Catalytic Converter based on Titanium Oxide (TiO

2

) to Reduce the

Emission of Carbon Monoxide and Hydrocarbon in Exhaust Gas of

Motor Vehicles

Ahmad Mustamil Khoiron

1

, Samsudin Anis

1

, Masugino

1

, Syahdan Sigit Maulana

1

, Saian Nur Fajri

2

1

Department of Mechanical Engineering, Universitas Negeri Semarang, Semarang, Indonesia

2

National Yunlin University of Science and Tecnology, Yunlin, Taiwan

msyahdan19@yahoo.com, saiannurfajri@gmail.com

Keywords: Catalytic Converter, Titanium Oxide, Emission, Carbon Monoxide, Hydro Carbon

Abstract: Motor vehicle is a transportation which uses petroleum fuels as its energy resource. Crude oil as the raw

materials processed into any kinds of petroleum fuels then used for the motor vehicle. Afterward, fuel is

changed into mechanical energy through the combustion process which also produces the dangerous

pollutant. Aimed to reduce the air pollution which has toxicity from internal combustion engine then used

Catalytic Converter. However, Catalytic Converter has a high price and causing most gasoline vehicles did

not fully use this technology. The case happened because catalytic made from Palladium, Platinum, and

Rhodium. The breakthrough is made by making a ceramic-based catalyst with Titanium Dioxide additive.

The purposes of the research are; (a) to know the reduction of carbon monoxide in the exhaust gas emission

using Titanium Oxide (TiO

2

), (b) to know the reduction of HC in the exhaust gas emission using Titanium

Oxide (TiO

2

), (c) to know the effect of the catalytic converter uses Titanium Oxide (TiO

2

) on engine

performance at 1,000; 1,500; and 2,000. The method used was a quasi-experimental design, which

compared experimentally before and after the exhaust gas through a catalytic converter based on TiO

2

.

1 INTRODUCTION

Motor vehicles are the means of transportation used

to assist human mobility in daily activities. The

number of motor vehicles is increasing every year.

The Statistic Indonesia (BPS) data shows that the

number of motor vehicles in 2013 has reached 104

million units, then in 2014, it has increased to 114

million units, by 2015 the number of motor vehicles

reaches more than 121 million units.

Motor vehicles use petroleum fuels as its

energy resource. Then the fuel is converted into

mechanical energy through the combustion process.

From this combustion process, motor vehicles

produce harmful pollutants. According to Sugiharto

et al. (2016), the total estimated CO pollutant of all

activities is about 686,864 tons per year or 48.6

percent of the total emissions of five pollutants. The

cause of air pollution is about 80 percent comes

from the transport sector, and 20 percent from

industry and domestic waste. Whereas, carbon

emissions from deforestation and forest degradation

are 20 percent.

Pollutant gases that generated by motor

vehicles have a harmful impact on human health and

the environment. According to research conducted

by Hajderi and Bozo (2014) conducted in Albania,

motor vehicle exhaust emissions Increase the risk of

chronic bronchitis, hormonal hyperactivity,

dermatitis, anemia, allergies and tumors in humans

and provide an increasing number of cancer patients

and liver disease that result in death to 400

casualties. Furthermore, vehicle exhaust gas can also

cause acid rain, greenhouse effect, and damage the

ozone layer. So the problem of gas dispose of this

motor vehicle requires severe handling.

Various studies have been undertaken to reduce

the impact and content of emissions, such as with

the use of filter material to reduce the pollutant from

the exhaust gas emissions of these vehicles. Ceramic

materials can be used to absorb HC and CO exhaust

emissions. The results of Sinuhaji (2017), which

uses ceramics as an absorbent material of CO up to

84.62%, and HC up to 71.64%. So, this acceptable

Khoiron, A., Anis, S., Masugino, ., Maulana, S. and Fajri, S.

Catalytic Converter based on Titanium Oxide (TiO2) to Reduce the Emission of Carbon Monoxide and Hydrocarbon in Exhaust Gas of Motor Vehicles.

DOI: 10.5220/0009005700150020

In Proceedings of the 7th Engineering International Conference on Education, Concept and Application on Green Technology (EIC 2018), pages 15-20

ISBN: 978-989-758-411-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

15

ceramic form can be used as a reference in reducing

vehicle exhaust pollutants.

Based on the research of Amin and Subri

(2016), the manufacture of emission filter material

from Ceramic Matrix Composite (CMC) material

has been successfully manufactured. Using Titanium

Oxide substances as additives are mixed with some

other additives, mixing with a rotational speed of 64

rpm for 30 minutes and molded with 25 MPa

pressure and 9,500C sintering temperature. The

decreasing performance of CO level, up to 99.67%

volume at 2,000 rpm engine speed. Thus, based on

the description, porous ceramics with additional

TiO2 additives may be used to reduce exhaust

emissions of motor vehicles.

Based on the description of the problem and the

results of previous research, it is necessary to

develop the design and use of materials on the

catalytic con-verter which is useful, efficient and

economical, so that all types of motor vehicles can

use catalytic con-verter technology to overcome the

problems of envi-ronmental pollution that will be

bad for human life.

2 METHOD

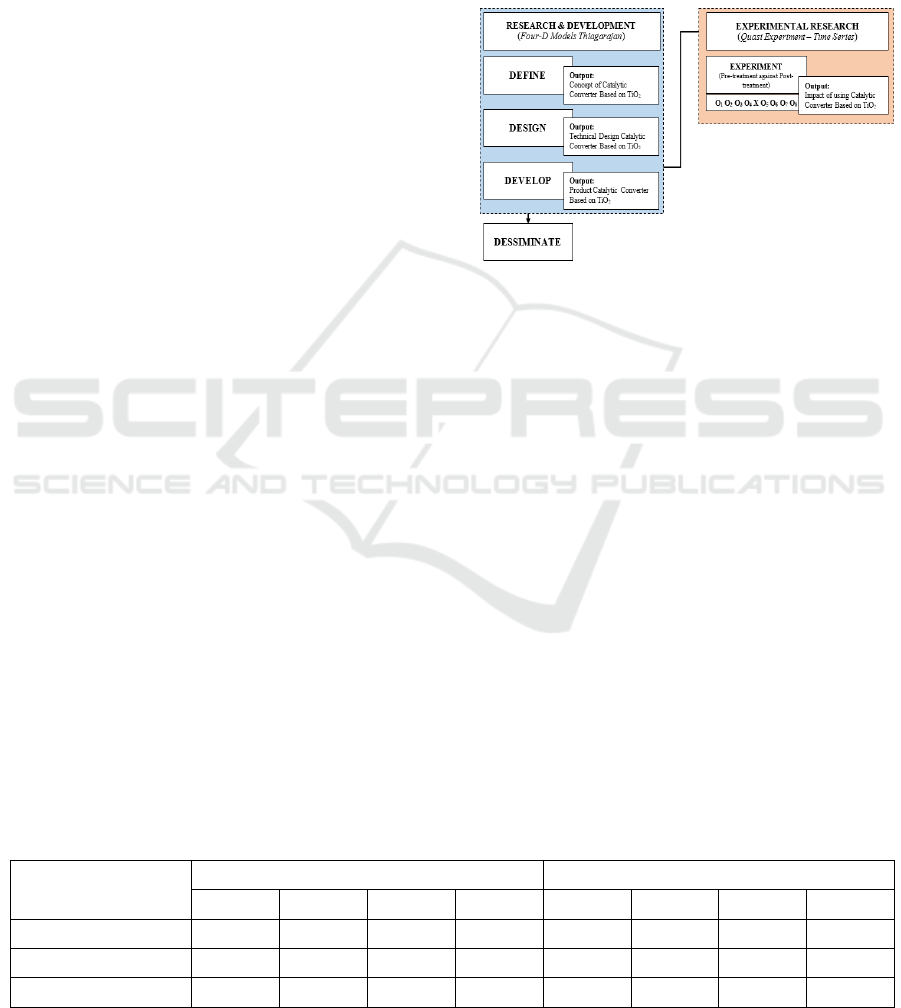

This study uses a mixed method, a combination of

research and development with experimental

research. Research produces to produce the right

products in the relevant laboratory and

environmental environments. Four D models are

used as a model of research and development which

consists of 4 stages of development. For valid

results, an experimental time series quasi-

experimental model was used to determine the use

of the designed catalytic converter.

In product development, the catalytic converter

design was designed using Autodesk inventor to

then be simulated using ANSYS Fluent. The

experimental research used: 1) independent variable

was a standard exhaust for a light vehicle without

catalytic converter and catalytic converter designed

with ceramic material with additive Titanium

Dioxide (TiO

2

), 2) control variables were rotation

variation for testing engine performance from 1,000

rpm, 1,500 rpm, and 2,000 rpm, and 3) dependent

variables were engine performance (torque and

power), exhaust emissions (carbon monoxide,

carbon dioxide, and hydrocarbons).

The research design can be described as in the

following figure:

Figure 1: Research design.

Note:

O

1

, O

2

, O

3

, O

4

= testing and measuring exhaust

emission before treatment

O

5

, O

6

, O

7

, O

8

= testing and measuring exhaust

emission after treatment

X = treatment using a designed catalytic converter

The result of carbon monoxide from the

exhaust gas measured using a gas analyzer then

incorporated into the test result table as follows

3. DATA ANALYSIS

Data analysis techniques are used to analyze data

that has been collected during the experimental

process. The data analysis technique used in this

research is the comparison of software with the

product. The design was observed by simulation

Table 1: The measurement instrument of HC and CO.

Revolution (rpm)

Without Catalytic Converter (%) With Catalytic Converter (%)

O

1

O

2

O

3

O

4

O

5

O

6

O

7

O

8

1000 (X

1

)

O

1

. X

1

O

2

. X

1

O

3

. X

1

O

4

. X

1

O

5

. X

1

O

6

. X

1

O

7

. X

1

O

8

. X

1

1500 (X

2

)

O

1

. X

2

O

2

. X

2

O

3

. X

2

O

4

. X

2

O

5

. X

2

O

6

. X

2

O

7

. X

2

O

8

. X

2

2000 (X

3

)

O

1

. X

3

O

2

. X

3

O

3

. X

3

O

4

. X

3

O

5

. X

3

O

6

. X

3

O

7

. X

3

O

8

. X

3

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

16

with ANSYS Fluent software, the analysis used was

pressure, temperature, and gas flow rate to be tested

on the catalytic converter made of ceramic with

Titanium Dioxide additive (TiO

2

). Ansys software

will show the pressure, temperature and flow rate on

the inside of the catalytic-based exhaust converter

made from ceramic with Titanium Dioxide additive

(TiO

2

).

The determination of adsorption power of carbon

dioxide (CO) through activated carbon adsorbent,

the effectiveness of adsorbent is measured by

percentage level of adsorbs to exhaust emission and

particulate lead. The formula for measuring the

effectiveness of adsorbents is as follows:

%CO

C1C2

C1

x100%

(1)

The determination of HC reduction power by

reducing ceramic materials, reducing effectiveness is

measured based on percentage reduction rate on HC

exhaust emissions. The formula for measuring the

effectiveness of adsorbents is as follows:

%HC

C1C2

C1

x100%

(2)

Note:

C1 is initial emission levels (without treatment)

C2 is gas emission level after treatment with the

reduction

The determination of exhaust volume through

catalytic converter:

SpaceVelocit

y

Volumeflowrate

Rectorvolume

(3)

where volume flow rate is

.

2

..

2

.60

(4)

and reactor volume, in this case as same as the

volume of the catalytic converter through the

following equation

4

.

.

(5)

4 RESULTS

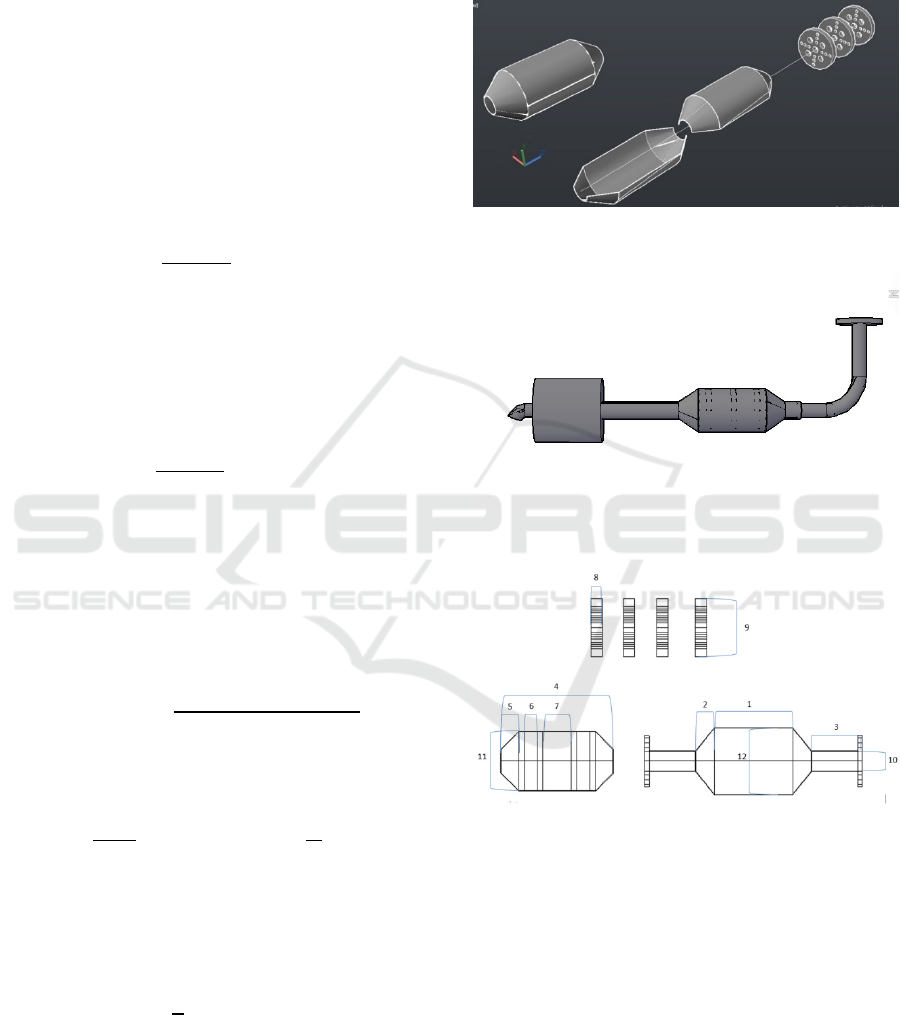

4.1 Catalytic Converter Design

Figure 2: Catalytic converter in assembly.

Figure 3: Catalytic converter.

Figure 4: Technical part of the catalytic converter.

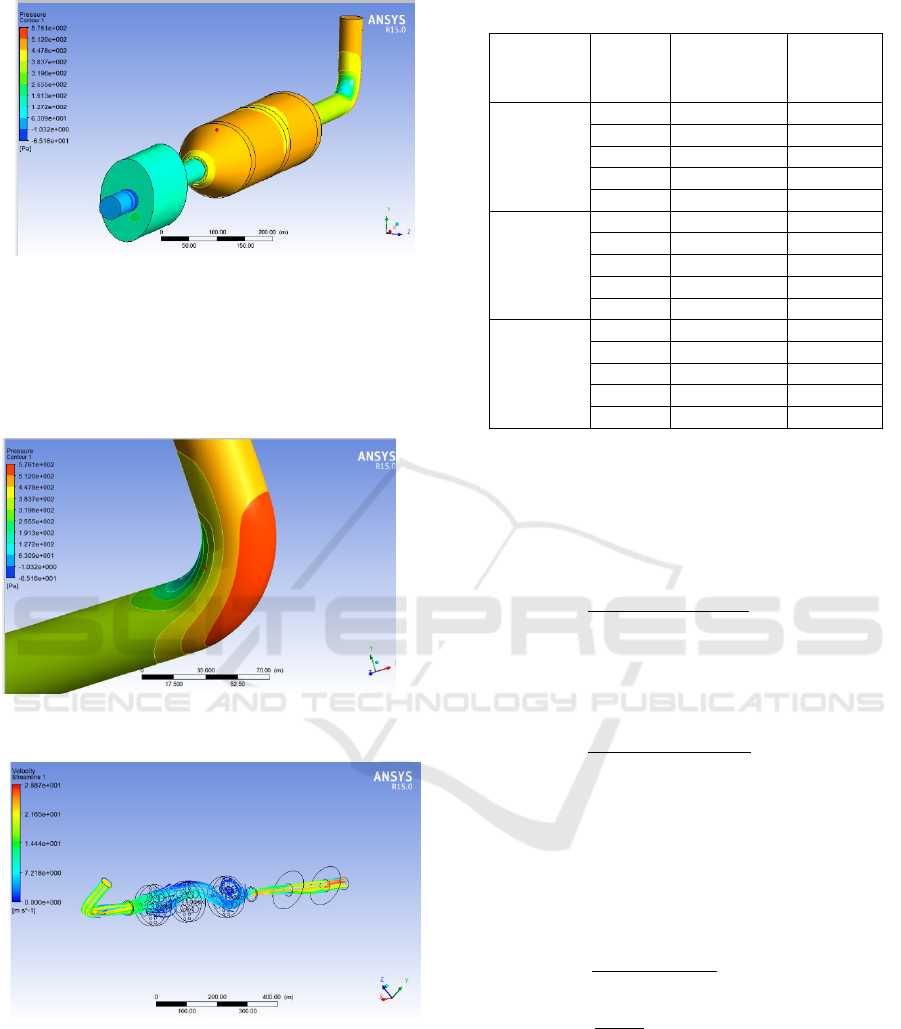

4.2 Simulation Result

Figure 5 shows the result of the pressure distribution

occurring on the product. The highest value is shown

in red which means that it is 5.761x10

2

, while the

lowest is -6.516x10

1

with blue. As the result of

pressure analysis, the unit used is Pascal (Pa). Figure

9 shows the drop in pressure from the pipe header to

the muffler tip.

Catalytic Converter based on Titanium Oxide (TiO2) to Reduce the Emission of Carbon Monoxide and Hydrocarbon in Exhaust Gas of

Motor Vehicles

17

Figure 5: Pressure distribution.

The highest pressure occurs at the bottom

radius of the pipe showing a value of 5.761x10

2

; this

indicates that the part is a critical part because it can

cause material damage due to the pressure that

occurs during the process of working

Figure 6: Pressure Distribution on header pipe.

Figure 7: Fluid flow through the catalytic converter.

4.3 Catalytic Converter Design

Based on the results of catalytic converter testing

using a ceramic catalyst with titanium dioxide

additives to reduce the emission levels of

hydrocarbon carbon monoxide gas shown in the

following table:

Table 2. The Measurement result of HC and CO

Revolution

(rpm)

Exhaust

Gases

Without

Catalytic

Converter

Using

Catalytic

Converter

1,000

CO 3.768% 3.101%

CO2 3.28% 4.03%

HC 111 ppm 140 ppm

O2 13.81% 13.30%

Λ 2.052 2.042

1,500

CO 0.586% 0.162%

CO2 5.40% 5.93%

HC 41 ppm 29 ppm

O2 13.25% 12.97%

Λ 2.467 2.44

2,000

CO 1.193% 1.615%

CO2 5.21% 5.55%

HC 89 ppm 46 ppm

O2 12.87% 12.33%

Λ 2.276 2.069

To calculate the adsorption power or the

decrease of the carbon monoxide and hydrocarbon

content of the catalytic converter design can be used

the following equation, for CO adsorption power

(AB) using:

x100%

(6)

for HC adsorption power formula using:

x100%

(7)

The results of catalytic converter testing using a

ceramic catalyst with titanium dioxide additive at

1000 rpm:

CO before treatment = 3.768 %

CO after treatment = 3.101 %

3.768 3.101

3.768

x100%

0.667

3.768

x100% 17.70%

(8)

The use of the ceramic material as a catalyst

material with the addition of titanium dioxide

additive at 1,000 rpm can reduce carbon monoxide

emission by 17.70% decrease from 3.768%

concentration without catalytic converter to 3.101%.

HC before treatment = 111

HC after treatment = 140

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

18

111140

111

x100%

29

111

x100% 26.12%

(9)

The use of the ceramic material as a catalyst

material with the addition of titanium dioxide

additive at 1,000 rpm cannot reduce the emission of

hydrocarbon gas, but increasing 26.12% of the

concentration of 111 ppm without catalytic

converter to 140 ppm.

The results of catalytic converter testing using

ceramic catalyst with titanium dioxide additive at

1,500 rpm:

CO before treatment = 0.586%

CO after treatment = 0.162%

0.5860.162

0.586

x100%

0.424

0.586

x100% 72.35%

(10)

The use of ceramic material as catalyst material

with the addition of additive at 1,500 rpm can reduce

carbon monoxide emission by 72.35% decrease from

0.586% concentration without catalytic converter to

0.162%.

The initial HC content = 41

The final HC content = 29

4129

41

x100%

12

41

x100% 29.26%

(11)

The use of the ceramic material as catalyst

material with the addition of titanium dioxide

additive at 1,500 rpm can reduce the hydrocarbon

emission by 29.26% from 41 ppm concentration

without catalytic converter down to 29 ppm.

The results of catalytic converter testing using a

ceramic catalyst with titanium dioxide additive at

2,000 rpm:

The initial CO content = 1.193 %

The final CO content = 1.615%

1.1931.615

1.193

x100%

0.422

1.193

x100% 35.37%

(12)

The use of the ceramic material as a catalyst

material with the addition of titanium dioxide

additive at 2,000 rpm cannot reduce carbon

monoxide emissions, but increasing 35.37% of the

1.193% concentration without catalytic converter to

1.615%.

The initial HC content = 89

The final HC content = 46

8946

89

x100%

43

89

x100% 50%

(11)

The use of the ceramic material as a catalyst

material with the addition of titanium dioxide

additive at 2,000 rpm can reduce hydrocarbon

emissions by 50% from 89 ppm concentration

without catalytic converter down to 46 ppm.

Table 3: The result of the exhaust emission test without

using a catalytic converter.

Test sequence 1 2 3

Oil

temperature

o

C 122 122 122

Revolution rpm 1,000 1,500 2,000

CO % vol 3.768 0.586 1.193

CO2 % vol 3.28 5.40 5.21

HC ppm vol 111 41 89

O2 % vol 13.81 2.467 12.87

Λ - 2.052 2.467 2.276

Table 4: The result of the exhaust emission test using a

catalytic converter.

Test sequence 1 2 3

Oil temperature

o

C 121 122 122

Revolution rpm 1,000 1,500 2,000

CO % vol 3.101 0.162 1.615

CO2 % vol 4.03 5.93 5.55

HC Ppm vol 140 29 46

O2 % vol 13.30 12.97 12.33

Λ - 2.042 2.445 2.069

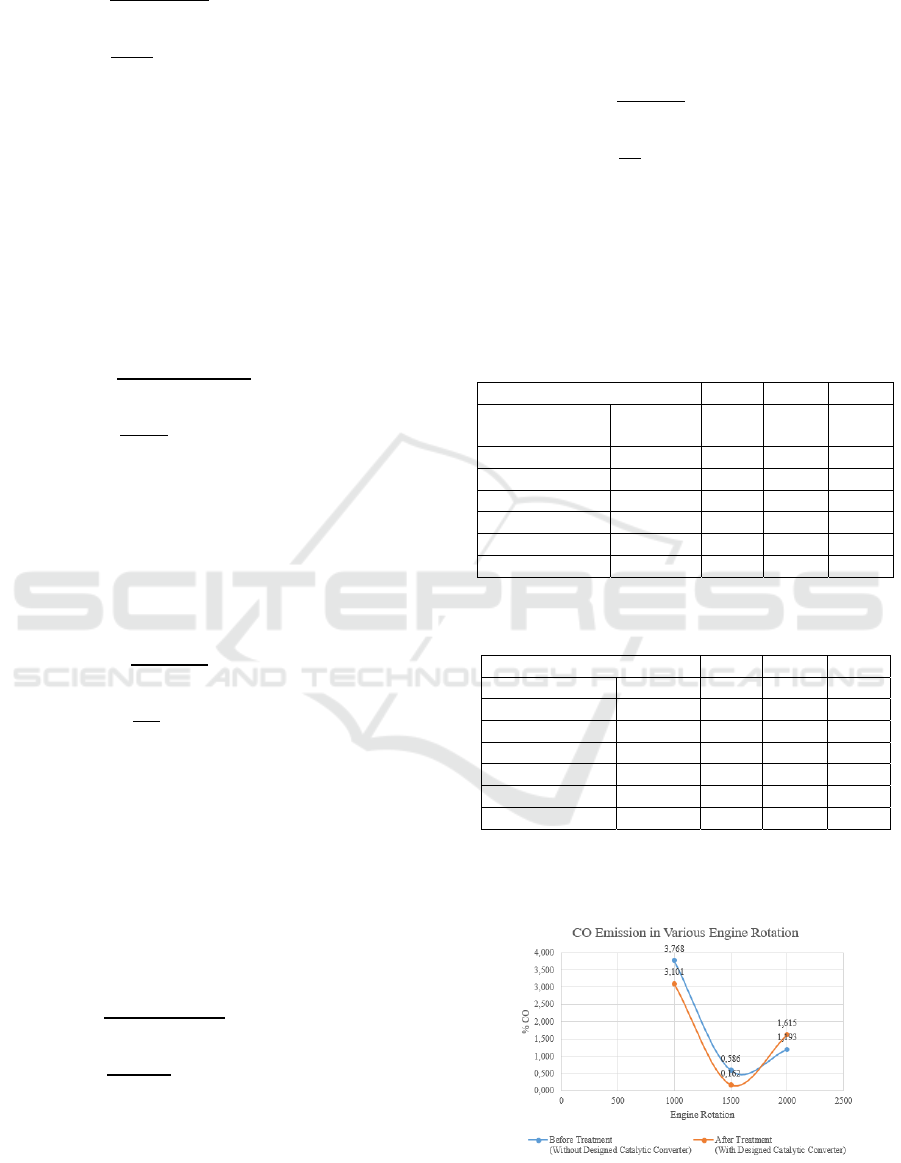

5 DISCUSSION

Figure 7: The graph of CO content in emission test with

and without a catalytic converter.

Catalytic Converter based on Titanium Oxide (TiO2) to Reduce the Emission of Carbon Monoxide and Hydrocarbon in Exhaust Gas of

Motor Vehicles

19

The result of gas emission test of a gasoline engine

in standard condition without using catalytic

converter showed the result of carbon monoxide

concentration 3.768% at 1,000 rpm, 0.586% at 1,500

rpm and 1.193% at 2,000 rpm. While, the resulting

hydrocarbon is 111 ppm at 1,000 rpm, 41 rpm at

1,500 rpm, and 89 ppm at 2,000 rpm. Then on the

exhaust gas emission test using catalytic converter

using porous ceramics with titanium dioxide

additives showed the results of carbon monoxide

concentration of 3.101% at 1,000 rpm, 0.162% at

1,500 rpm, and 1.615% at 2,000 rpm.

The use of a catalytic converter can reduce

carbon monoxide as a whole with an average of

18.22%. Test results look very significant at 1,500

rpm engine speed with a decrease of 72.35%. The

result is due to the effects of the reaction between

titanium dioxide and gasoline exhaust that has a

temperature of 700

o

-1,000

o

C so that it will heat

titanium dioxide up to speed up the reaction. The

porous ceramics present in the catalytic converter

system are capable of capturing and disentangling

the exhaust pollutant of a gasoline engine. The most

effective exhaust gas emission reduction is at 1,500

rpm engine speed, this is due to the engine that uses

the ideal mixed carbu-rettor with stoichiometry is at

medium engine speed.

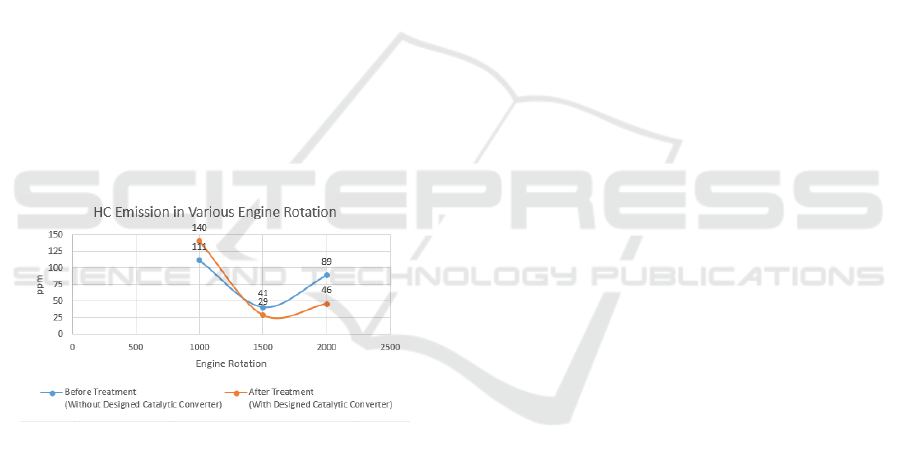

Figure 8: The graph of HC content in emission test with

and without a catalytic converter.

The use of a catalytic converter can reduce the

overall hydrocarbon level with an average of

17.71%. The most effective reductions occur at

2,000 rpm rotation that is able to reduce the

hydrocarbon level by 50%. The result is due to the

most optimal burning occurs at a speed of 2,000

rpm. On a gasoline engine using a carburetor, 2,000

rpm is classified within the engine speed with the

most optimal fuel consumption.

6 CONCLUSION

The results show that the ability of ceramic

catalytic converter with titanium dioxide additive in

gasoline engine has an average yield of CO emission

reduction with additive titanium dioxide additives

18.22% of a ceramic catalyst. The highest CO

emission reduction is in experimental group 2 that is

72, 35% with 1,500 rpm (medium engine speed).

The average HC emission reduction with a ceramic

catalyst with titanium dioxide additives is 17.71%,

and the highest reduction of HC emission is in

experimental group 3, i.e., 50% with 2,000 rpm.

REFERENCES

Amin, M., & Subri, M. 2016. Karakterisasi Penggunaan

Bahan Absorben dan Katalis Dalam Pembuatan

Material Cmc Untuk Filter Gas Buang Kendaraan

Bermotor. Jurnal Mekanika, 15.

Amin, M., Subri M.. 2016. Uji Performa Filter Gas Emisi

Kendaraan Bermotor Berbasis Keramik Porous

Dengan Aditif Tembaga, TiO

2

Dan Karbon Aktif

Dalam Penurunan Kadar Gas Carbon Monoksida.

Semarang: Universitas Muhammadiyah Semarang

Badan Pusat Statistik. 2015. Perkembangan Jumlah

Kendaraan Bermotor Menurut Jenis, 1949-2015.

Jakarta: Badan Pusat Statistik (https://www.bps.go.id

/linkTableDinamis/view/id/1133: accessed on 3 Mei

2018)

Hajderi, A., Bozo L. 2014. Air Pollution from Vehicles

and Their Effect on Human Health in Urban Areas.

Jurnal IJESIT, 2014.

Sugiharto, dkk. 2016. Pengaruh Letak Magnet Terhadap

Konsumsi Bahan Bakar dan Emisi Gas Buang Pada

Electronic Fuel Injection Pada Sepeda Motor.

Malang: Universitas Widyagama Malang.

EIC 2018 - The 7th Engineering International Conference (EIC), Engineering International Conference on Education, Concept and

Application on Green Technology

20