Inertia Effect on the Cavitation Phenomena of Textured Bearing

Mohammad Tauviqirrahman, Muchammad, J. Jamari and Eflita Yohana

Department of Mechanical Engineering, Universitas Diponegoro, Indonesia

Keywords: Cavitation, Computational Fluid Dynamic (CFD), Inertia, Slip, Texturing

Abstract: For more than a century, with increasing the demand for energy-saving, there has been a growing

application of surface texturing due to its good behaviour in enhancing the performances of tribological

pairs. As is known, in textured surface the inertia as well as the cavitation has a major effect on the

hydrodynamic pressure profile. The present paper examines the correlation between the cavitation and the

inertia effects in textured lubricated contact using computational fluid dynamic (CFD) approach. The multi-

phase cavitation model is adopted to obtain more realistic characteristic of the bearing. A quantitative

analysis of inertia influences on cavitation zone is made in this paper. The existence of slip at the bearing

pad is also particular interest. Based on the simulation results, it is found that increasing the inertia effect

will trigger the presence of the cavitation phenomena. It is also equally shown that the wall slip condition

appears to contribute to the reduced hydrodynamic lift. The present results illustrate a superior performance

of bearing with low inertia pattern in comparison to other bearing types.

1 INTRODUCTION

Over the past years, extensive research acitivity has

aimed at making machines more efficient by

reducing the power losses found in bearings.

Bearings are important components widely used in

propulsion and industrial applicatons because of

their efficiency, low cost, and simplicity.

Surface texturing as a tool for enhancing the

tribological performance of mechanical components

has been under intensive exploration over the last

two decades. Within the broad area of tribology, the

researches relating to the lubrication have paid much

attention to surface texturing, as is reflected in many

papers, for example (Tala-Ighil et al., 2011; Rao et

al., 2012; Tauviqirrahman et al., 2014; Meng et al.,

2015, Rahmani and Rahnejat, 2018). As mentioned

in the literature, appropriate texturing has been

found to increase hydrodynamic lift, reduce friction

and the wear rate.

However, the available literature survey indicates

that most of studies related to the texturing adopted

Reynolds boundary condition for modeling the

cavitation phenomena. As is known, the Reynolds

approach as well as Sommerfeld theory or Half-

Sommerfeld theory are often considered as a rough

approximation, because it is not based on real

physical phenomenon (Braun and Hannon, 2010).

For this reason, in order to obtain more accurate

result in solving the texturing problem in lubrication

numerically and theoretically, for modelling

cavitation tribologists have adopted either the mass-

conservative approach (Dobrica et al., 2010, M.

Tauviqirrahman, et al. 2016, Muchammad et al.,

2017 ) or multi-phase model (Concli, 2016; Zhang et

al., 2016, Lin et al., 2018). As a note, the lattest

model provides a physical approach to introducing

the influences of bubble dynamics.

Based on literatures ourvey, one can find that

Reynolds equation is quite populer to use in solving

the lubrication problem due to simplicity. However,

the use of the Reynolds equation instead of Navier-

Stokes equation in most published works limited the

validity of the performance of the textured contact

especially in explaining the inertia-related effect.

Concerning the inertia influence, contradictory

results among the published works were also

obtained. For example, Arghir et al. (2003)

postulated that the inertia could enhance the load

carrying capacity in fully textured parallel sliders,

while Dobrica and Fillon (2009) concluded the

opposite result; inertia terms have, in general, a

negative effect over the hydrodynamic performance.

Therefore, what mechanism which leads to the

Tauviqirrahman, M., Jamari, M. and Yohana, E.

Inertia Effect on the Cavitation Phenomena of Textured Bearing.

DOI: 10.5220/0009005900290035

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 29-35

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

29

generation of the enhanced lift hydrodynamic:

inertia or cavitation is still unclear. In addition, the

available references also indicate that the studies

related to the correlation between cavitation and

inertia are rather very limited.

In the application of lubricated contacts, in

addition to texturing, the introduction of wall slip

induced by hydrophobic coating has been subject to

both analytical and experimental research recently.

The use of wall slip has become popular since this

type of surface enhancement would give a better

tribological performance of the bearing significanlty,

i.e. high load support but low friction (Rao et al.,

2012, Tauviqirrahman et al., 2014, Tauviqirrahman

et al., 2016, Senatore and Rao, 2018).

As an extended exploration of the simple

textured bearing employed in the previously

published studies, more work is required to provide

the needful information for the inertia effect as well

as the cavitation effect. The contribution of this

paper is to explore the correlation between the

cavitation and the inertia effect based on CFD

(computational fluid dynamic) approach for two

situations, i.e. no-slip and slip. Initially, for a

reference design of textured bearing in conventional

(no-slip) condition, the effects of inertia have been

investigated. Finally, the effects of slip introduction

of each inertia pattern of the textured bearing have

been studied.

2 METHODOLOGY

2.1 Governing equations

In this work, a commercial CFD software based on

finite volume method ANSYS FLUENT® is used.

For all flows, ANSYS FLUENT® solves

conservation equations for momentum and mass

(Equations 1 and 2). The conservation equations for

laminar flow (in inertial reference frame) is

presented.

(u

) u = - p+

2

u (1)

u = 0 (2)

Once the film pressure is obtained through

Equations 1 and 2, the load support of lubrication

film on the bearing surface W can be calculated as:

Wpdx

(3)

The frictional force F acting on the stationary

surface due to the viscosity shear force

can be

written as:

Fdx

(4)

When the textured bearing operates, the

cavitation of lubricant often exists. When the

lubricant flow enters the texture cell, the

hydrodynamic pressure might fall below the

saturation lubricant vapor pressure, and the liquid

would rupture and cavitation occurs.

In ANSYS FLUENT®, there are three available

cavitation models: Singhal et al. model, Zwart-

Gerber-Belamri model and Schnerr and Sauer

model. However, in this study, the cavitation model

of Zwart-Gelber-Belamri (Equations 5 and 6) is

employed due to their capability (less sensitive to

mesh density, robust and converge quickly. In

cavitation, the liquid-vapor mass transfer

(evaporation and condensation) is governed by the

vapor transport equation (Zwart et al., 2004):

.v

vgvc

RR

t

(5)

where α

v

is vapor volume fraction and ρ

v

is vapor

density. R

g

and R

c

account for the mass transfer

between the liquid and vapor phases in cavitation.

If

,

v

pp

nuc υυ

υ

B

3α 1 ρ

PP

2

3 ρ

gevap

RF

R

(6)

If

,

v

pp

υυ υ

B

3αρ PP

2

3 ρ

c cond

RF

R

(7)

where F

evap

= evaporation coefficient = 50, F

cond

=

condensation coefficient = 0.01, R

B

= bubble radius

= 10

-6

m, α

nuc

= nucleation site volume fraction=

5x10

-4

, ρ

l

= liquid density and p

v

= vapour pressure.

In the application of sliding surfaces in very

narrow-gap conditions and the availability of

hydrophobic coating materials, the lubricant can slip

along a solid-liquid interface. In this way, the slip

length b is generally used to address the relation

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

30

between slip velocity and surface shear rate, that is,

surface

s

u

ub

z

(8)

where u

s

indicates the slip velocity at the slip

(hydrophobic) surface, b denotes the slip length, and

surface

/uz is the surface shear rate.

As evident from the available literature, a large

value of b was found to be crucial hypotheses to

imply great slip and thus reduced friction (Choo et

al., 2007). In the present study, the slip length

induced by a hydrophobic surface is assumed as

uniform in space and set to 10 µm based on the

experimental work of Choo et al. (2007).

2.2 Simulation model

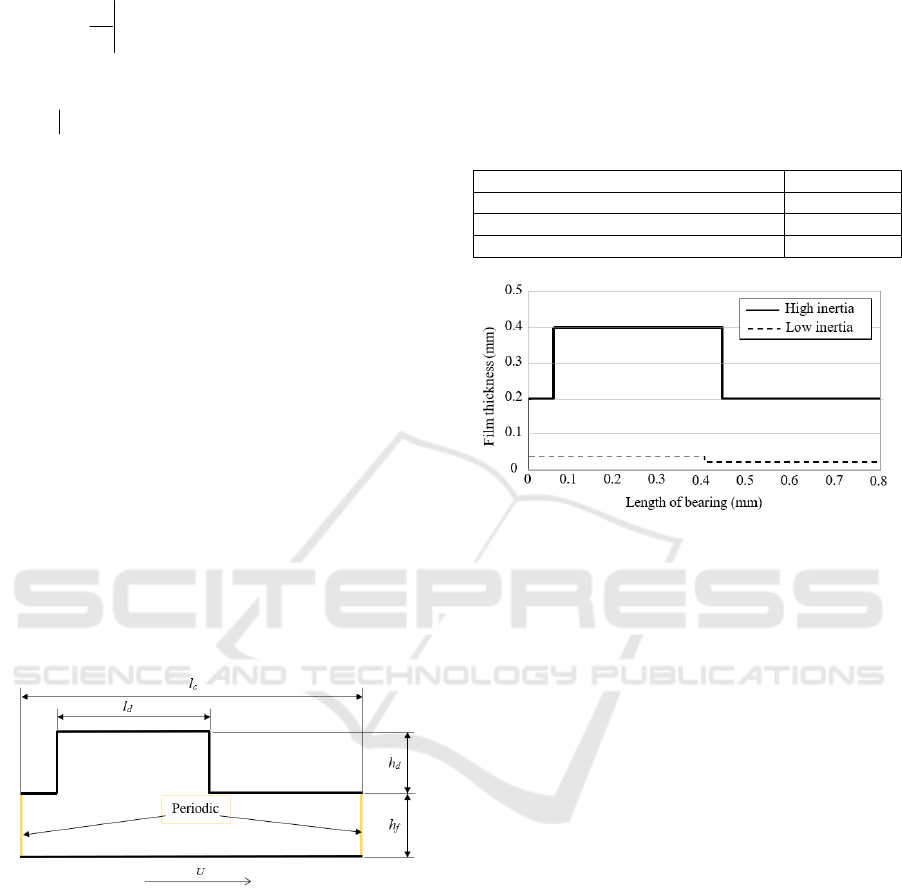

In this study, for modelling the textured bearing the

shape of texture cell is chosen to be rectangular as

this would be relatively easy to. Figure 1 shows a

schematic of a textured lubricated contact with

single texture cell. The texturing schematic studied

here adopts the work of Dobrica and Filllon (2009).

The flow is considered isothermal, steady and

incompressible. One side of the film gap as well as

the outlet is considered as periodic boundary

condition to simplify the flow model and to reduce

the computational cost. The operating pressure is set

to 101 325 Pa. The lubricant properties at 20°C

listed in Table 1 are employed.

Figure 1: Schematic of a lubricated texture sliding contact

with periodic boundary condition. (Note: h

d

= dimple

depth, h

f

= land film thickness, l

d

= dimple length, l

c

=

length of textured zone, U = sliding velocity).

In the present study, to explore the inertia effect,

two patterns of the texture contact are adopted as

shown in Figure 2, i.e. the pattern with high inertia

effect (λ = 2, R

e

= 57.3) and that with low inertia

effect (λ = 20, R

e

= 5.73). As a note, dimple aspect

ratio λ is defined as the ratio between the dimple

length l

D

and the dimple depth h

d

. For all following

computations, texture density (defined as the ratio

between the dimple length l

d

and the texture cell

length l

c

) and relative dimple depth (defined as the

ratio between the dimple depth h

D

and the land film

thickness h

F

) are set to 0.5 and 1.0, respectively. In

this paper, the variation of λ is performed by

changing the value of h

D

and keeping the l

d

as

constant.

Table 1: Lubricant properties at 20

°C.

Saturation pressure of lubricant vapour 3,540 Pa

Saturation density of lubricant 860 kg/m

3

Saturation density of lubricant vapour 12.56 kg/m

3

Dynamic viscosity of lubricant 0.03 Pa.s

Figure 2: Comparison of two patterns of textured contact

studied here (high inertia vs low inertia).

For modelling wall slip in ANSYS-FLUENT, an

additional subroutine to enhance FLUENT’s

capability is made. This subroutine called as User-

Defined-Function (UDF) is a function that allows a

user to define the boundary conditions, material

properties, and source terms for the flow regime, as

well as specify customized model parameters. In this

study, for the case analysis when the slip is

considered, the slip is applied on the top surface

while no-slip condition is employed on the bottom

sliding surface.

The generated grid for the simulations is

composed of 169,960 and 98,879 quadrilateral

elements for high inertia and low inertia pattern,

respectively. Since cavitation may occur in the

texture, mesh refinements are made inside the

texture cell. In this work, for the numerical analysis

in this research the pressure-based solver is adopted.

The velocity-pressure coupling is treated using

SIMPLE, while for spatial discretization of pressure,

PRESTO is adopted.

3 RESULTS AND DISCUSSION

This section reports the results obtained for the

periodic flow developed in one texture cell with

Inertia Effect on the Cavitation Phenomena of Textured Bearing

31

periodic boundary condition, at two conditions, low

inertia and high inertia effect.

3.1 No-slip condition

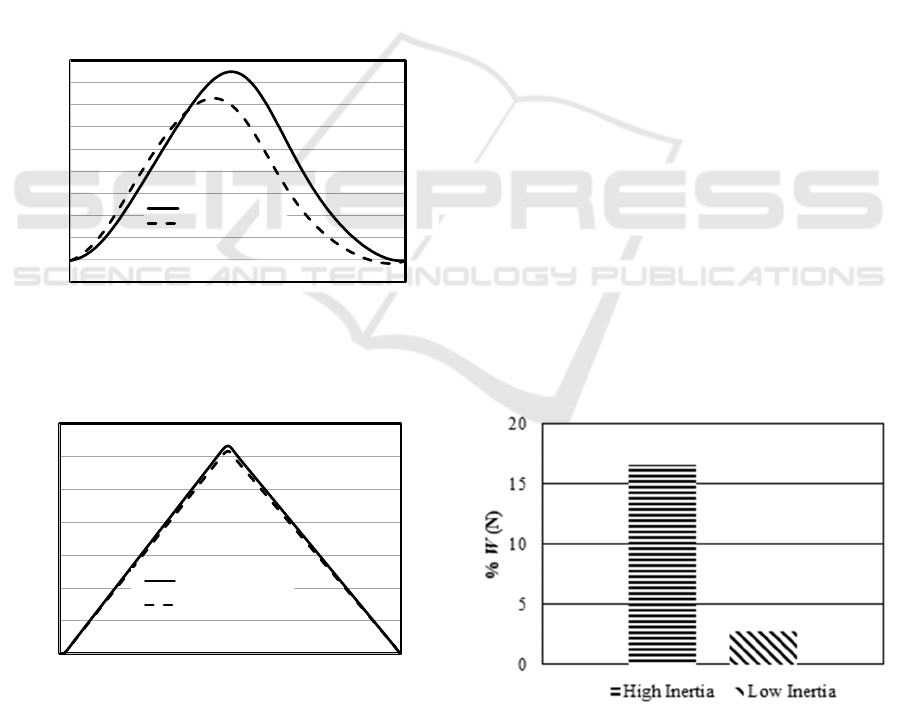

Figure 3 presents the hydrodynamic pressure along

the contact evaluated by two approaches, i.e.

“without cavitation modelling” versus “with

cavitation modelling” for the case of high and low

inertia effect, respectively. It can be seen that for the

case of high inertia effect (Fig. 3 (a)), the maximum

pressure is overestimated by about 15% when the

cavitation model is not used. It appears that at the

outlet edge of the contact, the deviation of the

pressure profiles becomes larger. For the case of low

inertia effect, it is evident that the prediction of two

methods for the pressure profile nearly coincides.

The discrepancy in the maximum pressure is just

around 2%.

(a)

(b)

Figure 3: Hydrodynamic pressure with (a) high inertia (λ =

2, Re = 57.3), (b) low inertia effect (λ = 20, Re = 5.73).

Based on two cases studied here, it seems that

the inertia effect has a strong correlation with the

cavitation effect. When the inertia effect is low at the

textured contact, the possibility of the occurrence of

the cavitation will become small. Thus, it means that

when the bearing is designed to operate in high

inertia effect, one should take into account the

cavitation model in the analysis.

In terms of load support, the discrepancy of the

load support prediction between “with cavitation

modelling” versus “without cavitation modelling” is

shown in Figure 4. It can be observed that in the

case of bearing with high inertia pattern, the

discrepancy is up to 17 %, while for low inertia

pattern, the discrepancy is just 3 %. This result

strengthens the previous finding which highlighted

that inertia can be a trigger to the occurrence of the

cavitation.

The same trend is also observed with respect to

the friction force as depicted in Figure 5. The

inclusion of cavitation model in the analysis leads to

the lower prediction of friction force compared to

the analysis which ignores cavitation model. The

most possible explanation is that based on physical

point of view, there is a larger recirculation zone

inside the texture cell in the case of high inertia

pattern compared to that in low inertia case as seen

in Figure 6. This recirculation may reduce the

availability of the lubricant to generate more

hydrodynamic lift and become a trigger to bring up

the cavitation phenomena. It seems that in this case,

the inertia has a negative effect in terms of load

support as well as friction force. This finding

matches well with the work of Dobrica and Fillon

(2009).

Figure 4: Discrepancy of predicted load support between

cavitation model versus no-cavitation model for two

inertia patterns.

-0.20

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

0 0.0002 0.0004 0.0006 0.0008

Hydrodynamuc pressure p (kPa)

Contact le ngth x (m)

without cavitation

with cavitation

0

3

6

9

12

15

18

21

0 0.0002 0.0004 0.0006 0.0008

Hydrodynamic pressure p (kPa)

Contact length x (m)

without cavitation

with cavitation

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

32

Figure 5: Discrepancy of predicted friction force between

cavitation model versus no-cavitation model for two

inertia patterns.

(a)

(b)

Figure 6: Stream function for different inertia patterns, (a)

high inertia, (b) low inertia.

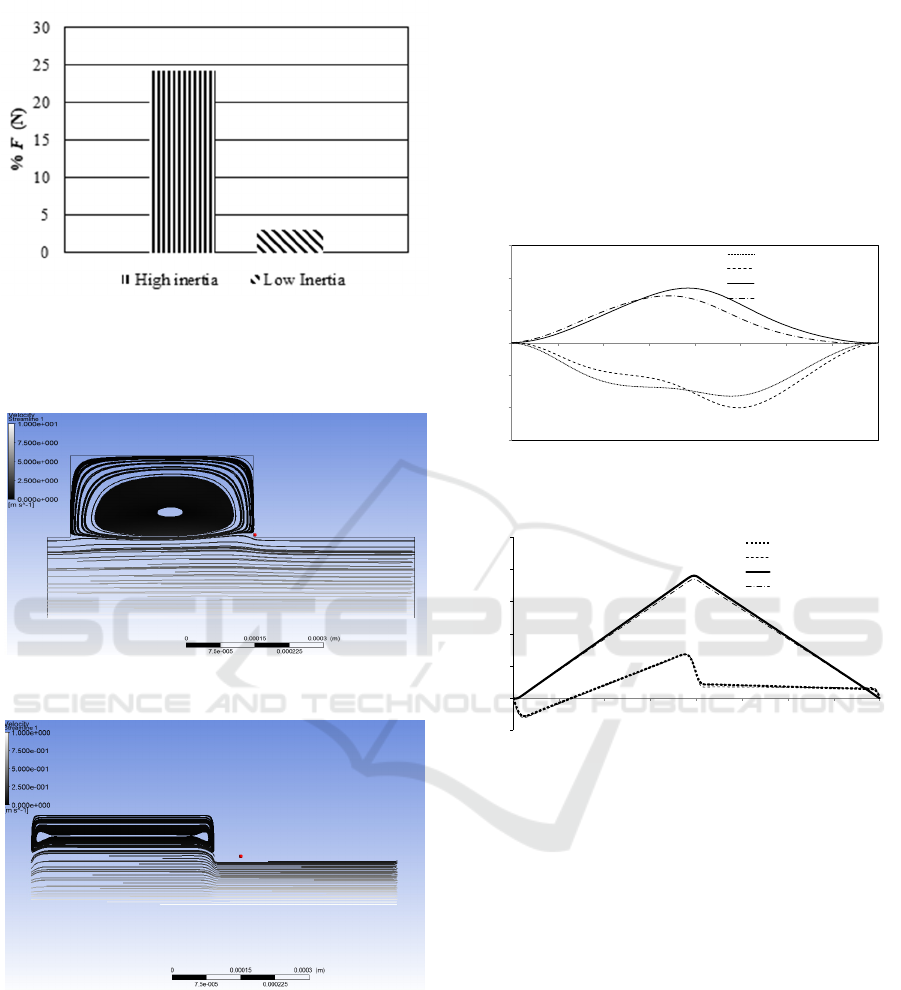

3.2 Slip condition

In this section, the surface of lubricated contact as

reflected in Figure 2 is modified by introducing the

wall slip boundary condition on top (stationary)

surface. In real, the wall slip condition can be

induced by giving the hydrophobic coating. In this

way, the correlation between the inertia and

cavitation effects in the presence of slip can be

investigated in more deep way.

Figure 7 shows the hydrodynamic pressure

profiles for various conditions (i.e., slip and no-slip,

with cavitation modelling and without cavitation

modelling). All results are evaluated for two

bearings whose different inertia terms.

(a)

(b)

Figure 7: Hydrodynamic pressure for different conditions

(slip and no-slip, with cavitation and without cavitation

modelling) for the case of: (a) high inertia, (b) low inertia.

Three specific characteristics can be made based

on Figure 7. Firstly, in the case of high inertia (Fig.

7 (a)), the slip-textured bearing shows the failure of

lubrication mechanism. It seems that the slip

boundary generates the large decrease in the

pressure gradient especially inside texture cell both

for the case of inclusion of cavitation modelling and

for the case of exclusion of cavitation modelling.

Secondly, in the case of the low inertia, unlike the

case of high inertia, the load support is generated for

the situation. It indicates that the slip has a more

dominant role compared to inertia effect in altering

the performance of bearing. The same trend of the

pressure profile is also observed either when the

cavitation modelling is considered or when ignoring

the cavitation modelling. Other interesting finding is

-3

-2

-1

0

1

2

3

0 0.00010.00020.00030.00040.00050.00060.00070.0008

Hydrodynamic pressure (kPa)

Length of bearing (m)

Slip (without cavitation)

Slip (with cavitation)

No-slip (without cavitation)

No- slip (with cavitation)

-5

0

5

10

15

20

25

0 0.0 001 0.000 2 0.000 3 0.0004 0.0005 0.0006 0.0007 0.0008

Hydrodynamic pressure (kPa)

Length of bearing (m)

slip (without cavitation)

slip (with cavitation)

no-slip (without cavitation)

no-slip (with cavitation)

Inertia Effect on the Cavitation Phenomena of Textured Bearing

33

that the pressure generation by the presence of slip is

much lower than that by neglecting the slip both for

low inertia and high inertia pattern. In general,

introducing the slip condition on top surface of the

bearing is not recommended, because it leads to

deterioration of the hydrodynamic pressure and thus

the generated load support. Thirdly, the increase of

the inertia effect by lowering λ and increasing R

e

in

this case is likely a trigger to bring up the occurrence

of cavitation. Based on Figure 7 (a), it can be found

that there is a deviation of the pressure profile

between the case of “with cavitation” and “without

cavitation modelling”.

4 CONCLUSIONS

In this study, the correlation between the inertia

effect and the cavitation effect on the texture

lubricated contact in terms of pressure profile based

on CFD (computational fluid dynamic) method was

explored in detail. Two patterns of textured bearing,

i.e. high inertia and low inertia were studied. The

presence of the wall slip on the bearing was also of

particular interest. From the CFD results, the main

conclusion can be drawn, that is, the inertia term

affects the occurrence of the cavitation strongly.

Whether the slip is present or not in bearing, the

impact of inertia forces on the occurrence of the

cavitation phenomena is observable distinctly. This

finding may guide a new way to improve the

operation stability of the bearing by controlling the

cavitation phenomena in order to enhance the life

time of the system.

ACKNOWLEDGEMENTS

This research is fully supported by RPI-BT

(Research Publication International-High

Reputation) Grant, No. 387-05/UN7.P4.3/PP/2018.

The authors fully acknowledged Institute for

Research and Community Services (LPPM)

Diponegoro University for the approved fund which

makes this important research viable and effective.

REFERENCES

Arghir, M., Roucou, N., Helene M., & Frene, J., 2003.

Theoretical analysis of the incompressible laminar

flow in a macro-roughness cell. ASME Journal of

Tribology, 125(2), 309–318.

Braun, M.J., & Hannon, W.M., 2010. Cavitation formation

and modelling for fluid film bearings: a review.

Proceedings of the Institution of Mechanical

Engineers, Part J: Journal of Engineering Tribology,

224 (9), 839–863.

Choo, J.H., Glovnea, R.P., Forrest, A.K., & Spikes, H.A.,

2007. A Low friction bearing based on liquid slip at

the wall. ASME Journal Tribology 129, 611–620.

Concli, F., 2016. Pressure distribution in small

hydrodynamic journal bearings considering cavitation:

a numerical approach based on the open-source CFD

code OpenFOAM. Lubrication Science 28(6), 329–

347.

Dobrica, M.B., & Fillon, M., 2009. About the validity of

Reynolds equation and inertia effects in textured

sliders of infinite width. Proceedings of the Institution

of Mechanical Engineers, Part J: Journal of

Engineering Tribology, 223, 69–78

.

Dobrica, M.B., Fillon, M., Pascovici, M.D., & Cicone, T.,

2010. Optimizing surface texture for hydrodynamic

lubricated contacts using a mass-conserving numerical

approach. Proceedings of the Institution of Mechanical

Engineers, Part J: Journal of Engineering Tribology,

224 (8), 737–750.

Lin, X., Jiang, S., Zhang, C., & Liu, X., 2018.

Thermohydrodynamic analysis of high speed water-

lubricated spiral groove thrust bearing considering

effects of cavitation, inertia and turbulence. Tribology

International 119, 645–658.

Meng, F.M., Zhang, L., Liu, Y., Li, & T.T., 2015. Effect

of compound dimple on tribological performance of

journal bearing. Tribology International 91, 91–110.

Muchammad, M., Tauviqirrahman, M., Jamari, J., &

Schipper, D.J., 2017. An analytical approach on the

tribological behaviour of pocketed slider bearings with

boundary slip including cavitation. Lubrication

Science, 29, 133–152.

Rahmani, R., Rahnejat, H., 2018. Enhanced performance

of optimized partially textured load bearing surfaces.

Tribology International 117, 272–282.

Rao, T. V. V. L. N., Rani, A. M. A., Nagarajan, T., &

Hashim, F. M., 2012. Analysis of slider and journal

bearing using partially textured slip surface. Tribology

International, 56, 121-128.

Senatore, A., & Rao, T.V.V.L.N., 2018. Partial slip texture

slider and journal bearing lubricated with Newtonian

fluids: a review. ASME Journal of Tribology, 140 (4).

DOI: 10.1115/1.4039226.

Tala-Ighil, N., Fillon, M., & Maspeyrot, P., 2011. Effect

of textured area on the performances of a

hydrodynamic journal bearing. Tribology

International, 44 (3), 211-219.

Tauviqirrahman, M., Ajie, W.K., Yohana, E.,

Muchammad, M., & Jamari., 2016. A study of slip

position on improving the hydrodynamic lubrication

performance of single-textured bearing using a mass

conserving numerical approach. International Journal

of Engineering and Technology, 8(2), 913–921.

Tauviqirrahman, M., Muchammad, Jamari, & Schipper,

D.J., 2014. Numerical study of the load carrying

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

34

capacity of lubricated parallel sliding textured surfaces

including wall slip. Tribology Transactions, 57 (1),

134–145.

Zhang, X., Yin, Z., Jiang, D., Gao, G., Wang, Y., &

Wang, X., 2016. Load carrying capacity of misaligned

hydrodynamic water-lubricated plain journal bearings

with rigid bush materials. Tribology International 99,

1–13.

Zwart, P., Gerber, A., & Belamri, T., 2004. A two -

phase flow model for predicting cavitation

dynamics, International Conference; 5th, Multiphase

flow, Yokohama, Japan, pp. 1–4

Inertia Effect on the Cavitation Phenomena of Textured Bearing

35