Bamboo Green Materials for Environmental Sustainability

Constructions

Iskandar Yasin, Agus Priyanto and Zainul Faizin Haza

Departement of Civil Engineering Universitas Sarjanawiyata Tamansiswa, Yogyakarta, Indonesia

Keywords: Deforestation, Global Warming, Bamboo, Mechanical Properties.

Abstract: Global warming causes an increase in average temperatures on Earth. Over the past decade there has been

13 million ha / year deforestation. South America and Africa experienced the highest deforestation rates (>

3.4 million ha / year) and Asia also experienced forest loss in many places. To restore the preservation of

the forest is needed plants that grow fast and able to absorb more carbon than crops. Bamboo is known as

one of the fastest growing plants in the world, with growth rates ranging from 30 to 100 mm per day in its

infancy. Due to the rapid accumulation of biomass and the effective fixation of solar and carbon dioxide

energy, the carbon sequestration ability of bamboo tends to be second to none compared to other plants.

According to estimates, a quarter of the biomass in the tropics and a fifth in the subtropical region comes

from bamboo. For the construction materials the effect of bamboo treatment on bamboo mechanical

properties requires further assessment. Testing mechanical properties is done after the specimen on the dry

conditions of the furnace. Water content of specimens in the range of 12 - 13% in accordance with ISO

3129-1975 standards. Analysis of Variance (Anova) bamboo treatment with lateral stress as a construction

material has an effect on bamboo mechanical properties. In strong bending, tensile strength and bamboo

shear strength with lateral stress up to 2.5 MPa have no significant effect on bamboo properties. While on

Eastic Modulus of Elasticity and bamboo compressive strength with lateral stress up to 2.5 MPa have

significant effect on bamboo properties.

1 INTRODUCTION

Global warming causes an increase in average

temperatures on Earth. An increase in average air

temperature of the earth's surface is less than 1

degree Celsius or 1.3 degrees Fahrenheit in the last

100 years. Increasing global warming severity is

also caused by deforestation. While the oceans are

no longer able to store carbon as they had in the

past. Burning fossil fuels such as natural gas, coal,

oil and gasoline increases the carbon dioxide levels

in the atmosphere, and carbon dioxide is a major

contributor to the greenhouse effect and global

warming. Climate change will increase the number

of people suffering deaths, illnesses and injuries

from catastrophic waves, floods, storms and

droughts. Major storms and floods have occurred in

the last two decades (Venkataramanan, 2011). Since

1880, global warming has accumulated in water,

soil, and water. During the same period, heat is

released into the atmosphere by the use of fossil

fuels and nuclear power. This thermal pollution

contributes to heating. The accumulated and emitted

heat ratio shows that heat emissions 55% of global

warming (Gervet, 2007).

Forests are huge carbon stocks and biodiversity

that must remain intact to control global warming

and preserve life on earth. Over the past decade

there has been 13 million ha / year deforestation.

South America and Africa experienced the highest

deforestation rates (> 3.4 million ha / year) and Asia

also experienced forest loss in many places. In

general, the causes of deforestation are infrastructure

development, agricultural land expansion, land

tenure, lack of adequate oversight by the

government, high demand for timber, settlement

expansion and mining. Increased international

demand for plantation commodities can also affect

deforestation. The resulting impacts of deforestation

include changes in rainfall that have an impact on

increasing the risk of forest fires during the dry

season and the negative changes in the water and

river basin levels, a huge loss of biodiversity as

more than half of the animals and plants that live on

206

Yasin, I., Priyanto, A. and Faizin Haza, Z.

Bamboo Green Materials for Environmental Sustainability Constructions.

DOI: 10.5220/0009008602060212

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 206-212

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the earth depend on forests . Deforestation

dramatically affects the human population living in

the forest. Indigenous peoples and traditional

communities that are natural forest guards have seen

their territories have been reduced or attacked by

deforestation actors (Paulo, 2012).

The polemic on the environmental sustainability

globally has risen significantly over the years from

the Stockholm Conference on the Environment in

June 1972 to the Earth Summit in Rio de Janeiro in

June 1992 onwards, having decided on international

action through the Framework Convention on

Climate Change for reducing carbon dioxide and

global warming on earth. In general there are three

carbon inventories: oceans, atmosphere and

terrestrial ecosystems. In terrestrial ecosystems,

forests are able to store the largest carbon and store

1146x1015 g of carbon that occupies 56 percent of

total carbon in terrestrial ecosystems. The bamboo

forest ecosystem is an important part of the forest

ecosystem and an important carbon source and

carbon sink on earth (Li, et al., 2003).

To restore the preservation of the forest is needed

plants that grow fast and able to absorb more carbon

than crops. Bamboo is known as one of the fastest

growing plants in the world, with growth rates

ranging from 30 to 100 mm per day in its infancy.

Can grow to a height of 36 m with a diameter of 1-

30 cm (United Nations, 1972). Considering the

characteristics of bamboo, so its the fastest growing

and renewable natural resource (Lessard and

Chouinard 1980).

Bamboo is the fastest growing plant in nature

(Alfonso, 1987); there are more than 70 genera and

more than 1000 species in the botanical literature,

(Anon., 1988). They grow in sub-tropical zones

especially on sandy topsoil up to clay mud. This

plant can adapt to a short life cycle. The growth of

bamboo stems is amazingly fast, about 70 mm daily

and can reach 350-450 mm. The development of the

trunk is completed within 4-6 months, Wong (1995)

states that the bamboo stem takes only 2-6 years to

mature depending on the species. Bamboo rods are

generally cylindrical and smooth, with diameters

ranging from 29 to 300 mm, 60-70% of bamboo is

made up of fibers, and the fiber substance is more

prominent at the edges than inside. The average

height of bamboo is about 100 times its diameter

(Atanda, 2015).

Bamboo plants can grow rapidly which only

takes about four years to reach adulthood, compared

with timber plants and fruits that take a long time to

reach adulthood. In addition, in terms of carbon

dioxide absorption, bamboo absorbs more carbon

dioxide than wood or fruit trees. One hectare of

bamboo plants can absorb more than 12 tons of

carbon dioxide in the air. This is a considerable

amount. By preserving the bamboo forests, we have

already had a large carbon dioxide suction machine

(Raka, et al., 2011). Bamboo forests are an

important type of forest in many countries,

especially in East and Southeast Asia and in African

countries. Bamboo is versatile not only in its

utilization but also for environmental protection.

There is an old saying "bamboo is the wood of the

poor", it shows its status in people's lives in the

alleviation of poverty and the preservation of rural

nature. Bamboo has great potential in soil erosion

control, water conservation, land rehabilitation and

carbon sequestration (Zhou, et al, 2005).

Bamboo is a giant grass in the Bambusoideae

family, shell-shaped, orthotropic, high-strength

longitudinal direction and low-power transverse

direction. The distribution of fiber varies along its

thickness. Fiber on bamboo is concentrated more

closely on the outer shell (Pic. 1), as the endurance

of wind gusts during its growth (Ghavami, 2008).

Figure 1: Bamboo Structures (Ghavami, 2008).

2 LITERATUR REVIEW

In tropical rainforest, bamboo spreads freely with

still disruption of logging and forest encroachment.

Bamboo is the fastest growing plant, reaching its

peak in two to four months, and branching begins as

soon as the stem reaches its optimum height. It is

estimated that bamboo clumps can develop in its

lifetime produce up to 15 km from the center grow

with the diameter of the stem can reach 30 cm. So

bamboo is very strong and dynamic in its growth.

Due to the rapid accumulation of biomass and the

effective fixation of solar and carbon dioxide

energy, the carbon sequestration ability of bamboo

tends to be second to none compared to other plants.

According to estimates, one quarter of the biomass

in the tropics and one fifth in the subtropical region

comes from bamboo (Anonymous, 1997).

Approximately 80% of bamboo-containing areas are

located in tropical regions of South and Southeast

Bamboo Green Materials for Environmental Sustainability Constructions

207

Asia, most likely contributing significantly to the

world's carbon sequestration by bamboo (Zahou et

al., 2005).

Bamboo leaves that fall under the bamboo is able

to keep the soil moisture. Thick bamboo sheets help

absorb and retain moisture more effectively, and

reduce evaporation of water from the soil surface.

Bamboo leaves also help increase soil organic

content. Bamboo waste has a high water retention

capacity. With respect to soil moisture, bamboo can

withstand 2.75 times more weight than its own dry

weight (Huang et al., 1997). Dendrocalamus

latiflorus density with a density of 825 cigarettes per

hm2, has the capacity to absorb moisture from 2.7 to

2.9 times the dry weight. The maximum forest

holding capacity with Phyllostachys pubescens

mixed with Cunninghamia lanceolata can reach

21.29 t.hm

-2

, much higher if only Cunninghamia

lanceolata reaches 7.37 t.hm

-2

(Chen, 2000). The

same conclusion has been generated by other

researchers (Wu, et al., 1992; Zheng, et al., 1995;

Zeng, et al., 1998; Zheng, 1998; Lin, 2002).

Bamboo has thick green leaves and thick clumps

that can help withstand large amounts of rainfall. A

study in China proves that bamboo clumps can hold

up to 25% of rain that falls directly to the soil

surface, a value much higher than conifers and

pines. The interception of clumps depends on the

quantity of rods and the index of leaf area (Wu et al.,

1992). Sympodial bamboo also has a high

interception capacity. Zhou, et al., (2005), states the

interception of rainfall in Dendrocalamopsis

latiflorus forest in South China. Interruption of

bamboo clumps each year is 128.1 mm for bamboo

forest with media spacing of 3 m x 4 m, 6 stems in

each clump and an overall density of 5,000 stems

per hectare. And the interception ratio was 14.5%,

with a runoff coefficient of 7.47%. It was found that

the interception of bamboo clumps has a positive

correlation to the density of clumps with total

rainfall.

Roots and bamboo rhizomes underground can

form like a woven mat that is effective in holding

the soil. The soil around bamboo plants is absorbed

by intertwined roots. Many studies show that most

80% bamboo rhizomes and roots are present at 0-30

cm of topsoil, ie areas where roots and rhizomes

work best in controlling soil erosion. The bamboo

species studied in this aspect are Phytlostachys

pubescens (Xiao, 1983; Wu, 1984; Zhou, et al.,

1985; Wang, et at., 2000), Pseudosasa amabilis

(Chen, 2002), Phytlostachys praecox (He, et al.,

1995; Hu, et al., 1994), Qiongzhuea tunffdinoda

(Dong, et al., 2002), Phyllostachys makinoi (Huang,

et al., 1994), Phyllostachys bissetti (Zeng et al.

1998), Dendrocalamus latiflorus (Lin, et al, 2000),

Dendrocalamopsis oldhami (Linet, al., 1998) dan

Bambusa tulda (White dan Childers, 1945). The

roots and rhizomes of bamboo though grow shallow

in the ground but horizontally widen. Bambusa tulsa

roots, simpodial bamboo species with short rhizomes

can extend horizontally up to a distance of 5.2 m

(White and Childers 1945). For monopodial species

with pervasive rhizomes, the total length of

rhizomes per hectare in Phyllostachys heterocycla,

Phyllostachys viridis and Phyllostachys nigra

respectively range from 50 to 170 km, 90 to 250 km

and 200 to 320 km (Xiao 2002).

Bamboo plants are very useful for controlling

soil erosion. Able to grow well on steep hillsides,

embankments, ditches, or on the banks of lakes and

rivers. In the Hakoneama Mountains of Japan, the

bamboo groves of Sasa and Indocalamus are

scattered in mountainous areas with an altitude of

1000 m asl. In Brazil introduced Bambusa blumeana

and Phyllostachys pubescens to control soil erosion,

prevent the loss of soil nutrients and improve soil

structure (Fu, et al., 2000). The advantages of

bamboo in controlling soil erosion are its broad

fibrous root system, interconnected rhizome system,

leafy leaves that can be produced on the soil surface,

its relatively dense foliage protects from high

rainfall, and always produces new stems from

underground and rhizomes that allow harvesting

without damaging the soil (Zhou, et al., 2005).

Erosion is one of the most severe types of soil

degradation, which causes the loss of topsoil and

greatly threatens the productivity of the land. The

Puerto Rican researchers experimenting with several

species of bamboo found that bamboo is one of the

most effective in controlling erosion. Bamboo

commonly used for erosion control purposes is the

Bambusa vulgaris species (White and Childers

1945; Anonymous 1997).

In Japan for erosion control purposes, bamboo is

generally grown in special places that are susceptible

to erosion. In southwestern Japan, bamboo is widely

grown in coastal areas overlooking the Pacific

Ocean. Particularly in Kagoshima prefecture, it has

been used as a protective web of hill erosion, a kind

of hedge fence called "Karami" for erosion control

for over 100 years (Shibata, et al., 2002). In China,

about 90% of bamboo forests are naturally located

upstream of rivers, lakes, reservoirs, or along the

banks of rivers. The bamboo forest area accounts for

5% of the total forest area in the Yangtze basin,

4.5% in the Pear river valley and 2.5% of the Huaihe

River basin (Li, 1998). Bamboo forests have played

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

208

an important role in protecting the river banks. In the

Dayingjiang river in Yunnan province and

Jiulongjiang river in Fujian province, bamboo has

succeeded in protecting the river banks after efforts

with tree planting failed to protect the river banks

(Anonymous, 1997; Fu, et al., 2000).

In the last five decades or so, 1,2 billion hm

2

of

land (11% of the total land vegetation) was reported

to have been degraded as far as their original biotic

function was damaged (Oldeman, et al., 1990).

According to a UNEP report (1992), at least a

quarter of agricultural land degradation is caused by

humans (agricultural practices, overgrowing,

deforestation, etc.). With green bamboo shoots, large

biomass accumulation, and abundant litterfall,

bamboo has played a major role in the rehabilitation

of degraded lands. In China, India and Thailand,

appropriate bamboo agro-forestry models for

planting in degraded lands have been developed. In

China, three types of bamboo-agroforestry models

have been established, which include an agro-

silvicultural system (bamboo + tea, bamboo + wood

needle or broadleaf, bamboo + food crop), silva-

pastoral system (bamboo + fish or poultry) and

special agro-forestry systems (bamboo + edible

fungus and bamboo + medicinal plants) (Fu, et al.,

2000).

From the literature study can be stated that

bamboo can reduce the effect of global warming.

Bamboo is very environmentally friendly so the use

of bamboo as green material for kontsruksi is very

important to do. At the age of 5 - 6 years bamboo

stems can be harvested continuously without the

need to plant again because of the growth of fast

growing bamboo shoots.

3 PROBLEM IDENTIFICATIONS

At this time the timber with good quality has been

difficult to obtain, so the wood is increasingly rare

for building construction. However, the wood will

be needed because it has several advantages over the

baton and steel. The advantages of wood of which

have good mechanical properties, where in the

weight ratio of the power compared to a higher kind

than concrete and steel in addition to approaching

the renewable nature and aesthetics (Yasin, et al.,

2015). To reduce deforestation due to logging for

construction materials, it is time to replace wood

with bamboo. Bamboo has a good strength when

used properly for construction.

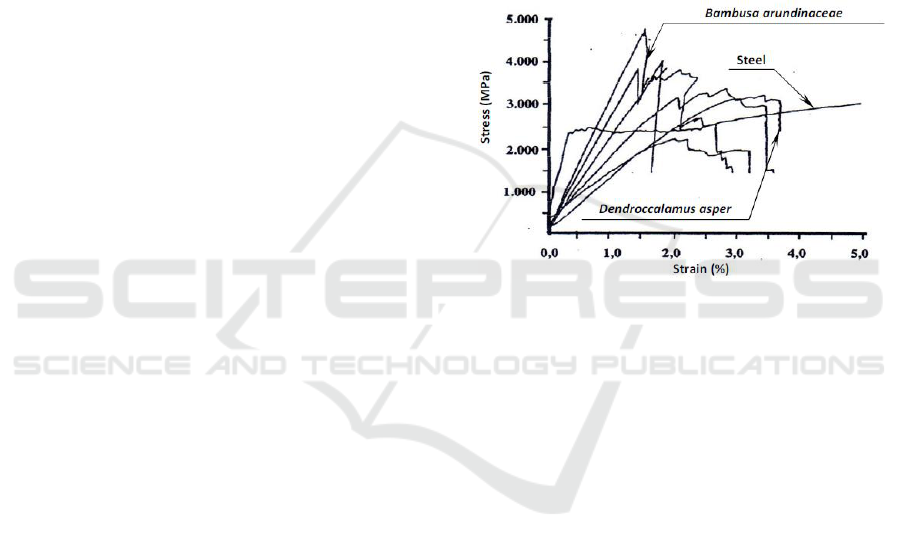

Bamboo fiber has a high tensile strength

(Ghavami, 2005). Tensile strength bamboo fiber

ranging between (150 - 320) MPa, greater than the

tensile strength of wood fibers ranges (34 - 220)

MPa. Parenchyma sell structures more dense with

age bamboo, the bamboo optimum density occurs in

4 years old (Li, et al., 1995). Describes the use of

bamboo which is divided into a traditional bamboo

(conventional) and bamboo engineering (experience

the manufacturing process) (Xiaohong and Yuloin,

2005). Morisco (2006), examined the tensile

strength of bamboo parallel fibers without the nodia

of the Bambusa arundinaceace skin much larger

than the tensile strength of the reinforcing steel, and

the tensile strength of the bamboo fiber in all the

thickness of Dendrocalamus asper.

Figure 2: Bamboo Stress-Strain Graphic (Morisco, 2006).

Abundant supply of bamboo is abundant, its use

is very effective and efficient, because cheap and

easy to train in processing / processing, do not

require many personnel and conventional method

used (Hermanto et al., 2010). For the construction

materials the effect of bamboo treatment on bamboo

mechanical properties requires further assessment.

4 OBJECTIVES

Bamboo as a green material can reduce the effects of

global warming needed for the sustainability of the

environment and the earth is back green and

comfortable as a place of human life and nature.

This study aims to determine the mechanical

properties of bamboo affected by the treatment

during construction. The treatment of bamboo

material in this study is the effect of pressure.

Because in the construction process to obtain the

desired shape, bamboo get pressure treatment, either

the pressure of the laminate on the bamboo, or the

pressure due to be hit at the time of grafting, etc.

Bamboo Green Materials for Environmental Sustainability Constructions

209

5 METHODOLOGY

The research material is bamboo Dendrocalamus

asper 5 years old originating from Purwobinangun

Slema region of Yogyakarta Special Province

region. The bamboo plants on the slopes of Mount

Merapi are thriving so as to become the bamboo

supplier of Dendrocalamus asper in the area around

Yogyakarta. The bamboo portion is selected to

obtain bamboo blades with an average thickness of

10 - 15 mm and the blade width averaging 35 mm.

The size and shape of bamboo test object

mechanical testing based on ISO 3129-1975

includes compressive strenght specimens, shear

strenght specimens, tensile strenght specimens and

modulus of elasticity specimens.

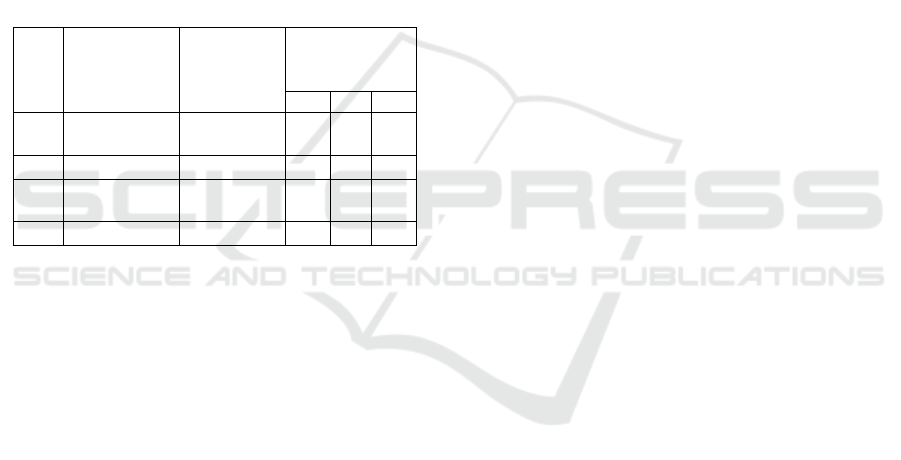

Table 1: Specimen Mechanical Properties Testing of

Dendrocalamus asper.

No

Mechanical

Properties of

Speciment

Without

Lateral

Compression

With Lateral

Compression

(MPa)

1.5

2

2.5

1

Compression

Strength

10

10

10

10

2

Shear Strength

10

10

10

10

3

Tensile

Strength

10

10

10

10

4

MoE

10

10

10

10

Mechanical properties testing were done after the

specimen on the dry conditions of the furnace. Water

content of specimens in the range of 12 - 13% in

accordance with ISO 3129-1975 standards. Testing

specimens were done using Universal Testing

Machine (UTM).

6 RESULT AND DISCUSSION

Anova calculation for bending strength on bamboo

base material with 1.5 MPa pressure resulted F

count

=

1.008 (less than F

table

= 4,41) and probability value

0,342. At the pressure of 2 MPa fitting yield value

F

count

= 0.896 (smaller than the value F

tabel

= 4.41)

and probability value 0.371. At the pressure of 2.5

MPa fitting yield value Fcount = 0.0002 (smaller

than the value F

table

= 4.41) and probability value

0.988. This means that the pressure variation of up

to 2.5 MPa does not give a significant difference to

the bending strength of the bamboo base material, in

other words that the pressed pressure up to 2.5 MPa

has no significant effect on the bending strength of

the bamboo base material.

Calculation of anova for MoE on bamboo base

material with 1.5 MPa pressure resulted F

count

=

0,934 (less than F

table

= 4,41) and probability value

0,362. At the pressure of 2 MPa fitting yield value

F

count

= 0.284 (smaller than the value F

table

= 4.41)

and probability value 0.608. At the pressure of 2.5

MPa fitting yield value F

count

= 6.140 (greater than

F

table

value = 4.41) and probability value 0,038. This

means that the pressed pressure variation up to 2

MPa does not give a significant difference to the

MoE of bamboo base material, in other words that

the pressed pressure up to 2 MPa does not give

significant effect to the MoE of bamboo base

material. While the pressure of 2.5 MPa has a very

significant effect on the basic material of bamboo so

that 2.5 MPa pressure gives a significant effect on

the basic material of bamboo.

The calculation of anova for tensile strength on

bamboo base material with 1.5 MPa fitting pressure

yields F

count

= 5,251 (greater than F

table

= 4,41) and

probability value 0.051. This shows that the pressure

of 1.5 MPa has a very significant effect on the

tensile strength of bamboo base material so as to

give a significant effect on the tensile strength of

bamboo base material. At the pressure of 2 MPa

fitting yield value F

count

= 0,048 (smaller than value

F

table

= 4,41) and probability value 0,831. At the

pressure of 2.5 MPa fitting yield value F

count

= 1.283

(smaller than the value F

table

= 4.41) and probability

value 0.290. This means that the variation of the

pressed pressure up to 2 MPa and 2.5 MPa pressure

does not give a significant difference to the tensile

strength of the bamboo base material, in other words

that the pressed pressure up to 2 MPa and 2.5 MPa

has no effect significant to tensile strength of

bamboo base material.

Calculation of anova for shear strength on

bamboo base material with 1.5 MPa fission pressure

yields F

count

= 0,301 (less than F

table

= 4,41) and

probability value 0,597. At the pressure of 2 MPa

fitting yield value F

count

= 0,006 (smaller than value

F

table

= 4,41) and probability value 0,942. At 2.5

MPa pressure, F

count

value = 0,4002 (less than F

table

=

4,41) and probability value 0,545. This means that

the variation of the pressed pressure up to 2.5 MPa

does not give a significant difference to the shear

strength of the bamboo base material, in other words

that the pressed pressure up to 2.5 MPa has no

significant effect on the shear strength of the

bamboo base material.

The calculation of anova for compressive

strength of perpendicular fiber on bamboo base

material with 1.5 MPa fitting pressure gives F

count

=

0,232 (less than F

table

= 4,41) and probability value

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

210

0,643. At 2 MPa fission pressure yields F

count

=

1.617 (less than F

table

= 4.41) and probability value

0.239. At 2.5 MPa pressure, F

count

= 4,874 (greater

than F

tabel

= 4,41) and probability value 0,058. This

means that the variation of the pressed pressure up to

2 MPa does not give a significant effect on the

compressive strength of upright bamboo fiber

material, in other words that the pressed pressure up

to 2 MPa does not give significant effect to the

compressive strength of the bamboo fiber. While the

compressive strength of the bamboo fiber upright at

the pressure of 2.5 MPa gives a significant

difference in effect so that 2.5 MPa felting pressure

gives a significant influence on the compressive

strength of the bamboo fiber base perpendicular

used.

7 CONCLUSIONS

Bamboo has great potential in reducing the impact

of global warming. With the ability of bamboo in the

control of soil erosion, water conservation,

environmental conservation, land rehabilitation, and

ability in carbon sequestration provide a promising

future of life on earth. Bamboo forests are important

to replace wood as a construction material of the

future.

Analysis of Variance (Anova) bamboo treatment

with lateral stress as a construction material has an

effect on bamboo mechanical properties. In strong

bending, tensile strength and bamboo shear strength

with lateral stress up to 2.5 MPa have no significant

effect on bamboo properties. While on Eastic

Modulus of Elasticity and bamboo compressive

strength with lateral stress up to 2.5 MPa have

significant effect on bamboo properties.

REFERENCES

Alfonso, D. J., 1987. “Let’s plant bamboo”, Agribusiness,

Vol. 1, No. 19, p. 25.

Anon, 1988. The New Encyclopedia Britannica

(Micropaedia), Vol. 1, Encyclopedia Britannia Inc.,

Chicago, p. 980.

Anonymous, 1997. Healing Degraded Land, INBAR

Magazine, Vol 5, No. 3, pp. 40-45.

Atanda, 2015. “Environmental impacts of bamboo as a

substitute constructional material in Nigeria, Case

Studies in Construction Materials”, Case Studies in

Construction Materials, Vol. 3, pp. 33–39.

Chen, K., 2000. “Study on Water Conservation Function

of Mixed Forests of Chinese Fir and Phyllostachys

pubescens”, Journal of Fujian Forestry College, Vol.

20, No. 3, pp. 258-261.

Chen, D., 2002. “Study on The Bamboo Rhizome Growth

of Pseudosasa amabilis McCl”, Journal of Bamboo

Research, Vol. 21, No. 2, pp. 48-53.

Dong, W., Huang, B. & Xie, Z., 2002. “Study on The

Pattern of Rhizome Growth of Qiongzhuea

tumidinoda clone”, Journal of Bamboo Research, Vol.

21, No. 4, pp. 56-60. (In Chinese).

Fu, M., Jianghua, X. & Yiping, L., 2000, Cultivation and

Utilization on Bamboo, Beijing: China Forestry

Publishing House.

Gervet, B., 2007. Deforestation Contributes to Global

Warming, Renewable Energy Research Group,

Division of Architecture and Infrastructure, Lulea

University of Technology, SE-97187 Lulea, Sweden.

Ghavami, K., 2005, Bamboo as Reinforcement in

Structural Concrete Elements, Cement & Concrete

Composites, 27 pages 637–649.

Ghavami, K., 2008, “Bamboo: Low cost and energy

saving construction materials”, Proceeding Bamboo

Modern Structures, CRC Press, London.

He, J., Fang, W. & Lu, X., 1995. “Subterranean Structure

of High-Yield and High Effective Phyllostachys

praecon Forest for Shoot and Timber”, Journal of

Zhejiang Forestry College, Vol. 12, No. 3, 247-252.

Hermanto, N. I. S., Eratodi, I. G. L. B., Masdar, A. &

Morisco, 2010. Pemanfaatan Bambu Sebagai Material

Pilihan Pada Struktur Bambu Modern, Prosiding

Konferensi Nasional Teknik Sipil 4 (KoNTekS 4),

Sanur-Bali, 2-3 Juni 2010.

Hu, C., Jin, A. & Zheng, J., 1994. “Systematic Structure of

Phillostachys praecon Rhizome”, Journal of Zhejiang

Forestry College, Vol. 11, No. 3, pp. 264-268.

Huang, K., Liang, D. & Zeng, Z., 1994. “Rhizome

Distribution of Phyllostachys makinio”, Journal of

Fujian Forestry College, Vol. 14, No. 3, pp. 191-194.

(In Chinese).

Lessard, G. & Chouinard, A., 1980. Bamboo research in

Asia, In: Proceedings of a workshop held in

Singarpore, IDRC, Ottawa, Canada.

Li, S.H., Zeng, Q.Y., Xiao, Y.L., Fu, S.Y. & Zhou, B.L.,

1995, Biomimicry of Bamboo Bast Fiber with

Engineering Composite Materials, Materials Science

and Engineering, C3 pages125-130.

Li, Y., 1998, Current Status and Prospects of Bamboo

Resources in China, Workshop of developing bamboo

and rattan, Beijing, INBAR.

Li, Z., Fu M. & Xu, D., 2003. “Bamboo Ecosystem and

Carbon Dioxide Sequestration”, Journal of Bamboo

Research, Vol. 22, No. 4, 1-6.

Lin, H., 2002. “Studies on Water Conservation Function

of Phyllostachys makinoi and Fokienia hodginsii

Mixed Forests”, Fujian Forestry Sci & Tech, Vol. 29,

No. 3, pp. 18-22. (In Chinese)

Lin, Y., Lin, P. & Ye, Y., 1998. “Biomass and Structure of

Dendrocalamopsis oldhami Population”, Journal of

Bamboo Research, Vol. 17, No. 2, pp. 9-13. (In

Chinese).

Bamboo Green Materials for Environmental Sustainability Constructions

211

Lin, Y., Li, H. & Lin P., 2000. “Biomass Structure and

Energy Distribution of Dendrocalamus latiflorus

Population”, Journal of Bamboo Research, Vol. 19,

No. 4, 36-41. (In Chinese).

Morisco, 2006. Teknologi Bambu. Departement of Civil

Engingeering and Enviromental, Gadjah Mada

University, Yogyakarta.

Oldeman, L., R., 1990. World Map of the Status of

Human-Induced Soil Degradation, Wageningen,

Netherlands: International Soil Reference and

Information Center.

Paulo, M., 2012. Deforestation around the World, Intech,

First published March, Croatia, ISBN 978-953-51-

0417-9.

Raka, I. D. N., Wiswasta, I. G. N. A. & Budiasa, I. M.,

2011. “Pelestarian Tanaman Bambu Sebagai Uapaya

Rehabilitasi Lahan Dan Konservasi Tanah Di Daerah

Sekitar Mata Air Pada Lahan Marginal Di Bali Timur,

Agrimeta”, Jurnal Pertanian Berbasis Keseimbangan

Ekosistem, Vol. 1, No. 1.

Shibata, S., Iwanaga, Y. & Kamimura, K., 2002.

Revegetation of Roadside Manmade Slopes with

Karami Fencing and by Burying Bambusa multiplex

Raeushel Culms, In: Lou, Y., (ed) Bamboo in disaster

avoidance, Beijing: INBAR, 3-11.

UNEP, 1992. The World Environment 1972-1992 - Two

Decades of Challenge, London: Chapman and Hall.

United Nations, 1972. The Use of Bamboo and Reeds in

Building Construction, New York: United Nations, pp

95.

Venkataraman, M. & Smitha, 2011. “Causes and Effects

of Global Warming”, Indian Journal of Science and

Technology, Vol. 4, No. 3.

Wang, K., He, Q. & Weng, P., 2000. “Investigation and

Analysis on Underground Rhizome and Root System

of Phyllostacys pubescens for Shoot and Timber”,

Journal of Bamboo Research, Vol. 19, No. 1, 38-43.

White, D. G. & Childers, N. E., 1945. “Bamboo for

Erosion Control”, J. American Society of Agronomy,

Vol. 37, pp. 839-847.

Wong, K. M., 1995. The Bamboos of Peninsular Malaysia

Forest, Research Institute Malaysia (FRIM) in

collaboration with Forest Research Center, Forestry

Department, Sabah, Malaysia. Malayan Forest

Records, No. 41.

Wu, B., 1984. “Subterranean Structure and Production

Analysis of Moso Bamboo Forest”, Journal of

Bamboo Research, Vol. 3, No. 1, pp. 49-58.

Wu, B., Xie, H. & Tan, Shu., 1992. “Preliminary study on

water conservation function of Phyllostachys

pubescens community”, Journal of Bamboo Research,

Vol. 1, No. 4, pp. 18-25.

Xiao, J., 1983. “Subterranean Structure of Timber

Bamboo Forest”, Bamboo Research, Vol. 2, No. 1, pp.

114-119.

Xiao, J., 2002. Pay More Attention to Ecological Benefits

of Bamboo Forests, In: Lou, Y. (ed.), Bamboo in

disaster avoidance, Beijing: INBAR, 49450.

Xiaohong, G. & Yulong, D., 2005. “Bamboo Science and

Culture”, The Journal of the American Bamboo

Society, Vol. 19, No. 1, pp. 16-22.

Yasin, I., Priyosulistyo, H., Siswosukarto, S. & Saputra,

A., 2015. “The Effect of Variable Lateral Stress of

Laminated Bamboo with Artificially Dent Surface on

Mechanical Properties”, International Journal of Civil

and Structural Engineering, Vol. 2, No. 2.

Zeng, L., Ren, P. & Li, Z., 1998. “Observation of

Biological Characteristics of Phyllostachys niduluria”,

Economic Forest Research, Vol. 16, No. 4, pp. 9-11.

Zheng, Y. & Yang, L., 1995. “Hydrologic Effect of Mixed

Stands of Cunninghamia lanceolata and Phyllostachys

pubescens Forests”, Journal of Fujian Forestry

College, Vol. 13, No. 3, pp. 18-22.

Zhou, B., Fu, M., Xie, J., Yang, X. & Li, Z., 2005.

“Ecological functions of bamboo forest: Research and

Application”, Journal of Forestry Research, Vol. 16,

No. 2, pp. 143-147.

Zhou, J., Hu, C. & Yang, L., 1985. “Investigation of

Rhizomes of Shoot-Oriented High-Yield Bamboo

Forest”, Journal of Bamboo Research, Vol. 4, No. 1,

p. 5745

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

212