those buildings are potential for

PV panel placement.

Figure 1: Buildings of Electrical Engineering Dept.

Figure 2: Electrical department building from left

side.

Photovoltaic energy is the transformation of

sunlight into electrical energy through PV array

panel which is depend on irradiance and

temperature. The production of this energy

fluctuates in nonlinear characteristic because of

intermittency condition and the depending on the

amount of radiation striking the surface of the PV

array and temperature of the location. Based on the

location, meteorological data can be obtained. Daily

radiation and temperature data are provided by

NASA Surface Meterology and Solar Energy

Database for monthly average values over 22 year

period. Those data are global irradiation and ambient

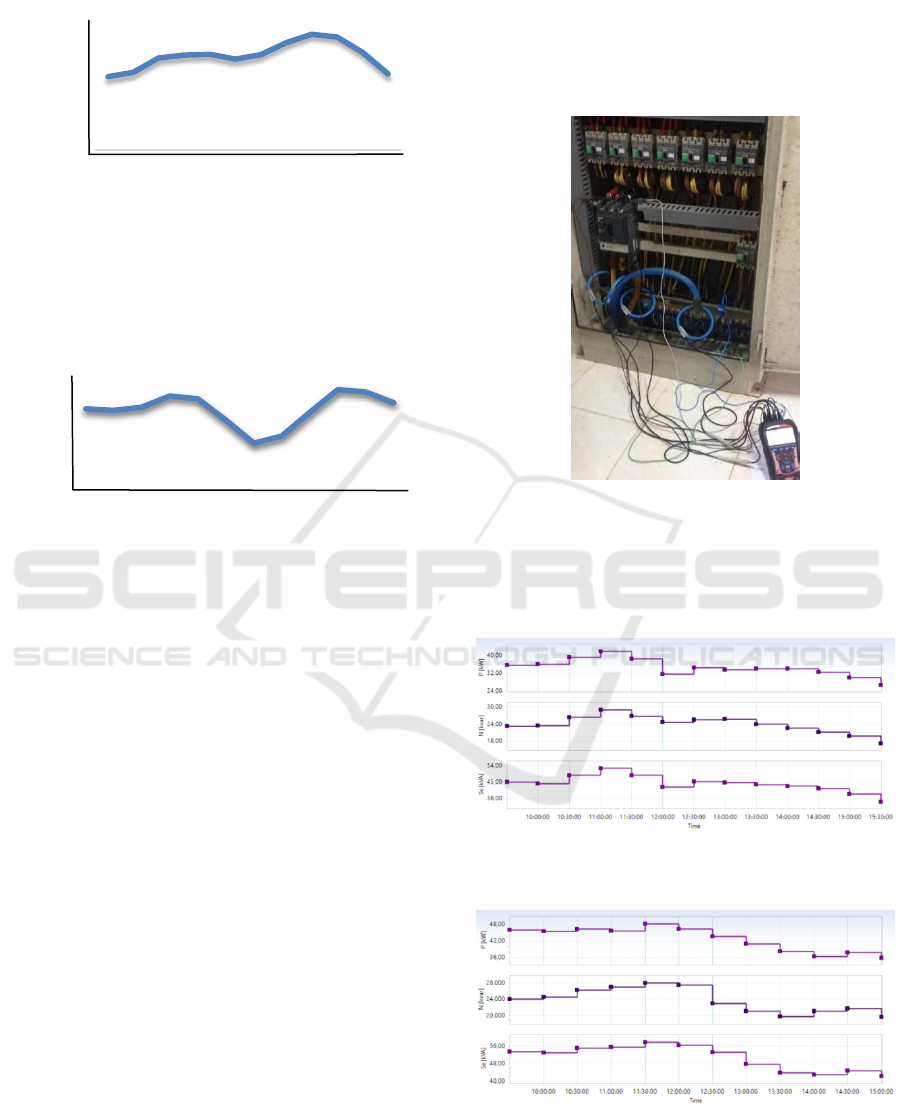

temperature for a year. From Figure 3, the highest

global irradiation is in September. The average

irradiation is around 5.87 kWh/m

2

/day. Basically, on

July till October is the higher irradiation during the

dry season in this area. The lower global irradiance

is in December and January because of cloudy and

rainy season in this area.

Temperature in this location is high enough. The

data are shown in Figure 4. The average temperature

is 26.38 °C. Basically, temperature influences the

behavior of solar PV because increased temperature

will increase the current of PV and the effect is the

decreasing of the maximum harvesting power from

the panel (Hedi et al., 2017). However, global

Rooftop Photovoltaic System for Microgrid Design in State Polytechnic of Ujung Pandang

241

irradiation and temperature in this location is

potential for solar photovoltaic system installation.

Figure 3: Average daily radiation.

Figure 4: Average daily temperature.

2.2 Campus Load Characteristic

Electrical Engineering Department in campus 2 is

new buildings. Majority of teaching activity is still

in campus 1 of Tamalanrea but some of laboratories

are located in campus 2. Therefore the consumed

energy is not yet really significant. The kind of loads

in these buildings are lighting lamps, electric

machines, water pumps, power electronics devices,

computers and laboratory devices. Most of big

energy comsumption is from laboratory equipments

such as electric machines. Normally, daily operation

is from 8 to 16 o’clock during weekdays (Monday to

Friday). On the weekend, the electrical load is only

lightings in the hall and parking area. Peak hour of

energy consumption is around 10 to 12 0’clock

every weekdays

Daily load of the buildings is measured and

recorded with power quality meter METREL for 5

days from monday to friday during working hours.

Range of data is every 30 minutes. Combined power

(active, reactive and apparent power) are measured

to define the load characteristic of these building.

The instalation is in three phase R, S and T to supply

load in electrical department buildings.

Measurement device installation is took place in the

distribution panel of the buildings as shown in

Figure 5.

Figure 5: Installation of combined power measurement.

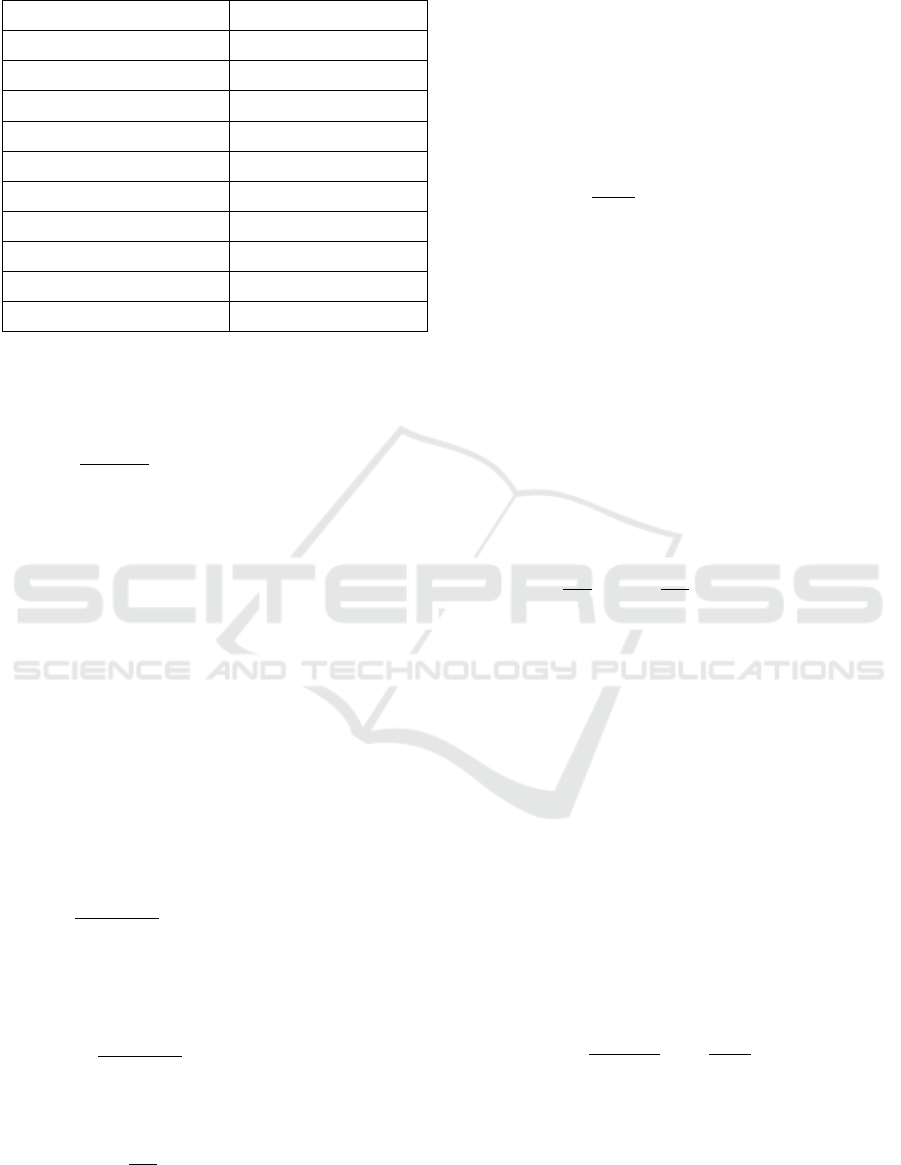

Following figures from Figure 6, Figure 7, Figure 8,

Figure 9, and Figure 10 are measured data from 12

to 16 March 2018 or Monday to Friday during

working hours.

Figure 6: Consumed power on Monday 12 March 2018.

Figure 7: Consumed power on Tuesday 13 March 2018.

0

1

2

3

4

5

6

7

8

January

February

March

April

May

June

July

August

September

October

November

December

Radiation (kWh/m2/day)

Months

25

25,5

26

26,5

27

January

February

March

April

May

June

July

August

September

October

November

December

temperature (°C)

Months

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

242

Figure 8: Consumed power on Wednesday 14 March

2018.

Figure 9: Consumed power on Thursday 15 March

2018.

Figure 10: Consumed power on Friday 16 March 2018.

From Figure 6 to 10, it is shown the condition of

consumed power in the buildings. Peak hour on

Monday is from 10.30 to 12 o’clock in which

maximum active power 41.77 kW, maximum

reactive power 29.01 kVAR and maximum apparent

power 52.69 kVA. Peak hour on Tuesday is from

11.30 to 12.30 o’clock, where maximum active,

reactive and apparent power are 47.50 kW, 27.99

kVAR and 57.92 kVA. On Wednesday, the peak

hour is from 10 to 11.30 o’clock and the maximum

active, reactive and apparent power are 42.66 kW,

28.62 kVAR and 52.26 kVA. Peak hour on

Thursday is around 10 to 11 o’clock and the

maximum active, reactive and apparent power are

45.31 kW, 30.86 kVAR and 59.65 kVA. For the last

day of research data, the peak hour is from 10 to

11.30 o’clock with maximum active power 43.64

kW, maximum reactive power 28.96 kVAR and

maximum apparent power 54.09 kVA.

The varied data and peak hour depend on the

teaching activities in campus. Most laboratory and

workshop activities are in the morning from 8 to 14

o’clock. Most of operated laboratory devices for

obtained data is from 10 to 12 o’clock. Therefore,

that is the reason why the peak hour is around that

time.

Consumed reactive power for electrical

applience is high. It is indicated that many inductive

load operated in campus. Electric machines, air

conditioner, water pumps are example of applied

inductive loads. For solar system design, only active

power will be considered because reactive power is

produced from electrical moving sources such

generator.

3 RESULT AND DISCUSSION

PV panels placement planning is on the rooftop

of Theater and Laboratory building because of better

position to the sun. The roof shape of the theater

building is combination of concrete deck roof and

hipped roof with estimated area 528 m

2

meanwhile

laboratory building roof shape is shed roof in west

facing with 10 degree inclination and wide area is

782 m

2

. So total estimated area of the two building is

1310 m

2

. However the PV panel placement area

must be smaller than the wide area of both buildings.

To design this system, choosing the PV panel

and inverter is very important. In this research,

polycrystalline 300 W

P

will be chosen because of

availability on the market and certified PV panel and

the capacity of chosen inverter is 20 kW. Table 1

provides the specification of applied PV panel.

Rooftop Photovoltaic System for Microgrid Design in State Polytechnic of Ujung Pandang

243

Table 1: PV panel specification.

Parameter

Value

Pmax

300 W

Imp

8.28 A

Vmp

36.2 V

Isc

9.27 A

Voc

43.4 V

NOTC

45±2 °C

Max. System Voltage

1000 V

Max. Series Fuse

16 A

Weight

20.65 kg

Dimension

1956 x 992 x 40mm

To calculate the power capacity of PV system

daily load supply, it can be determined using this

equation [10]:

(1)

Where:

: Power capacity of PV [kWp]

:Total energy demand per day [kWh]

: Sun hour per day [h]

: System efficiency [%]

Maximum active power consumed from all data is

47.5 kW on Tuesday and it is shown on Figure 8.

This data becomes the base to determine the load

demand. So the total consumed energy for 8 hours

(working hours) is 380 kWh. Normally, total sun

hour in Indonesia especially in South Sulawesi is 4

hour/day, the condition when the PV panel working

in maximum point to harvesting energy from sun. If

the system efficiency is 88%, then the power

capacity of PV will be:

From the table 1, capacity of the PV panel is 300

Wp so number of PV panel need is:

To determine the number of series connection of

PV panel, formula (2) can be applied:

(2)

Where;

: number of series connestion [unit]

: inverter voltage [volt]

: maximum power voltage [volt]

Maximum power voltage (V

MP

) from the PV

specification is 36.2 V and the maximum input

voltage of inverter (V

INV

) is 800 V. So number of

series connection is:

Therefore, there are 16 panel arrays in parallel

which consist of 23 PV panels in series connection.

This system is design to operate in connected

grid mode and islanded mode. Islanded mode will

handle the system in the weekend or vacation to

supply only lighting loads in campus because of

lower consumed energy. Then if the system is

islanded mode, it means need batteries. Total

capacity of battery is usually signed with C, which

means measurement of how much energy can be

store in the battery. The battery capacity is

calculated using formula as follows (Giriantari,

2016):

(3)

Where;

C

bat

: Battery Capacity [Ah

c10

]

E

C

: Total Energy Demand per day [VAh]

Usys: DC System Voltage [V

DC

]

H

aut

: Autonomous day [day]

DoD : Depth of Discharge [%]

DoD means how much energy that the battery

delivered to the load. If the battery is 100% fully

charged, it indicates the DoD of the battery is 0%

and if the battery is 100% empty, DoD is 100%. In

order to provide a longer cycle life of battery, DoD

cannot be 100%. Therefore, the DoD of this battery

storage system is 80%. DC system voltage is usually

24 V or 48 V and this system is design for 48 V. the

autonomous day is set for 1 day, so battery capacity

will be:

The battery capacity can be designed to be

10000 Ah, therefore the energy storage capacity is

480 kVAh.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

244

Applied inverter for this design is bidirectional

inverter because of the connection of on grid and off

grid mode.

For the placement of PV panel on the roof,

needed space on the roof is 700 m

2

or around 54% of

the total wide of the rooftop buildings. This is

available because of the total rooftop area is 1310

m

2

. However, the weight of the installed panels

should be seriously considered because of the

structural elements of building. For this design, the

weight of the panels will be 7.434 kg, so it is heavy

enough for the existing buildings which are not

constructed for PV panels on the roof.

To keep the continuity of electric supply if the

PLN utility supply is collapse or the energy from the

solar panel and battery are not enough to supply the

loads, diesel generator is set to back up the system.

Output of the diesel generator for these buildings is

80 kVA. Specification of the diesel generator can be

seen in Table 2.

Table 2: Diesel generator specification

Parameter

Value

Model

HT - 80

Output

80 KVA

Voltage

220/380 V

Current

122 Amp

Pf/Phase

0.8 / 3

Speed

1500 Rpm

Frequency

50 Hz

Rating Cont.

80%

4 CONCLUSIONS

Rooftop photovoltaic system for microgrid design

is presented in this paper and the results can be

concluded as this system for daily energy demand

380 kWh of 3 phase connected system in Electrical

Engineering Department, Campus 2, State

Polytechnic of Ujung Pandang needs 360 PV panels

to supply the loads. The power capacity of the PV

panels is 108 kWp with installed battery capacity

10.000 Ah. Roof space needs 54% of the total

existing roofs for installed PV panels. To keep the

continuity power supply, diesel generator with 80

kVA capacity is set to back up the system.

Campus as a role model to develop microgrid

system to response the government policy of applied

renewable energy sources as an environmentally

impact consideration to reduce the thermal power

generation. Microgrid system design in campus is

very important as the basic knowledge to develop

microgrid system.

To explore the potential of renewable energy in

this location, future research will be developed a

microgrid system with considering wind turbine as a

hybrid power generation. Wind speed in this

location is considerable to harvest electrical energy.

REFERENCES

C. T. T. Ho, R. Yan, T. K. Saha, S. E. Goodwin. (2013)

“Design Microgrid for a Distribution Network: A Case

Study of the University of Queensland”, IEEE, pp 1-5

ESDM.

https://www.esdm.go.id/assets/media/content/content-

rasio-elektrifikasi.pdf

Giriantari, IAD., Irawati., R. (2016) “Smart Microgrid

System with Hybrid System Supply: Udayana

University Pilot Project Design”, ICSGTEIS, Vol 16

(3), pp 8-12

Hedi,T. Mourad., E. (2017) “MPPT controllers for PV

array panel connected to grid”, 18th International

Conference on Science and Techniques of Automatic

Control and Computer Engineering-STA 2017,

Monasir, Tunisia, pp 505-510

Hirsch, A., Parag, Y., Guerrero, J. (2018) “Microgrids: A

Review of Technologies, Key Drivers, and

Outstanding Issues”, Renewable and Sustainable

Energy Review, Vol 90, pp 402 – 411

Sahoo, A. K., Abhitharan, K. P., Kalaivani, A., Karthik, T.

J. (2015) “Feasibility Study of Microgrid Installation

in an Educational Institution with Grid Uncertainty”,

4th International Conference on Eco-friendly

Computing and Communication System, ICECCS

Tahri, F., Tahri, A., Oozeki., T. (2018) “Performance

evaluation of grid-connected photovoltaic systems

based on two photovoltaic module technologies under

tropical climate conditions”, Energy Conversion and

Management, Vol 165, pp 244 – 252.

Yuan, J., Farnham, C., Emura, K. S. Lu. (2016) “A

Method to Estimate the Potential of Rooftop

Photovoltaic Power Generation for a Region”, Urban

Climate, Vol 17, pp 1 – 19

Yusran, Ashari M, and Soeprijanto A. (2013)

“Optimization Scheme of Distributed Generation

Installation Growth Considering Network Power

Quality”, Journal of Theoretical and Applied

Information (JATIT), Vol 53(1), pp 30-39, ISSN

1992-8645, E-ISSN : 2339-1553

Rooftop Photovoltaic System for Microgrid Design in State Polytechnic of Ujung Pandang

245