Overload Effect on National Road Overlay Planning in North

Kalimantan

Adi Lazuardi Perdana

1

, Ari Setyawan

2

, Budi Yulianto

2

1

Student of Master Program of Civil Engineering, University of Sebelas Maret, Surakarta, Indonesia.

2

Lecturer of Department of Civil Engineering, University of Sebelas Maret, Surakarta, Indonesia.

Keywords: Overloading, Service life,Pd T-05-2005-B, SDPJL, Kenpave

Abstract: The issue in the community that causes damage to the road was by trucks carrying fresh fruit bunches (FFB)

of oil palm. The purpose of this study is to know the effect of overload on the service life, knowing the overlay

thickness, thickness due to overloading and determining the effective thickness from the method used. This

study was conducted by surveying overloaded FFB transport trucks. The location of research was on Tanjung

Selor Road Section, limited to Bulungan in Sta 16 + 000 to Sta 18 + 000. Analysis of overload data uses

overload scenarios, while for planning the overlay layer thickness uses deflection method Pd T-05-2005-B

and Bending Pavement Design Software (SDPJL). Both methods are mechanically evaluated by the Kanpave

program to determine the efficient overlay thickness. The results showed that the ESAL

overload

>

ESAL

Standard

.Based on the analysis of the high load on service life since the road was opened, there was a

reduction in service life, an overlay thickness of 4.86cm with Pd T-05-2005-B method, 4cm with SDPJL

method. Based on analysis of overload on planning occurred an increase in each scenario where d

Overload

>

d

Planning

. The mechanical results from the Kenpave program showed that the load repetition that was close to

the design load was the Pd T-05-2005-B method of 130,606,838.49 ESA, thus planning the Overlay thickness

with the Pd T-05-2005-B method was more efficient than the SDPJL method.

1 INTRODUCTION

In Indonesia the movement of goods and services is

dominated by the modes of land transportation by

using Trucking vehicles because it can be done door-

to-door with the right time, exact quantity, quality,

and exact receiver. In addition, transportation costs

are the largest cost component in the logistics cost

structure. No less than 60% of the total cost is the cost

of transportation.

With the increasing economic growth of a region

and the lack of supervision, some transport services

are willing to carry relatively large quantities of

goods to reduce transportation costs in a travel

process at once, making it more cost effective to

transport. This will have a negative impact on road

pavement conditions due to overloading repeated

loads.

Repeated loads caused by heavy vehicles will

have an impact on the degradation of the highway

bending structure of the road which further leads to a

decrease in the hardness of the pavement support

because it always receives a voltage greater than the

standard load.

If this condition continues to occur it will result in

the occurrence of road damage early because the load

received has been reached before the age of the

planned road at the time of the initial design.

Any vehicle of a certain weight that crosses a

road, will contribute to the destruction of the road.

Overload contributes a power of 4 (four) to the road

destructive factor or Vehicle damage factor (VDF).

The increase in damaged power of road is much

greater than the percentage of the burden that is

violated.

So this cause is considered to be the most

responsible cause for road damage. This condition

may be made possible by changes in vehicle

dimensions and weight across the road when

compared to the dimensions and weight of the vehicle

used in the planning.

Therefore, this study conducts more cargo survey

of fresh palm fruit bunch (FFB) vehicles using more

load scenarios, calculates Equivalent Single Axle

Load (ESAL), Age of service. In this research, the

Lazuardi Perdana, A., Setyawan, A. and Yulianto, B.

Overload Effect on National Road Overlay Planning In North Kalimantan.

DOI: 10.5220/0009008802170222

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 217-222

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

217

overlay thickness planning process with PdT-05-

2005-B deflection method, the software design

method of flexible pavement stretching (SDPJL),

comparing the thickness value of overlay due to more

load with thickness of planning, knowing the

thickness of the effective overlay layer with using

kenpave mechanical program of both methods used.

2 METHOD

The research location is in National road North

Kalimantan, Bulungan precisely located on the

boundary roads Bulungan Tanjung Selor Sta 16 + 000

to Sta 18 + 000.

Obtained primary data by surveying the damage

to roads and fruit bunches weighing and measuring

tailgate loading and unloading at the site of FFB.

Secondary data is supportive data obtained from

the Planning and Monitoring Unit of the National

Road North Kalimantan.

Once the data is acquired then the next stage

analysis of both the analysis and planning

overloading Overlay, phases as follows:

The first stage manage the resulting data fruit

bunches weighing, measuring the volume of the

container box FFB and Volume tailgate using the

formula Density =

. So of the relationship

between the volume of the truck with a cargo of oil

palm FFB can be obtained. Furthermore, oil palm

FFB Freight transported by trucks is assumed to be 60

cm above the truck bed with a full payload, making

the scenario more payload carried by TBS load

variation of a high rise above the truck every 10

cm.dengan these assumptions can be made 7 more

payload scenarios so obtained a charge over each

scenario.

Based on secondary data Roads Bulungan

Tanjung Selor limit is a class IIIA collector roads with

the heaviest axle load (MST) ≤ 8 tons. Damage Factor

(ESAL

overload

) and (ESAL

Standard

) with the formula D

= (

)

4

, Configuration trucks axis palm with 1.2

L type truck front axis configuration with 34% and

66% rear axis. Can be calculated Equivalent Single

Axle Load (ESAL) Based on data from more payload

scenarios and formulas to find the value can be

obtained ESAL

overload

for all scenarios and

ESAL

Standard

overloading.

Further analyzes Overlay design life based on the

cumulative results ESAL planning data and survey

data scenario more cargo truck field. Cumulative

ESAL calculated per year starting from the first year

until the end of service life with the traffic growth of

5% and a service life of over 10 years of age.

The second stage the planning process with a thick

layer of additional deflection method use Pd T-05-

2005-B and methods of road pavement design

software malleable (SDPJL).

Using the method of deflection Pd T-05-2005-B,

the Code was initiated by the Transport Infrastructure

R & D Center, Research and Development Agency

Infrastructure Development district. Guidelines

ex.Departemen a road Pavement Inspection Manual

revision by means of Benkelman Beam (01 / MN / B

/ 1983) and in addition to apply to the data deflection

allowed based tool Benkelman Beam. with this

method Overlay layer thickness is obtained in

accordance with the data obtained.

Using methods of road pavement design software

malleable (SDPJL), the calculation process with only

input required data and software will execute to

generate output roughness. Method additional layer

thickness was approved by the Ministry of Public

Works General Directorate of Highways in 2013

became Manual Design pavement No. 02 / M.BM /

2013. with this method Overlay layer thickness is

obtained in accordance with the data obtained.

Further analyzes of the high payloads Overlay

layer. By using methods Pd T-05-2005-B because the

method is flexible in its application VDF value,

according to the road conditions are analyzed,

whereas the method of Software pavement Road

Bending (SDPJL) can not be used because the data

VDF has been programmed.

Based on an analysis of more obtained load

scenarios resulting increase Overlay thickness of each

scenario.

The third thos thick evaluate Overlay using the

program mechanistic Kenpeva of both the method

used to produce a thick layer of Overlay. This

program is the planning of pavement design software

developed by Dr.Yang H Huang, PE Professor

Emeritus of CIVEL Engineering University of

Kentuck. Software is also written in Visual Basic

programming language and can be run with any

version of Windows 95 or above, this program can

only be run in the Windows 95 operating system to

windows xp professional service park 2.

Program kenpave second edition 'Pavement

Analysis and Design' is a Windows version of DOS

substitute four programs Layernip, Kenlayer,

Slabship and Kenslap. Layerinp and Kenlayer an

analysis program for flexible pavements, while

Slabinp and Kenslab an analysis program for rigid

pavement.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

218

After the evaluation of the two methods will

retrieved results pavement structure response data in

the form of a vertical strain on the upper layer

subgrade (ɛv) and tensile strain at the bottom of the

surface layer (ɛt). Furthermore, the data will be

processed further by using a transfer function of

asphalt Institute then obtained values Nf and Nd.

The fourth overall stage evaluation results, this

stage determine an efficient method for the additional

layer thickness, provided the value Nd of the second

method is used closest to the value of the design load

repatisi.

3 RESULTS AND DISCUSSION

3.1 Scenario overload

Calculations from 7 to charge more oil palm scenario

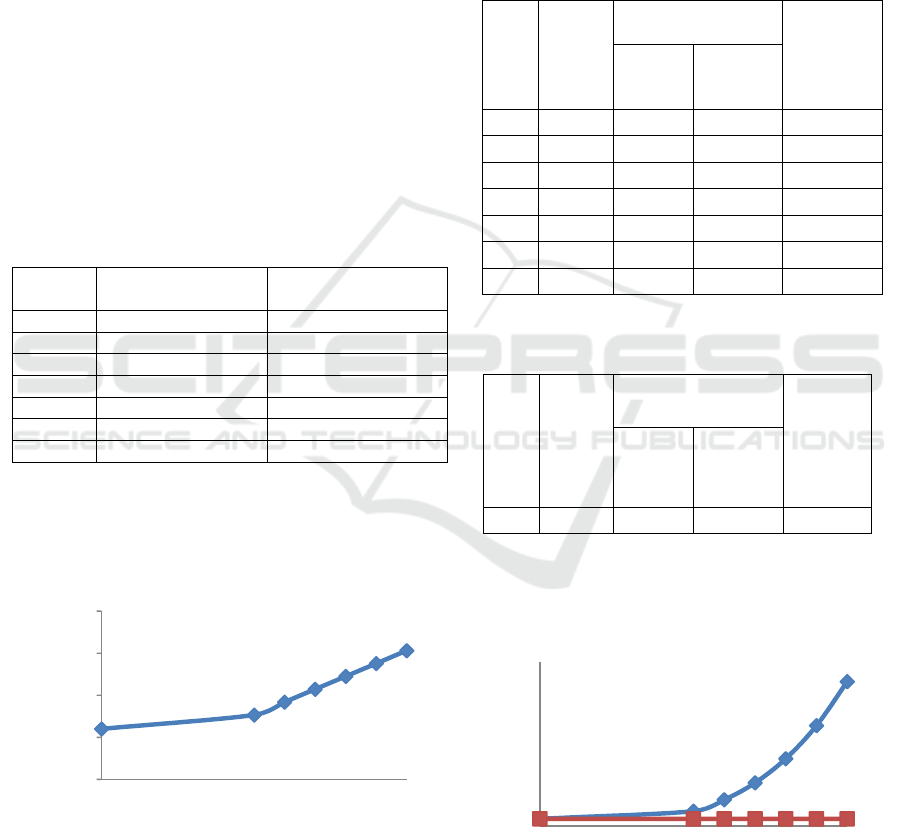

can be seen in Table 1 below:

Table 1: Scenario Truck Loads More Palm Oil

Scenario

High payload FFB Payload more

( m ) ( Ton )

1 0 6

2 1 7.66

3 1.2 9.19

4 1.4 10.72

5 1.6 12.25

6 1.8 13.78

7 2 15.31

Source: Analysis

From the results of the calculations in Table 1, it

can be graphed the relationship between high-load

FFB with more cargo truck as shown below:

Figure 1: Graph relationship between height FFB with more

payload cargo truck.

In Figure 1 it can be seen that there is an increase

in load in scenario 2 to scenario 7 exceeding 6 tons,

where the Tanjung Selor road is the Bulungan limit of

the allowed load of 6 tons for medium truck type

1.2L.

3.2 Equivalent Single Axle Load

Calculation of Equivalent Single Axle Load (ESAL)

based on scenarios more payload and standard ESAL

calculation can be seen in the table below:

Table 2: ESAL

overload

All Scenarios Loads More

No

Weight

Configuration ESAL

Axis total

total Front Back

load

more

(kg) 34% 66% truck

1 8300 2822.00 5478.00 0.22

2 9960 3386.40 6573.60 0.45

3 11490 3906.60 7583.40 0.80

4 13020 4426.80 8593.20 1.32

5 14550 4947.00 9603.00 2.05

6 16080 5467.20 10612.80 3.06

7 17610 5987.40 11622.60 4.41

Source: Analysis

Table 3: ESALstandard

No

Weight

Configuration ESAL

Axis total

total Depan Belakang

more

load

(kg) 34% 66% truck

1 8300 2822.00 5478.00 0.22

Source: Analysis

ESAL

standard

= 0.22 has the same number for each

scenario loading.

Source: Analysis

Figure 2: Graph the relationship between high-value cargo

FFB with VDF.

0.00

5.00

10.00

15.00

20.00

00.511.52

Value overload (Ton)

The height of overload ( mater )

0.00

1.00

2.00

3.00

4.00

5.00

00.511.52

VDF ESAL

The height for Overload (meter)

ESAL for Overload

ESAL Standard

Overload Effect on National Road Overlay Planning In North Kalimantan

219

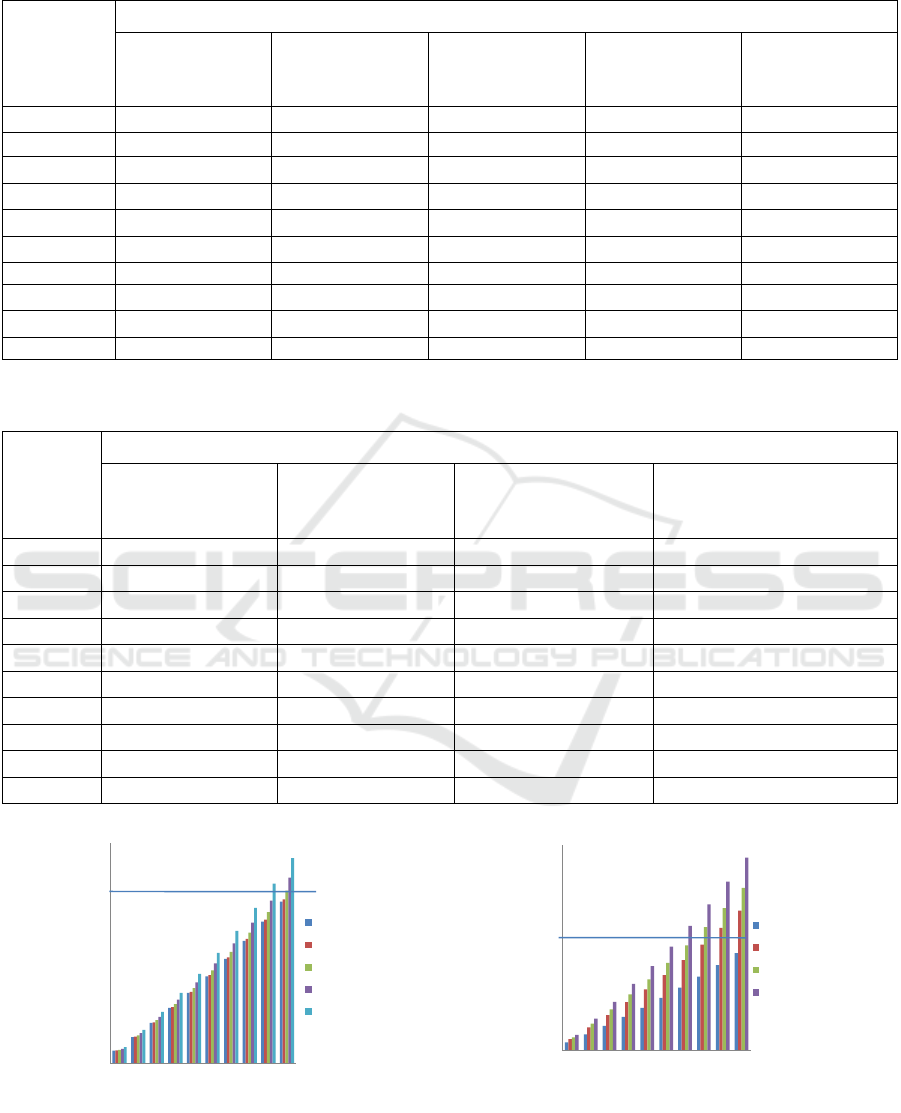

Table 4: Analysis of the charge of the lifetime high serviceability

Year

Comulative ESAL

Planning

Height Overload

0 m

Height Overload

1 m

Height Overload

1,2 m

Height Overload

1,4 m

(ESA) (ESA) (ESA) (ESA) (ESA)

2017 52,906.20 53,649.63 56,461.96 60,741.58 67,099.88

2018 108,457.72 109,981.75 115,747.02 124,520.25 137,554.76

2019 166,786.80 169,130.47 177,996.33 191,487.85 211,532.39

2020 228,032.35 231,236.63 243,358.10 261,803.82 289,208.89

2021 289,277.89 293,342.79 308,719.88 332,119.80 366,885.39

2022 356,801.10 361,814.83 380,781.24 409,643.16 452,523.74

2023 427,700.47 433,710.47 456,445.66 491,042.70 542,444.00

2024 502,144.81 509,200.89 535,893.31 576,512.20 636,860.28

2025 580,311.37 588,465.84 619,313.34 666,255.19 735,997.37

2026 662,386.25 671,694.03 706,904.37 760,485.32 840,091.31

Table 5: Analysis of the charge of the lifetime high serviceability

Year

Comulative ESAL

Planning

Height overload

1,6 m

Height overload

1,8 m

Height overload

2 m

(ESA) (ESA) (ESA) (ESA)

2017 52,906.20 76,025.96 88,375.73 104,882.86

2018 108,457.72 155,853.22 181,170.26 215,009.86

2019 166,786.80 239,671.84 278,604.50 330,643.21

2020 228,032.35 327,681.39 380,910.46 452,058.23

2021 289,277.89 415,690.94 483,216.42 573,473.26

2022 356,801.10 512,721.47 596,008.74 707,333.31

2023 427,700.47 614,603.53 714,440.68 847,886.38

2024 502,144.81 721,579.69 838,794.21 995,467.09

2025 580,311.37 833,904.65 969,365.42 1,150,426.85

2026 662,386.25 951,845.87 1,106,465.19 1,313,134.58

Figure 3: Graph the relationship between high-load FFB

with Age serviceability.

Figure 4: Graph the relationship between high-load FFB

with Age serviceability.

‐

100,000.00

200,000.00

300,000.00

400,000.00

500,000.00

600,000.00

700,000.00

800,000.00

900,000.00

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

ESAL

Year

Planning

Heightoverload0m

Heightoverload1m

Heightoverload1,2m

Heightoverload1,4m

Service

Life

‐

200,000.00

400,000.00

600,000.00

800,000.00

1,000,000.00

1,200,000.00

1,400,000.00

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

ESAL

Year

Planning

Heightoverload1,6m

Heightoverload1,8m

Heightoverload2m

Service

Life

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

220

In the Figure 2, it can be seen that ESAL

load

is

greater than ESAL

Standard

, so that there is an overload

on the Tanjung Selor road in the Bulungan boundary.

3.3 Service life

Cumulative ESAL calculated per year starting from

the first year until the end of service life with the

traffic growth of 5% and a service life of over 10

years of age. Results of analysis of the high payloads

of the lifetime serviceability shown in the Table 4 and

Figure 3.

When viewed from the graph above, there is a

decrease in service life for 1 (one) year from the

planned age caused by a high 1.4 meter load. For the

next high load can be seen in Table 5 and Figure 4.

When viewed from the graph above, there is a

decrease in the age of Layan for 4 (four) years from

the age of the 10-year plan, which is caused by a high

load of 2 meters.

3.4 Metode defletion PdT-05-2005-B

and SDPJL

Planning an extra layer thickness (Overlay) using the

method of deflection Pd T-05-2005-B and methods of

road pavement design software malleable (SDPJL)

each obtained result Overlay thickness values as

follows:

Pd T-05-2005-B = 4,86 cm

SDPJL = 4,00 cm

3.5 Kenpave mechanical program

Kenpave mechanistic program evaluation results of

deflection methods Pd T-05-2005-B and methods of

road pavement design software malleable (SDPJL)

respectively results obtained Nd values as follows:

Pd T-05-2005-B = 130.606.838,49 ESA

SDPJL = 113.903.693,48 ESA

Overall Evaluation Results With ESA repatisi

589,561,48 the design load of the two methods is the

method of Pd T-05-2005-B with a value of

130,606,838.49 ESA and SDPJL value with a value

of 113,903,693.48 ESA, so we can conclude planning

of additional layer thickness (Overlay) efficient

SDPJL method than Pd T-05-2005-B method.

4 CONCLUSIONS

From the results of this study can be summarized that

from the truck load scenario, the value of scenario 2

to 7 is greater than the National Road permit load on

the Tanjung Selor road, the Bulungan limit is 6 tons.

so that the ESAL

Overload

value is greater than the

ESAL

Standard

. Truck loads with a height of 2 meters

have a deteriorating effect on the service life of 4

(four) years from the age of the 10-year plan.

Planning additional layer thickness by the method of

deflection Pd T-05-2005-B obtained amounted to

4.86 cm thick layer and methods of road pavement

design software malleable (SDPJL) obtained layer

thickness of 4.00 cm with a design life of 10 years.

The evaluation results with program loading

mechanistic kenpave of both the methods used

obtained value of Nd, Pd deflection method T-05-

2005-B obtained Nd value of 130,606,838.49 ESA

and methods of road pavement design software

malleable (SDPJL) Nd values obtained by ESA

113,903,693.48. With ESA repatisi 589,561.48 the

design load of the two methods is the method of Pd

T-05-2005-B with a value of 130,606,838.49 ESA

and SDPJL value with a value of 113,903,693.48

ESA, so we can conclude planning of additional layer

thickness (Overlay) efficient SDPJL method than Pd

T-05-2005-B method. Trucks carrying FFB oil palm

are not the main factor causing the initial damage to

the national road on the Tanjung Selor road to the

Bulungan boundary.

ACKNOWLEDGEMENTS

Hereby I express my gratitude for Ir. Ary setyawan,

M.Sc ( Eng ).,Ph.D, Budi Yulianto,S.T. M.Sc.,Ph.D,

as the promoter and copromoter as Thesis who have

allowed the writer to publish the result of this

introductory study. This article is expected to be

useful for as a reference in decision making, or as

a material of study.

REFERENCES

Anugrah, D. 2012. Analysis of the cost of

rehabilitation and maintenance of roads due to

overloading. Bangka.

Associatio of American State Highway and

Organizational Transportation (AASHTO),

Overload Effect on National Road Overlay Planning In North Kalimantan

221

(1993). Planning of Thickness of Bending,

Washington.

Directorate General of Highways, 2005. Planning

Guidelines Thickness of Supplemental Layers

Boundary Hardenability by PdT-05-2005-B

deflection method. Ministry of Public Works,

Jakarta.

Directorate General of Highways, Operations of

SDPJL Version 1.0.0. Ministry of Public Works,

Jakarta.

Fikri, H. F., 2013. Analysis additional layer thickness

calculation (overlay) on pavement supple

component analysis method and the method of

design software pavement plexible road. East

Kalimantan.

Huang Y.H., 1993. Pavement Analysis and Design,

University of Kentucky, Prentice Hall, Englewood

Cliffs, New Jersey.

Helmi, A., 1999. A study on the formula for damaged

vehicle wheels from several countries and

agencies, Proceedings of the 6 th Regional

Western Line of Engineering Conference.

Indriani, N. I., 2014. Pavement response due to

overloading on performance degradation and

road damage (case study of pantura national

road).

Sari, N. D., 2014. Analysis of vehicle load on the

degree of damage to roads and residual life. South

Sumatra.

SAAdisasmitha.et al., 2018. Effect of overload of the

lifetime of the plan. Gowa.

Widodo, S., 2009. Influence of asphalt damage to

service life of highway in national road kartasura-

klaten.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

222