Investigation of Structural Response Due to Impact Load on the

Small Water Plane Area Twin Hull Autonomous Surface Vehicles

(SWATH-ASV)

Ahmad Fauzan Zakki

1

, Aris Triwiyatno

2

and Bandi Sasmito

3

1

Naval Architecture Department, Engineering Faculty, Diponegoro University, Indonesia

2

Electrical Engineering Department, Engineering Faculty, Diponegoro University, Indonesia

3

Geodetical Engineering Department, Engineering Faculty, Diponegoro University, Indonesia

Keywords: Structural Response, Impact Load, SWATH-ASV.

Abstract: The main objective of the research was to investigate the structural response of The Small Water Plane Area

Twin Hull Autonomous Surface Vehicles (SWATH-ASV) due to the impact load. The impact load was

defined as the drop phenomena that might be occurred while SWATH-ASV is being carried and transported.

The behavior of the absorbed energy in several drop scenarios also was studied. Numerical simulation was

performed using nonlinear finite element method to obtain the numerical simulation data. The size of the

damage of the SWATH-ASV was estimated as a design consideration for the structure strength. The external

dynamics parameters which include as the contact point location and drop velocity is being considered on the

simulation analysis. The internal energy and deformation size which is caused by the drop phenomena will

be discussed.

1 INTRODUCTION

Rapid development in the growth of numerical

simulation technology, capability of computational

speed and relatively large memory capacity makes

designers able to create and evaluate of new product

designs performance in a virtual world.

Through the finite element method, complex

simulations able to provide any valuable information

for the design and development of reliable new

products like those that have already existed and even

better as an improvement on the existing product

capabilities. The manufacturer confirmed that this

method is very useful, as this method has facilitated

them enormously in achieving a better productivity at

lower unit costs. This method is also capable for

supporting manufacturers to develop engineering

components that are easily produced and to create any

products that are efficient in terms of material

expenditure.

In 2018, an autonomous surface vehicle (ASV)

has been developed by Zakki et. al. (2018) which is

adopted the Small Water plane Area Twin Hull

(SWATH) technology for the hull form. The ASV

was developed to support bathymetry survey

activities in coastal area. In the development of the

SWATH-ASV, the designers attempt to obtain a

product that has reliable quality for its hull

components. For achieving these quality standards,

the SWATH-ASV products must meet the

requirements of being able to withstand loads that can

result in high stress structures (Ali, et.al, 2011).

Therefore this study is focused on the investigation of

structural responses that were subjected for impact

loading, especially in the drop phenomena. The

structure load is the impact load that is occurred when

the SWATH-ASV product is dropped from a certain

height. Therefore it can be predicted that the

developed ASV product has reliable structural

integrity when it drops from the certain height during

the survey activities.

2 DROP TEST AND FINITE

ELEMENT ANALYSIS

2.1 Drop Test

Durability assessment that is important to be

conducted for the development of new products is a

144

Zakki, A., Triwiyatno, A. and Sasmito, B.

Investigation of Structural Response Due to Impact Load on the Small Water Plane Area Twin Hull Autonomous Surface Vehicles (SWATH-ASV).

DOI: 10.5220/0008565001440148

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 144-148

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

drop test. Drop tests are carried out in the full load

conditions and it is dropped from a certain height on

a solid floor such as a steel floor or concrete floor.

Drop test experiments are costly and require

relatively extensive experimental setting times.

However with the computational simulation using

finite element analysis (FEA), the drop test can be

performed without conducting a physical product

prototype which is required moulding process and

experimental studies. FEA is able to estimate the

performance of the response of product structure that

is loaded nearly realistic conditions (Abunawas,

2010).

2.2 Finite Element Analysis

Finite Element Analysis is numerical procedure that

is accurate and flexible to estimate the performance

of a structure, mechanism or process in a loading

condition while being operated. FEA is generally

associated with the design validation process before

the manufacturing process is carried out. Furthermore

FEA is also widely used in the initial stages of the

design process to try / evaluate new concepts before

physical prototypes are made and tested. Some

advantages of FEA include:

1. Supporting innovation, as FEA supports designers

to think creatively with the accepted risk level.

2. Supporting the process to achieve an optimum

design rather than acceptable design, resulting in

better performance and lower material costs, as

FEA is able to support numerical evaluation

processes through evaluation study with multiple

scenarios.

3. Understanding and controlling operations in the

parametric study of product design, as FEA

provides information about detailed performance

that cannot be obtained through experimental test.

4. Reducing development research costs and

working time, by replacing experimental test into

numerical studies, as FEA models are usually

faster than creating the physical prototypes and

setting up the experimental equipment.

In the last four decades, finite element method

becomes a well-known numerical method, since

computer applications are widely implemented on the

manufacture industries. Versatility and flexibility

have been offered by FEA and it is applicable for

solving the complex boundary problems. FEA

commonly used for the structure analysis in the static

and dynamic characteristics. Instead of structure

analysis, FEA might be applied for solving the heat

conduction, fluid mechanics, electromagnetic and the

other continuity problems (Zakki and Windyandari,

2016; Windyandari and Zakki,, 2018; Windyandari,

et.al, 2018; Yudo, et.al, 2017; Prabowo, et.al, 2018).

There are many commercial finite element analysis

software that already support the manufacture

industries such as: ANSYS, MSC

NASTRAN/PATRAN, SOLIDWORK, LS-DYNA,

HYPERWORKS, and many others.

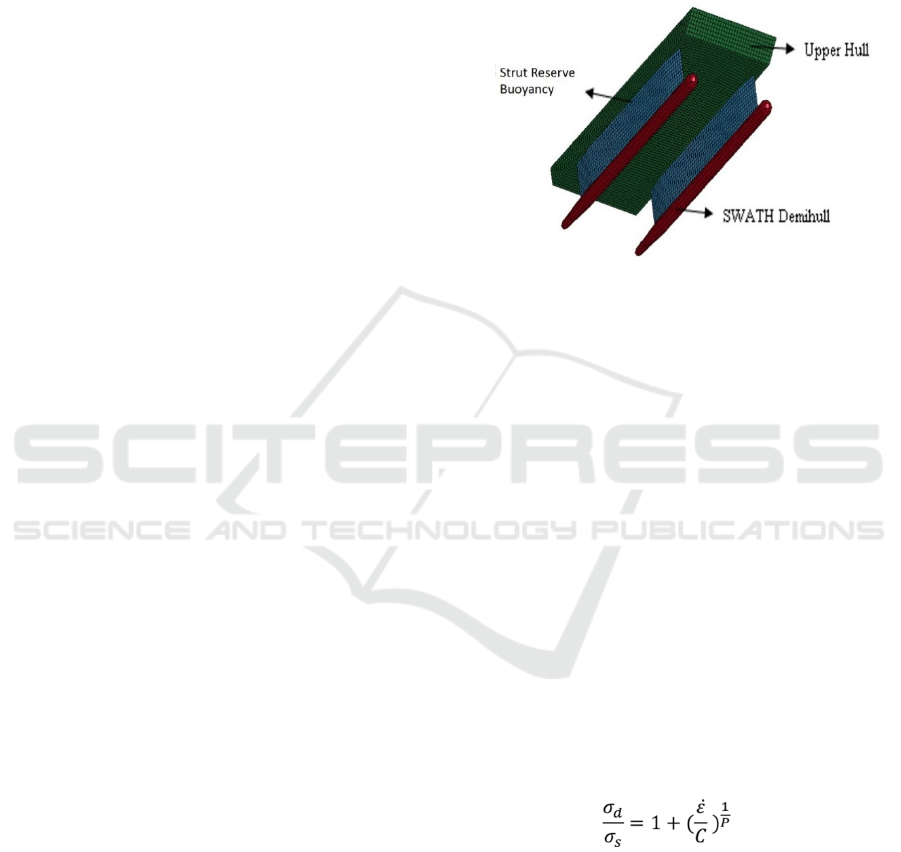

Figure 1: Finite Element Model of SWATH-ASV.

3 DROP TEST SIMULATION

MODELLING

The finite element analysis model of the SWATH-

ASV is described in the Fig. 1. The meshing process

of the SWATH-ASV model is carried out using LS-

PREPOST (LSTC, 2009). All of the plate/shell of the

SWATH-ASV structures was modelled using 2D

elements which is 4 nodded bilinear Belytchko-Tsay

shell element is adopted. The finite element model of

SWATH-ASV consists of 11706 numbers of nodes

and 11674 numbers of shell elements.

In the case of material modelling, Cowper-

Symonds strain rate material model is adopted to

capture the material behaviour, since the impact

problem such as drop test is a high strain rate loading

condition. The equation of Cowper-Symonds is

defined as follow:

(1)

Where is dynamic yield stress, is static stress, is

strain rate, C is material constant which is defined as

100, P is material constant which is defined as 10. The

mechanical properties of the FE model can be seen on

the Table 1.

Investigation of Structural Response Due to Impact Load on the Small Water Plane Area Twin Hull Autonomous Surface Vehicles

(SWATH-ASV)

145

Table 1: FE Model mechanical properties.

Properties Item Material of FE

Model

Density (kg/mm

3

) 1.522 ×10

-06

Poisson Ratio 0.30

Longitudinal Young Modulus (GPa) 67.28

Transverse Young Modulus (GPa) 14.25

Longitudinal Tensile Strength (GPa) 1.05

Transverse Tensile Strength (GPa) 0.43

Strain Rate Model Cowper-

Symmonds

C= 100 and

P=10

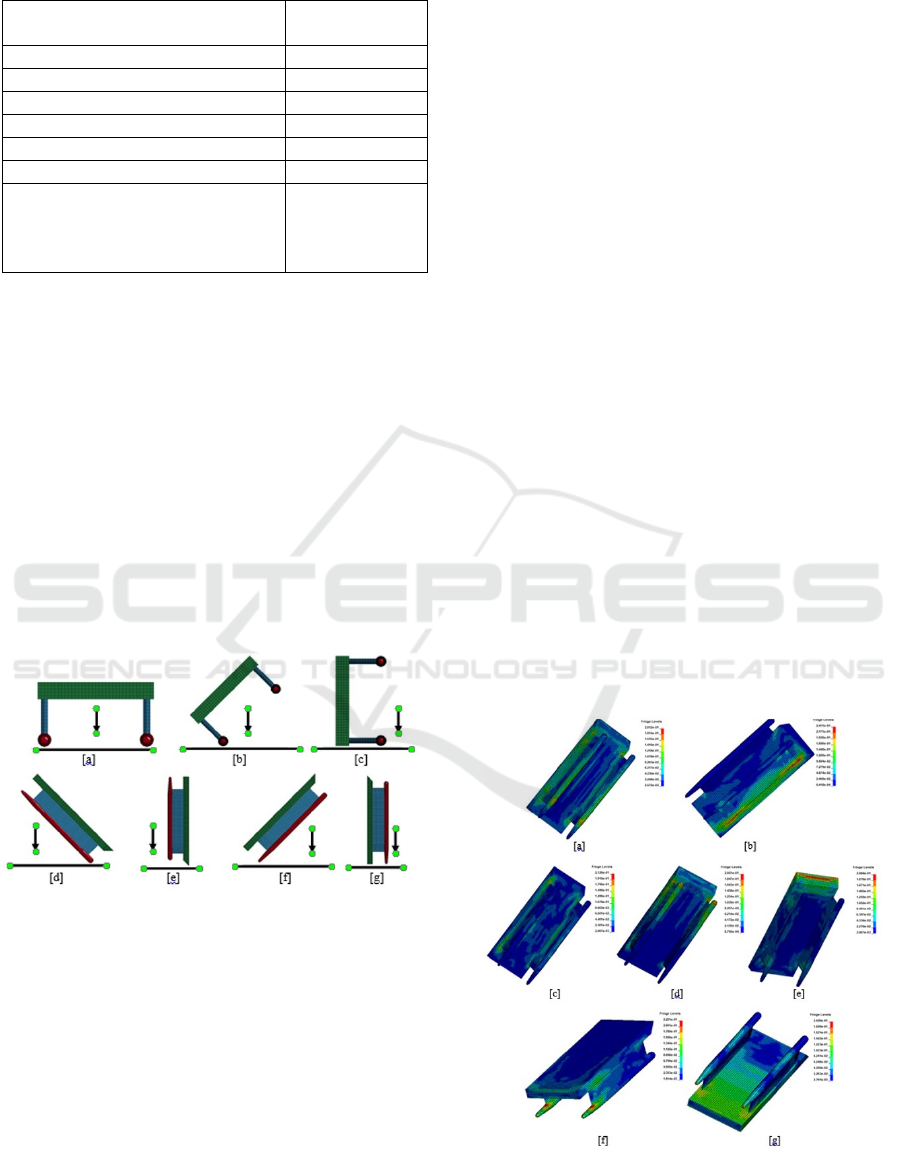

The boundary condition of the simulation has

been defined as the drop orientations which are

considered for the numerical analysis. The drop

orientations are consist of even keel, 45 degrees heel,

90 degrees heel, 45 degrees trim by stern, 90 degrees

trim by stern, 45 degrees trim by bow and 90 degrees

trim by bow, see Fig. 2. The floor material is

considered as an infinite planer rigid material. For the

numerical simulation, the SWATH-ASV is given an

initial velocity of 6.26 m/s that is equivalent with the

2m drop velocity before striking the rigid floor. The

type of contact algorithm used is node to surface

contact with the contact thickness of 0.0001 m for the

analysis. Non friction contact is adopted for the

SWATH-ASV and the rigid floor.

Figure 2: Drop test orientation: [a] even keel; [b] heel 45º;

[c] heel 90º; [d] trim by bow 45º; [e] trim by bow 90º; [f]

trim by stern 45º; [g] trim by stern 90º.

4 RESULT AND DISCUSSIONS

The drop phenomena for seven different orientations

of SWATH-ASV have been simulated. The integrity

of the SWATH-ASV structure was analysed to study

the various essential parameters such as Von Misses

Stress and crash energy absorbed by the SWATH-

ASV components.

4.1 Maximum Effective Stress

In the event keel drop condition, the maximum Von-

Mises stress obtained on the bottom part of demihull

and the connection between strut and upper hull, see

Fig 3a. It can be explained that the bottom part of the

demihull is exerted the impact force and distributed

the load to the ASV structure. Since the maximum

Von-Mises of 201 MPa is below the tensile strength,

therefore the ASV is not expected to be failed during

the event keel drop.

The maximum Von–Misses stress on the

connection between strut and upper hull also can be

found on the other drop conditions such as heel 45º,

heel 90º, trim by bow 45º and trim by stern 45º, see

Fig. 3. It is indicated that the connection of strut and

upper hull is a vulnerable area that might be failure if

the ASV has experiencing the higher drop height. The

tendency can be explained since the connection

design have a sharp geometry that could be identified

as a stress concentrator. Therefore the rounded joint

design should be considered to reduce the maximum

stress that might be occurred.

According to the result of numerical simulation, it

is shown that the maximum Von-Misses stress

obtained on the heel 45 degrees condition is 241 MPa.

Failure of the connection of strut and the upper hull

can lead the leakage of the hull structure. However

the Von Misses stress of the connection area is below

the tensile strength of 1.05 GPa. Therefore the

connection of strut and upper hull is expected not

failed under 2 m drop.

Figure 3: The Maximum Von-Misses stress: [a] even keel;

[b] heel 45º; [c] heel 90º; [d] trim by bow 45º; [e] trim by

bow 90º; [f] trim by stern 45º; [g] trim by stern 90º.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

146

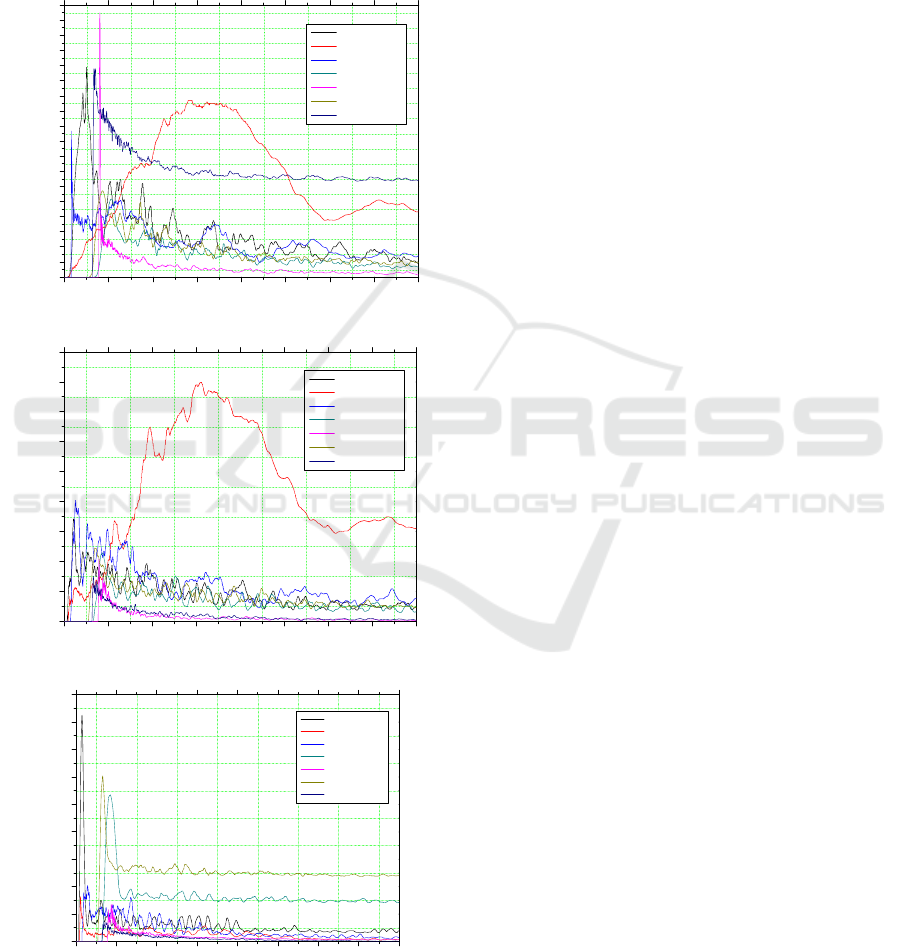

4.2 Absorbed Rupture Energy

The rupture energy absorbed by all of the components

of SWATH-ASV structure after 2m drop is shown in

the Fig. 4. It can be seen that the maximum energy

which is absorbed by the upper hull is observed in the

trim by stern 90º. It might be explained that the upper

hull is experiencing the impact energy while the ASV

0 1020304050607080

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

Rupture Energy [kNmm]

Time [ms]

Even Keel

Heel 45 Deg

Heel 90 deg

Stern 45 deg

Stern 90 deg

Bow 45 deg

Bow 90 deg

(a)

0 1020304050607080

0

10

20

30

40

50

60

70

80

90

Rupture Energy [kNmm]

Time [ms]

Even Keel

Heel 45 Deg

Heel 90 deg

Stern 45 deg

Stern 90 deg

Bow 45 deg

Bow 90 deg

(b)

0 1020304050607080

0

10

20

30

40

50

60

70

80

90

Rupture Energy [kNmm]

Time [ms]

Even Keel

Heel 45 Deg

Heel 90 deg

Stern 45 deg

Stern 90 deg

Bow 45 deg

Bow 90 deg

(c)

Figure 4: The rupture energy absorbed: [a] by upper hull;

[b] by strut; [c] by demihull.

was striking the rigid floor. Although the upper hull

absorbed most of the impact energy, however the

maximum stress is occurred on the stern peak

structure because the stern peak have a narrow shape

hull form as the stress concentrator.

On the strut part of the structure, the maximum

rupture energy is occurred on the heel 45º condition.

It can be explained that during the collision period the

strut was experiencing the collision energy and the

maximum effective stress have shown in the

connection between strut and upper hull as the

structure response. Otherwise the design geometry of

the connection between strut and upper hull have a

sharp shaped that would concentrate the stress in the

area. Therefore the connection area is the

vulnerableregion that should be improved by

providing the smooth connection such as rounded

joint and hull haunch.

Finally, the demihull part was shown a maximum

absorbed energy on the even keel drop condition. The

rupture energy was absorbed when the demihull strike

the rigid floor and then the energy was distributed to

the upper hull through the strut structure. Therefore

the upper hull part has shown larger absorbed rupture

energy, especially in the connection between strut and

upper hull. According to the numerical simulation

result, it can be concluded that the connection

between strut and upper hull is critical region that

should be modified to improve the drop performance

of the SWATH-ASV.

5 CONCLUSIONS

The investigation of SWATH-ASV structural

response was made due to the impact load on the 2m

drop phenomena. It was obtained that the maximum

effective stress (Von –Misses stress) was occurred on

the Heel 45º condition. The maximum effective stress

of 241 MPa is smaller than the tensile strength of the

SWATH-ASV material. Therefore it could be

concluded that the SWATH-ASV structure is able to

withstand the impact load during the 2m drop test.

In the case of absorbed rupture energy that might

influence the strength integrity of the SWATH-ASV

structure, the maximum absorbed rupture energy is

occurred on the trim by stern 90º, it is indicated that

the upper hull have absorbed most of the impact

energy. Although the maximum rupture energy was

shown by the trim by stern 90º, However the most

critical region of the SWATH-ASV structure is the

connection between strut and upper hull, since the

area have a sharp shaped that might become as stress

concentrator. Therefore it can be concluded that the

Investigation of Structural Response Due to Impact Load on the Small Water Plane Area Twin Hull Autonomous Surface Vehicles

(SWATH-ASV)

147

connection between strut and upper hull is vulnerable

region that should be modified to provide smooth

connection for eliminating the stress concentration

that might be increased the effective stress.

REFERENCES

A. F. Zakki, A. Triwiyatno, B. Sasmito, M. H. Nubly, 2018.

MATEC Conf. 177.

A. F. Zakki, A. Windyandari, D. M. Bae, 2016. JMST-

Taiwan 24, 3.

A. R. Prabowo, D. M. Bae, J. M. Sohn, A. F. Zakki, B. Cao,

B., Q. Wang, 2018. AEJ 57, 3.

A. R. Prabowo, J. M. Sohn, D. M. Bae, A. F. Zakki, B. I.

Hasrianto, 2018. Curved and Layered Struct. 5, 1.

A. Windyandari, A. F. Zakki, 2018. MATEC Conf. 158.

A. Windyandari, H. Yudo, A. F. Zakki, 2018. ARPN JEAS

13, 6.

H. Yudo, A. Windyandari, A. F. Zakki, 2017. IJCIET 8, 8.

LSTC, LS-DYNA User’s Manual, 2009.

M. B. Ali, S. Abdullah, M. Z. Nuawi, and A. K. Ariffin,

2011. IOP Conf. MSE. 17.

M. Kh. Abunawas, 2010. Int. Jour. Comp. Sc. Net. Secur.

10, 5.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

148