The Effect of Heating, Boiling and Acidification Techniques on the

Total and Exchangeable Contents of K, Ca, and Mg in Volcanic Ash

of Sinabung of North Sumatra

Basyaruddin

1

, Khusrizal

1

and A. Malik

2

1

Faculty of Agriculture, Universitas Islam Sumatera Utara, Medan, Indonesia

2

Faculty of Agriculture, Universitas Malikussaleh, Aceh Indonesia

Keywords: Volcanic Ash, Heating, Boiling, Acidification.

Abstract: This research is aimed at studying the effect of heating, boiling, and acidification techniques of Sinabung

Volcanic Ash (AVS) material on the total and exchangeable concentrartion of K, Ca, and Mg, to obtain a

technique that can increase the exchangeable content of K, Ca, and Mg, and to produce products of

agrotechnolgy containing exchangeable K, Ca, and Mg in high concentration. This experiment uses a non

factorial completely randomized design. The treatments tested were 3 types of techniques consisting of:

oven-heating technique of 100oC (PO), 100oC (PA) water-boiling technique, and 0.01N HCl acidification

technique (US). Each treatment technique was carried out for 6 hours. The variables observed included the

total content of K, Ca, and Mg (extractant ingredients H2SO4 (p) and HCl (p), and the exchangeable content

of K, Ca, and Mg (NHOAc, pH 7.0), the ratio of K, Ca, and Mg to be exchangeable for the total amount,

and the relative ratio between elements K, Ca, and Mg. Measurement of K, Ca and Mg elements uses the

Atomic Absorption Spectrophotometer (AAS) tool. The results showed that the effect of heating technique

treatment with oven 100

o

C (PO), boiling water 100

o

C (PA), and acidification techniques with 0.01 N HCl

were significantly different in increasing total and exchangeable contents of K, Ca, and Mg, releasing rate

of exchangeable contents of K,Ca, and Mg. Acidification technique is the best technique in increasing all

the variables observed and manufacturing products of agrotechnology, followed by heating and boiling

techniques. Three products were found and marked by codings of AVS-A0,01-6, AVS-O100-6, dan AVS-

W100-6.

1 INTRODUCTION

Sinabung Mountain is one of the mountains located

in Karo District of North Sumatra, Indonesia at

coordinate position of 03

o

10’ NL and 98

o

23’ EL

and highest peak of 2.460 m from the sea level.

Historically, Sinabung Mountain has never erupted

since 1600. However it is reactive and some

eruptions have occured, and the first one occured on

August 27, 2010.

Although Sinabung eruptions have distructed the

crops, resulting bad impacts on the people in its

surroundings, and high financial loss (Retnaningsih,

2013; Sudiarso, 1987), the volcanic ash produced

from the Sinabung eruption is reported to be able to

improve the quality of chemical and physical

properties of soil (Andhika, 2011; Rostaman et al.

2011). It is also reported that Volcanic Ash of

Sinabung (VAS) contains some nutrients (Sinuhaji,

2011; Barasa, 2012) and primary minerals as sources

of plant nutrients (Khusrizal et al.2018). According

to Khusrizal et.al (Khusrizal et.al. 2018), the VAS in

depth of 0-24 cm contains primary minerals such as

plagioclas (34%), hipersthene (9%), augite (3%),

and amphibole/hornblende (5%). These minerals are

sources of plant nutrients such as K, Mg, and Ca.

The total contents of each element in VAS are

found in the amount of 2,27 %, 8,12 %, and 2,28 %

respectively. All these cations are unavailable to be

absorbed by plants as they are still in mineral

structures. These cations can be available to plants if

the minerals have been weathered by the rections as

the following:

Calsium (Ca) sources from weathering of Ca-

plagiclase

Basyaruddin, ., Khusrizal, . and Malik, A.

The Effect of Heating, Boiling and Acidification Techniques on the Total and Exchangeable Contents of K, Ca, and Mg in Volcanic Ash of Sinabung of North Sumatra.

DOI: 10.5220/0008881700190025

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 19-25

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

19

CaAlSi

2

O

8

+H

2

CO

3

+ ½O

2

= Al

2

Si

2

O

5

(OH)

4

+ Ca

2+

+ CO

3

2-

..............(1)

Magnesium (Mg) sources from weathering of

hypersthene are:

MgFeSi

2

O

3

+ 2H

2

CO

3

= Mg

2+

+ Fe

2+

+ 2HCO

3-

+ SiO

2

+ H

2

O.......(2)

Potassium (K) sources from weathering of feldspar

or orthoclase are:

2KAlSi

3

O

8

+ 2H

+

+ 9H

2

O = HAlSi

2

+ 4H

4

SiO

4

+

2K

+

.......... (3)

The concentration of K, Ca, and Mg is

exchangeable form and/or available to the plants

depending on the reaction rate that is controlled by

some factors such as mineral species, temperatures,

soil acidity, and soil moisture. According to Bowen

Series, the rate of weatherable minerals is

deteriorated from amphibole, biotite until K-felsdpar

(Bowen, 1928). Under the condition of high

temperature and low pH, it could support promoting

the rate of dilution process resulted from the

minerals destroyed releasing exchangeable cations.

Soil moistures are responsible to control hydration

and reduction–oxidation process. By this process,

iron (Fe) in mineral structure, and pyroxene can be

reduced or oxidized so that the mineral is destroyed

and some cations are released (Schott et al., 1981).

All the processes are able to increase the

concentration of exchangeable cations.

In order to improve the concentration of

exchangeable contents of K, Ca, and Mg, the

volcanic ashes can be treated by promoting the

decomposition of mineral such as heating, boiling,

acidification, and fermentation. All of these

technique tereatments are recommended to be

conducted by Khusrizal et al (Khusrizal et al. 2018).

This research aims to study the effect of heating,

boiling, and acidification techniques on total and

exchangeable form contents of K, Ca, and Mg, to

find technique that is able to increase the

exchangeable forms of K, Ca, and Mg and to

produce the argotechnology product containing

exchangeable forms of K, Ca, and Mg in high

amount.

In addition, these products can potentially be

applied to substitute or reduce the fertilizer material

from other sources, such as KCl and/or dolomite

(CaMgCO

3

). Finally, it can reduce the financial

budget or increases benefits in farming.

2 RESEARCH METHOD

The experiment was conducted in Laboratory of

Faculty of Agriculture, Islamic University of North

Sumatra. The materials of VAS were colleted in

depth of 0-10 cm from Karo District, Taman Taran

Sub District, Sigarang-garang village. The location

is in coordinate position of 3

0

11’27.1“N 98

0

24’52.1” E. Morphologically, VAS is characterized

by gray color, and used to distinguish between VAS

and soil materials in its surrounding. The VAS

collected was sieved by using the screener of 40

mesh in size in order to minimize the texture and

homogenity of VAS materials.

The experiment was arranged in Non Factorial

Randomized Complete Design. Three techniques as

treatments were tested consiting of heating 100

o

C

by oven (PO), boiling 100

o

C (PA), and acidification

by HCl 0,01N (AS) techniques. Heating technique

of 100

o

C by oven was run in accordance with the

procedure in which 2 kg of VAS material was

heated in 100

o

C in oven for 6 hours. Afterwards,

the VAS material was cooled under closed room

temperature, and direct blow of wind is to be

avoided. After VAS material was cool, it was put in

a bucket of 2 kg in capacity. This product was

marked with a code as AVS-O100-6.

Boiling technique was conducted by using the

procedure in which 2 kg of VAS material was boiled

in 1 liter of water in 100

o

C for 6 hours, and stirred

until turning into mud. Then, The VAS material was

cooled under closed room temperature, and the

direct blow of wind is to be avoided. The cooled

VAS material was put into a bucket of 2 kg in

capacity.

This product is signed with a code as

AVS-W100-6.

Acidification technique was done by the

procedure in which 2 kg of VAS material was mixed

with 1 liter of 0,01N HCl and stirred for 6 hours in

mixer. VAS material was dried in closed room

temperature for 6 hours, and then put into the bucket

of 2 kg in capacity. This was marked with a code as

AVS-A0,01-6

The variables observed consisted of the total

concentration of K,Ca, and Mg (extracted by

concentrate of H

2

SO

4(c)

dan HCl

(c)

), exchangeable

content of K, Ca, and Mg (NH

4

OAc, pH 7,0),

exchangeable ratio of K,Ca, and Mg to totality of

K,Ca, dan Mg, and each product of AVS-O100-6,

AVS-W100-6 and AVS-A0,01-6 and VAS was

standard. Both the total or exchangeable contents of

K, Ca, and Mg were determined by using Atomic

Absorption Spectrophotometer (AAS).

ICMR 2018 - International Conference on Multidisciplinary Research

20

3 RESULTS AND DISCUSSION

3.1 The Effect of Heating, Boiling, and

Acidification Techniques on Total

Contents of K, Ca, and Mg in VAS

3.1.1 Potassium Total (K)

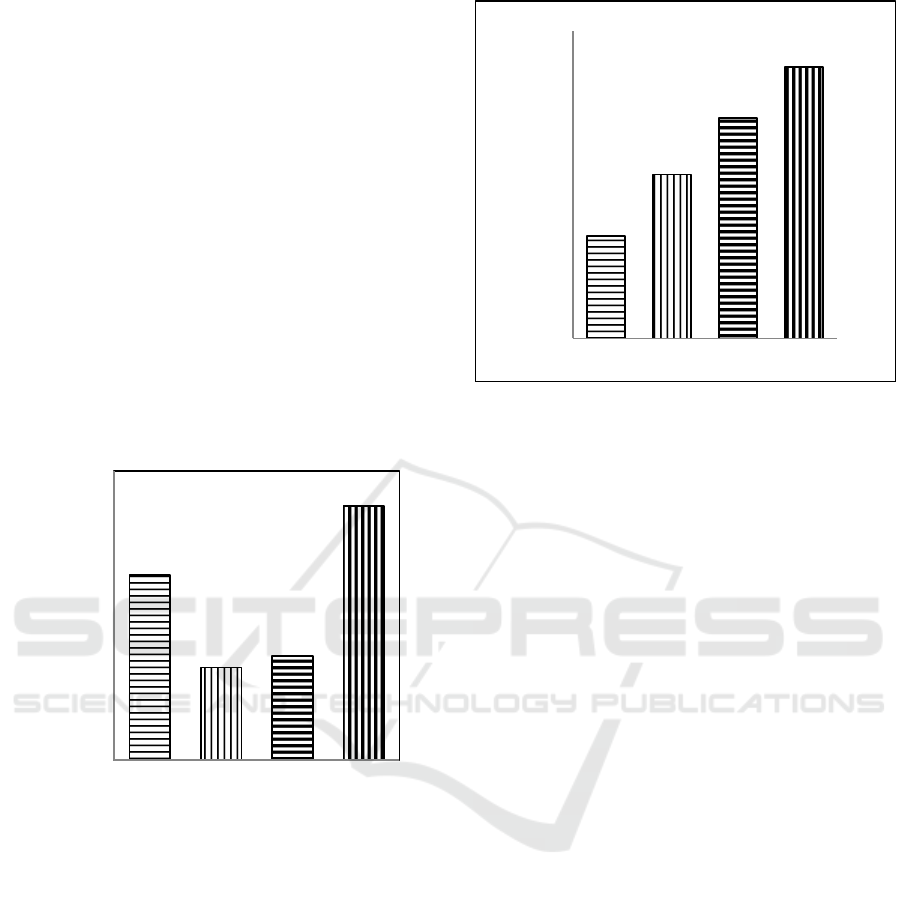

The effects of heating, boiling, and acidification

techniques on total content of K in VAS are

presented in Figure 1. Figure 1 shows that the effect

of heating and boiling techniques (oven and water)

and acidification technique are different significantly

on the total concentration of K, Ca, and Mg in VAS.

The effect of acidification technique is the highest of

that of heating and boiling techniques. The latter

techniques of heating and boiling are not different

significatly according to DMRT test.

Treatments

Figure 1: The Effects of Heating (PO), Boiling (PA) , and

Acidification (AS) Techniques on Total content of K in

VAS.

Treatments

Figure 2: The Effects of Heating (PO), Boiling (PA), and

Acidification (AS) Techniques on Total of Ca in VAS.

3.1.2 Calsium Total (Ca)

The effects of heating, boiling, and acidification

techniques on total content of Ca in VAS are

presented in Figure 2. The effect of acidification

technique is highest on the total content of Ca

(8,46%) folowed by boiling technique (8,26%), and

heating technique (8,04%), and controlled

treatments (7,80%).

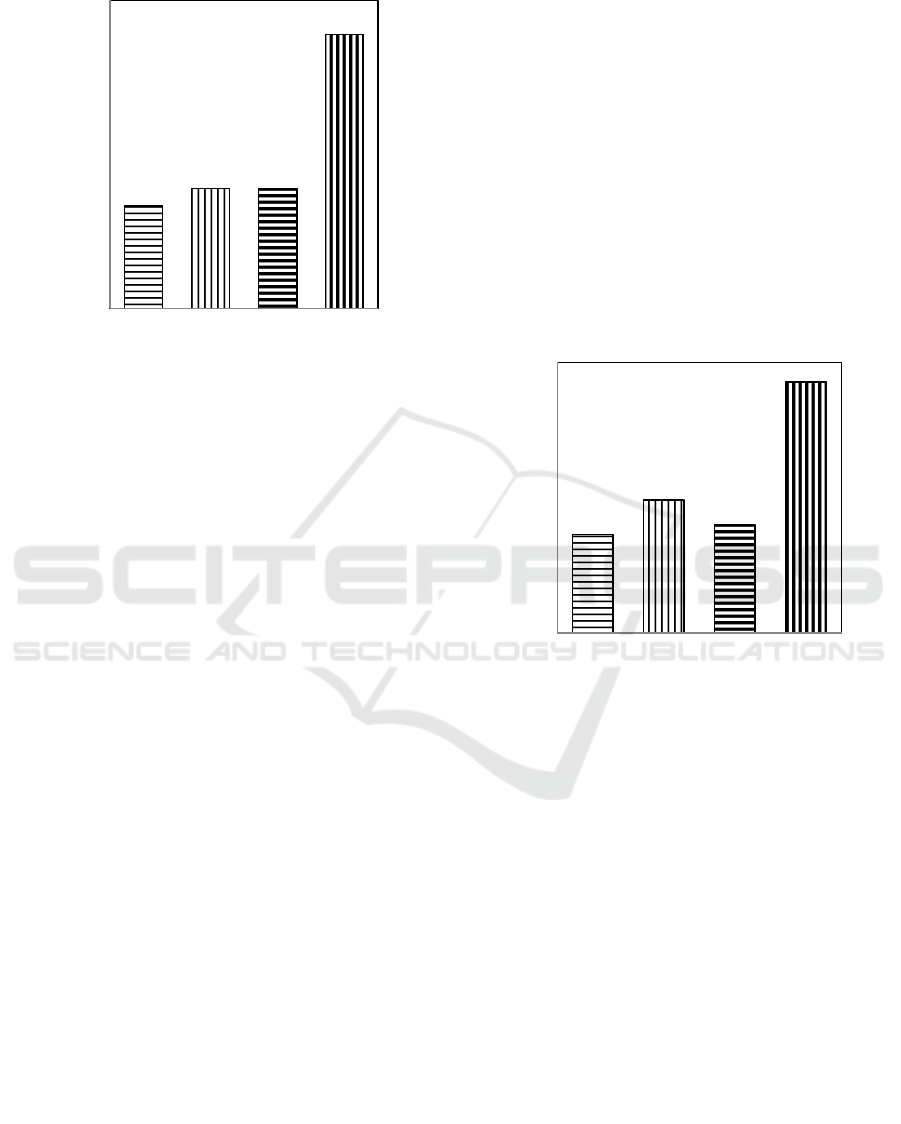

3.1.3 Magnesium Total (Mg)

The effects of heating, boiling, and acidification

techniques on total of Ca in VAS are presented in

Figure 3.

2,26 b

2,18 a

2,19 a

2,32 c

2,1

2,15

2,2

2,25

2,3

2,35

AO PO PA AS

Concentration of Total K (%)

7,80cd

8,04c

8,26 b

8,46 a

7,40

7,60

7,80

8,00

8,20

8,40

8,60

AO PO PA AS

Concentration of Ca-total ,%

The Effect of Heating, Boiling and Acidification Techniques on the Total and Exchangeable Contents of K, Ca, and Mg in Volcanic Ash of

Sinabung of North Sumatra

21

Treatments

Figure 3: The Effects of Heating (PO), Boiling (PA), and

Acidification (AS) Techniques on Total of Ca in VAS.

Figure 3 shows that the effects of the techniques

are significantly different on concentration of total

of Mg. Acidification techniques produce highest

concentration of total of Mg followed by boiling

(2,27%), heating technique (2,27%), and VAS as

standard tereatment (2,26%). Both the techniques,

boiling and heating are not significanly different.

Acidification technique produces highest

concentration of total of K, Ca, and Mg, and it can

be caused by some alternative reasons such as: (1)

acidification reaction involved is responsible in

weathering of minerals as representive in weathering

reaction of Ca-plagioklas (equation 1), hipersten

(equation 2), and feldspar/orthoklas (equation 3) in

naturally weak acid (H

2

CO

3

) (Scott et al 1998); (2)

in acidification technique there are double

acidification treatments, both of which are by HCl

0.01N and in extraction using the mixed hard acids

(H

2

SO

4

and HCl). This action can possibly destroy

the minerals in big amount so that Ca should be

released; and (4) under natural condition, the

weathering of minerals involves carbonate acid.

(H

2

CO

3

) is weak acid; while in application of

acidification technique, the hard acid (HCl) is used.

Environment under control by hard acid can

support to accelarate the reaction rate to improve

weathering of mineral intensively and dialution of

K, Ca, and Mg could be exchangeable increasing the

concentration.

3.2 The Effect of Heating, Boiling, and

Acidification Techniques on

Exchangeable Contents of K, Ca,

and Mg in VAS

3.2.1 Exchangeable Content of K

The effects of heating, boiling, and acidification

techniques on exchangeable content of K in VAS

are significantly different as presented in Figure 4.

Figure 4 shows that the concentration of

exchangeable content of K is treated by acidification

technique of the highest of (2,01 me%), and then

the heating is decreased to (1,77 me%) and (1,72

me%) and AVS is standard (1,70 me%)

respectively.

Treatments

Figure 4: The Effect of Heating (PO), Boiling (PA) , and

Acidification (AS) Techniques on Exchangeable content

of K in VAS.

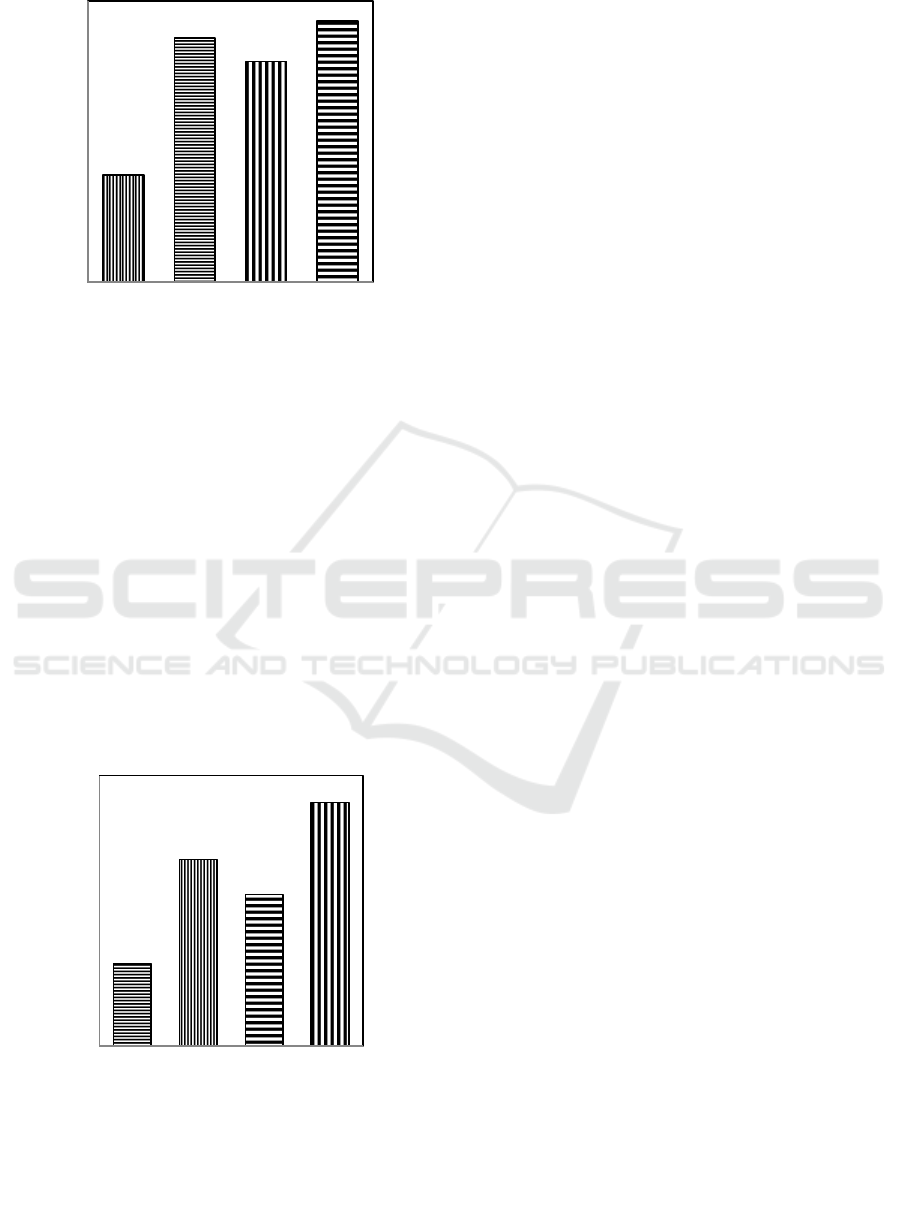

3.2.2 Exchangeable Content of Ca

The effects of heating, boiling, and acidification

techniques on exchangeable content of Ca in VAS

are presented in Figure 5. The Figure 5 shows that

the exchangeable concentration of Ca in VAS that

are treated by heating, boiling, and acidification

techniques produce 21,7 me%, 21,46 me%, and 21,8

me% respectively. All the techniques are not

significantly different, but they are significantly

different from the standard treatment (20,45 me%).

2,26b

2,27b 2,27b

2,36 a

2,20

2,22

2,24

2,26

2,28

2,30

2,32

2,34

2,36

2,38

AO PO PA AS

Concentration of Mg Total (%)

1,70b

1,77b

1,72b

2,01a

1,50

1,55

1,60

1,65

1,70

1,75

1,80

1,85

1,90

1,95

2,00

2,05

AO PO PA AS

Exchangeable of K (me %)

ICMR 2018 - International Conference on Multidisciplinary Research

22

Treatments

Figure 5: The Effects of Heating (PO), Boiling (PA), and

Acidification (AS) Techniques on Exchangeable Content

of Ca in VAS.

3.2.3 Exchangeable Content of Mg

The effects of heating, boiling, and acidification

techniques on exchangeable content of Mg in VAS

are presented in Figure 6. Figure 6 shows that

heating and boiling techniques are not different, but

signifiacantly different with acidifiacation

techniques in producing the concentration of

exchangeable content of Mg. Acidification

technique produces the highest exchangeable

concentration of Mg, and decreases in heating (8,41

me%), boiling (8,34 me%), and AVS is in standard

treatment (8,18 me%).

Treatments

Figure 6: The Effect of Heating (PO), Boiling (PA) , and

Acidification (AS) Techniques on Exchangeable Content

of Ca in VAS.

Treatment by using acidification technique

produces significantly the highest exchangeable

concentration of K and Mg compared to Ca. This

fact can be caused by some possible reasons such as:

(1) acidification is able to distruct directly the

mineral structure by reaction with elements in

meneral structure and release K,Ca, and Mg to be

exchangeble form or available to plant. (2)

meanwhile, both heating and boiling techniques only

occur in the addition of heat energy, and indirectly

react with elements in mineral structure with lower

result in releasing K,Ca, and Mg in exchangeable

form; (3) duration of heating and boiling for 6 hours

is not enough to optimalize to destruct or dilute the

primer minerals and release the exchangeable forms

of K,Ca, and Mg. But, both of the techniques have

the ability to produce the exchangeable forms of K,

Ca, and Mg higher than standard treatment or

control of VAS. On the other hand, all of the

techniques have potential ability to increase or

release the exchangeable concentration of K, Ca,

and Mg or available to plant.

3.3 Rates of K,Ca, and Mg Release

Release of K,Ca, and Mg is an exchangeable form

due to destruction of mineral structure resulted from

the treatment of heating, boiling, and acidification

techniques. The exchangeable contents of K, Ca,

and Mg are available form that can be absorbed by

plant roots. Rate of K,Ca,and Mg release can be

predicted base on the exchangeable ratio to total

form of K, Ca, and Mg. The ratio value is presented

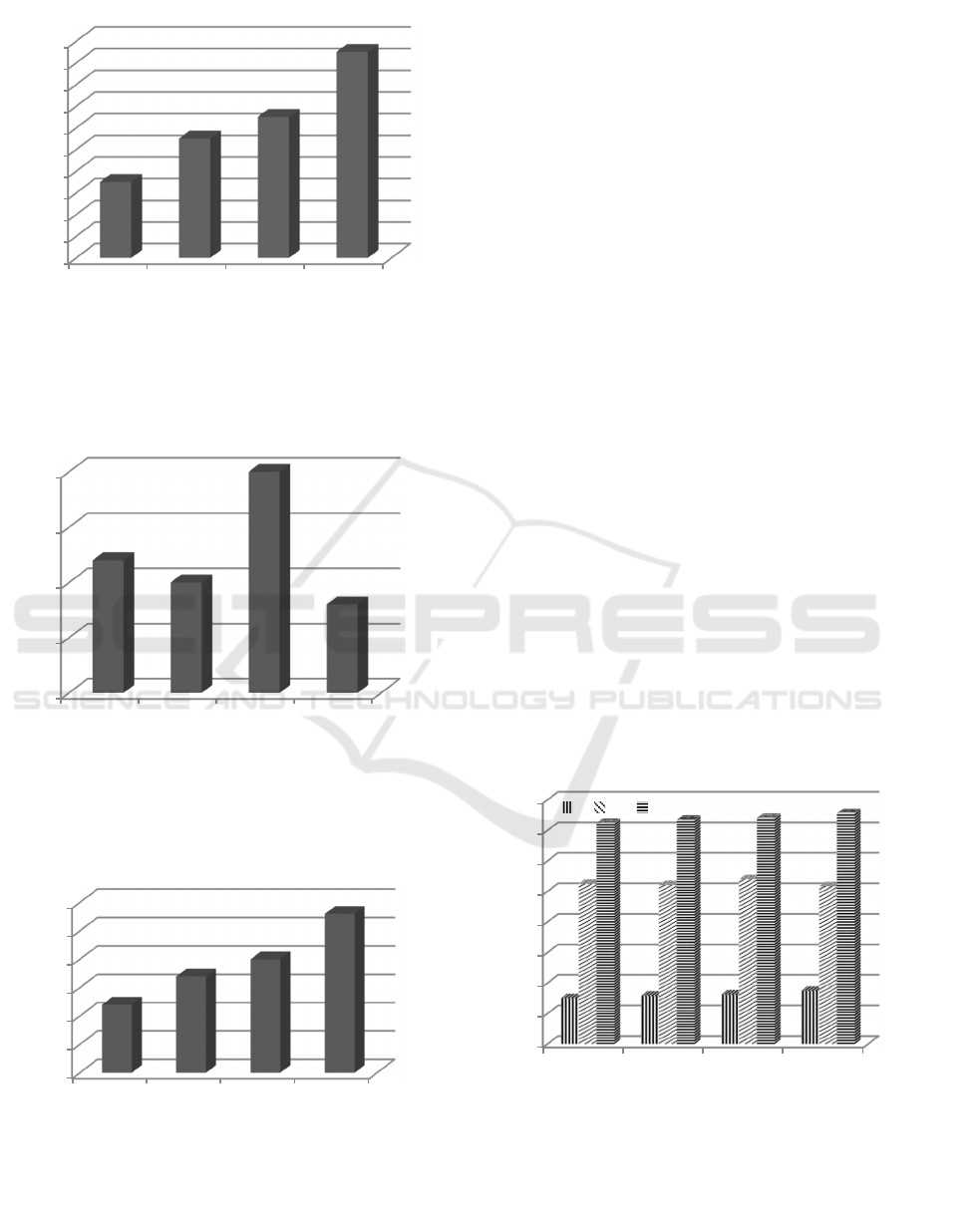

in Figure 7, 8, and 9. Figur 7 and 9 show that the

rate of release of the exchangeable contents of K and

Mg are significantly different. The highest

concentrations of K and Mg are found in treatment

of acidification technique and decreased in boiling

technique and heating respectively (Figure 7).

Meanwhile, rate of Ca release is also significantly

different and highest concentration is found in

treatment of boiling technique, but there is no

difference to all other treatments (AO, PO, and AS)

(Figure 8).

20,45 a

21,7 b

21,46 b

21,8 b

19,50

20,00

20,50

21,00

21,50

22,00

AO PO PA AS

Exchangeable of Ca (me%)

8,18b

8,41b

8,34b

8,54a

8,00

8,10

8,20

8,30

8,40

8,50

8,60

AO PO PA AS

Exchangeable of Mg (me/100g)

Treatmen

The Effect of Heating, Boiling and Acidification Techniques on the Total and Exchangeable Contents of K, Ca, and Mg in Volcanic Ash of

Sinabung of North Sumatra

23

Treatments

Figure 7: The Effect of Heating (PO), Boiling (PA), and

Acidification (AS) Techniques on Ratio of K-exch./K-

total in VAS.

Treatments

Figure 8: The Effect of Heating (PO), Boiling (PA) , and

Acidification (AS) Techniques on Ratio of Ca-exch./Ca-

total in VAS.

Treatments

Figure 9: The Effect of Heating (PO), Boiling (PA) , and

Acidification (AS) Techniques on Ratio of Mg-exch./Mg-

total in VAS.

3.4 Relative Rate of Release for

Exchangeable Contents of K,Ca,

and Mg

Relative rate of release for exchangeable contents of

K,Ca, and Mg can be explained based on ratio of

the exchangeable concentration to total

concentration of K,Ca, and Mg. Based on the ratio,

relative rate of release of K,Ca, and Mg shows

significant difference in all treatments as presented

in Figure 10. The figure also shows that the relative

rate of release between elements of K, Ca, and Mg

in all of treatments are different significantly.

Relative rate of release for Mg is highest and

decreased for Ca and K (Mg>Ca> K) and in

standard treatment respectively.

The highest release for Mg is possibly correlated

with source of Mg originating from hipersthene that

contains Fe in its structure. Hypersthene belongs to

mineral of ferromagnesian group. It is relatively

weathering minerals due to exchanges of Fe

3+

(ferri)

to Fe

2+

(fero) resulted from the influence of

reduction-oxidation condition and low stage in pH

(VAS pH, more or less 4.0). Under this condition

this can facilitate or support the weathering of

hipersthene efectively and release Mg to be

exchangeable form faster than those of K and Ca.

Both of the elements, K and Ca, are sourced from

felspar/orthoclase and plagioclase. These minerals

do not have Fe in their structure resulted from the

weathering that may occur in relative lower stage so

that the release rate of the element becomes

exchangable form, also relatively low.

Treatments

Figure 10: The Effect of Heating (PO), Boiling (PA) , and

Acidification (AS) Techniques on Ratio of K-exch/K-

total,Ca-exch/Ca-total, dan Mg-exch/Mg-total AVS.

0,68

0,70

0,72

0,74

0,76

0,78

0,80

0,82

0,84

0,86

0,88

AO PO PA AS

2,50

2,55

2,60

2,65

2,70

AO PO PA AS

3,50

3,55

3,60

3,65

3,70

3,75

3,80

AO PO PA AS

0,00

0,50

1,00

1,50

2,00

2,50

3,00

3,50

4,00

AO PO PA AS

K Ca Mg

ICMR 2018 - International Conference on Multidisciplinary Research

24

4 CONCLUSIONS

1. The effects of heating by oven at 100

o

C, boiling

at 100

o

C, and acidification techniques are

different significantly and could increase the

total and exchangeable concentration, and release

rate of K, Ca, and Mg

2. The effect of acidification technique is highest in

producing the total and exchangeble

concentration of and in improving the release

rate of K, Ca, and Mg and decreased for heating

and boiling techniques respectively.

3. The acidification is the best technique and can

be potentially used to manufacture VAS, useful

as a soil amendment product in future.

4. The best product based on exchangeable

concentration of K,Ca, and Mg or available form

is produced by acidification technique and

folowed by heating and boiling techniques.

5. Each product is marked by the coding as AVS-

A.01-6, AVS-O100-6, and AVS-W100-6

respectively.

5 RECOMMENDATION

Exchangeable concentration of K,Ca, and Mg are

still relatively low compared to total concentration.

All products produced above can potentially be used

in agrotechnology, but need to be tested in order to

impove all the existing techniques.

REFFERENCES

Andhika, M. M. 2011. Dampak Debu Vulkanik Gunung

Sinabung Terhadap Perubahan Sifat Fisika Dan

Kandungan Logam Berat Pada Tanah Inceptisol.

Skripsi Universitas Sumatera Utara. Medan.

Barasa, R., F. 2012. Dampak DebuVulkanik Letusan

Gunung Sinabung Terhadap Kadar Cu, Pb dan B

Tanah di Kabupaten Karo. Skripsi. Universitas

Sumatera Utara. Medan.

Bowen, N. 1928. The Evolution on the Igneous Rock.

Princeton University Press, New Jersey.

Fiantis. D. 2006. Laju Pelapukan Kimia Debu Vulkanis

Gunung Talang dan Pengaruhnya Terhadap Proses

Pembentukan Mineral Liat Non Kristalin. Universitas

Andalas, Padang.

Khusrizal, Basyaruddin, R.D.H. Rambe, I. Setiawan,

2018. Study of Mineralogy Composition, Total, and

Exchangable Content of K, Ca, and Mg of Volcanic

Ash from Sinabung Mountain Eruption in North

Sumatera, Indonesia" In Proceedings of MICoMS

2017. Published online: 11 Jul 2018; 199-

207.Permanent link to this document:

https://doi.org/10.1108/978-1-78756-793-1-00029

Lubis, A. H. 2011. Dampak Debu Vulkanik Letusan

Gunung Sinabung terhadap Ketersediaan dan Serapan

Hara P oleh Tanaman Jagung Serta terhadap Respirasi

Mikroorganisme pada Tanah Dystrandepts. Skripsi

Universita Sumatera Utara. Medan.

Retnaningsih, H. 2013. Letusan Gunung Sinabung dan

Penanganan Bencana di Indonesia.Info Singkat

Kesejahteraan Sosial Vol. V, No. 18/II/P3DI.

Rostaman, T., A. Kasno dan L. Anggaria.2011.Perbaikan

Sifat Tanah dengan Dosis AbuVulkanik pada Tanah

Oxisols. Bdan Litbang Pertanian. Bogor

Schott, J., Berner, R.A. and Sjoberg, E.L. 1981.

Geochemical et chosmochimica Acta, Vol. 45, pp.

2123-2135.

Sinuhaji, N. F. 2011. Analisis Logam Berat dan Unsur

Hara Debu Vulkanik Gunung Sinabung Kabupaten

Karo - Sumatera Utara. Skripsi USU. MEDAN.

Surdiyarso, A. S. 1987. Dampak Negatif Abu Vulkanik

Terhadap Lingkungan dan Kesehatan. Pusat

Pengkajian, Pengolahan Data dan Informasi, Medan

The Effect of Heating, Boiling and Acidification Techniques on the Total and Exchangeable Contents of K, Ca, and Mg in Volcanic Ash of

Sinabung of North Sumatra

25