Investigating the Effect of Inlet Velocity on Temperature Distribution

and Solid Volume Fraction in Fluidized Bed Dryer using CFD

Efflita Yohana

1

, M. Tauviqirrahman

1

, Muh. Ilham Mahawan

1

, Kwang-Hwan Choi

2

and

M. Syahreza Al Mulqi

1

1

Department of Mechanical Engineering, Universitas Diponegoro, Indonesia

2

Department of Agricultural Biotechnology, Seoul National University, Seoul, Republic of Korea

Keyword: Fluidized Bed Dryer, CFD, Drying, Tea.

Abstract: Tea leaves drying is a process to stop polyphenol oxidation and reduce the humidity of the leaves by

roasting technique. The roasting techniques uses heat which generated from wood burning. The roasting

must be monitored carefully so that the leaves are not too dry or even singed. The process of roasting from

wood burning (organic material) increasing the levels of Polycyclic Aromatic Hydrocarbon (PAH) of the tea

because of the fume from its combustion. Polycyclic Aromatic Hydrocarbon (PAH) is a member of

Hydrocarbon which consisting of two or more close aromatic ring structures. Each of structure consist of

benzo[a]pyrene. Benzo[a]pyrene formed from the imperfect combustion which are carcinogenic and

mutagenic which can cause cancer. One of the ways that can be done to reduce the negative impact of

drying with a wood burning is using a fluidized bed dryer (FBD). Fluidized bed dryer is a drying technique

by reducing and eliminating humidity on the solid particle and change the humidity to gas (evaporation), in

another word, this technique is called convective drying. On the drying technique, water has a role as

evaporating fluid (evaporated) and air as gas cleaner. This research aims to analyze the effect of velocity

variation on temperature and solid volume fraction distribution. This research uses Computational Fluid

Dynamics (CFD) software in 2D modelling with a constant temperature at 130 ˚C and varying velocity at

1.152 m/s, 1.536 m/s, 1.728 m/s and 1.8 m/s to get the average particle temperature distribution. Simulation

results obtained error on temperature distribution of particles with an average error of 0.67625%. Solid

volume fraction contour, velocity contour, and temperature distribution contour show that the optimum

velocity of fluidization and particle temperature distribution optimum velocity is 1.728 m/s.

1 INTRODUCTION

Development of tea business in Indonesia is located

at North Sumatra region, however, tea estates in

Indonesia lately are on declining condition.

Development of tea plants area in Indonesia has

declined since 2002, so there is 126.251 Ha left in

2009. Indonesia’s tea agro-industries have recorded

as the biggest earning of foreign exchange in the

national economy at the time. Declining of the cast

of planting area causes the tea production in

Indonesia declined too. Tea production in 2008 was

recorded as many as 137.499 tons, however, in 2010

the production became 129.200 tons (Sudjarmoko,

2014). Indonesia’s tea agro-industries are currently

undergoing declined because it has not been able to

overcome the problems which were faced by tea

producers in Indonesia, like the low crop

productivity because it has not used superior seeds,

the limit of technology to make a product, and

farmers’ inability to use technology in GMP

standard (Good Manufacture Process), GAP (Good

Agriculture Practice), and quality product standards

such as ISO standards (Sudjarmoko, 2014). The

desired standard product condition can be reached

by increasing the quality of tea production. Tea

companies in Indonesia commonly do the drying

process by using a roasting technique. The roasting

technique uses heat which produced by burnt wood

(organic material) for triggering and increasing the

levels of Polycyclic Aromatic Hydrocarbon (PAH)

of the tea because of the smoke from its combustion.

Polycyclic Aromatic Hydrocarbon (PAH) is a

member of hydrocarbon which consists of two or

more close aromatic ring structures, where each of

structure is consisting of benzo[a]pyrene.

Yohana, E., Tauviqirrahman, M., Mahawan, M., Choi, K. and Mulqi, M.

Investigating the Effect of Inlet Velocity on Temperature Distribution and Solid Volume Fraction in Fluidized Bed Dryer using CFD.

DOI: 10.5220/0009005800210028

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 21-28

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

21

Benzo[a]pyrene is formed by completing burn which

is carcinogenic and mutagenic, those characteristic is

believed to contribute to forming of cancer cells

(Philips, 1999). In this research, the drying process

has a role to stop the fermentation process and to

decline the water content on tea leaves with

fluidized bed dryer technique. Fluidized bed dryer is

one of a few drying techniques that used in industry

to produce the dried particulate product. Particle or

object is dried by fluidized bed dryer has to size

about 50-2000 µm. The using of a fluidized bed

dryer has several advantages such as simple

construction and low maintenance cost. Fluidization

is the key of the success of the fluidized bed dryer.

Figure 1 shows the scheme from several fluidized

bed characteristics. The characteristics are affected

by two factors that are gas velocity and pressure

drop (∆Pb). Bed or place of particle support in

which used as insulation between water distributor

with the particle is made from holey slabs

(distributor).

Basically, the higher velocity of the gas, the

higher pressure drop. they both have a linear

relation. At the particular velocity, called a

minimum of fluidization (umf), and pressure drop

along the area of the object (particle) will equally as

the weight of particles per area (∆Pmf). The particle

in this condition will levitate in the air and spread

out. Increasing of the gas velocity would make the

particle spread out easily, it is caused by the forming

of bubble gas and (∆Pb) would be constant at

(∆Pmf). Minimum point of fluidization can be

clearly identified when the gas velocity decreasing

(Bahu, 1997).

This research is focused on temperature

distribution condition and fluidization effect by

varying inlet velocity on fluidized bed dryer. The

analysis is necessary to do because the temperature

condition and fluidization effect (seeing from solid

volume fraction) from the fluidized bed dryer during

the drying process of tea leaves will be seen. To get

the temperature distribution and fluidization effect

of solid volume fraction, a mathematical model of

computational fluid dynamics (CFD) is used

(Versteeg and Malalasekera, 2007).

2 RESEARCH METHOD

The research on the fluidized bed dryer is done with

aiming to compare the experimental result and the

research (Ngoh and Lim, 2016). Invalidation,

modeling corresponding to the paper is used to

analyze temperature distribution and fluidization

effect. CFD is used for analyzing hydrodynamics

phenomena and heat transfer in the 2D modeling of

solid-gas fluidized bed dryer. Modeling by using

“Eulerian-eulerian (gas-solid) model multiphase”

and turbulent model k-omega are used to analyze

hydrodynamics phenomena and heat transfer in

fluidized bed dryer. On the Eulerian-eulerian

modeling, gas phase and solid phase are modeled by

a mathematical model which continue and

conservative so that could be written for each phase.

CFD software, Ansys Fluent, is used to solve mass

equation, momentum equation, and energy

conservation equation simultaneously. Kinetic

energy theory is used to get phase characteristic on

granular flow, the equation which used to solve the

model is written as follows (Ngoh and Lim, 2016):

Continuity equation for gas phase (g) and solid

phase (s):

.0

gg ggg

t

v

(1)

.0

ss sss

t

v

(2)

Momentum equation for gas phase and solid

phase:

. .

g

ggg gggg g g gg gs s g

t

vvvp gKvv

(3)

..()

s

s

ss s sss s g s s s gs g s

t

vvvpp gKvv

(4)

In momentum equation, τ is Reynold tensor

stress, g is gravity acceleration, and interaction force

(tension and buoyant) describes momentum

displacement between a gas phase and solid phase

(solid) which shown with the following equation

sg gsg s

pKvv

The fluctuating conservative energy equation for

solid particle is as follows:

3

.:..

2

s

s

ss s sss s s s s s

t

vIvk

(5)

Drag model from (Gidaspow, 1994) is used to

evaluate the changing on momentum coefficient.

The change in momentum coefficient based on drag

model from Gidaspow is as follows:

2.65

3

0.8

4

sgg s g

gs D g g

s

vv

KC for

d

(6)

2

2

150 1.75 0.8

sg g s

sg

gs g

gs s

vv

Kfor

dd

(7)

where,

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

22

0.687

24

1 0.15( ) 1000

Dgss

gs

CReforRe

Re

(8)

0.44 1000

Ds

CforRe

(9)

Reynold number for particle (solid), Re

s

, is as below

g

ss g

s

g

dv v

Re

(10)

Constitutive equation is used to completing the

equations relation. Solid phase tensor stress (solid),

τ

s

, is given as follows

2

().

3

T

s

s

ss g ss ss

vv vI

(11)

Where shear stress on solid phase, µ

s

, is given as

follows

,,,

s

scol skin s fr

(12)

Viscosity of particle collision, µ

s,col

, is given below

1/2

,0,

4

(1 )

5

s

scol s s s ss ss

dg e

(13)

Kinetic viscosity (Gidaspow model), µ

s,col

, is

2

,0,

0,

10

4

11

96 1 5

ss s

skin ss s ss

sssss

d

ge

eg

(14)

And shear viscosity of particle (solid), µ

s,col

, is

,

2

sin

2

s

sfr

D

p

I

(15)

Shear viscosity of particle (µ

s,col

), p

s

shows the

particle pressure, ɸ shows the inner shear angle, and

I

2D

shows both variation from stress tensor deviator.

Particle pressure, ps, is determined as follows

2

0,

21

s

sss s ssssss

peg

(16)

Particle pressure (solid pressure) or termed as

kinetic time (α

s

ρ

s

θ

s

) while

2

0,

21

s

ss s ss s

eg

stated the particle

collision effect. On the granular flow case, particle

pressure can be calculated separately (itself). e

ss

as

restitution coefficient for particle which collide,

while

0,

s

s

g

as function of radial distribution and can

be written as follows

1

1/3

0,

,

1

s

ss

smax

g

(17)

Viscosity of solids, λ

s

, can be written

1/2

0,

4

1

3

s

s s s s ss ss

dg e

(18)

Solid viscosity (λ

s

) calculates resistance of

particle granules to tension and pressure. Diffusion

coefficient from particle temperature based on

Gidaspow’s drag model is

2

2

0, 0,

0,

150

6

112 1

384 1 5

ss s

s

s s ss ss s s s ss ss

ss ss

d

kgedge

eg

(19)

Energy equation is written as below

T

eff

eff j j h

f

t

E

vEp k hJ v S

(20)

Where k

eff

is the effective and combined of k + k

t

,

where k

t

is turbulent conductivity which is

determined on turbulent model. J

j

as diffusion flows

from object “j”. Equation on the right side shows

energy transfer in conduction, diffused object, and

dissipation of each viscosity. S

h

shows the heat

which occurs because of chemical reaction.

Heat transfer convection equation

1/ 4

1/ 2 2/3 0.4

2 0.4 0.06

sph

s

hD

Nu Re Re Pr

k

(21)

Where 3.5 ≤ Re ≤ 80.000 and 0.7 ≤ Pr ≤ 380.

Heating of particle based on time

()t

bt

i

TT

e

TT

(22)

Where

s

p

hA

b

VC

(23)

3 RESULT AND ANALYSIS

3.1 Validation with Previous Research

In this research, ANSYS fluent using 2D with 3

boundary condition, that is the inlet, outlet, and the

wall is used. Be height shows how tall or vast will

be modeled as a particle (solid) which has material

properties and operating parameter as shown in

Table 1. The first step, drawing the geometry in

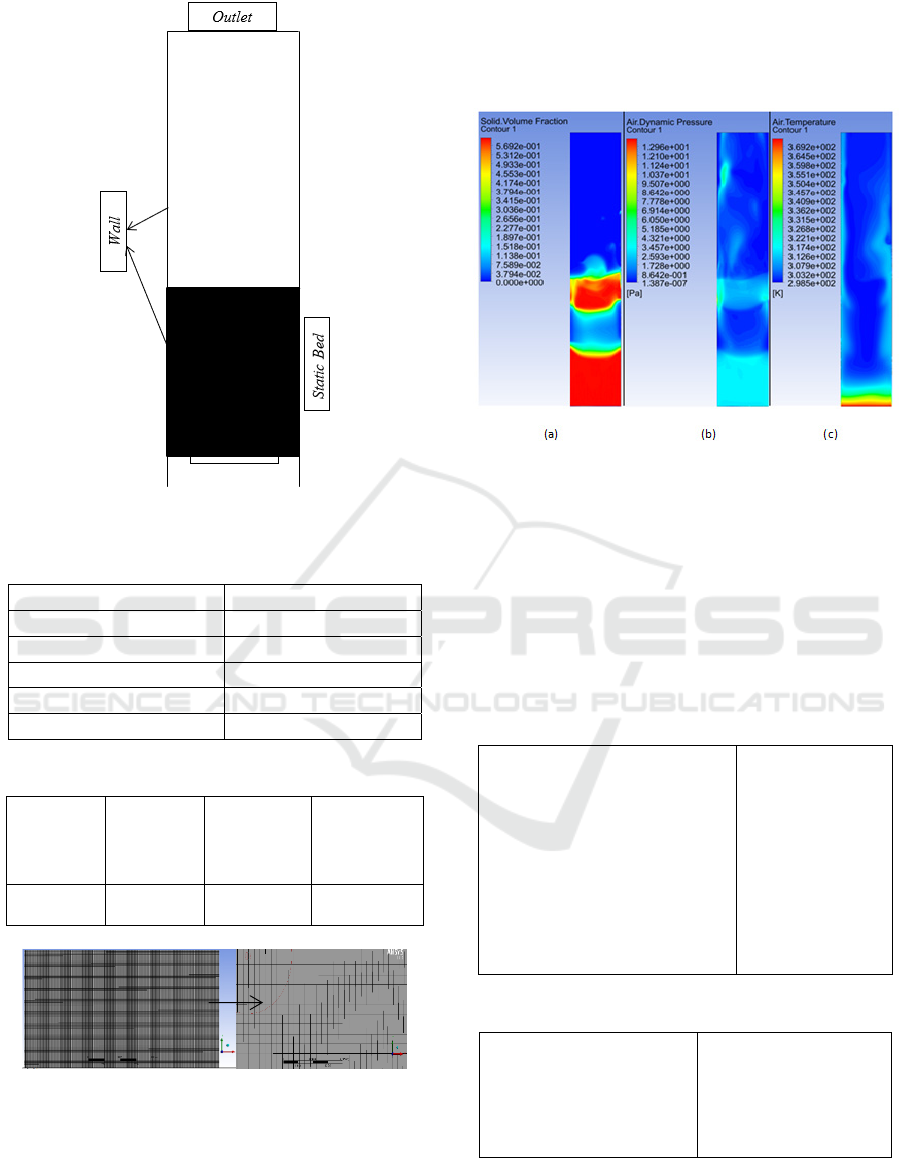

ANSYS Fluent, as shown in Figure 1.

CFD program do analysis on obsject by deviding

the volume into small parts (mesh), meshing process

is shown below.

Investigating the Effect of Inlet Velocity on Temperature Distribution and Solid Volume Fraction in Fluidized Bed Dryer using CFD

23

Figure 1: Fluidized bed dryer sketch.

Table 1: Operational Condition.

Parameter value

Bed height 500 mm

Bed widht 90 mm

Static bed height 176 mm

Bed thickness 24 mm

Time step 10

-4

s

Table 2: Mesh details.

Number of

divisons

Skewnees

Max

Skewnees

Max

Skewnees

on Fluent

400x800 7.75E-004 1.77E-003 0.85

Figure 2: Generating mesh.

Geometry manufacture and mesh processing is the

pre-processing stage. In the processing, the stage is

using the Fluent software.a Set-up or variable value

uses set-up according to the previous research (Ngoh

and Lim, 2016). In post-processing stage is getting

the result of temperature distribution result and

fluidization effect on fluidized bed dryer. Fig 3a, 3b,

and 3c show the fluidization effect, air dynamic

pressure, and air temperature distribution.

Figure 3: Contour of (a) Solid volume fraction, (b)

Dynamics pressure, dan (c) Air temperature distribution.

Fluidization and heat transfer can be seen from

solid volume fraction and temperature distribution

by using Eulerian-eulerian model. Fig 3 shows

temperature distribution which can be seen at low

part (approaching inlet) has the temperature at

100

o

C, this is in corresponding to the simulation

previously (Ngoh and Lim, 2016).

Table 3: Material properties.

Particle density, ρ

p

Gas density, ρ

g

Initial solid packing, e

s0

Particle diameter, d

p

Superficial gas velocity, U

Gas temperature fluidization, T

f

Initial particle temperature, T

p

Particle thermal conductivity, k

p

Particle specific heat, c

p

Air thermal conductivity, k

g

Air specific heat, c

g

640 kg/m

3

1.225 kg/m

3

0.6

5 mm

1.152-1.728 m/s

130

o

C

25

o

C

0.17 W/(m K)

1780 J/(kg K)

0.0242 W/(m K)

1006.43 J/(kg K)

Table 4: Simulation settings.

Time step

Number of iteration

Multiphase

Pressure

Momentum

Turbulent

10

-4

s

30000

Eularian-eularian

SIMPLE

First order upwind

K-omega

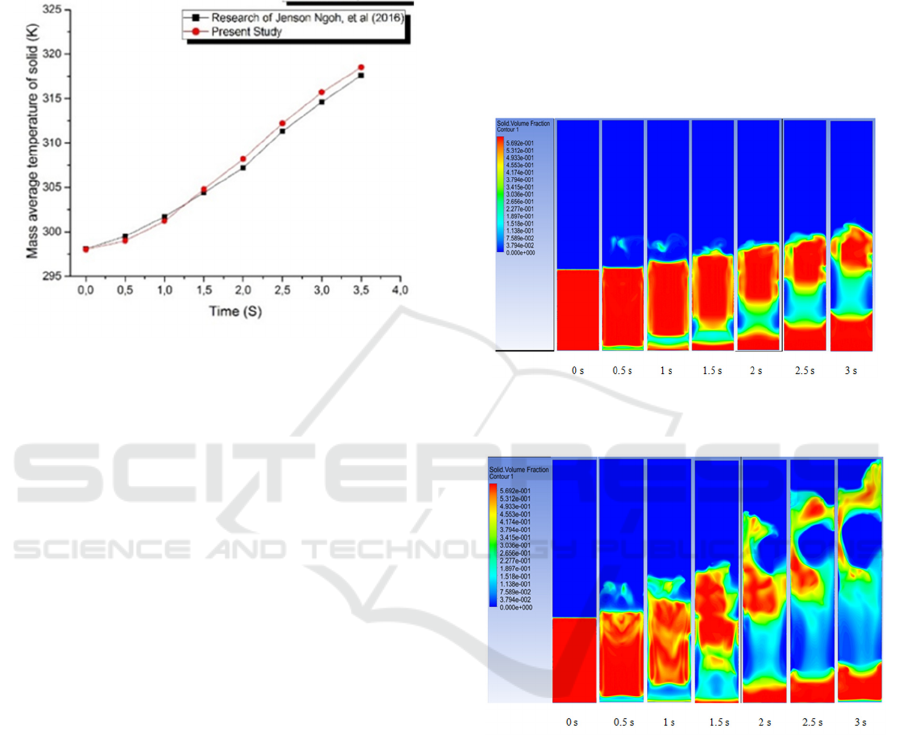

Simulation result which interpreted as

temperature distribution chart can be seen in Fig 4.

Charts from the simulation are compared with

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

24

reference paper. From the compared result which

has done is got the average error 0.67625%, with the

highest and the lowest value is 1.226% and 0.033%

respectively. An error got from validation is under

10%, then the method can be applied in this

research.

Figure 4: Particle average temperature vs fluidization time

chart.

3.2 Gas Inlet Velocity Effect

Heat transfer which occurs on fluidization effect can

be investigated with different operation condi-tions,

the simulation is done repeatedly by varying inlet air

velocity as well as the keeping of operation

parameters and constant material proper-ties. The

fluidized bed is heated by flowing hot air constantly

at temperature 130 oC and particle initial

temperature is 25 oC. Particle size used is 5 mm and

the air velocity used is 1.152 m/s, 1.536 m/s, dan

1.728 m/s.

Analyses were done on solid volume fraction

profile, temperature profile, and velocity profile

explain the heat transfer that occurred. Figure 5

shows solid volume fraction contour (solid volume

fraction) at a velocity of 1.152 m/s, where air

bubblethat is formed is lifting the particle (bed) as

initial fluidization’s step.

Particle concentration at the bottom tends to lift

uniformly, this thing indicates gas inlet velocity

uniform according to the characteristic of a fluidized

bed dryer. Contour profile of solid volume fraction

showing bubble which created near the bottom has

the smaller size and will get bigger as it moves

upward as seen in the second 1.5s to 2s, this

statement corresponds to simulation (Ngoh and Lim,

2016). The contour profile shows that the particle

tends to fix and will move downward again when

gas inlet velocity is small as shown at time 2s. The

solid particle will have a good heat transfer when

they contact each other. However, in the case of a

fluidized bed dryer, the convection heat transfer

more concerned than conduction heat transfer. This

research is done to analyze optimum velocity that

makes a particle of tea which later undergoes a

drying process with fluidiszed bed dryer does not

leap out of the fluidized bed chamber. Figure 6 and

figure 7 show the velocity contour profile at 1.536

m/s and 1.728 m/s.

Figure 5: Contour of solid volume fraction at velocity

1.152 m/s.

Figure 6: Velocity contour of solid volume fraction

velocity at 1.536 m/s.

Figure 6 shows inlet velocity variation at 1.536

m/s. Compared to the velocity at 1.152 m/s as shown

at Figure 5, it shows that the increasing of velocity

makes the bubble which produced becomes bigger

and so does separation effect, this phenomenon be

seen at time 1s. From Figure 6, it is seen that the

contour at 2s shows the particle moving downward,

but the bubble will begin to reform at a time 3s. At

3s, it shows that the particle got the highest point of

the chamber, this is not same as the purpose of

research, where it was originally intend to get

optimum velocity so that the particle does not leap

Investigating the Effect of Inlet Velocity on Temperature Distribution and Solid Volume Fraction in Fluidized Bed Dryer using CFD

25

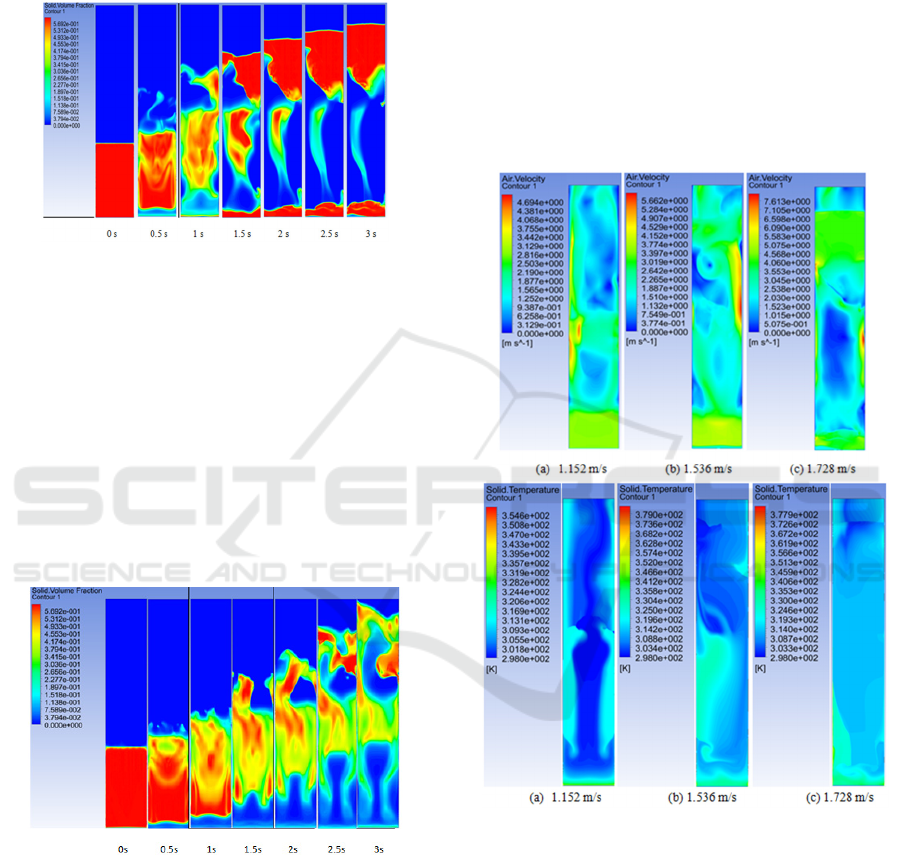

out of the chamber. In Figure 7, it shows the

variation speed at 1.728 m/s, from the figure, it can

be seen that the particle is steady until 3s when

comparing with previous speed and the particles that

come back down look less than the previous speed.

Figure 7: Velocity contour of solid volume fraction at

1.728 m/s.

(Bahu, 1997), his book, explaining, basically, the

increasing of gas inlet velocity that occurs on

fluidized bed dryer was causing an increase in

pressure drop (∆Pb) and it is linear with gas velocity

(u). In particular gas velocity, it is called as the

optimum velocity of fluidization (umf), and pressure

drop along with object area (particles) would be

equi-valent to the weight of particles per area

(∆Pmf). The particle at this condition will fly out

freely and it will begin to expand as shown in figure

7 (Bahu, 1997).

Figure 8: Velocity contour of solid volume fraction at 1.8

m/s.

The contour at 1.8 m/s shows that there is a high

enough fluctuation at 2s, and it increases until 3s.

Tea particles at 3s reach the highest point of the

chamber and make the possibility of the particle to

leap out of the chamber, although in this velocity

does not any precipitation of the particles at the

bottom of the chamber.

3.3 Temperature Distribution

Temperature distribution and heat transfer effect on

the particle can be seen from gas inlet velocity and

gas temperature distribution, which will have an

effect on particle temperature. Gas inlet velocity will

influence particles speed and vector speed of the

particle. The small gas inlet speed will cause the

vector speed of the particles becomes low, the low

speed of the particles makes the convection heat

transfer becomes slow.

Figure 9: Contour of gas velocity (a) 1.152 m/s, (b)

1.536 m/s, dan (c) 1.728 m/s

.

Figure 10: Contour of particle temperature (a) 1.152 m/s,

(b) 1.536 m/s, dan (c) 1.728 m/s.

Figure 9.c which velocity at 1.728 m/s shows

the gas velocity value of particle 4.568 m/s, where it

is higher than gas velocity on the particle with inlet

velocity 1.152 m/s and 1.536 m/s. This value shows

that the gas velocity is linear with velocity vector of

particle. Figure 9.c has a high particle velocity

vector, so it causes good convection heat transfer.

This result is proportional to contour of temperature

distribution of particle, it is seen at Figure 10.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

26

Figure 10 shows contour of particle

temperature with variation speed at 3s. At Figure 10,

the increasing of temperature is proportional to its

velocity, but the temperature distribution at 1.728

m/s looks more evenly. The uniform of temperature

distribution is in accordance with opinion of (Ngoh

and Lim, 2016). which says that the higher particle

velocity vector, the better convection heat

transfer.convection heat transfer in simulation can be

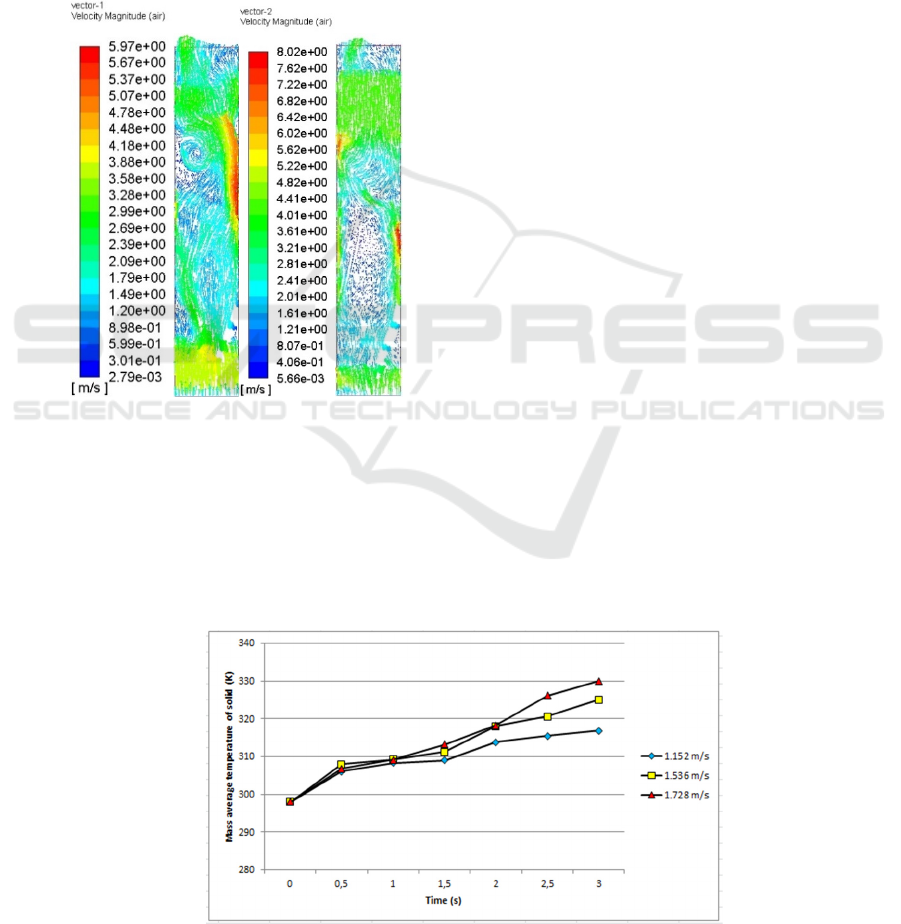

seen from its gas velocity vector. Figure 11 shows

gas velocity vector at 1.536 m/s and 1.728 m/s at

time 3s.

(a) (b)

Figure 11: Velocity vector at (a) 1.536 m/s and (b) z1.728

m/s.

Convection heat transfer is strongly

influencedby velocity fluid flows when passing or

pounding an object. Figure 11 shows gas velocity

vector when passing the tea particle, Figure 11.b

shows velocity vector which is passing the tea

particle is bigger than that velocity vector that

happens on the particle, Figure 11.b shows the

velocity vector passing the particle is bigger than the

velocity vector at Figure 11.a. The value of the

velocity vector when passing the particle will

influence the heat transfer happening on the particle.

The higher velocity vector, the better heat

transfer, because the higher velocity vector passing

the particle then the higher Nusselt number of the

fluid. Optimum velocity at 1.728 m/s has the highest

Nusselt number 10.5 (equation 21). Nusselt number

influence the convection heat transfer coefficient

value which is linear with the convection heat

transfer value (Cengel, 2003).

Figure 12 shows the temperature distribution

chart with various velocity from 0s to 3s and

increase of gas inlet velocity will influence the

particle average temperature. The increasing of

temperature is influenced by Nusselt number, and

Figure 12 shows that longer fluidization time, the

higher temperature (Cengel, 2004) mentioned that

heat transfer on the object along time “t” is same as

the energy increase on the object along time “t”

(equation 22) (Cengel, 2004).

4 CONCLUSIONS

Analysis of fluidization effect and heat transfer on

this research is using software Computational Fluid

Dynamics (CFD). Simulation is done by varying of

gas inlet velocity at 1.152 m/s, 1.536 m/s, 1.728 m/s

and 1.8 m/s and keeping the temperature operation

constant at 130 oC to determine optimum

fluidization velocity and optimum temperature

distribution velocity. The results show that optimum

fluidization velocity by assuming no tea particle leap

out from the chamber is 1.728 m/s, it is seen in

Figure 7. Heat transfer becomes one of the essential

Figure12: Particle average temperature vs fluidization time with various velocity chart.

Investigating the Effect of Inlet Velocity on Temperature Distribution and Solid Volume Fraction in Fluidized Bed Dryer using CFD

27

things of a fluidized bed dryer because the key of

drying is the heat transfer. The heat transfer that

occurs is convection heat transfer. According to the

simulation, convection heat transfer can be seen

from the particle velocity vector, it means the

optimum heat transfer occurring at 1.728 m/s. The

optimum heat transfer is proven by the contour of

the temperature distribution of the particle (Figure

10), the optimum temperature distribution is

influenced by gas inlet velocity which is linear

particle velocity vector. Particle temperature

distribution is increased linearly with the gas inlet.

And it is proven by Nusselt number with a value

10.5 at optimum velocity 1.728 m/s affection

convection heat transfer, it is seen at temperature

distribution chart (Figure 12).

REFERENCES

Bahu, R. E., 1997. Fluidized bed dryers. Industrial Drying

of Foods, pp.65-88.

Cengel, Y. A. 2003. Heat Transfer: A Practical Approach,

2

nd

Ed. McGraw-Hill. Boston.

Gidaspow, D. 1994. Multiphase Flow and Fluidization:

Continuum and Kinetic Theory Descriptions. Boston,

USA: Academic Press.

Ngoh, J. & Lim, E. W. C., 2016. Effects of particle size

and bubbling behavior on heat transfer in gas fluidized

beds. Applied Thermal Engineering, 105, pp.225-242.

Phillips, D. H., 1999. Polycyclic aromatic hydrocarbons in

the diet. Mutation Research/Genetic Toxicology and

Environmental Mutagenesis, 443(1), pp.139-147.

Sudjarmoko, B. 2014. Perkembangan Pasar Teh

Indonesia Di Pasar Domestik Dan Pasar

Internasional. Badan Penelitian Tanaman Industri dan

Penyegar Kementrian Pertanian.

Versteeg, H. K. & Malalasekera, W., 2007. An

introduction to computational fluid dynamics: the

finite volume method. Pearson Education.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

28