Utilization of Waste Beef Cattle-corn as Formulation Material

in Compost Fertilizer Manufacturing

Muji Paramuji

Agricultural Product Engineering Study Program, Faculty of Agriculture, Medan UISU

Keywords: Compost, Formulation Material, Waste Beef Cattle-Corn, Manufacturing.

Abstract: The success of corn agro-industry is influenced by the availability of fertilizers, especially of artificial

fertilizers whose availability continues to decrease. The solution is to increase compost production through

the use of wet/ dry stover (WS/DS), commercial/ traditional cattle waste (C/T CW) in EM4 solutions (5 ml/l

and 10 ml/l). The purpose of this study was to obtain the formulation of compost making materials.

Composting was done by mixing C/T CW, WS and DS with formulation material (Control; 1: 0: 3; 1: 1: 2;

1: 2: 1; 1: 3: 0), putting into polybags in a bucket covered, performing an anaerobic fermentation for 40

days, and checking and stirring once in three days. Compost is ripely characterized by a distinctive

fermented aroma. The treatment of compost material formulation used a nonfactorial Completely

Randomized Design Model (non-factorial CRDM). Parameters observed were yield, moisture content

(oven), pH (potentiometry), P

2

O

5

(spectrophotometry), K

2

O (AAS), organic C (Gravimetric), N-total

(Volumetric), C/N ratio. The results showed that EM4 performance of 10 ml/l of water was better than 5

ml/l of water which could speed up the composting process, K

2

-1: 0: 3 compost material formulation

produced more compost in accordance with SNI quality standards with a yield of 30.86%, moisture content

28.92%, pH 5.97, P

2

O

5

1.12%, K

2

O 2.01%, organic C 50.06%, N total 1.95% and C / N ratio 25.67.

1 INTRODUCTION

The demand for maize in the country increases. This

is in line with the development of the corn

processing industry and the development of animal

husbandry sector (BPS, 2011; Kementan, 2016a). In

addition to the procurement of food and feed, corn is

also widely used in the food industry, beverages,

chemicals, and pharmaceuticals which give added

value to the commodity corn farming (Suarni and

Widowati, 2014).

According to BPS, corn production reached

19.61 million of shelled corn in 2015. This

production rose 3.17 percent if compared to 2014

(Kementan, 2016b). However, to meet the needs of

livestock feed in 2016, the government of Indonesia

imported corn as much as 2.4 million tons gradually

by as much as 200 thousand tons per month. In

2017, it was predicted that Indonesia imported corn

in 30% of the total national maize needs, which

reached 8.6 million tons per year or approximately

665 thousand tonnes per month (Kemenperin, 2016).

The problems faced in the development of agro-

industries, the corn are in low productivity. The

price of corn is fluctuating because of extensive land

and more small businesses and the risk of failed

harvest due to weather changes. One of the factors

of the success of industrial agriculture of maize was

strongly influenced by the availability of fertilizer.

Recently, most farmers have still used artificial

fertilizers. In addition to its decreasing availability,

the use of which is not wise. This also affects the

ecological balance so that resources support

neighborhood continues to decline and productivity

corn which still remains low.

The alternative is the counter measures which

increase the production of organic fertilizer

(compost) through the management and utilization

of the waste corn (waste is produced in the form of

stems, leaves, cornhusk about 14.88 million tons and

maize cobs as much as 34.06 million ton) (Setiawan.

2014). Corn plants produce waste whose proportions

vary. The largest proportion of corn stalks is (stover)

followed by leaf, fruit peels, and corn cobs. The

proportion of waste from several varieties of maize

was developed by maize and cereal crops research

hall Maros i.e. the proportion of stems varies

between 55.38-62.29%, the proportion of leaves

Paramuji, M.

Utilization of Waste Beef Cattle-corn as Formulation Material in Compost Fertilizer Manufacturing.

DOI: 10.5220/0008887401990205

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 199-205

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

199

between 22.57-27.38% and the proportion between

cornhusk 11.88-16.41% (Anggraeny et al. 2006).

The proportion of the waste corn plants percent dry

ingredients consist of 50% of the stem, leaves 20%,

20% and 10% of cob, cornhusk (BPS, 2009). Cow

manure has excellent potential as a provider of plant

nutrients (fresh feces as much as 15-20 kg/head/day

and urine 10-15 liters/head/day) (Lutojo et al. 2010;

Wahyuni. 2010). The amount of waste is quite a lot

and it is very potential if it can be utilized

appropriately and optimally. Therefore, is it

important to handle it by utilizing waste such as

livestock droppings of organic fertilizer. Processing

beef cattle droppings into the compost (composting)

needs to consider a sustainable technology because it

aims for environmental conservation, and the use of

compost (organic fertilizer) can reduce the use of

chemical fertilizers and the larger value breeders

(Indrawaty, 2015). So far, the utilization of waste

stool and urine has still been untapped with

maximum livestock excrement. Many have

accumulated around the enclosure and not many are

utilized. Stool that was not processed can only be

allowed naturally into organic fertilizer, while the

urine passing from the cage can only be put into the

tub without treatment. Therefore, this will produce

solid organic fertilizers that are moist, not crumb,

immature, easily moldy, save time and the

manufacturing process (Swastike et al, 2015).

2 RESEARCH METHODS

2.1 Research Time and Location

This research was conducted from June to

September 2018. The research location was in Deli

Serdang regency, North Sumatra province. This

location was chosen by considering the area of corn

farming and beef cattle, in which transportation

facilities (axle road and sub-district ring road),

location plantations and beef cattle farms that are

close together were available.

2.2 Research Materials and Tools

The materials used in this study were corn waste

(wet stover/dry stover; WS/DS), cattle waste

commercial (C) and cattle waste traditional (T),

EM4, water. The equipments used in this study were

tissue, label paper, polybag, plastic bucket/tube,

wood stirrer, chopper machine, oven, furnace,

micropipette (Socorex Calibra 832; 1-10 ml, Gilson;

1000 μl, Transferpette; 10-100 μl), analytical scales

(mettler ae 100 ), whatmen paper, desiccator, and

other analysis tools.

2.3 Research Implementation

The process of making compost was done in several

steps of finely chopping WS/DS and mixing, cattle

waste (C/T) mixed with EM4 solution with a

concentration of 5 ml/l of water and 10 ml/l of

stirred water evenly. The composting formulation

was then carried out by comparing 1 part C/T: 3

parts WS/DS. Formulation of C/T : WS : DS

(Control; 1: 0: 3; 1: 1: 2; 1: 2:1; 1: 3: 0). The mixture

of WS/DS and cow manure was evenly mixed, then

put in a polybag in a closed bucket, followed by

checking and reversing once in three days. It was

estimated that after forty days the compost had been

ready. During the decomposition process, it did not

emit a foul odor, even the fermented aroma. The

parameters observed were closely related to the

quality of compost, namely yield, moisture content

(Oven), pH of compost (Potentiometry), P

2

O

5

(Spectrophotometry), K

2

O (AAS), compost organic

C content (Gravimetry), N-total compost content

(Volumetric), and C/N ratio (Supatma and

Arthagama, 2008; Surtinah, 2013).

2.4 Statistical Analysis

The experimental design used for the treatment of

compost material was a nonfactorial Completely

Randomized Design Model (non-factorial CRDM).

The independent variable used for the treatment of

compost material is the compost material

formulation, namely the C/T: WS: DS (Control; 1:

0: 3; 1: 1: 2; 1: 2: 1; 1: 3: 0). The compost produced

was then tested for yield, moisture content, and pH

of compost, P

2

O

5

compost, K

2

O compost, compost

organic C content, N-total compost content, C/N

compost ratio. A statistical model for complete

random design is as follow:

Y

ij

= μ + τ

i

+ ε

ij

(1)

information :

i : factor (i = 1,2,3,4 .... n)

j : replication (j = 1,2,3 ... n)

Y

ij

: the experimental response to compost material

is the factor and the jth test

μ: general average

τ

i

: influence of compost material factors

ε

ij

: trial error

ICMR 2018 - International Conference on Multidisciplinary Research

200

3 RESULTS AND DISCUSSION

Parameter test results and analysis of compost data

generated with the anaerobic composting system

using EM4 activator (Table 1) can be explained that

in general, the compost material formulation

treatment shows a very significant difference in

Duncan's test level of 5% although there were

several treatments which showed the difference that

was not real. The results showed that during the

composting process the performance of EM4

activator at a concentration of 10 ml/l of water was

better than 5 ml/l of water because it could speed up

the composting process. The results of compost

chemistry analysis showed that most of the compost

material formulation treatment had met the

requirements of quality standards of organic

fertilizer from SNI.

During the composting process, color changes

occur gradually. Brownish green-yellow color

changed to dark brown color. At the end of the

composting process the color changed to brownish

black due to the formation of humic acid. In addition

to discoloration, when the process took place, the

compost emited an unpleasant odor due to the

decomposition of the organic material that was still

running. However, at the end of composting,

compost smelled of perfection.

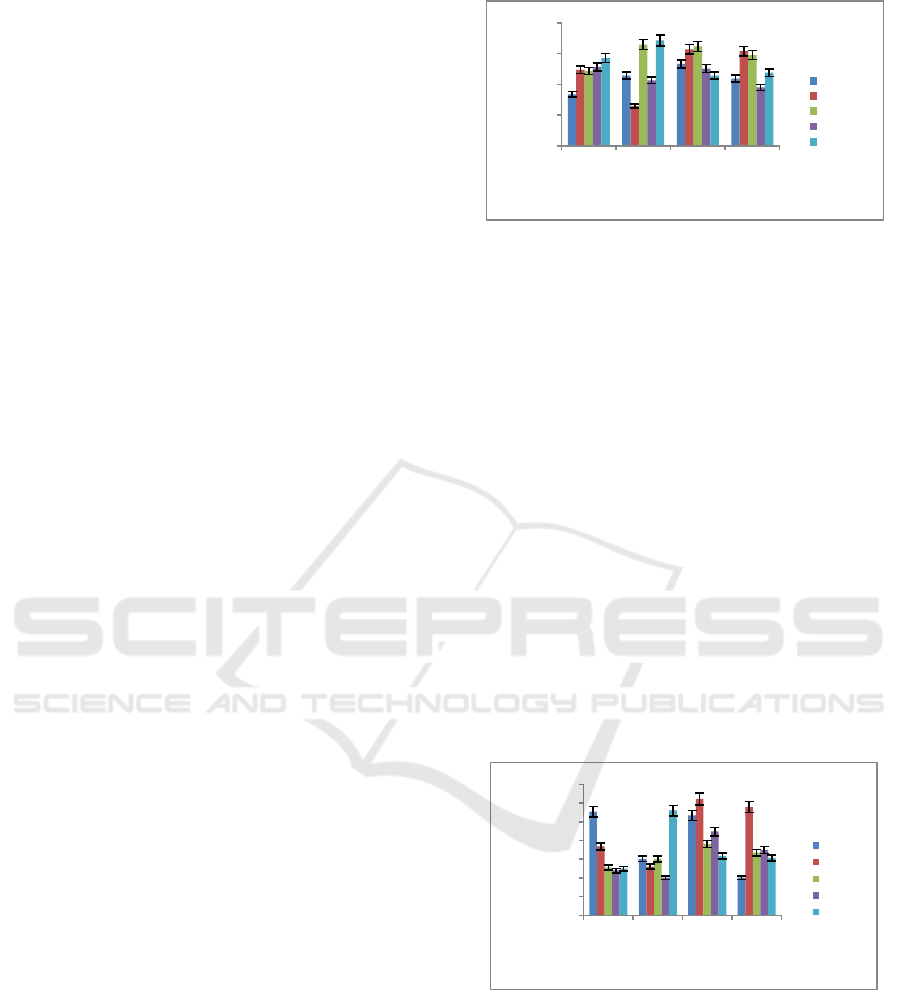

3.1 Yield

The decomposition process depends on the content

of the material used, where cellulose is more easily

decomposed than lignin. The decrease in compost

yield (Figure 1) is quite high. This is because the

compost material, especially corn stover contains

more cellulose than lignin and porous which ware

easy to absorb and release water. Depreciation of

compost material in the material formulation

because at the time of composting takes place a

process of decomposition of compost material by

microorganisms that convert organic matter into

carbon dioxide, water, hummus, and energy.

Depreciation of final mature compost is about 50-

75% of the initial weight of compost (Wahyono et

al, 2011). The lowest compost was in the T

2

-1: 0: 3

formulation (12.95%) and the highest was in T

2

-1: 3:

0 (34.29%).

Figure 1: The relationship between Formulation of

Compost Material and Yield.

3.2 Moisture Content

Compost moisture content depicts moisture during

the composting process. When composting takes

place, the compost water content is quite high. High

water content is due to compost material consisting

of cattle waste in wet conditions, wet/dry field corn

stover and the addition of 1 liter EM4 solution

(Table 1). Compost water content is obtained from

the decomposition of organic matter into carbon

dioxide, water vapor and compost (Arumsari et al,

2012). Besides being needed directly by a

microorganism, water also affects the aeration

system and oxygen supply in the bucket media. The

compost water content produced (Figure 2) is lower

than SNI quality standards. This has met SNI quality

standards. The lowest compost moisture content was

in C

2

Control formulation (10.07%) and the highest

in C

1

-1: 0: 3 (31.08%).

Figure 2: The Relationship between Formulation of

Compost Material and Moisture Content.

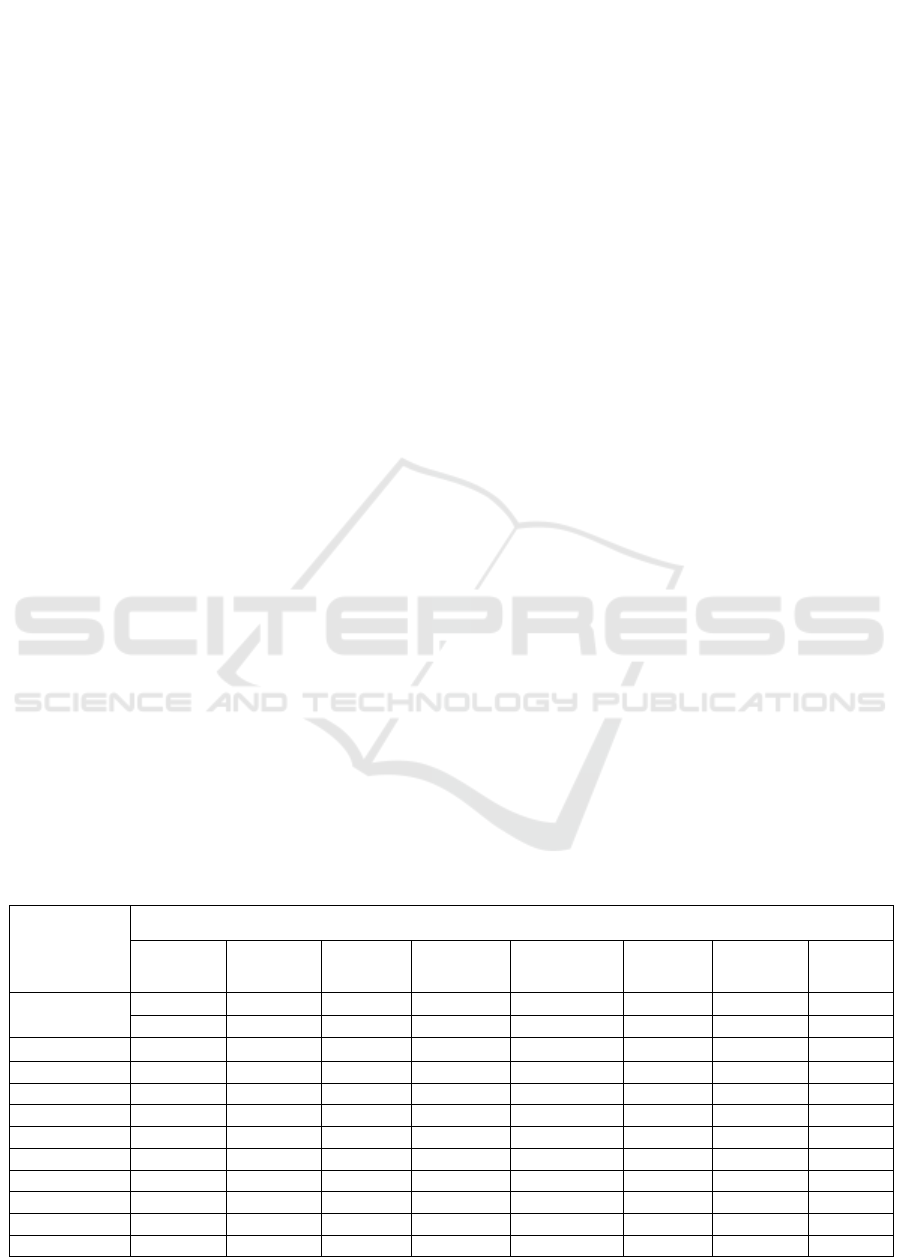

3.3 pH

The level of acidity or alkalinity of a solution can be

seen from the pH. When composting takes place,

organic matter decomposes into organic compounds.

The pH value of compost produced from compost

material formulation is not in accordance with SNI

quality standards (Table 1), because some pH is too

0

10

20

30

40

T1 T2 K1 K2

Yield%

FormulationofCompostMaterial

Kontrol

(1:0:3)

(1:1:2)

(1:2:1)

(1:3:0)

0,00

5,00

10,00

15,00

20,00

25,00

30,00

35,00

T1 T2 K1 K2

MoistureContent%

FormulationofCompostMaterial

Kontrol

(1:0:3)

(1:1:2)

(1:2:1)

(1:3:0:)

Utilization of Waste Beef Cattle-corn as Formulation Material in Compost Fertilizer Manufacturing

201

high and the others are too low (Figure 3). The

lowest compost pH was in T

2

-1: 0: 3 formulation

(4,51) and highest was in T

2

Control (9,15).

Figure 3: The relationship between Formulation of

Compost Material and pH.

3.4 P

2

O

5

P

2

O

5

levels show high values (Figure 4). This is

because the control formulation is 100% cattle

waste. As stated by Miftahul (Miftahul, 2003) that

the high and low content of phosphorus in compost

is probably due to a large amount of phosphorus

contained in the raw material used and the number

of microbes involved in composting. The lowest

compost P

2

O

5

level was in C

1

Control formulation

(0.40%) and the highest was in T

2

-1:3:0 (2.12%).

P

2

O

5

compost from all compost material

formulations has met SNI quality standards (Table

1).

Figure 4: The relationship between Formulation of

Compost Material and P

2

O

5

.

3.5 K

2

O

The results of the analysis of compost material

formulation had a higher K

2

O compared to SNI

quality standards (Table 1). This condition was

possible because the formulation of compost

material also greatly affected the content of

potassium in composting for bacterial activity. This

is in accordance with the statement of Agustina

(Agustina, 2004), that potassium is a compound

produced by microbial metabolism, in which

microbes use free K

+

ions which are present in

fertilizer raw materials for metabolic purposes. K

2

O

of all compost material formulations have met SNI

quality standards (Table 1). The lowest compost

K

2

O was in C2-1: 3: 0 formulation (1.15%) and the

highest was in T

1

Control (2.48%).

Figure 5: The relationship between Formulation of

Compost Material and K

2

O.

3.6 Organic C

The results of the analysis of compost organic C

levels are still too high (Figure 6), because corn

stover and cattle waste contain high carbon. Jannah

(Jannah, 2003) has explained that during the process

of decomposition of organic matter, the activity of

microorganisms produces element C so that the level

of organic C increases. Then when the compost is

made, the decomposers will die and the C organic

content will slowly drop. The lowest compost

organic C was in the C

2

Control formulation

(40.01%) and the highest was in T

1

-1: 0: 3 (54.21%).

Figure 6: The relationship between Formulation of

Compost Material and Organic C.

3.7 Total N

The decomposition of organic matter by

microorganisms in the composting process will

produce a number of nitrogen elements. This is one

of the parameters in the quality standard of organic

fertilizer. The greater the content of N, P, and K

nutrients in compost, the better the compost used for

plants because it provides enough nutrients for

0

2

4

6

8

10

T1 T2 K1 K2

pH

FormulationofCompostMaterial

Kontrol

(1:0:3)

(1:1:2)

(1:2:1)

(1:3:0)

‐0,5

0,5

1,5

2,5

T1 T2 K1 K2

P2O%

FormulationofCompostMaterial

Kontrol

(1:0:3)

(1:1:2)

(1:2:1)

(1:3:0)

0

1

2

T1 T2 K1 K2

K2O%

FormulationofCompostMaterial

Kontrol

(1:0:3)

(1:1:2)

(1:2:1)

0,00

20,00

40,00

60,00

T1 T2 K1 K2

OrganikC%

FormulationofCompostMaterial

Kontrol

(1:0:3)

(1:1:2)

(1:2:1)

(1:3:0)

ICMR 2018 - International Conference on Multidisciplinary Research

202

plants and soil (Putro et al. 2016). In general, the

total N of all compost material formulations has met

the requirements and this is higher than the total N

SNI quality standard (Figure 7). The lowest total N

was in T

1

-1: 0: 3 (1.21%) and the highest was in T

1

Control (2.20%).

Figure 7: The relationship between Formulation of

Compost Material and Total N.

3.8 C/N Ratio

The C/N ratio of the formulation of compost

material is still in the range required by the quality

standard although there is a C/N ratio that is too

high. The lowest C/N ratio analysis results were in

C

1

Control (18.27%) and the highest was in T

1

-1: 3:

0 (44.32%). The high C/N ratio generated from the

compost material formulation (Figure 8) is in

accordance with Sulaeman (Sulaeman., 2011), that

compost materials, such as husks, rice straw, corn

stalks, and sawdust, have a C/N ratio between 50-

100.

Figure 8: The relationship between Formulation of

Compost Material and C/N Ratio.

4 CONCLUSION

The results showed that the EM4 performance of 10

ml/l of water was better than that of 5 ml/l of water,

which could speed up the composting process of

compost material formulation. Compost formulation

C

2

-1: 0: 3 produced compost with a yield of 30.86%,

moisture content 28.92 %, pH 5.97, P

2

O5 1.12%,

K

2

O 2.01%, organic C 50.06%, N total 1.95% and

C/N ratio 25.67 more. This is in accordance with

SNI quality standards.

RECOMMENDATION

1. Similar research needs to be done by increasing

fermentation time to obtain more quality

compost with a C/N ratio to meet quality

standards.

2. To follow up and support the development of

integrated corn agro-industry in Deli Serdang,

North Sumatra, it is better to apply compost

produced from compost material formulation.

THANK YOU NOTE

This research was funded by the Menristek Dikti

through the PDD Scheme in the LLDikti I and the

LP UISU Medan in the 2018 Budget Year; Faculty

of Agriculture UISU and RISPA Medan for

greenhouse facilities and compost parameter testing.

REFERENCES

Agustina. 2004. Book, Basic Plant Nutrition. Jakarta :

Rineka Cipta. Page 54.

Anggraeny, YN., Umiyasih, U., Krishna, NH. 2006. The

Potential for Corn Waste is Ready to be Released as a

Source of Forage for Beef Cattle. Pros. National

Workshop on Corn - Cattle Integration System

Development Network. Pontianak, 9-10 August 2006.

Bogor: Research Center for Animal Husbandry. p. 149

- 153.

Anonymous. 2015. Harvest and Postharvest Corn

Management. Corn Cultivation Technical Training for

Agricultural Extension. Agricultural Human

Resources Counseling and Development Agency.

Bogor: Agricultural Training Center.

Arumsari, A., Syafrudin, Winardi. 2012. Utilization of

Sludge Resulting from Wastewater Treatment PT.

Indofood Cbp. with the Addition of Domestic Waste

and Effective Microorganism (EM4) and Activated

Sludge as Activators Through the Composting

Process. Semarang: Diponegoro University. Faculty of

Engineering. Environmental Engineering Study

Program.

BPS (Statistics Center). 2009. Agricultural Statistics.

Center for Agricultural Data and Information. Ministry

of Agriculture. Jakarta.

0

0,5

1

1,5

2

2,5

T1 T2 K1 K2

TotalN(%)

FormulationofCompostMaterial

Kontrol

1;0;3

1;1;2

1;2;1

1;3;0

0

10

20

30

40

50

T1 T2 K1 K2

C/NRatio

FormulationofCompostMaterial

Kontrol

1;0;3

1;1;2

1;2;1

1;3;0

Utilization of Waste Beef Cattle-corn as Formulation Material in Compost Fertilizer Manufacturing

203

BPS (Statistics Center). 2011. Food Crop Production

Statistics. South Sulawesi: Directorate General of

Food Crops.

SNI (Standart of National Indonesian). 2004. SNI 19-

7030-2004: Specifications for compost from domestic

organic waste. Jakarta: BSN Pr.

Indrawaty, PV. 2015. Effect of the use of urine as a source

of nitrogen on the physical form and nutrients of cow

feces compost [Thesis]. Jambi: Jambi University

Jannah, M. 2003. Compost Quality Evaluation from

Various Cities as a Basis for Composting Compilation

of SOP (Standard Operating Procedure). Bogor:

Bogor Agricultural University, Faculty of Agricultural

Engineering.

Kementan (Ministry of Agriculture). 2016a. Corn

Production in 2016 is Enough to Fulfill the Feed

Industry. Retrieved from http: /www.repu-

blika.co.id/berita/kementan/berita-kementan/ 16/

06/28/o9gve7383-kementan-production-maize-2016-

quite-full-industry-feed.

Kementan (Ministry of Agriculture). 2016b. Harvested

Area and Productivity Increased, 2016 Corn

Production is Predicted to Penetrate 23 Million Tons.

Retrieved from http: //www.agro-

farm.co.id/m/pertanian/3548/ebaran-panen-dan-prod

Productivity-up-production-corn-2016-pre-dicted-

translucent-23-million-ton / # wgude9j97iu.

Agrofarm.co.id.

Kemenperin (Ministry of Industry). 2016. 2016 RI Imports

of Corn 2.4 Million Tons. Retrieved from

http://www.kemenperin.go.id/artikel/13892/2016,-ri-

import-corn-2,4- million-ton.

Lutojo, Sihombing G., & Rriyanto J. 2010. Application of

Integrated Installation Design of Faecal and Urine

Waste Processing for Solid and Liquid Organic

Fertilizer Industry in Beef Cattle Fattening Business.

Appl. Science and Technology. Semarang: Dipa Blu

UNS.

Mifathul. 2003. Evaluation of Compost Quality from

Various Cities as a Basis for Making Composting

SOPs. Bogor: IPB.

Putro, BP., Walidaini, RA., Samudro, G., Nugraha, WD.

2016. Quality Improvement of Campus Organic Waste

Compost Enriched with NPK and Urea Fertilizer.

Proceedings of the 7th 2016 SNTS. Semarang: Wahid

Hasyim University, Faculty of Engineering. Page.17-

22.ISBN 978-602-99334-5-1.

Setiawan, E. 2014. Utilization of Corn Waste (Cob,

Cornhusk, and Straw) as Animal Feed. Retrieved from

http://i1122.photobucket.com/albums/ l524/

riyosuke/tail2.gif. Tuesday, February 4, 2014. Broken

HTTP://ekasetiawanfapetunja .blog spot. co.id /

2014/02 / corn-waste-use-tongkol.html.

Suarni & Widowati, S. 2014. Corn Structure, Composition

and Nutrition. Bogor: Bogor Center for Agricultural

Postharvest Research and Development.

Sulaiman, D. 2011. Effect of Waste Compost Baglog White

Oyster Mushroom (Pleurotus ostreatus Jacquin) on

Soil Physical Properties and Growth of Yellow

Passion Fruit Seeds (Passiflora edulis var.

Flavicarpa Degner) [Thesis]. Bogor: Bogor

Agricultural University, Faculty of Agriculture,

Department of Soil Science.

Swastika, W., Handayanta, E., Purnomo, SH. 2015. The

Application of Faecal and Urine Waste Processing

Technology as an Entrepreneurial Business

Establishment in Jatikuwung Sebelas Maret University

Mini Farm. Proceedings of the 2015 National Seminar

on the 4th UNS SME Summit & Awards "Synergy of

MSME Development in the Era of the ASEAN

Economic Community (MEA)". Semarang: UNS Pr.

Wahyono, S., Sahwan, FL., Suryanto F. 2011. Making

Granule Organic Fertilizers from Various Wastes.

Jakarta: Agromedia Library.

Wahyuni. S. 2010. Produces Biogas from Various Wastes.

Jakarta: Argromedia Pustaka.

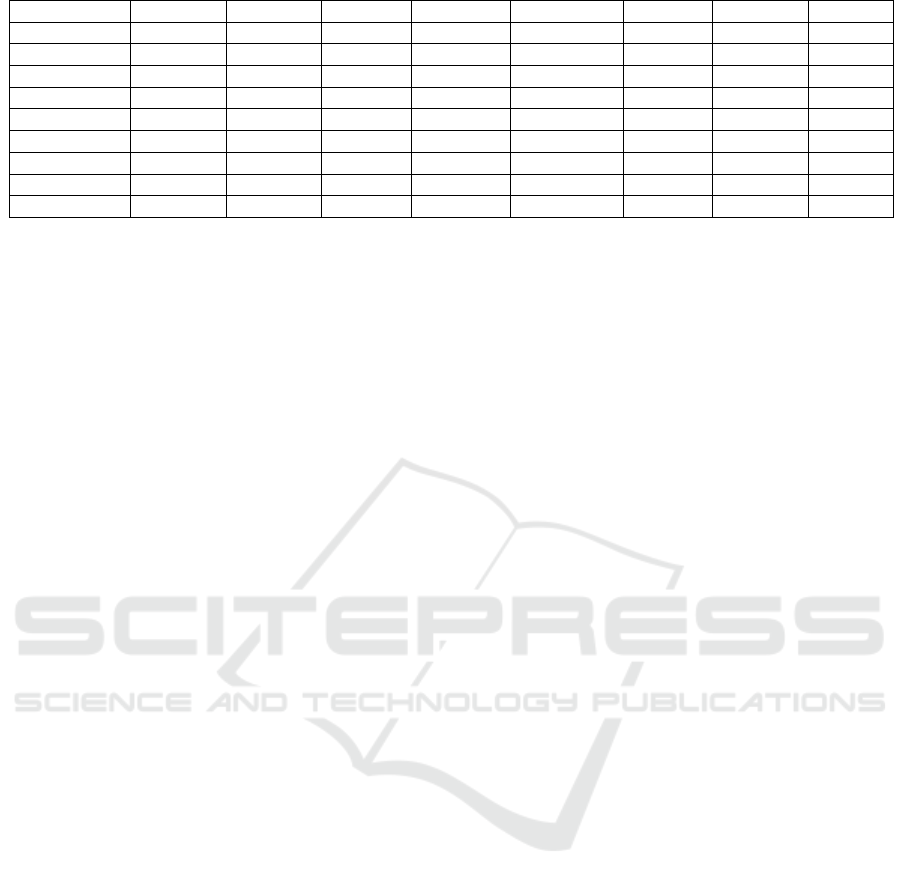

Table 1. Compost Composition Based on SNI and Compost Formulation Test Results

Formulation

Parameter (%)

Yield Moisture

Content

pH P

2

O

5

K

2

O Organic

C

N-total C/N

Ratio

* Minimum

Maximum

- - 6,8 0,10 0,20 9,8 0,40 10

- 50 7,49 - - 30 - 20

** Control T

1

16,78 b 27,70 k 8,96 j 0,77 e 2,48 i 46,00 c 2,20 g 20,91 b

T

1

(1:0:3) 24,76 fg 18,41 g 5,66 efg 0,57 abc

d

1,48 bcde 54,21

m

1,44 abc 37,65 l

T

1

(1:1:2) 24,38 efg 12,81 c 5,43 c

d

0,54 abc 1,41 abcde 52,96 j

k

1,35 ab 39,23

m

T

1

(

1:2:1

)

25,71

g

h 11,96 b 5,56 cde 0,45 ab 1,46 bcde 53,02

k

1,36 ab 38,99

m

T

1

(

1:3:0

)

28,57 i 12,50 bc 5,46 c

d

0,60 bc

d

1,34 abc

d

53,63 l 1,21 a 44,32 n

Control T

2

22,86 de 15,09

d

9,15

k

2,12 h 2,32 i 46,23 c 2,19

g

22,77 c

T

2

(1:0:3) 12,95 a 13,03 c 4,51 a 0,62 cde 1,65 efg 52,72 j 1,47 abc 35,86

k

T

2

(1:1:2) 32,95 kl 15,04

d

4,84 b 0,63 cde 1,27 abc

d

52,71 j 1,50 abc

d

35,14 j

T

2

(1:2:1) 21,33

d

10,08 a 5,59 def 0,50 ab 1,26 abc 52,34 i 1,34 ab 39,06 m

T

2

(

1:3:0

)

34,29 l 28,00

k

5,40 c 0,40 a 1,16 a 52,96

jk

1,39 abc 38,10 l

ICMR 2018 - International Conference on Multidisciplinary Research

204

Control C

1

26,67 h 26,69

j

8,92

j

0,70 e 1,78 f

g

40,01 b 2,03 f

g

18,27 a

C

1

(1:0:3) 31,43 j

k

31,08 l 5,98 i 1,02 f 1,79 gh 49,23

d

1,52 abc

d

32,39 g

C

1

(1:1:2) 32,38 j

k

19,10 h 5,74 efgh 0,65 cde 1,33 abc

d

50,99 g 1,69 cde 30,17 e

C

1

(

1:2:1

)

25,14 f

g

h 22,39

j

5,78

g

h 0,67 de 1,40 abcde 50,54 f 1,61 bc

d

31,39 f

C

1

(

1:3:0

)

22,86 de 15,86

d

5,77 f

g

h 0,56 abc

d

1,22 ab 52,84

jk

1,69 cde 31,27 f

Control C

2

21,91

d

10,07 a 8,98

jk

1,79

g

1,54 def

g

37,50 a 1,80 def 20,83 b

C

2

(1:0:3) 30,86 j 28,92

m

5,97 i 1,12 f 2,01 h 50,06 e 1,95 efg 25,67

d

C

2

(1:1:2) 29,52 i 16,75 e 5,42 c

d

0,61 c

d

1,51 cdef 51,83 h 1,57 bc

d

33,01 h

C

2

(1:2:1) 19,05 c 17,46 f 5,91 hi 0,59 bc

d

1,26 abc 51,94 h 1,62 bc

d

32,06 g

C

2

(

1:3:0

)

23,81 ef 15,36

d

5,92 hi 0,60 bc

d

1,15 a 50,39 f 1,49 abc

d

33,82 i

Description: Numbers followed by the same letter in the same column showed no significant

difference In Duncan's test level of 5%.

Source : * SNI (2004); ** Research Data (2018).

Utilization of Waste Beef Cattle-corn as Formulation Material in Compost Fertilizer Manufacturing

205