Limitation in Conventional Oedometer Consolidation Test for Deep

Layered Soil

Adhya Nanda Kumara, Widjojo Adi Prakoso and Tommy Ilyas

Department of Civil Engineering, Faculty of Engineering, Universitas Indonesia, Depok, Indonesia

Keywords: Oedometer, Consolidation, Preconsolidation, Geotechnical, Soil Test, Terzaghi.

Abstract: Consolidation test for soil is a very common test to find compression parameter in geotechnical

investigation. Terzaghi invented the theory of consolidation in 1925 and the test became geotechnical

standard in 1945. Since then, the theory and mechanical in this test has no meaningful improvement,

whereas due to the rise in numbers of high-rise buildings, the foundation depth requirements are increasing.

In consolidation test, deeper foundation means higher pressure required to find the preconsolidation

pressure (pc). Meanwhile, the conventional equipment is still very popularly used in commercial

geotechnical laboratories causing the result from consolidation less accurate. This paper will discuss the

impact in consolidation test using conventional equipment for deep- layered soil and how to improve the

result of consolidation test.

1 INTRODUCTION

Consolidation test is one of the most common and

important test in geotechnical investigation. Its

purpose is to find the compression parameter from

soil, so that soil engineer can predict soil settlement

caused by the additional load from the construction

or structure. The theories of consolidation was

proposed by Terzaghi in 1925 and by 1945 this test

has become standard test in geotechnical society

(Head, 1998).

When the theory of consolidation was developed,

geotechnical world was still very young and

complex computer computations were still in early

stage, so like any other theory in its time, Terzaghi

developed the theory of consolidation with some

assumptions to simplify the mathematical

calculations. He developed testing apparatus called

Oedometer that only allowed the soil specimens to

move in one direction or also known as One-

Dimension Test (1D). But due to its simplicity and

accuracy, Terzaghi’s consolidation testing method

can easily be accepted in geotechnical society and

largely used in geotechnical practices all over the

world.

The oedometer consolidation apparatus works by

molding an undisturbed soil specimen inside a thin-

steel ring (1-inch) to confine the soil, then the soil

will be loaded with loading mechanism to simulate

the overburdened soil pressure. The steel ring is then

placed inside a watertight steel cell filled with water

to fully saturate the soil. By applying some load to

the soil with loading mechanism and monitoring the

deformation of the soil using a dial gauge, soil

settlement or consolidation could be observed from

this test. Later, the load will be added step by step to

observe the soil behavior to different loads, therefore

the apparatus is known as Incremental Loading (IL)

apparatus.

As technology development increases,

consolidation test was also developed further, but

the basic concept is still using the same principle.

Additional data acquisition and automatic loading

mechanism using step-motor or pneumatic pressure

only to simplify and automate the testing, but the

main concept is still based on Terzaghi’s theory of

consolidation. There are several new developments

in consolidation testing such as Constant Rate Strain

(CRS) and rowe cell, but they are not as popular as

Terzaghi’s Oedometer and not widely accepted in

geotechnical community.

When the apparatus become world standard, the

load requirement was not high. Back then, the final

set load for incremental loading is 800 kPa for

normal range of soil, and it could be extended to

1600 and 3200 kPa for stiff or overconsolidated

clays. These pressure equal to weight set of 64kg as

Kumara, A., Prakoso, W. and Ilyas, T.

Limitation in Conventional Oedometer Consolidation Test for Deep Layered Soil.

DOI: 10.5220/0009007601450150

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 145-150

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

standard weight when someone purchase the normal

oedometer equipment.

With the development of high-rise buildings,

deeper foundation is required, so the geotechnical

investigation which used to be only 20-30m depth, is

now required to be deeper to 50-80m, some even

requires more than 100m depth. With this additional

depth, it means the load requirement for the

geotechnical test also increases (BS1377:5, 1990).

With the increase in load requirement to simulate

the overburden pressure, this gives new challenges

for geotechnical testings, especially in laboratories.

The equipments being used in the laboratories also

needed to be checked for its specifications, since

most laboratory equipments has their limitations.

These laboratory equipment limitations never

became a problem for geotechnical laboratories in

Indonesia, since typically in Indonesia the soil

consist of soft soil, but now with the increase in load

requirement, it becomes a new challenge for

geotechnical laboratories in Indonesia.

This paper will discuss about the background

theory of load requirement for the consolidation test.

Then, then this paper will discuss equipment

limitations and what might happen when the soil

tested with less than load requirement. At the end,

we will discuss how to increase test accuracy in

consolidation testing.

2 PRECONDOLIDATE

PRESSURE

In 1920, Terzaghi introduced principle of effective

stress, where he demonstrate an apparatus filled with

water and on the bottom filled with cohesive soil

(Figure 1), by measuring the height of water (hw)

and unit weight of water, pressure applied to the soil

by the water could be measured. This principle is

called neutral stress (Terzaghi, 1943).

Figure 1: Terzaghi’s apparatus to simulate neutral stress.

With the same principle, this principle also

applied to the soil specimen beneath the earth, but

for the soil, there are overburden soil above the soil

specimen, so that by measuring the soil depth and

unit weight of overburden soil, pressure applied to

the soil specimen could be achieved. This pressure

known as total stress.

The difference between pressure caused by

overburden soil (total stress) and the pressure caused

by water (neutral stress) is known as effective stress.

This effective stress is a very important principle in

geotechnical testing, because soil deformation is not

affected by total stress, but only by effective stress

(Budhu, 2010).

Soil has a unique characteristic, where the soil

could maintain memory of the past maximum

effective stress (Budhu, 2010). This is known as soil

loading history and this value could be determined

from the consolidation test. In consolidation test, the

past maximum vertical effective stress that soil has

experienced is known as preconsolidation pressure

(ASTM D653-03, 2003). If the preconsolidation

pressure is less than the overburden effective stress,

it is known as normally consolidated soil, if the

preconsolidation pressure is more than the

overburden effective pressure, it is known as

overconsolidated soil.

According to ASTM D2435 (2011), to find

preconsolidation pressure the final pressure should

be minimum four times the preconsolidated

pressure. This means that the loading requirement is

four times the overburden effective stress from soil

specimen (ASTM D2435-11, 2011).

For example, to perform consolidation test for

soil with 77m-depth, the overburden effective

pressure would be around 600 kPa. The final

pressure for the consolidation test should be around

2400 kPa. Now, if the soil specimen taken from

140m-depth, the overburden effective pressure

would be around 1050 kPa, and the final pressure for

consolidation test should be minimum 4200 kPa.

What would happened if the final pressure is less

than four times the overburden pressure? For

example, this test was conducted for 139.5-meter-

depth soil specimen. The test was conducted in

Japan up to 10240 kPa. As discussed before, for

140m-depth specimen, final pressure required is

4200 kPa, so the final pressure for this test is more

than four times the overburden pressure. As shown

from Figure 2, the preconsolidation pressure of the

sample is 1900 kPa, which shown that the soil is

overconsolidated soil.

If the test stops at 2560 kPa which is more than

overburden pressure, but it does not reach four times

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

146

Figure 2: Consolidation result of Stress vs Void Ratio Graph for soil specimen with 139.5m-depth. (Data from Pondasi

Kisocon tested in Japan).

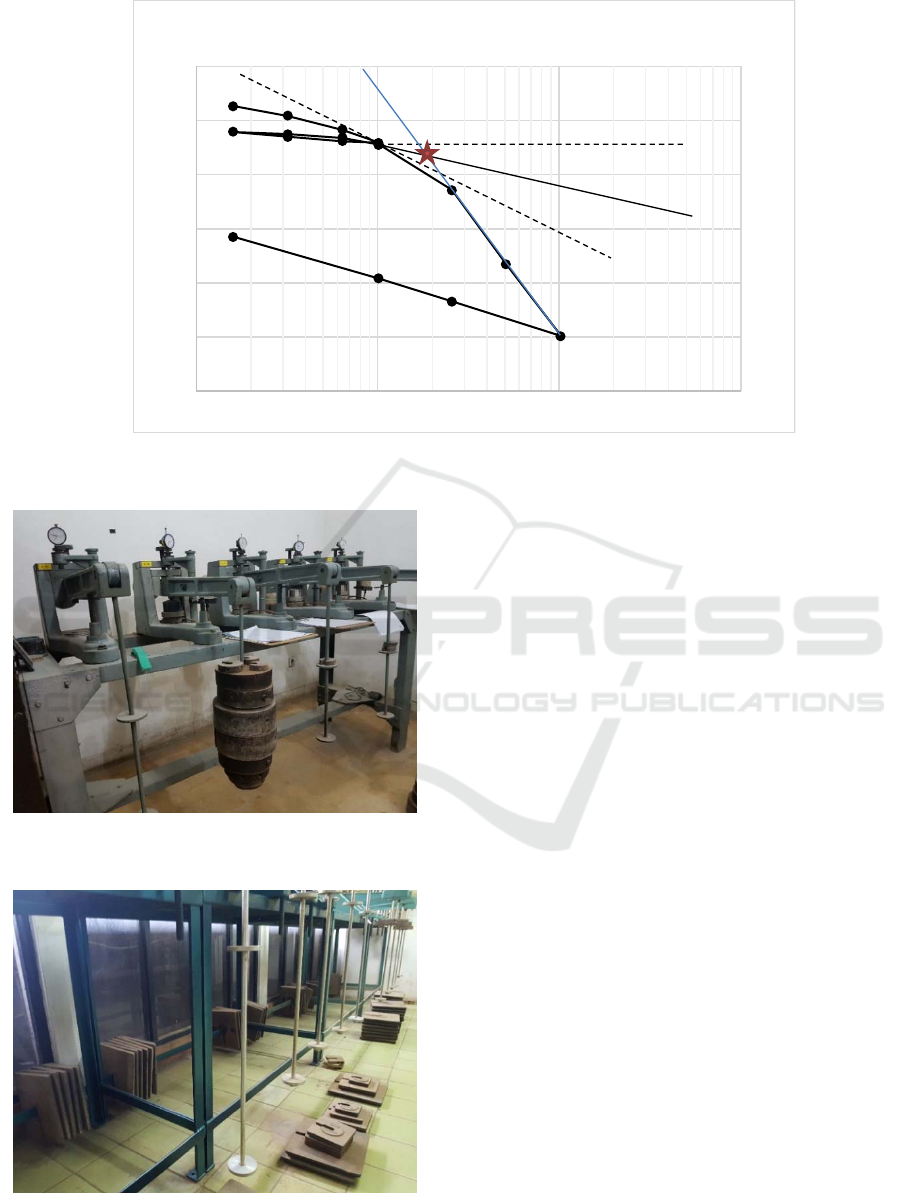

Figure 4: Maximum weight set up to 128 kg (2560 kPa).

And not possible to add more weight.

Figure 5: Counterweight to prevent equipment from

tilting.

the overburden pressure, the preconsolidation

pressure is only 750 kPa as Figure 3 shows and the

soil becomes normally consolidated. This would

make an error in the result of the consolidation test.

Another difference is in Compression Index

Value (Cc), where if the final load is properly set up

the Cc value is around 0.52, but if the final load only

stops at 2560 kPa the Cc becomes 0.78. Not only

Compression Index, Recompression Index (Cr) will

also be different.

From this exercise, the decision for final pressure

in consolidation testing is very important.

3 EQUIPMENT LIMITATIONS

To understand how difficult it is to increase load

pressure for deeper soil, we need to understand the

equipment specifications. Every equipment was

made with its specifications and limitations. If we

over-specify the equipment, there must be some

accuracy that being compromised.

Equipment specifications also depend on the year

that equipment was made. As discussed before, in

the old days load requirement is not as high as it is

as today, so most of old equipments were not

designed for very high load. This is one of the issue

in geotechnical practices in Indonesia, because most

geotechnical testing were done using very old

equipment. For example, the equipment that the

writer uses daily only have maximum weight up to

1280 kPa. We manage to add up to 2560 kPa by

0.400

0.500

0.600

0.700

0.800

0.900

1.000

100.00 1000.00 10000.00 100000.00

DB2‐139.5m (final:10240kPa)

pc‐a:1900

Limitation in Conventional Oedometer Consolidation Test for Deep Layered Soil

147

borrowing the weight set from other equipment. The

equipment itself is not possible to be added to more

than 2560 kPa, since there is no more room to add

more weight (Figure 4). The CRS consolidation

machine that the writer faces daily has load cell only

up to 2000 lbf or 2800 kPa, but after using it for

testing several samples with 2500 kPa, the motor

starts to break down. The equipment from the

university that the writer uses also only have weight

set up to 32 kg (1000 kPa). Since the equipment

from university was made from original ELE,

according to the specification, the equipment has

maximum load up to 8800 kPa, but in reality to set

up 8800 kPa is not easy because when such a high

load being used on the apparatus, the whole

apparatus needs to be counterweighted to prevent the

equipment from tilting (Figure 5).

As discussed before, to test 77m soil sample,

minimum load for consolidation test is around 2400

kPa and for 140m depth, the minimum load is 4200

kPa. Meanwhile if the equipment maximum capacity

is only up to 2560 kPa, the equipment is only accurate

up to 70-80m depth and not suitable to be used for

more than 80m depth. This is the reason why some

geotechnical companies send their sample to Japan

only for consolidation testing. The example above

was tested in Japan with load up to 10.000 kPa.

The quality-made of the equipment also affecting

the accuracy of the test. According to ASTM

D2435-03 the loading device shall have precision of

+/- 0.5% of applied load. With this precision, the

quality of equipment can make a difference

especially when the equipment is being pushed up to

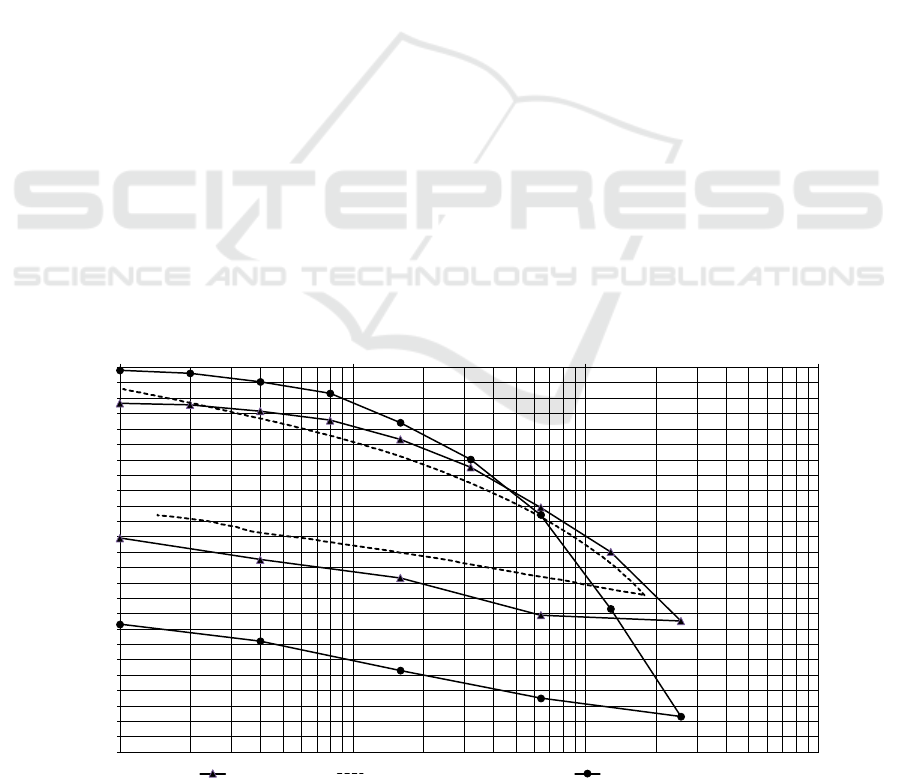

its limit. To compare between equipments, the writer

compares consolidation results between several

different equipments which are available (Figure 6).

For information, the CRS consolidation machine

was made in America, Oedometer E4 was made in

Japan, and Oedometer B3 was made in Singapore.

These equipments also have different models, while

CRS and Oedometer E4 has typical vertical load

frame, meanwhile the Oedometer B3 is typical ELE-

type consolidation machine with yoke and beam

mechanism. Shown in Figure 6, the CRS and

Oedometer E4 give similar results, where

Oedometer B3 gives a completely different result.

At lower stress, Oedometer B3 still gives similar

result as the rest up to 500 kPa, where the line start

to separate from the other equipments.

Oedometer B3 also shows higher strain result

where it could happen due to soil starts to creep out

from the oedometer ring. This creep phenomenon

are quite common happening in Oedometer with

yoke and beam model.

When checking the equipment manufacturer’s

website, the specification from the equipment varies,

but the latest equipment already prepared for higher

load as specified in Table 1 where the latest trend of

equipment has maximum load capacity above 5000

kPa.

Figure 6: Graph of comparison between different equipments.

0.00

5.00

10.00

15.00

20.00

25.00

10 100 1000 10000

STRAIN(%)

STRESS(kPa)

CONSOLIDATIONAT48MDEPTH

OEDOE4 CRS‐effectivestress OEDOB3

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

148

Table 1: Maximum equipment specification.

Band Type

Maximum

Load

Load Applied on Sample

D: 6.35 cm/ 2.5 inch D: 5 cm Note

Hogentogler Geostar Consolidometer 8.9 kN 2800 kPa 4500 kPa Since 1991

GCTS CRS-10 10 kN 3150 kPa 5000 kPa

Controls Group ACE-Ems 20 kN 6300 kPa 10000 kPa

Conrols Group Oedometer 18 kN 5700 kPa 9000 kPa 168 kg weight (11:1)

VJ Tech ACONS 15 kN 4800 kPa 8000 kPa

ELE Oedometer 12.5 kN 4000 kPa 6400 kPa 128 kg weight (10:1)

For note in Table 1, these are maximum

specifications for the equipment, where some

equipments need extra modifications to reach these

limits. For example, for ELE oedometer the standard

weight is set only up to 64kg. Extra weight set needs

to be purchased separately, and a special table is

needed to prevent the equipment from tilting.

4 IMPROVING THE

CONSOLIDATION TEST

RESULT

As discussed before, incorrect use of final load could

lead to inaccuracy in consolidation test result, so the

decision to determine correct final load is very

important in consolidation testing. There are several

methods that could be applied to current equipment

to increase load.

The first method is by adding the weight set to

increase the load for the test. Most of geotechnical

practices, usually has more than 1 consolidation

equipment. To increase the load, it is very easy to

add more weight by borrowing weight set from the

other equipments since the weight set from the same

equipment usually already calibrated and compatible

with each other. Buying another weight set from

manufacture also possible to add more load. But this

method only applicable up to equipment

specification. Making weight set is also possible, but

each weight needs to be calibrated.

Second method is by increasing the beam ratio.

For beam and yoke type of equipment, usually the

beam ratio could be change from 10:1 to 11:1, which

will increase the load applied on the sample.

The third solution is by decreasing sample

diameter could increase the load applied to the

sample. The standard sample diameter usually 2.5

inch (6.35 cm). According to ASTM, minimum

sample diameter is 5 cm. By decreasing the sample

diameter could increase the load applied to the

sample. Table 1 shows comparison between samples

diameter 6.35 cm to 5 cm, where the load could

increase quite significantly. Changing sample from

6.35cm to 5 cm is not as easy as changing the ring,

since most oedometer ring is set with its oedometer

cell. So to change the sample size, the whole

oedometer cell needs to be replaced as well. This

becomes a problem for old equipment where the

oedometer cell with 5 cm diameter is not available.

Last method is by purchasing higher capacity

consolidation machine. Of course, purchasing new

equipment with higher capacity will solve this

problem, but with such low fee for consolidation

testing in Indonesia, not everybody is able to

purchase expensive equipment from well-known

equipment manufacturer. It is not a secret that some

geotechnical practices has equipments made in

Indonesia, which is not a problem for low capacity,

but by pushing the equipment above its limit would

not give a good and accurate result.

5 CONCLUSIONS

In consolidation testing for deep soil, to determine

final load is very important to get a reliable and

accurate data. According to ASTM D2435-03, to

calculate preconsolidation pressure, the final load

should be minimum four times effective overburden

pressure, which for deep soil sample would be very

high pressure. When the final load does not meet

four time the effective overburden, the

preconsolidation pressure (pc), compression index

(Cc), and Recompression Index (Cr) would not be

accurate and could lead the overconsolidated soil to

be normal consolidated soil.

To be able to achieve this high load,

consolidation apparatus needs to be checked for its

specification since the old model apparatus usually

does not have capability for high-pressure testing.

Checking for available weight set, diameter of

oedometer ring, and beam ratio would show the

equipment capability. Some model of consolidation

apparatus could have high load pressure with some

modification like changing the beam ratio, adding

weight set, and reduce the oedometer ring size.

Limitation in Conventional Oedometer Consolidation Test for Deep Layered Soil

149

Purchasing a new equipment need to check

equipment capability, although most new

equipments are capable to have high load pressure,

but not all equipments have similar specifications.

ACKNOWLEDGEMENTS

Acknowledgments and gratitude to all the parties

who have assisted and supported the research of this

paper, especially to research grant from PITTA

Universitas Indonesia with Contract No.

2548/UN2.R3.1/HKP.05.00/2018, PT. Pondasi

Kisocon Raya (Mr. Y. P. Chandra), and PT

SOFOCO (Mr. Benny Kumara).

REFERENCES

ASTM D653-03, 2003. Standard Terminology Relating to

Soil, Rock, and Contained Fluids, ASTM

International. West Conshohocken: PA.

ASTM D2435/D2435M-11, 2011. “Standard Test

Methods for One-Dimensional Consolidation

Properties of Soils Using Incremental Loading.”

ASTM International. West Conshohocken: PA.

Budhu, M., 2010. Soil Mechanic and Foundations, Wiley,

USA.

BS 1377-2:1990, 1990. Methods of test for soils for civil

engineering purposes. Compressibility, permeability

and durability tests, British Standard Institution.

London, UK.

Head, K. H., 1994. Manual of Soil Laboratory Testing:

Volume 2: Permeability, Shear Strength and

Compressibility Tests, Chichester: Wiley.

Terzaghi, K., 1943. Theoretical Soil Mechanics, USA:

John Wiley & Sons.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

150