Effect of Addition Silica Gel from Volcanic Ash of Sinabung

Mountains to Tensile Strength on Chitosan Composite Membrane

Maulida

1

, Lilis Sukeksi

1

, Mara Bangun Harahap

2

, Melva Ginting

1

, Herlinawati Wici

1

and Ghendis

Ekawati Ayu

1

1

Departement of Chemical Engineering, Faculty of Engineering, University of Sumatera Utara, Almamater Street,Medan,

20155, Indonesia

2

Departement of Physics, Faculty of Mathematic and Science, University of Negeri Medan, Medan Estate, North Sumatera

20222, Indonesia

Keywords: Silica gel, volcanic ash, chitosan, composite membrane

Abstract: Silica gel is a glassy grain with a very porous shape. Silica is made synthetically from sodium silicate. In

this study, volcanic ash can be used as silica, which is silica can be applied in the manufacture of composite

membranes as fillers because it can increase the conductivity of composite membranes. The method used

for making silica gel was extraction method and composite membrane made using phase inversion method

with the composition of chitosan and silica used are 2 grams of chitosan and variations of fillers 0.6, 0.9 and

1.2 grams of silica, and the stirring time is 8,12 and 16 hours. The characteristics and analysis carried out in

this study were FTIR and SEM. Based on the results of the study, the best membrane conditions were

obtained from composite membrane analysis with a tensile strength of 34,118 Mpa. In the Scanning

Electron Microscopy (SEM) analysis, the lowest composite membrane has a dense and homogeneous pore,

while the highest composite membrane has a hollow pore and has been homogeneous.

1 INTRODUCTION

The composite membrane consists of organic

polymers and inorganic fillers which can improve

the performance of membranes eg, zeolites have

been added into polymer membrane to increase

selectivity of gas separation. Silica is one of the

abundant metal oxides in volcanic ash can be

utilized as the basic material of silica gel synthesis

through the formation of alkali silicate precursors.

Sodium silicate can be converted into silica gel by

condensation process and hydrolysis using solvent,

both polar and non polar. By extracting the silica in

the alkaline state so that sodium silicate will form.

Sodium silicate will undergo polymerization process

to form silica gel on some difference of pH and

solvent (Uhlmann and Kreidhl, 1980). Silica is use

to reduce excessive swilling as to control the

moisture content, reduce the permeability of

methanol, increase mechanical stability and the

conductivity of proton in PEM for fuel cell (Siniwi,

2014). The chitosan is attractive for use as a

membrane base material because it has a functional

group -NH

2

and -OH which is easy to modify.

Chitosan membranes are hydrophilic, non-toxic,

biodegradable, large surface area and reactive to

metal ions because they have an active group -NH

2

and -OH. Chitosan membranes also have

disadvantages of low mechanical properties

indicated by the price of tensile strength (tensile

strength), percent elongation (percent extension),

and low modulus young. The basic ingredients of

inorganic compounds are silica which aims to

improve the stability of the chitosan membrane

through the formation of crosslinks with silica

through the formation of hydrogen bonds between

the chitosan structure and the silica (Widhi

Mahatmanti, 2014). The selection of chitosan as an

alternative to modify the plastic cause chitosan has

biodegradable characteristic (Maulida, et,al., 2018).

(Neburchilov et al., 2007) reported that the addition

of nanosilika to the membrane nafion (nafion / SiO

2

)

for DMFC can increase proton conductivity by a

ratio of 0.33 to 0.38 compared to a membrane

nation. Volcanic ash or volcanic sand is a falling

volcanic material that is ejected into the air during

an eruption. Low-energy basal eruptions (basal: dark

Maulida, ., Sukeksi, L., Harahap, M., Ginting, M., Wici, H. and Ayu, G.

Effect of Addition Silica Gel from Volcanic Ash of Sinabung Mountains to Tensile Strength on Chitosan Composite Membrane.

DOI: 10.5220/0008886500570061

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 57-61

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

57

frosted rocks, fine-grained clays of lava from

volcanoes) produce a distinctively dark ash

containing 45-55% silica which is generally rich in

iron (Fe) and magnesium (Mg). Based on research of

(Nakada and Yoshimoto, 2014) stated that the silica

content in volcanic ash of Sinabung Mount was

58.10%. The high content of silica in volcanic ash of

Mount Sinabung is an interesting subject for further

investigation, especially regarding the use of

volcanic ash as the base material of silica adsorbent

to bind lead weight metal.

2 MATERIALS DAN METHODS

2.1 Raw Materials and Equipments

The material used chitosan was obtained from

Faculty of Mathematics and Natural Sciences, silica

was obtained from volcanic ash of Sinabung

Mountain, NaOH, aquadest, acetic acid

(CH

3

COOH) and hydrochloric acid (HCl) were

obtained from CV. Rudang Jaya The equipment

used in this research were hot plate, 50 mesh sieve

and 230 mesh sieve, filter paper, magnetic stirrer,

funnel, measuring cup, oven and glass beaker.

2.2 Preparation of Volcanic Ash

The volcanic ash was sieved with a 230 mesh sieve

to homogenize the ash size. The sifted ash was taken

as much as 50 grams and soaked with HCl and

filtered. Then the ash washed and dried with oven.

2.3 Extraction of Sodium Silica

Solution

Volcanic ash was dissolved with 500 ml of 4 M

NaOH and heated at 190 °C with a variation of 120

minutes. It was filtered to get the filtrate. The filtrate

was tested with gravimetric (Maulida, et.al., 2017).

2.4 Process of making Silica Gel

The sodium silica solution inserted into the beaker

glass. Then dripped with HCl with a variety of

concentrations of 8 M to form a white gel with pH of

7. Silica gel was precipitated 24 hours and filtered

with paper washed with aquadest. Silica gel was

dried using an oven at 100 °C to remove excess acid

(Maulida, et.al., 2017).

2.5 Process of Making Chitosan

Composite Membranes with Silica

Fillers

Composite membrane synthesis was carried out

using phase inversion method. First, 2 grams of

chitosan dissolved in 100 mL of 2% acetic acid at

room temperature for 2 hours. Second, silica

composition is 0.6, 0.9, 1.2 grams, respectively. then

stirred at a temperature of 600 °C for 8.12.16 hours.

The homogeneous solution is also referred to as a

dope solution which has no air bubbles, then the

filtered solution is then poured onto a 20 x 20 cm

glass meld and dried at room temperature resulting

in a dry membrane. Dry membrane soaked with 1 M

NaOH for 2 hours then washed with aquadest to

neutral pH and dried at room temperature.

3 RESULTS AND DISCUSSION

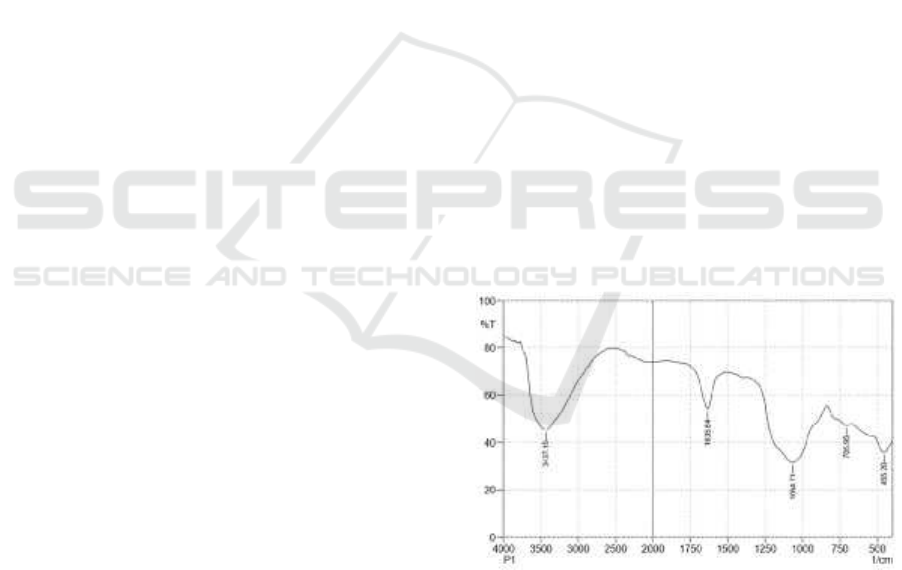

3.1 Characteristic of Fourier

Transform Infra - Red (FTIR)

Silica Gel

Characteristic of FTIR silica gel were carried out to

identify functional groups of silica gel. The

characteristics of FTIR silica gel can be see in the

figure 1.

Figure 1: Characteristic of FTIR Silica Gel from Volcanic

Ash of Sinabung Mountain (Maulida,et.al.,2017).

The FTIR test on silica gel obtained by the

absorption peak at wave number 3437.15 cm

-1

shown the presence of silanol function group

derived from hydroxyl group bond Si-Si, at wave

number 1635.64 cm

-1

was indicated the presence of

hydroxyl (OH) group, on the wave number 1064.71

cm

-1

was indicated the presence of siloxane

ICMR 2018 - International Conference on Multidisciplinary Research

58

functional groups (Si-O-Si), at the wave numbers

705.95 cm

-1

and 455. 20 cm

-1

was indicated the

presence of Si-O functional groups (Silverstein,

1981).

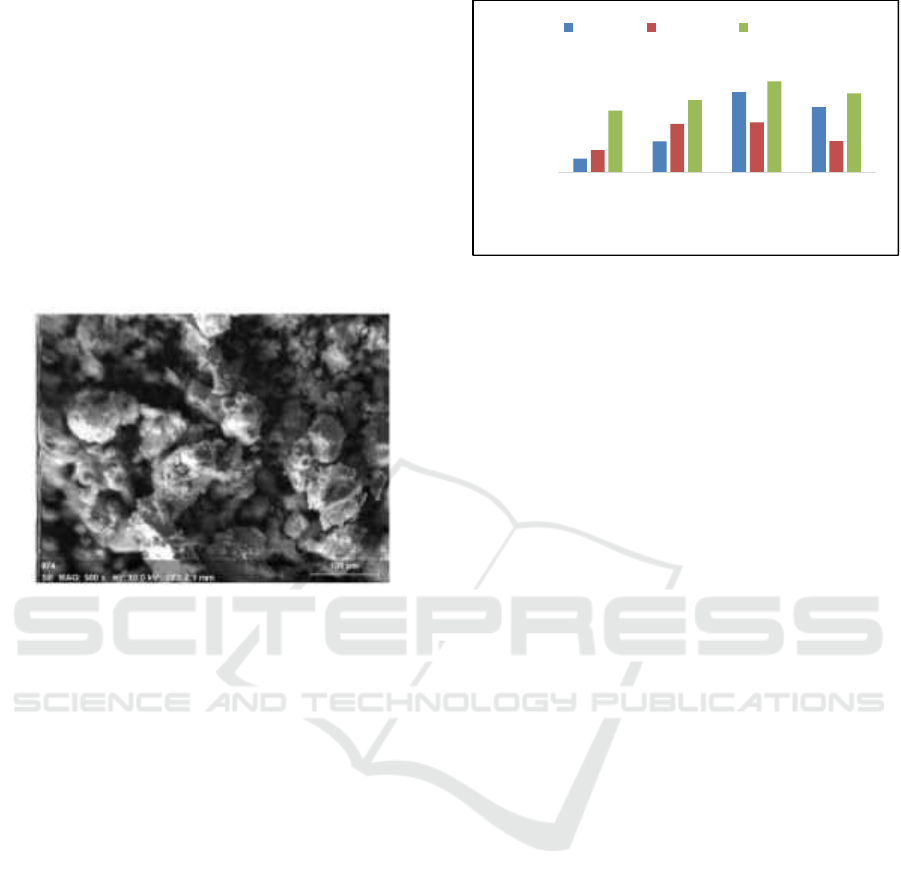

3.2 Characteristic of Scanning Electron

Microscopy (SEM) Silica Gel from

Volcanic Ash of Sinabung

Mountain

Analysis of SEM was conducted to determine

membrane pores.

Figure 2 : Characteristic of Scanning Electron Microscopy

(SEM) Silica Gel from Volcanic Ash of Sinabung

Mountain.

In this study, it was cleared at the sample surfaces

that there were uneven and composed of clumps,

which has shown a wide variety of grains with

uneven distribution on the surface. The separation

between lumps is also seen quite clearly, it was

micro-cracking found among clusters (Maulida,

et.al.,2017).

3.3 The Effect of Silica Gel Mass

Variation and Stirring Time to

Tensile Strength of Composite

Membrane

Characteristics of mechanical properties need to

know the strength of membrane against forces

outside, which can damage the membrane. The

following graph shown the effect of silica variation

and stirring time to tensile strength of the composite.

Figure 3 : The Effect of Silica Gel Mass Variation and

Stirring Time to Tensile Strength Of Composite

Membrane.

Based on figure 3, the mass of silica and the length

of stirring time increase; the value of tensile strength

increases too. The results of this study was indicated

that at 8 hours of stirring time, the tensile strength of

membrane was 7,793 MPa on silica variation of 0.6

gram, then increased to 11,735 MPa at variation of

1.2 gram silica. At 12 hours of stirring time, tensile

strength was 18.260 MPa at 0.6 gram, then increased

to 23,140 MPa at variation of 1.2 grams of silica. In

the 16 hour stirring time, the membrane flux value

of 27.168 MPa at 0.6 grams, then increased to

34.118 MPa in a variation of 1.2 grams of silica.

From Figure 4, we can see the effect of adding silica

filler to the tensile strength of composite membrane.

The increased amount of silica can cause the tensile

strength of the membrane increased too. Tensile

strength is the maximum resistance that can be

retained by the material when given a force before

the material is broken. The more silica added to the

membrane, the more interaction between the silica

and the chitosan. This will lead to stronger bonds

and intermolecular forces in the membrane. The

addition of silica will cause crosslinks between silica

and chitosan by hydrogen bond (Karlina, 2016). The

tensile strength of this membrane has increased as

the percentage of silica increased. The more silica

added to the membrane, the more interaction

between the silica and the chitosan. This will lead to

stronger bonds and intermolecular forces in the

membrane. The addition of silica will lead to

crosslinking between silica and chitosan by

hydrogen bonding. The increase in tensile strength

in the addition of 0.6 grams of silica to 1.2 grams of

silica followed by a drop in tensile strength at the

next point of 1.5 grams of silica. The occurrence of a

drop in the value of tensile strength is likely due to

the excess amount of silica that causes during the

0

10

20

30

40

0.6 0.9 1.2 1.5

Tensile Strength (MPa)

Massa of Silica (gram)

8 hours 12 hours 16 hours

Effect of Addition Silica Gel from Volcanic Ash of Sinabung Mountains to Tensile Strength on Chitosan Composite Membrane

59

drying process of the cracked composite membrane.

This indicates that the increase in concentration does

not guarantee an increase in the value of tensile

strength.

Generally, the results show the greater filler to the

membrane and stirring time. They give higher

tensile strength results. Previous research on the

manufacture of composite membranes from chitosan

showed similar results where the tensile strength

value obtained was greater by increasing the

addition of silica, it is. due to its dense structure

which causes the distance between the molecules in

the membrane to be denser so as to have a large

tensile strength (Thermo, 2001).

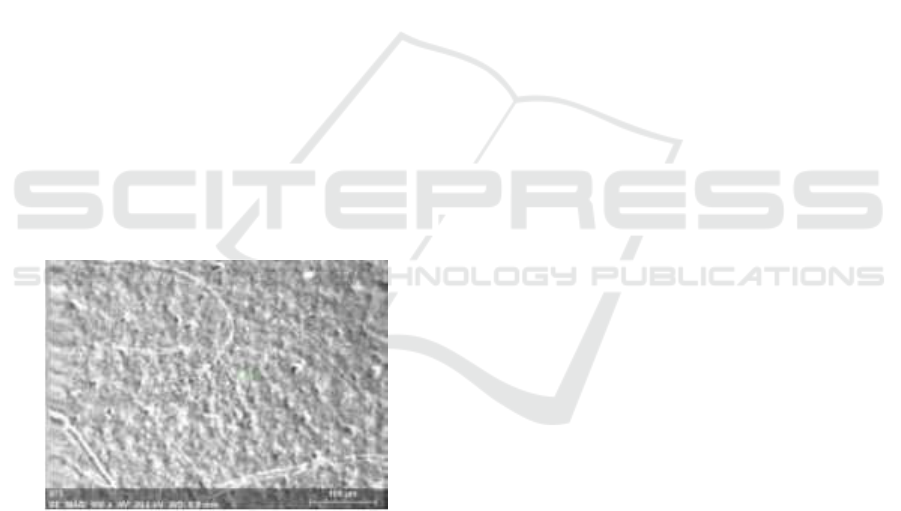

3.4 Characteristic of Scanning Electron

Microscopy (SEM) Chitosan

Composite Membrane with Silica

Gel

An analysis of SEM was performed to determine

membrane pores. The test was performed at 0.6

gram silica fused chitosan membrane with 8 hours of

stirring time and composite membrane with silica

addition of 1.2 grams of silica with a stirring time of

16 hours. Because the composite membrane with 0.6

gram of silica filler has a low flux value, while 1.2

grams of silica has a high flux value.

Figure 4: Characteristic of Scanning Electron Microscopy

(SEM) Chitosan Composite Membrane with Silica Gel.

Figure 4 shows the result analysis SEM of the

membrane product with the addition of 1.2 grams of

silica and 16 hours of stirring time has a relatively

more dense morphology, which indicated that silica

was evenly mixed in the resulting membrane. The

addition of silica causes a dense chitosan membrane

to be hollow because the negative charge of the

chitosan OH-reacts with the silica so that it will

attract and form a small cavity (Siniwi, 2014). Based

on Figure 4 it can be seen that the pore size of the

membrane composites with 1.2 g silica added with

16 hours of stirring time was homogeneous. It’s due

to the addition of silica which made the membrane

structure hollowed with longer stirring time, so the

membrane becomes more homogeneous and can be

applied for filtration.

4 CONCLUSIONS

The addition of silica too much and string of time

too long causes the composite membrane to overlap

until homogeneous so that the tensile strength

increases, acetic acid is a good solvent use in

dissolving chitosan and silica, addition of the filler

on making composite membrane cause the greater

pore in membrane.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge that the present

research is supported by Ministry of Research and

Technology and Higher Education Republic of

Indonesia. The support is under the research grant

BP-PTN USU of Year 2016 Contract Number

XXX/XXX.

REFERENCES

D.R. Uhlmann, and N. J. Kreidhl., 1980. “Glass Sciences

and Technology”. Academy Press.

Karlina, Yhuni. 2016. Peran Abu Vulkanik sebagai Filler

Pada Sintesis Polymer Electrolyte Membrane (PEM)

Terbuat dari Chitosan. Fakultas Matematika dan Sains.

Universitas Negeri Semarang.

Maulida, G. Melva., W, Herlinawati., 2017. Extraction

Volcanic Ash of Sinabung Mount Silica to Production

Silica Gel. J. Teknik Kimia USU.

Maulida, Harahap, Mara Bangun., Alfarodo, Anita

Manulang and Ginting, M.H.S., 2018. Utilization of

Jackfruit Seeds (Artocarpus Heterophyllus) in The

Preparing of Bioplastics by Plasticizer Ethylene Glycol

and Chitosan Filler. Journal of Engineering and

Applied Sciences. Asian Research Publishing Network.

Nakada,S and M. Yoshimoto., 2014. Earthquake Research

Institute, University of Tokyo http://www.eri.u-

tokyo.ac.jp/en/2014/02/04/eruptive-activity-of-

sinabung-volcano-in-2013-and-2014.

Neburchilov, V., J. Martin, H. Wang and J. Zhang., 2007.

Polymer Electrolyte Membranes for Direct Methanol

Fuel Cell, Journal of Power Sources.

Widhi Mahatmanti, F., 2014. Physical Characteristics of

Chitosan Based Film Modified With Silica and

ICMR 2018 - International Conference on Multidisciplinary Research

60

Polyethylene Glycol. Indo. J. Chem. ResearchGate.

Silverstein, R.M., Basslerr, G.C., and Morrill, T.C., 1981.

Spectrometric Identification of Organic Compounds,

John Wiley and Sons. Ney York, 4

th

edition.

Siniwi,,Widasari Trisna., 2014. Sintesis dan Karakterisasi

Proton Exchange membrane Kitosan- Nanosilika.

Jurusan Kimia, Fakultas Matematika dan Ilmu

Pengetahuan Alam, Universitas Negri Semarang.

Thermo Nicolet., 2001. Introduction to Fourier Transform

Infrared Spectrometry. Thermo Nicolet Corporation :

Madison – US.

Effect of Addition Silica Gel from Volcanic Ash of Sinabung Mountains to Tensile Strength on Chitosan Composite Membrane

61