The Flexural Strength of Wood Connection using Different Lengths

of Waste Plastic Bottle as Connector

Taufiq Lilo Adi Sucipto and Anis Rahmawati

Department of Civil Engineering, Faculty of Teacher Training and Education, Sebelas Maret University, Indonesia

Keywords: Flexural strength, Wood connection, Wood connector, Waste plastic bottle

Abstract: Various types of wood processing produce wood waste beside indeed the wood products. Wood waste can be

re used by joining it using wood connector, which was in this current study used waste plastic bottle by heating

the plastic using a hot air gun at a certain temperature. The length of the connector could be influence to the

strength of the wood connection. Therefor this study was conducted to observe the flexural strength of the

wood connection using waste plastic bottle as connector in some different lengths by doing an experimental

study. Thirty samples with 5x5x76 cm in dimension were prepared from five variations of the connection

length that were 5, 10, 15, 20, and 25 cm. Eight samples made for each variations of length. The results

indicate that the length of the connector significantly influence in the flexural strength of the wood connection.

The length of the plastic connector which met the highest flexural strength was 20 cm which was reach 65.091

kg / cm2 or 7.58% of the undamaged wood or wood without connection.

1 INTRODUCTION

Muhi (2011) states that global warming is basically a

phenomenon of global temperature increase from

year to year due to the greenhouse effect caused by

increased emissions of gases such as carbon dioxide

(CO2), methane (CH

4

), dinitrooxide (N

2

O) and

chloro fluoro carbon (CFC) so that solar energy is

trapped in the Earth's atmosphere. According to the

Green Building Council Indonesia 2009 in Utomo

(2012) all CO

2

emissions in the world, 30-40% are

produced by buildings, so that any reduction in

emissions in buildings will be of great leverage to

anticipate global warming.

The building sector has the potential to anticipate

damage to the earth, which is one of them by

implementing a concept of environmentally friendly

buildings or commonly referred to as the concept of

"green building", where the concept demands a

building with attention to environmental aspects,

starting from the planning, development process,

selection building materials, installation up to the

operational period. One effort that can be made by

humans to reduce CO

2

emissions using wood material

so that the Green Open Space is maintained, so that

the balance goes well.

Various types of wood processed to meet the

needs of construction, furniture and decorations that

produce products and waste. Wood cut waste is found

mostly in the timber sector processing. Wood pieces

can be used to increase the value of the function by

connecting. The connector that can be used is a plastic

bottle. Its presence in the environment is very large

and has not been utilized optimally, especially in the

field of wood connections.

Based on Jambeck (2015) Indonesia ranks the 2nd

largest country producing plastic waste. Whereas

plastic waste specifically, Baruno (2015) stated that

consumption of bottled drinking water in Indonesia

throughout 2014 was recorded at 23.1 billion liters. It

can be estimated that the number of plastic bottles in

Indonesia in 2014 is 15.4 billion bottles if all bottles

are 1.5 liters. Plastics used in bottled drinking water

generally from PET (Polyethylene Terephthalate)

plastic types. Quoted from Derucher et al 1981 in

Shinta (2008) states that PET has tensile strength

(1.5-1.8) x 10

3

psi, modulus of elasticity 0, 19 x 10

3

psi and impact strength <16 psi. While the resistance

to plastic bottles for weathering is estimated to be 500

years to 1,000 years until decomposition (Juniarta,

2016). So it is very necessary to do research on plastic

bottles used as wood connectors.

Plastic bottle connectors are made using a hot air

gun to heat the plastic until the entire surface of the

158

Lilo Adi Sucipto, T. and Rahmawati, A.

The Flexural Strength of Wood Connection using Different Lengths of Waste Plastic Bottle as Connector.

DOI: 10.5220/0009007801580162

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 158-162

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

plastic bottle shrinks and attaches to the wooden

surface of the connected part. This connection

technique was first exhibited in 2016 by Micaella

Pedros, an artist from London. Therefor this study

was conducted to observe the flexural strength of the

wood connection using waste plastic bottle as

connector in some different lengths by doing an

experimental study.

2 RESEARCH METHODLOGY

The flexural test based on the standard wood bending

test at the SNI 03-3959-1995 laboratory. The sample

used is 6 samples in each variation, while the number

of variations is 5 variations in connection length.

wood type is local teak wood from Kaliyoso, Central

Java with a size of 5 x 5 x 76 cm. The total sample

used is 30 samples.

The plastic bottles used are PET bottles

(Terephalate Polyethylene) with a capacity of 1500

ml. PET plastic bottles are used all from only one

brand. Variations in joint length were 5 cm, 10 cm, 15

cm, 20 cm and 25 cm. Plastic bottles are connected to

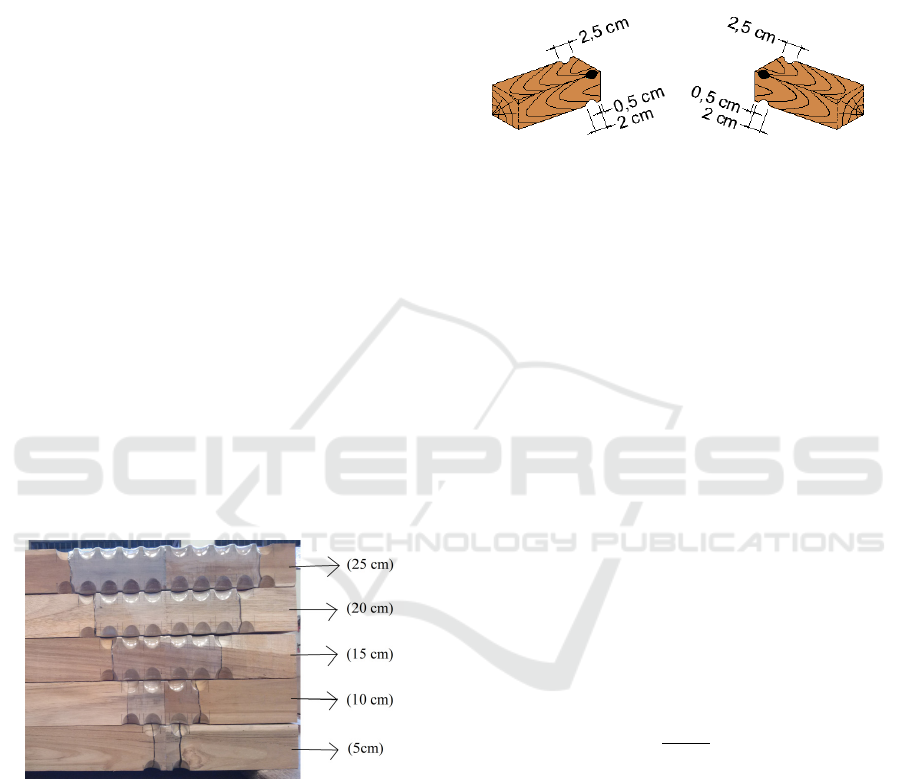

the center of the wood to be joined. The samples of

the connection for each variation can be seen in

Figure 1. The independent variables were the length

of the plastic bottle connector and the dependent

variable in this study was the flexural strength.

Figure 1: Wood joinned with plastic bottle in different

connector length variations.

The moisture content test was done so that the test

requirements are met. The maximum moisture

content for flexural strength test is 20%. Calculation

of water content according to ASTM D 4442-92-

2003. When wood moisture content requirements

were met, the wood were processed to a dimension of

5 x 5 cm and a length of 38 cm with 60 bars to be

connected, and 6 bars without being connected along

76 cm.

The wood bars were then given notches on each

corner of the wood crossing with the first notch edge

distance with a 0.5 cm from connection. The shape of

the semicircular notch is 2 cm in diameter with a

distance of 0.5 cm from the notch edge. The detail

projection is shown in Figure 2.

Figure 2: Projection of wood with semicircular notch.

The length of the plastic bottles were adjusted to

the length of the connection variation. The wood that

has been notched is then installed with plastic bottles

according to the length of the variation by means of

being heated using a hot air gun. The distance of the

hot air gun to the plastic bottle when the heating

process was around 7-10 cm. Plastic bottles were

heated to the entire plastic surface attached to the

wooden surface that was connected.

Excessive heating can make plastic bottles

whitening or melting should be avoided during

heating the plastic bottles. If both things happen, then

the strength will be different.

Test specimens that have been prepared were then

tested for flexural strength using the GoTech U60

type UTM (Universal Testing Machine). After

testing, the data were obtained maximum load or

maximum load received by the test spsciment (P).

Furthermore, calculating the flexural strength has the

following Equation (1).

σl

t

3PL

2bh²

(2)

Where, σlt is flexural strenght (kg/cm

2

), P is

maximum load (kg), L is support distance (cm), b is

speciment widht (cm) and h is speciment hight (cm).

The data obtained from the test were then

processed by doing outlier detection, i.e. cleaning

data from outlier data. Outlier data in this study were

data that have a z-score outside the range for data less

than 80 that is -2.5 to 2.5. If outlier data were found,

the data should be discarded because it cannot be

used. This data were then analyzed using simple

linear regression analysis using the SPSS application.

Before performing regression analysis, normality and

linearity tests were used as prerequisites.

The Flexural Strength of Wood Connection using Different Lengths of Waste Plastic Bottle as Connector

159

3 RESULTS AND DISCUSSION

The wood moisture content testing based on ASTM

D 4442-92-2003 produces an average moisture

content of 15.90%. The moisture content had met the

requirements of flexural testing.

Relative strength is a comparison of the flexural

strength of original wood (without connection) with

joinned wood in percentage form. Flexural strength

test results can be seen in Table 1.

Table 1: Flexural strength test result.

Connector Length

(cm)

Flexural

Strenght

(kgf/cm

2

)

Relative

Strenght (%)

5 22.881 2.666

10 37.759 4.400

15 50.799 5.919

20 65.091 7.584

25 61.662 7.185

Wood without

connection 858.228 100

Figure 3. Stretched plastic.

Figure 4. Torned plastic.

Figure 5. (A) Broken wood and (B) Torned plastic.

Plastic bottle as connector behave along the

testing deforming, streching and torning slowly. It

torn at the wood edges near the bottom connection.

Meanwhile, it strech shown when the plastic detached

from the semicircular notch. In line with Stoebe's

(2007) statement that if polyethylene is stretched, the

molecule moves so that it becomes longer and

inherence with the direction of attraction. With a load

speed of 2.5 mm per minute with ± 25% deviation

allowed (SNI 03-3959-1995), the plastic will stretch

as long as it receives the load in the form of tensile

force (bottom section) and will tear if it is no longer

able to stretch.

In addition to plastic, wood breaks at the cross-

sectional angle of the upper joint (compressive force).

When the wood is broken, the flexural strength

decreases drastically and will rise again as long as the

plastic is still able to withstand the load. The cause of

this break in wood is estimated because the distance

of the notch is too close to the connection. As quoted

from Handayani (2009) states that there is a minimum

distance between connecting devices, so that the

wood can avoid the possibility of rupture.

The value of the wood flexural strength of this

connection can also be affected by the number of

connection layers. The number of connecting devices

greatly affects the strength of the connection (Sadiyo

et al, 2012). A connection layer that uses only one

layer less contributes to good flexural strength. It is

proven that only one layer of plastic connection will

be easier to stretch and the plastic part that in the

notch is easy to return straight because the size of the

thickness of the plastic bottle is very thin.

This plastic bottle connection is also compared to

other types of connections obtained from Safitri &

Gunawan (2010) study of flexural testing of wooden

beams in the cross section of 6 cm x 12 cm with

phenol epoxy adhesive consisting of two types of

components, namely adhesive components (resin)

and hardener component with finger joint connection

1: 2 slope ratio of 115,541 kg / cm², 1: 4 equal to

151,014 kg / cm² value of woodless joint flexural

strength of 537,268 kg / cm². Whereas based on

research (Aji & Dermawan, 2013) from testing the

flexural strength of wood beams 6 cm x 12 cm with

ALF Epoxi Adhesive adhesive material, hooked

bevel lip connection (BSBMB) has decreased flexural

strength of 91.14% or has flexural strength 8.86% of

timber without connection. Graph comparison of the

percentage of flexural strength can be seen in Figure

6.

In Figure 6, PBC (Plastic Bottle Connection) is a

wooden connection that uses plastic bottle connectors

that tested in this study, SLC (Sloped Lip Connection)

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

160

is a wooden connection using ALF Epoxi Adhesive

glue joint, FJC 1: 2 (Finger Joint Connection with a

slope ratio of 1: 2) is a wooden connection using

Phenol Epoxy glue joints and FJC 1: 4 (Finger Joint

Connection with a slope ratio of 1: 4) is a wooden

connection using Phenol Epoxy glue joints.

Figure 6: Flexural strenght rasio comparison of various

connected wood to wood without connection.

Figure 7: SLC wood speciment when collapsed (Aji &

Dermawan, 2013).

Figure 8. FJC Design (Safitri & Gunawan, 2010).

Based on Figure 6 plastic bottle connection is the

lowest strength type of connection compared to other

types of connections. So it can be concluded that the

innovation of plastic bottle joints is not good enough

to be used in the construction of dominant wood

withstand bending forces. But this plastic bottle

connection has advantages, including easy to get,

easy to make, elastic and shaped according to the

shape of wood. However, its use is still limited to

connecting longitudinal wood so that new

innovations are needed.

4 CONCLUSIONS AND

RECOMMENDATION

The results indicate that the length of the connector

significantly influence in the flexural strength of the

wood connection. The length of the plastic connector

which met the highest flexural strength was 20 cm

which was reach 65.091 kg / cm

2

or 7.58% of the

undamaged wood or wood without connection.

From this study, several recommendations can be

stated. The need for further research on how much

plastic bottles shrink so that the connection can be

installed according to the plan. Hereafter, notch

design as shear connector and the distance to the edge

of wood connections need to be observe to get

condition that between wood and plastic bottles can

collapse simultaneously, so that it can provide

maximum flexural strength. In order to get better

flexural strength, wood connections using plastic

bottle connectors need to be combined with other

connection devices such as glue.

ACKNOWLEDGEMENTS

We thank the Directorate General of Higher

Education (DIKTI), the Ministry of Research

Technology and Higher Education RI, for the

research funding.

REFERENCES

Aji, S. & Dermawan. L., 2013. “Alternatif Sambungan

Finger Joint Pada Balok Kayu Terhadap Pengujian

Kuat Lentur”, Majalah Ilmiah UKRIM, Vol. 2, pp. 12 -

26.

American Society Testing and Materials International,

2003. Designation: D 4442 – 92: Standard Test

Methods for Direct Moisture Content Measurement of

Wood and Wood-Base Materials. ASTM.

Baruno, H., 2015. Konsumsi Air Minuman Dalam Kemasan

di Indonesia Capai 23,1 Miliar Liter. Tribun News.

Retrieved on 27

th

February 2018, from http://www.

tribunnews.com/bisnis/2015/01/19/konsumsi-air-

minuman-dalam–kem asan-di-indonesia-capai-231-

miliar-liter.

Dwisetyowati, S., 2008. Studi Sifat-Sifat Mekanis Beton

Yang Menggunakan Agregat Kasar Dari Plastik Jenis

Polyethylen Terephtalate (PET). Skripsi. Departemen

Teknik Sipil Fakultas Teknik Universitas Indonesia,

Depok.

Handayani, S., 2009. “Metode Perekatan Dengan Lem

Pada Sambungan Pelebaran Kayu”, Jurnal Teknik

Sipil & Perencanaan UNNES, Vol. 11, pp. 11–20.

7.58

8.86

21.51

28.11

0

5

10

15

20

25

30

PBC SLC FJC 1:2 FJC 1:4

Flexural strength ratio of

connected wood to wood

without connection (%)

The Flexural Strength of Wood Connection using Different Lengths of Waste Plastic Bottle as Connector

161

Jambeck, J. R., Geyer, R., Wilcox, R., Siegler, T. R.,

Perryman, M., Andrady, A., Narayan, R. & Law, K. L.,

2015. “Plastic waste inputs from land into the ocean”,

Science, Vol. 347, pp. 768 - 771.

Jihannanda, P., 2013. Studi Kuat Lentur Balok Laminasi

Kayu Sengon dengan Kayu Kelapa di Daerah Gunung

Pati Semarang. Retrieved on 23

th

January 2017, from

http://lib.unnes.ac.id/19159/1/ 5101409104.pdf.

Juniarta, F., 2016. Berapa Lama Sampah Plastik Dapat

Terurai?. Klik Dokter. Retrieved on 6

th

May 2017, dari

http://www.klikdokter. com/info-sehat/read/2697192/

berapa-lama-sampah-plastik-dapat-terurai.

Muhi, A.H., 2011. Pemanasan Global (Global Warming).

Jawa Barat: Institut Pemerintahan Dalam Negeri

(IPDN).

Pedros, M. 2016. Joining Bottle. Retrieved on 27

th

January

2017, from http://micaellapeedros. com.

Sadiyo, S., 2012. “Analisis Kekuatan Sambungan Geser

Ganda Enam Jenis Kayu pada Berbagai Sesaran

Menurut Diameter dan Jumlah Baut”, Jurnal Perennial,

Vol. 8, No. 2, pp. 52-61.

Safitri, E. & Gunawan, P. 2010. “Pengujian Sambungan

Finger Joint Untuk Mengkaji Kuat Lentur Pada Balok

Kayu”, Media Teknik Sipil, Vol. X, No. 2, pp. 113-118.

SNI 03-3959-1995. Metode Pengujian Kuat Lentur Kayu di

Laboratorium.

Stoebe, T., 2007. Plastic Stretch. University of

Washington: Copyright Edmonds Community College.

Retrieved on 6

th

March 2018, from

http://www.materials education.org/educators/matedu-

modules/docs/Plastic_ STRETCH.

Utomo, C. & Firsani, T., 2012. “Analisa Life Cycle Cost

pada Green Building Diamond Building Malaysia”,

Jurnal Teknik ITS, Vol. 1, No. 1, pp. D34-D39.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

162