Effects of Design Parameters on the Transmitted Torque of a Coaxial

Magnetic Gear with Halbach Permanent-Magnet Array

Yi-Chang Wu, Saian Nur Fajri

National Yunlin University of Science and Tecnology, Yunlin, Taiwan

Keywords: Magnetic Gear, Halbach Array, Transmitted Torque, Taguchi Method, Critical Parameter.

Abstract: The magnetic gear with Halbach Permanent-Magnet array can offer higher on transmitted torque compare to

radially magnetized permanent magnet and also capable of increasing the magnetic field. Then, the study of

this paper focuses on the effects of critical design parameters on the transmitted torque. Furthermore, the

magnetic field and the steady-state torque characteristic of Halbach type computed by commercial software

ANSYS/Maxwell. Under the use of Taguchi method, determined parameters in four levels, and focused on

five factors comprise the length of outer and inner rotor iron part, the length of outer and inner rotor

permanent magnet, and the length of pole pieces. Analysis result shows the optimum condition, the

percentage contribution of the design parameter using the ANOVA test, and the prediction torque was also

obtained. Finally, this paper shows the contribution of the outer and inner rotor permanent magnet with

0.35% and 15.53%. The radial length of the pole pieces contributed 3.21%. While the percentage of the

outer rotor iron part is 77.18%, and the inner rotor iron part does not significantly affect to the steady-state

torque, then it pooled. The estimated torque at optimum condition is 2179.55 Nm.

1 INTRODUCTION

The magnetic gear developed since 1941 (Fau,

1941). At that time, the magnet has two gears, and

the rotating axes are parallel to each other. Then,

Atallah and Howe (2001) discovered a new

magnetic gear type which still being developed until

now. The magnetic gear has a low-speed rotor, high-

speed rotor, permanent magnets and stationary steel

pole-pieces (Atallah and Howe, 2001). Generally,

the use of magnetic gear is to replace the functions

of mechanical gear. This idea based on the

disadvantage of mechanical gear and the advantage

of a magnetic gear. Mechanical gear has

disadvantages at risk of transmission failure

(because of the physical contact between the gears),

need periodic maintenance, generates friction and

vibration. Moreover, mechanical gear also at risk of

overheating. Overheating condition can destruct the

structure of the gear, and if the rotation speed is too

high, the gear teeth will be melted. In contrast,

magnetic gear can be a solution. Magnetic gear has

the advantage of transmitting power without

physical contact. The other advantages are no

vibration and noise, and no maintenance, and its

inherent overload protection (Atallah and Howe,

2001; Acharya et al., 2013; Uppalapati et al., 2014).

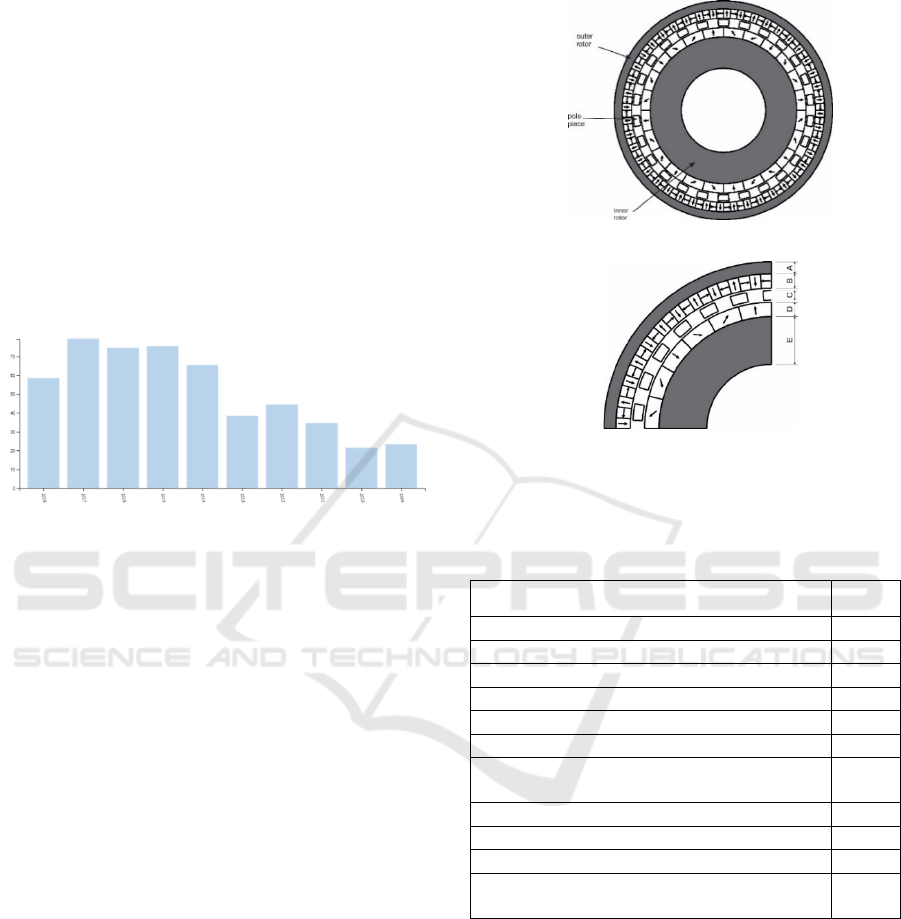

In the last ten years, industry and institution did

research and development about magnetic gear

technology. From the research approach, shown in

Figure 1 is some publications about magnetic gear

accessed from web of science (2018). Those

institutions’ study not only about the characteristic

of magnetic gear, but also about the application of

magnetic gear. The researches about magnetic gear

characteristics, for example, investigates torque,

torque density, eddy current, pole piece shapes,

topologies, and noise-vibration. The examples of

magnetic gear application are for wind turbine, wave

energy conversion, geared-motor, vehicles

transmission, and so on. This topic is strongly

possible to reach steps for commercial application

(Wu et al., 2018; Li, K. et al., 2017; Liu et al., 2014;

Li, W. et al., 2017).

The most popular type of magnetic gear is

coaxial magnetic gear. Not only more accessible in

the manufacturing process, but this type also

produces higher transmitted torque than mechanical

gear. Using magnetic gear can produce a stable

transmitted torque when the rotor rotates at different

speeds (Neves and Flores, 2014). Beside coaxial

36

Wu, Y. and Fajri, S.

Effects of Design Parameters on the Transmitted Torque of a Coaxial Magnetic Gear with Halbach Permanent-Magnet Array.

DOI: 10.5220/0009006000360042

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 36-42

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

type, there are other types which are radial magnetic

gear, transverse magnetic gear, worm magnetic gear,

planetary magnetic gear, rack and pinion gear, bevel

gear, and harmonic gear (Chen et al., 2014; Tlali et

al., 2014). Coaxial magnetic gear also has various

topologies for example radially magnetized, and

Halbach magnetized. Based on previous researches,

Halbach permanent-magnet array can offer higher

maximum torque. It also has lower torque ripple,

lower iron losses and also capable of increasing

magnetic field (Choi and Yoo, 2008; Jian et al.,

2009; Jian, 2010). It means that for transmitted

torque demand, Halbach arrangement is a good

choice to be developed. Finally, this study of this

paper focuses on the effects of Halbach critical

design parameters on the transmitted torque.

Figure 1: The publication on magnetic gears. (Source: web

of science).

1.1 Design Parameters

The Halbach permanent-magnet arrangement used in

this paper shown in Figure 2(a). As shown in Figure

2(a), the magnet direction in permanent-magnet

arranged by outward-concentrated magnetic field for

the inner rotor and inward-concentrated field for the

outer rotor.

Figure 2(b) shows the radial length of outer rotor

iron part coded as A. B defines radial length of outer

rotor permanent magnet. C and D in sequence define

radial length of pole piece and radial length of inner

rotor permanent magnet. The code E defines radial

length of inner rotor iron part. This codes (A, B, C,

D, and E) made as factors in this study. Then, these

parameters investigated by ANSYS/Maxwell

software.

The magnetic gear used in this research has

parameters shown in Table 1. This magnetic gear

has one input and one output. Under steady-state

condition, the simulation of magnetic gear needs to

be rotated in a reverse direction between input and

output. The input of this simulation is inner rotor,

and the output of the simulation is outer rotor. Using

2D ANSYS/Maxwell simulation, set two motion set

up to investigate the maximum torque produced by

the magnetic gear. The design parameters in this

study are identical with the previous research

(Mateev et al., 2016) shown in Table 1.

(a)

(b)

Figure 2: (a) Halbach permanent magnet array (b) Critical

design parameters.

Table 1: Design parameters of a coaxial magnetic gear

mechanism.

Parameter Value

N

umber of outer rotor pole pairs (P

o

) 26

N

umber of inner rotor pole pairs (P

i

) 4

N

umber of pole piece (z) 22

Diamete

r

of outer rotor (mm) 140

Diamete

r

of inner rotor (mm) 54

Ai

r

-gap length (mm) 1

Radial length of outer rotor iron part

(mm)

5

Radial length of outer rotor PM (mm) 6

Radial length of pole piece (mm) 4

Radial length of inner rotor PM (mm) 6

Radial length of inner rotor iron part

(mm)

20

Based on Table 1, had been shown the value of

parameters. The number of inner rotor pole pairs

(p

1

), outer rotor pole pairs (p

2

) and pole pieces (Ns)

defined by (1). The obtaining of pole pair number

effected to the gear ratio. The gear ratio of magnetic

gear used in this research is 5.5. The number of Gear

ratio (Gr) defined by (2). Otherwise, to simulating

gear rotation need to consider the rotation speed of

the input and output links. The rotational speed of

inner rotor (w

1

) defined by gear ratio and the

Effects of Design Parameters on the Transmitted Torque of a Coaxial Magnetic Gear with Halbach Permanent-Magnet Array

37

rotational speed of outer rotor (w

2

) as presented in

(3) (Kim et al., 2015).

During the simulation process using ANSYS/

Maxwell, the material for inner and outer rotor is

iron. The material for a permanent magnet is

NdFeB35. The material for pole pieces is Steel

1008. The objective of simulation is to gain the

transmitted torque in a steady-state condition. Inner

rotor and outer rotor rotate in reverse direction with

the amount 150 rpm and 27.27 rpm.

2 TAGUCHI METHOD

This research used Taguchi method which the use of

this experimental method allows examining under

various circumstances (factors). Taguchi Method has

three quality characteristics: nominal the best, larger

the better and smaller the better. Because of this

research investigated transmitted torque with an

unlimited number. Therefore the fit characteristic

was larger the better characteristic (Taguchi et al.

2005). Based on the previous explanation, the

factors for the research variable were factor A, B, C,

D, and E. The factors observed in 4 different levels.

The used of 5 factors and four levels were

demonstrated by Standard Orthogonal Array

L16(5

4

). These mean there were 16 various

experiments with five factors and four levels as

shown in Table 2 and Table 3.

The simulation processed based on the various

parameters shown in the Table 3. By using the

Taguchi Method, the observer could gather the

optimum condition, contribution each factor to the

result and estimate the result under the optimum

conditions. After investigating, the result analyzed

using Analysis of Variance (ANOVA), so the final

result would be established the percentage

contribution of each factor to the transmitted torque

(Taguchi et al., 2005; Roy, 1990).

Table 2: Factor and Level.

Facto

r

Level 1 Level 2 Level 3 Level 4

A 5 10 15 20

B 6 4 7 5

C 4 7 5 6

D 6 5 4 7

E 20 15 10 5

Table 3: Orthogonal Array.

A B C D E

1 5 6 4 6 20

2 5 4 7 5 15

3 5 7 5 4 10

4 5 5 6 7 5

5 10 6 7 4 5

6 10 4 4 7 10

7 10 7 6 6 15

8 10 5 5 5 20

9 15 6 5 7 15

10 15 4 6 4 20

11 15 7 4 5 5

12 15 5 7 6 10

13 20 6 6 5 10

14 20 4 5 6 5

15 20 7 7 7 20

16 20 5 4 4 15

3 RESULT AND DISCUSSION

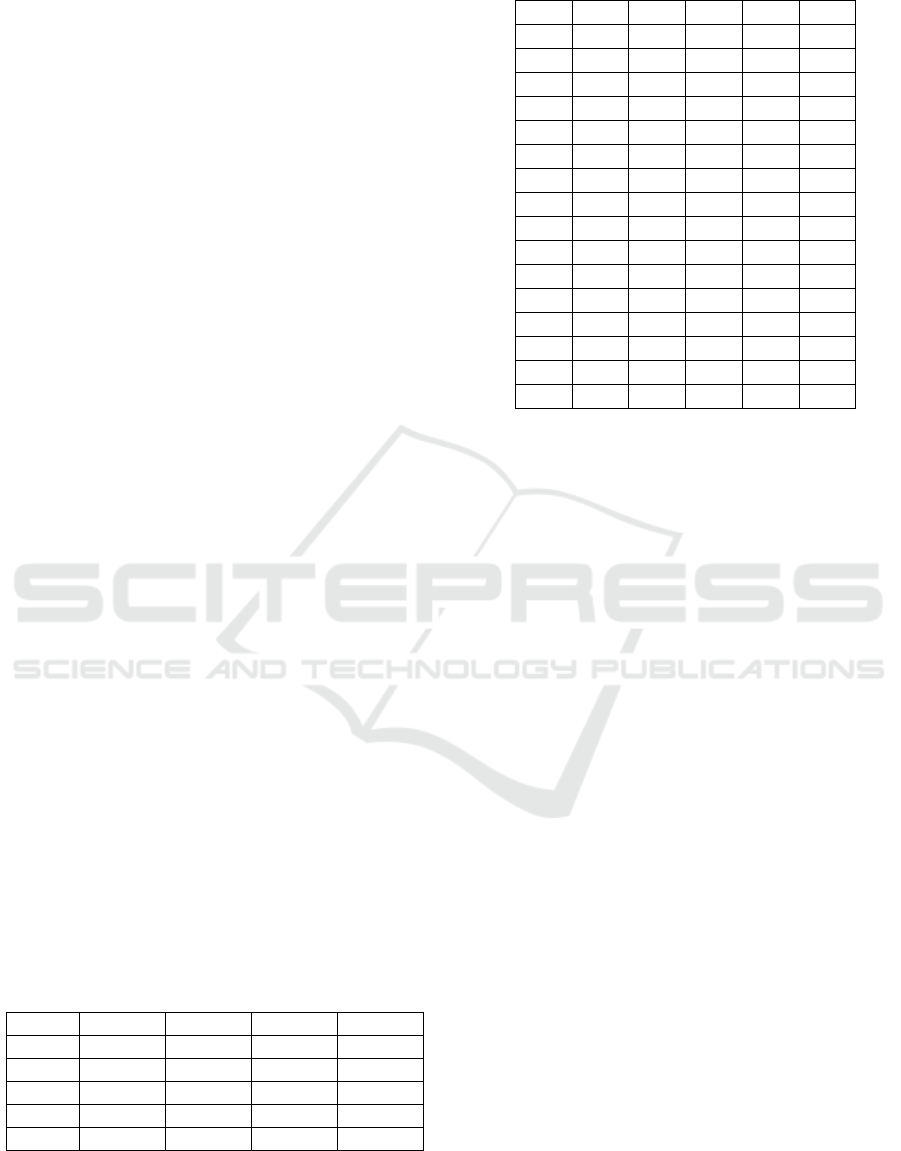

Using ANSYS/Maxwell software obtain magnetos

tatic field and transmitted torque. The magnetostatic

field will be useful for future research assistant tool

in optimizing magnetic gear design (Wu, 2015). It is

related to increasing its field based on pole piece

shapes as well as permanent magnet arrangement.

Figure 3 presents the magnetostatic field in angle

45

0

from 16 experiments. Magnetostatic field

presented in the same color scale which can be

compared to another experiment from the color.

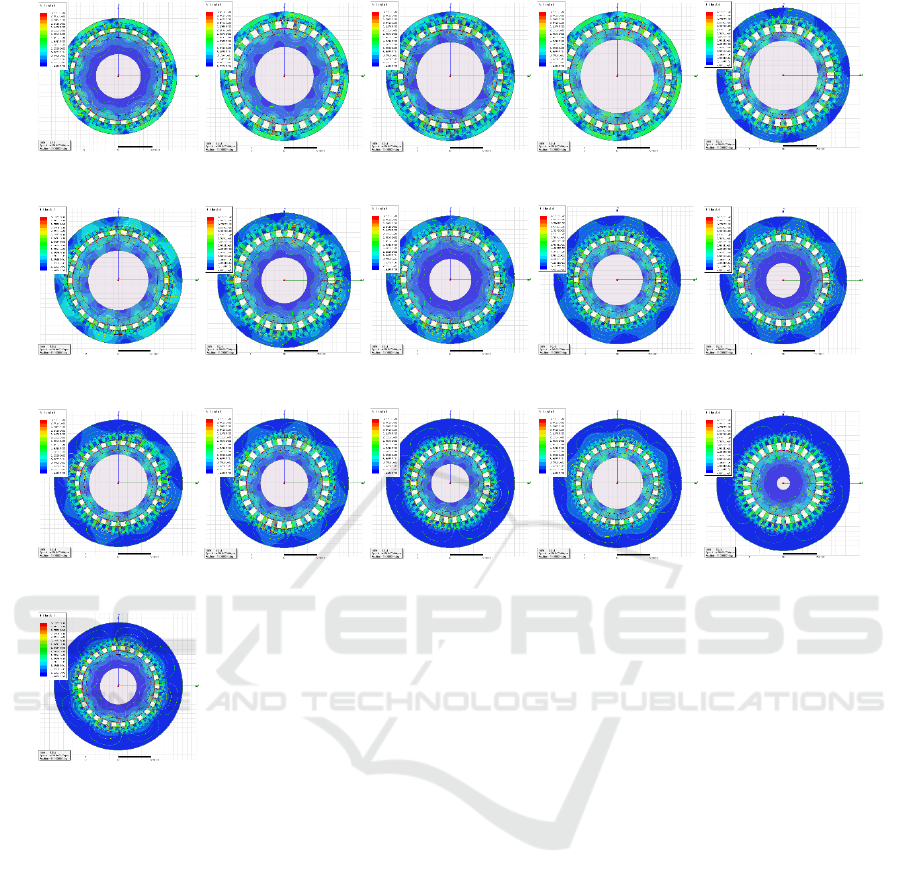

Moreover, the value of the steady-state

transmitted torque shown in Table 4. This value then

shows the ability of every single magnetic gear

experiments to transmit power and torque. The table

also shows the signal to noise which measures the

sensitivity and external influencing factors, not

under control.

Based on Table 4, the transmitted torque in

optimum condition attains 2150.76 Nm which came

from experiment 4. The factors value in experiment

4 were level 1 for A factor and level 4 for another

factor. The lowest transmitted torque found in

experiment 16 which only 989.62 Nm. The factors

value in experiment 16 were level 4 for A and B

factor, level 1 for C factor, level 3 for D factor and

level 2 for E factor.

Ns = p

1

+ p

2

(1)

w

1

= -Gr w

2

(2)

w

1

= -Gr w

2

(3)

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

38

(a) (b)

(c)

(d) (e)

(f) (g) (h) (i) (j)

(k) (l) (m) (n) (o)

(p)

Figure 3: Magnetostatic Field Analysis in (a) Experiment 1, (b) Experiment 2, (c) Experiment 3, (d) Experiment 4, (e)

Experiment 5, (f) Experiment 6, (g) Experiment 7, (h) Experiment 8, (i) Experiment 9, (j) Experiment 10, (k) Experiment

11, (l) Experiment 12, (m) Experiment 13, (n) Experiment 14, (o) Experiment 15, (p) Experiment 16.

After got the data shown in Table 4, the data

were analyzed to perceive the average performance

of the main effect on S/N and transmitted torque.

Because this research used higher the better

characteristic, so, based on Figure 4 can be

concluded that the optimum level by radial length of

outer rotor iron part is level 1. The optimum level by

radial length of outer rotor permanent magnet is

level 1. The radial length of pole pieces can affect

strongly in level 1. On the other hand, radial length

of inner rotor permanent magnet and inner rotor iron

part can perform better in level 4 and level 2.

Furthermore, the effects of research variable

analyzed using ANOVA down to percentage

contribution. The radial length of outer rotor iron

part factor has the highest percentage contribution

that is 77.92% followed by radial length of inner

rotor permanent magnet with 16.28%. Radial length

of outer rotor permanent magnet and radial length of

pole piece factors consecutively with 1.10% and

3.95%, while radial length of inner rotor iron part

factor affecting not significantly in the amount of

0.75%. Because it is under 1%, so this factor needs

to be pooled. Table 5 shows the result of ANOVA

analysis. The description symbols mentioned in

Table 5 are degree of freedom (f), Sum of Squares

(S), Variance (V), Variance Ratio (F), and

Percentage Contribution (P) in percent (%).

Effects of Design Parameters on the Transmitted Torque of a Coaxial Magnetic Gear with Halbach Permanent-Magnet Array

39

Table 4: The result of transmitted torque

.

A B C D E

Maximum

Torque

S/N

1 5 6 4 6 20 2081.7311 66.3685

2 5 4 7 5 15 1687.6924 64.5459

3 5 7 5 4 10 1667.5242 64.4414

4 5 5 6 7 5 2150.7576 66.6518

5 10 6 7 4 5 1373.1758 62.7545

6 10 4 4 7 10 1751.7327 64.8694

7 10 7 6 6 15 1747.7003 64.8493

8 10 5 5 5 20 1580.9525 63.9784

9 15 6 5 7 15 1599.5511 64.0800

10 15 4 6 4 20 1106.7157 60.8807

11 15 7 4 5 5 1307.2708 62.3273

12 15 5 7 6 10 1255.7313 61.9779

13 20 6 6 5 10 1037.6316 60.3209

14 20 4 5 6 5 1156.4207 61.2623

15 20 7 7 7 20

1106.7295 60.8808

16 20 5 4 4 15 989.6207 59.9094

(a)

(b)

Figure 4: Plots of factors main effect.

After pooled, the percentage contribution turned to

77.18% for outer rotor iron part. The contribution

value was 0.35% for outer rotor permanent magnet

and 3.21% for pole pieces. Moreover, 15.53%

contribution was given by radial length of inner

rotor permanent magnet. Hence, the other

contribution (error) contributes 3.73%. Pooled

ANOVA table is shown in Table 6.

Table 5: ANOVA table

.

Factors f S V F P

A 3 153585

1.226

511950.41 77.92

B 3 21706.9

63

7235.6543 1.10

C 3 77895.3

50

25965.12 3.95

D 3 320800.

948

106933.65 16.28

E 3 14718.8

48

4906.28 0.75

All other/

error

0 0 0

Total 15 1970

973.3

35

100

Table 6: Pooled ANOVA table

.

Fac-

tors

f S V F P

A 3 1535851.23 511950.41 104.4 77.18

B 3 21706.96 7235.65 1.5 0.35

C 3 77895.35 25965.12 5.3 3.21

D 3 320800.95 106933.65 21.8 15.53

E

(3

)

14718.85 Pooled

All

other/

error

3 14718.85 4906.28 3.73

Total

1

5

1970973.34 100

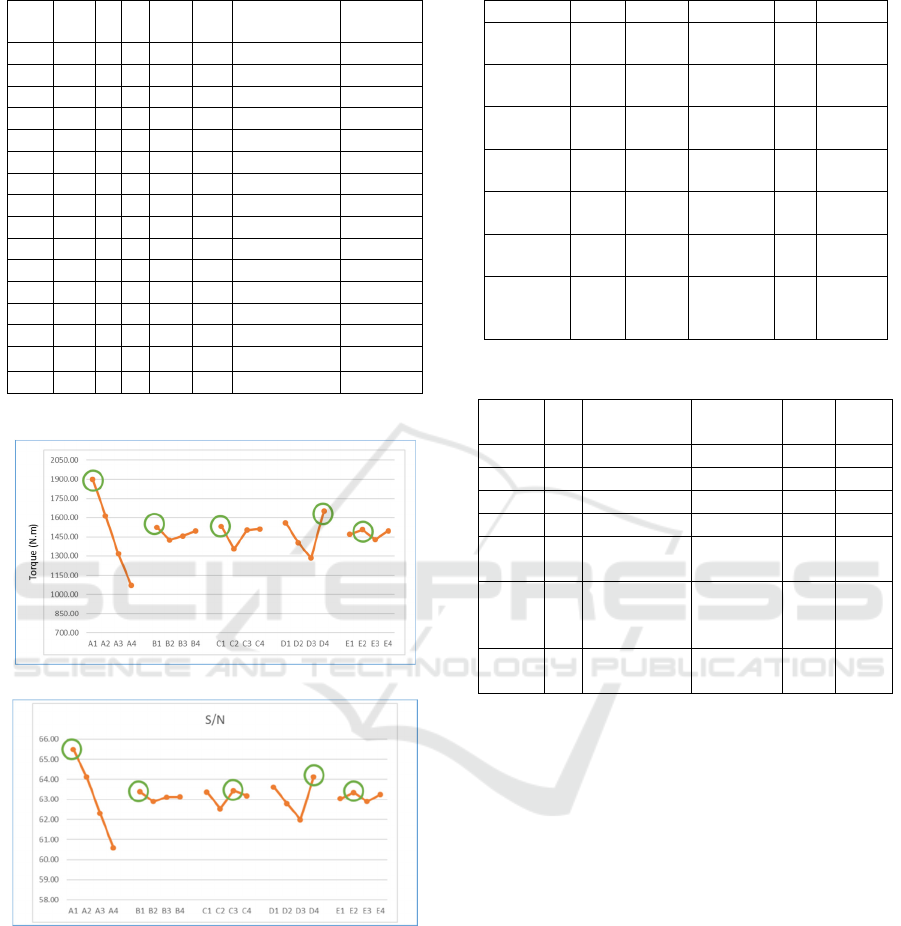

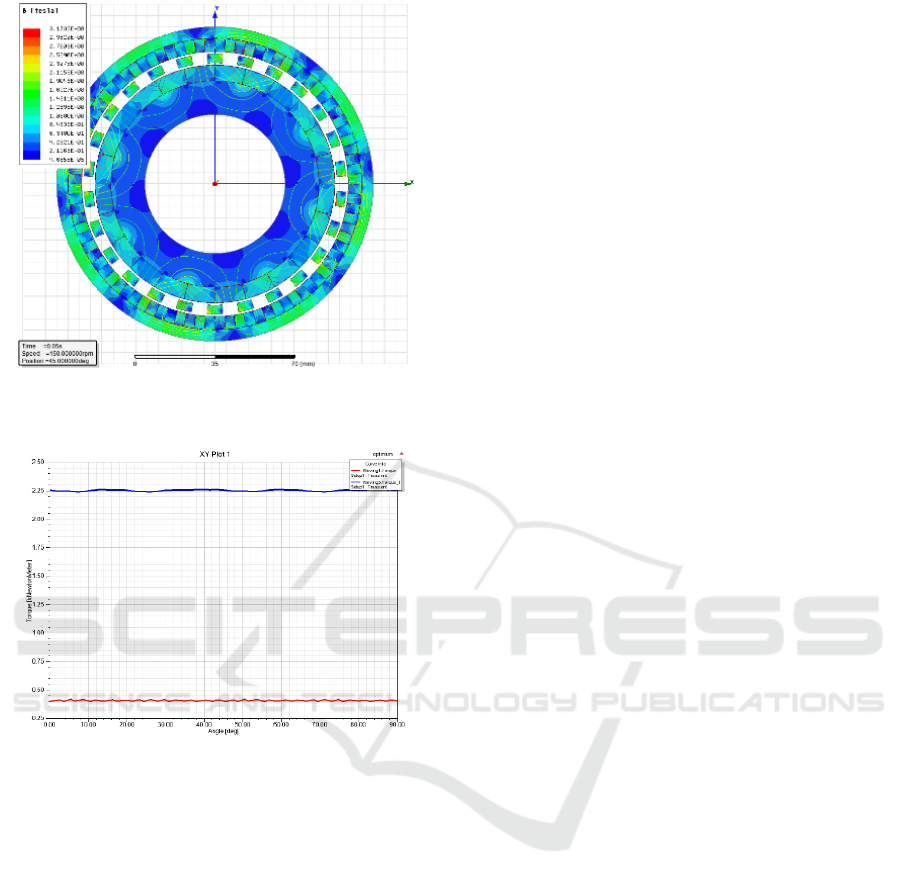

Furthermore, to estimate the transmitted torque

under the optimum conditions, the data from Figure

3 used for the simulation. Every highest effect

calculated as parameters then obtained transmitted

torque with 2179.55 Nm This value had to be

confirmed with the simulation and obtained 2261.40

Nm transmitted torque. The magnetostatic field of

this optimum condition shown in Figure 5, and

Figure 6 shows the transmitted torque graphic.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

40

Figure 5: Magnetostatic Field in Optimum Condition.

Figure 6: Steady-State Torque in Optimum Condition.

4 CONCLUSIONS

In the case of this research, the effects of critical

design parameter to the magnetostatic field and

transmitted torque had been obtained. By using

Taguchi method, the transmitted torque in optimum

condition, percentage contribution of research

variable (factors) and estimate torque in optimum

condition had been presented. This research will be a

useful assistant to design coaxial magnetic gear with

transmitted torque demand by considering the radial

length of the critical design parameter. The best

parameters in this research are 5mm for radial length

of outer rotor iron part, 6mm for radial length of

outer rotor permanent magnet, and 4mm for radial

length of pole pieces. Furthermore, the radial length

of inner rotor permanent magnet and inner rotor iron

part are 7mm and 15mm. Future work on this study

will investigate the effects to the flux density, iron

losses, torque ripple and efficiency of coaxial

magnetic gear and solve the problem about

manufacturing Halbach magnetized type.

ACKNOWLEDGEMENTS

The authors are grateful to the Ministry of Science

and Technology (Taiwan, R.O.C.) for supporting

this research under Grants MOST 107-2628-E-224-

002-MY3 and MOST 107-2622-8-006-015.

REFERENCES

Acharya, V.M., J.Z. Bird, & M. Calvin, 2013. A Flux

Focusing Axial Magnetic Gear. IEEE Transactions on

Magnetics 49(7): 4092-4095.

Atallah, K. & Howe, D., 2001. A novel high-performance

magnetic gear. IEEE Transactions on Magnetics

37(4): 2844-2846.

Chen, Y., W.N. Fu, S.L. Ho, an& H. Liu., 2014. A

Quantitative Comparison Analysis of Radial-Flux,

Transverse-Flux, and Axial-Flux Magnetic Gears.

IEEE Transactions on Magnetics 50(11).

Choi, J.S. & Yoo, J., 2008. Design of a Halbach Magnet

Array Based on Optimization Techniques. IEEE

Transactions on Magnetics 44(10): 2361-2366.

Fau, H.T., 1941. Magnet gearing. U.S. Patent No.

2,243,555.

Jian, L., 2010. Coaxial Magnetic Gear with Halbach

Permanent-Magnet Arrays. IEEE Transactions on

Energy Conversion 25(2): 319-328.

Jian, L., Chau, K.T., Gong, Y., Jiang, J.Z., Yu, C., & Li,

W., 2009. Comparison of Coaxial Magnetic Gears

with Different Topologies. IEEE Transactions on

Magnetics 45(10): 4526-4529.

Kim, S.J., C.H. Kim, S.Y. Jung,. 2015. Optimal Design of

Novel Pole Piece for Power Density Improvement of

Magnetic Gear Using Polynomial Regression

Analysis. IEEE Transactions on Energy Conversion

30(3): 1171-1179.

Li, K., J. Wright, S. Modaresahmadi, D. Som, W.

Wiliams, & J.Z. Bird., 2017. Designing the First Stage

of Series Connected Multistage Coaxial Magnetic

Gearbox for a Wind Turbine Demonstrator. IEEE

Energy Conversion Congress and Exposition (ECCE)

pp. 1247-1254.

Li, W., K.T. Chau, C.H.T. Lee, T.W. Ching, M. Chen, &

J.Z. Jiang., 2017. A New Linear Magnetic Gear with

Adjustable Gear Ratios and Its Application for Direct-

Drive Wave Energy Extraction. Renewable Energy

105: 199-208.

Liu, C.T., H.Y. Chung, & C.C. Hwang., 2014. Design

Assessments of a Magnetic-Geared Double-Rotor

Permanent Magnet Generator. IEEE Transactions on

Magnetics 50(1).

Effects of Design Parameters on the Transmitted Torque of a Coaxial Magnetic Gear with Halbach Permanent-Magnet Array

41

Mateev, V., M. Todorova, & I. Marinova., 2016. Torque

Transmission Characteristics of a Coaxial Magnetic

Gear. In: 19th International Symposium on Electrical

Apparatus and Technologies (SIELA), Bourgas,

Bulgaria, 29 May – 1 June 2016, pp. 1-4.

Neves, C.G.C., & Flores, A.F., 2014. Coaxial Magnetic

Gear Analysis and Optimization. In: 3rd International

Conference on Renewable Energy Research and

Applications, Milwaukee, WI, United States, 19-22

October 2014.

Roy, Ranjit K., 1990. A primer on the Taguchi Method.

New York: Van Nostrand Reinhold.

Taguchi, Genichi, Subir Chowdhury, & Yuin Wu (2005)

Taguchi’s Quality Engineering Handbook. New

Jersey: John Wiley & Sons, Inc.

Tlali, P.M., R-J. Wang, & S. Gerber., 2014. Magnetic

Gear Technologies: A Review. In: International

Conference on Electrical Machines (ICEM), Berlin,

Germany, 2-5 September 2014, pp. 544-550.

Uppalapati, K.K., W.B. Bomela, J.Z. Bird, & J.D. Wright.,

2014. Experimental Evaluation of Low-Speed Flux-

Focusing Magnetic Gearboxes. IEEE Transactions on

Industry Applications 50(6): 3637-3643.

Web of Science,. 2018. Magnetic Gear. Available at:

http://webofknowledge.com (accessed 11 September

2018).

Wu, Y.C., & Jian, B.S., 2015. Magnetic field analysis of a

coaxial magnetic gear mechanism by two-dimensional

equivalent magnetic circuit network method and

finite-element method. Applied Mathematical

Modelling 39(19): 5746-5758.

Wu, Y.C., M.C. Tsai, & C.T. Chan,. 2018. Creative

Mechanism Design of Magnetic Gears Integrated with

Continuously Variable Transmissions. Advances in

Mechanical Engineering 10(5): 1-8.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

42