Thermodynamic Analysis of Cascade Refrigeration System using

CO

2

– NH

3

Refrigerant for Fish Cold Storage Application

Nazaruddin Abubakar

1,

Sutopo Purwono Fitri

1

1

Department of Marine Engineering, Faculty of Marine Technology, Technology Institute of Sepuluh Nopember, Surabaya

Keywords: Thermodynamic, cascade, refrigeration, cold storage, CO2, NH3

Abstract: The adverse effects on the earth's atmosphere due to the use of non-environmentally friendly

refrigerants have increased significantly which has resulted in an increase in Ozone Depletion

Potential (ODP) and Global Warming Potential (GWP). This phenomenon encourages

industries to use natural alternative refrigerants such as ammonia (NH

3

) and carbon dioxide

(CO

2

). The application of a cascade refrigeration system that uses CO

2

refrigerant on the Low-

Temperature Circuit (LTC) and NH

3

on the High-Temperature Circuit (HTC) becomes an

excellent alternative to the application of fish freezing at low temperatures. In this paper, a

cascade refrigeration system with CO

2

working fluid on the LTC and NH

3

on the HTC have

been analyzed. Design and operation parameters considered in this study include evaporation

temperature, a temperature difference in the cascade heat exchanger, condensation

temperature, suction and discharge pressure on the system.

.

1 INTRODUCTION

Refrigeration systems have played a very important

role in everyday life. The development of technology

in the field of refrigeration provides many benefits for

human needs. In the industrial world, refrigeration

systems are used for the storage and distribution of

food ingredients, so that the quality and freshness can

be maintained for several weeks until the time they

are needed to be distributed to consumers. One type

of food product whose quality and freshness needs to

be maintained is fishery products.

Fishery products are food that is easily damaged.

Post-harvest handling greatly determines the quality

and durability of the fish. According to reference

(Handayani et al, 2014), basically, handling and

processing of fish aim to prevent damage or decay.

Efforts are being made to extend the duration of

storing fresh fish which is stored in cold storage.

Cold storage is a room that is used to store fishery

products that require cold temperatures. Cold storage

has a larger room size than other refrigerators with

room temperature ranging from 15

o

C to -45

o

C.

This very low temperature range can be met by a

one-level refrigeration system with one compressor,

many pressurized systems that use more than one

compressor such as multilevel refrigeration systems

and a combination of two or more single refrigeration

systems (cascade), where the first system is a

High-

Temperature Circuit (LTC)

and others as Low-

Temperature Circuit (LTC)

. A cascade refrigeration

system is the best way to get power savings and

increase the coefficient of performance (COP). The

advantages of the cascade refrigeration system can

still be enlarged to produce very low temperature

conditions and save power. One way is to use

different types of refrigerants on each circuit.

Environmental problems related to Ozone

Depletion Potential (ODP) and Global Warming

Potential (GWP) caused by the use of synthetic

refrigerants (CFC's, HCFC's and HFC's) that have

occurred in recent decades, makes the effort to reuse

natural substances as refrigerants are rational. This

will be a better solution for using environmentally

friendly substances as alternative refrigerants in

170

Abubakar, N. and Fitri, S.

Thermodynamic Analysis of Cascade Refrigeration System using CO2 – NH3 Refrigerant for Fish Cold Storage Application.

DOI: 10.5220/0008544101700175

In Proceedings of the 3rd International Conference on Marine Technology (SENTA 2018), pages 170-175

ISBN: 978-989-758-436-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

refrigeration systems (Dopazo et al, 2009). The

natural refrigerant is a substance that occurs through

a biochemical process and does not have an adverse

effect on the environment, but some of them have side

effects for users such as being exposed to high

toxicity and flammability. Natural refrigerants

commonly used are water, air, noble gases,

hydrocarbons, ammonia, and carbon dioxide.

As a natural refrigerant, ammonia is very suitable

to replace CFCs and HCFCs in modern refrigeration

systems. In terms of environmental aspects, ammonia

is the most acceptable refrigerant and a long-term

alternative, because its release into the atmosphere

has no impact on ozone depletion (ODP = 0) or

greenhouse effect (GWP = 0) (Jankovich & Osman,

2015). Whereas carbon dioxide has emerged as a

credible natural refrigerant to replace HFCs in retail

food applications. CO

2

is non-combustible and non-

toxic, it has no impact on ozone depletion (ODP = 0)

and negligible global warming potential (GWP = 1).

CO

2

has favorable thermophysical properties such as

high density, specific heat, volumetric cooling

capacity, latent heat and thermal conductivity

(Tsamos et al, 2017).

The application of natural refrigerants NH

3

and

CO

2

as working fluids in cascade refrigeration

systems is an excellent alternative to very low

temperature cooling applications. With a cascade

refrigeration system, NH

3

which is quite toxic will

separate from the cooling chamber so that it will

improve the safety of workers, property and

refrigerated products. The use of CO

2

is currently

well received in the industry and in large commercial

cooling systems where it is used as a refrigerant in the

NH

3

/CO

2

cascade refrigeration system with a

temperature range between -10ºC to -50ºC. CO

2

provides great electricity savings, excellent energy

efficiency, and has a good heat transfer coefficient.

Some researchers have evaluated the

thermodynamic performance of a cascade

refrigeration system. Getu and Bansal have

thermodynamically analyzed the cascade carbon

dioxide-ammonia refrigeration system (R744-R717)

to optimize the evaporation temperature of the R717

and its mass flow rate, which can provide a maximum

COP of the system (Getu & Bansal, 2008). Rawat et

al. analyzed thermodynamic cascade refrigeration

systems that use NH

3

on HTC and CO

2

on LTC, to

determine the effect of various types of design and

operating parameters which include condenser

temperature, evaporator temperature, coupling

temperature, compressor isentropic efficiency and

temperature difference in the cascade heat exchanger,

the influence of subcooling and superheating was also

investigated (Rawat et al, 2015). Messineo

thermodynamically analyzed the cascade

refrigeration system (R744-R717) based on operating

parameters, then the results were compared with the

thermodynamic analysis of a two-stage refrigeration

system using R404A refrigerant (Messineo, 2012).

However, there is still a lack of research analyzing the

effect of several operating parameters on the

coefficients of the performance of the system and the

work required by the compressor of each circuit.

Therefore, this study aims to analyze the effect of the

operating parameters of the cascade refrigeration

system on the COP cascade system and the work

required by the HTC and the LTC. The effect of

operating parameters on the mass flow rate of

refrigerant was also analyzed in this study.

2 SYSTEM DESCRIPTION

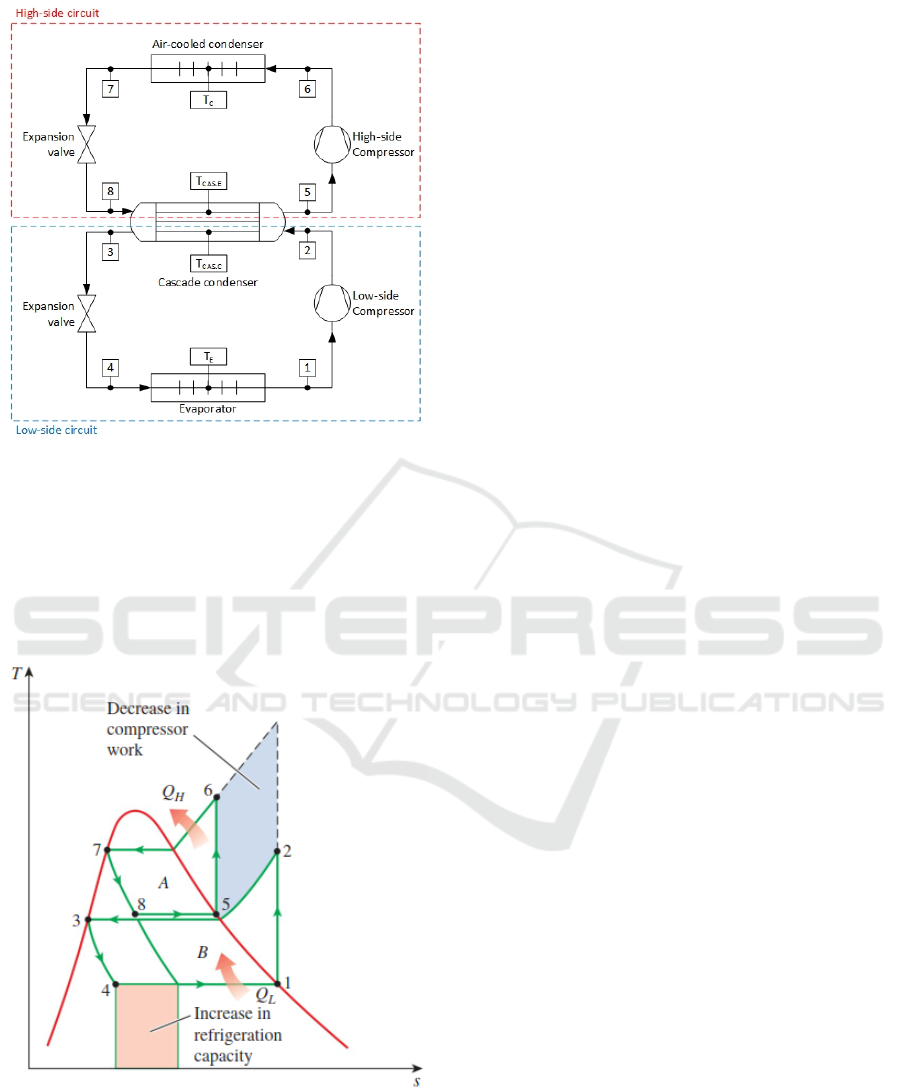

A schematic diagram of a cascade refrigeration

system for fish cold storage is shown in Figure 1.

This system consists of two units of vapor

compression refrigeration systems that work

separately with different refrigerants. The system

consists of several components such as a compressor,

evaporator, condenser, cascade condenser, cascade

evaporator, expansion valve, etc.

Low-Temperature Circuit (LTC) that using

Carbon dioxide as a refrigerant and High-

Temperature Circuit (HTC) that using Ammonia as a

refrigerant, are thermally connected by cascade heat

exchanger and it is assumed that the cascade heat

exchanger is perfectly insulated, kinetic energy and

potential is neglected. heat transfer from the fluid in

LTC must be the same as heat transfer to fluid on

HTC.

The Evaporator on HTC which has a relatively

higher temperature is used to absorb heat in the LTC

condenser so that the evaporator at LTC has a lower

temperature.

The cascade system is very effective when very

low temperature refrigeration is needed. The cascade

system allows the use of different refrigerants

depending on the work pressure and type of

compressor to be used.

Thermodynamic Analysis of Cascade Refrigeration System using CO2 – NH3 Refrigerant for Fish Cold Storage Application

171

Figure 1: Schematic diagram of a cascade refrigeration

system.

As shown in the T-s diagram in Figure 2, the

compressor's work decreases, and the amount of heat

absorbed from the refrigerated increases as a result of

cascading. Therefore, cascading improves the COP of

the refrigeration system.

Figure 2: Cascade refrigeration system cycles on T-s

property plots. [8]

3 NUMERICAL MODEL

3.1 Mathematical Modelling

The mathematical model of the cascade

refrigeration system has been designed to simulate

mass and energy balances on each one of the

components of the entire system.

Thermodynamic analysis of the cascade

refrigeration system is based on the assumptions

below:

1. The system is in a steady-state and steady-flow

state.

2. Changes in kinetic and potential energy are

negligible.

3. The compressor isentropic efficiency is constant.

4. The cascade heat exchanger and piping are

completely insulated.

Thermodynamic analysis of the cascade

refrigeration system in this study is based on the

cooling load (Q

E

) of cold fish storage that is equal to

76.21 kW, while for the operating parameters of the

designed cascade refrigeration system are as follows:

evaporator temperature (T

E

= -30

o

C),

condenser temperature (T

C

= 40

o

C)

and cascade condenser temperature (T

CAS

= -5

o

C).

The temperature difference in the cascade condenser

is assumed to be (ΔT

CAS

= 5 K).

3.2 Thermodynamic Analysis

Thermodynamic analysis of a cascade refrigeration

system has been carried out by simulating the

thermodynamic state of the refrigerant.

The thermophysical properties of Ammonia and

Carbon dioxide refrigerants are calculated using

software called Engineering Equation Solver (EES)

(EES, 2013), which has a property function of many

types of refrigerants.

Simulations of various design parameters such as

evaporator temperature, condenser temperature, and

cascade condenser temperature variations are carried

out with parametric table features that can perform

calculations quickly and accurately.

Based on the assumptions that have been made

previously, the following is a series of calculations

used for thermodynamic analysis of a cascade

refrigeration system.

SENTA 2018 - The 3rd International Conference on Marine Technology

172

The capacity of the evaporator is determined from:

𝑄

𝑚

ℎ

ℎ

(1)

Compressor power consumption for the HTC is

defined by:

𝑊

𝑚

ℎ

ℎ

(2)

Whereas for the LTC, it is defined by:

𝑊

𝑚

ℎ

ℎ

(3)

The rate of heat transfer in the cascade heat

exchanger is given by:

𝑄

𝑚

ℎ

ℎ

𝑚

ℎ

ℎ

(4)

The mass flow ratio can be derived from Eq. (4):

𝑚

𝑚

(5)

The rate of heat rejection by the condenser is defined

by:

𝑄

𝑚

ℎ

ℎ

(6)

The overall COP of the system is determined by:

𝐶𝑂𝑃

(7)

4 RESULT AND DISCUSSION

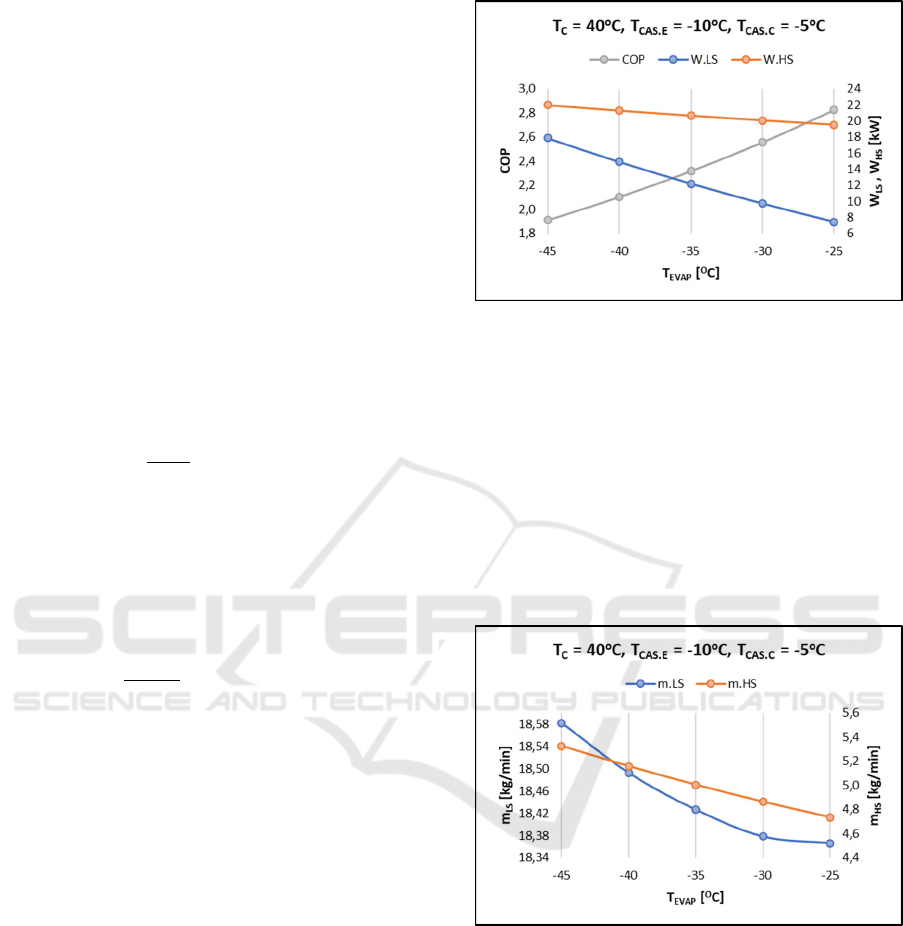

4.1 Effect of Evaporator Temperature

The temperature of the evaporator (T

E

) was varied

from -25

o

C to -45

o

C by keeping the condenser

temperature and the cascade condenser temperature at

the operating design parameters.

Figure 3. System performance and compressor work with

variations in evaporator temperature.

Figure 3 shows the effect of the evaporator

temperature change on the work required by LTC

compressor (W

LS

), HTC compressor (W

HS

) and the

coefficient of performance (COP) of the cascade

refrigeration system.

As the evaporator temperature increases, the COP

of the system increases significantly, therefore the

work required by the LTC compressor decreases

significantly, but the work required by HTC

compressor is only slightly decreased.

Figure 4. Mass flow rate of refrigerant with variations in

evaporator temperature.

The effect of the temperature change of the

evaporator on the mass flow rate on the LTC and HTC

is described in Figure 4.

As the evaporator temperature increases, the mass

flow rate of the refrigerant on HTC decreases

constantly and significantly, while the mass flow rate

on the LTC initially decreases significantly but then

decreases slightly.

Thermodynamic Analysis of Cascade Refrigeration System using CO2 – NH3 Refrigerant for Fish Cold Storage Application

173

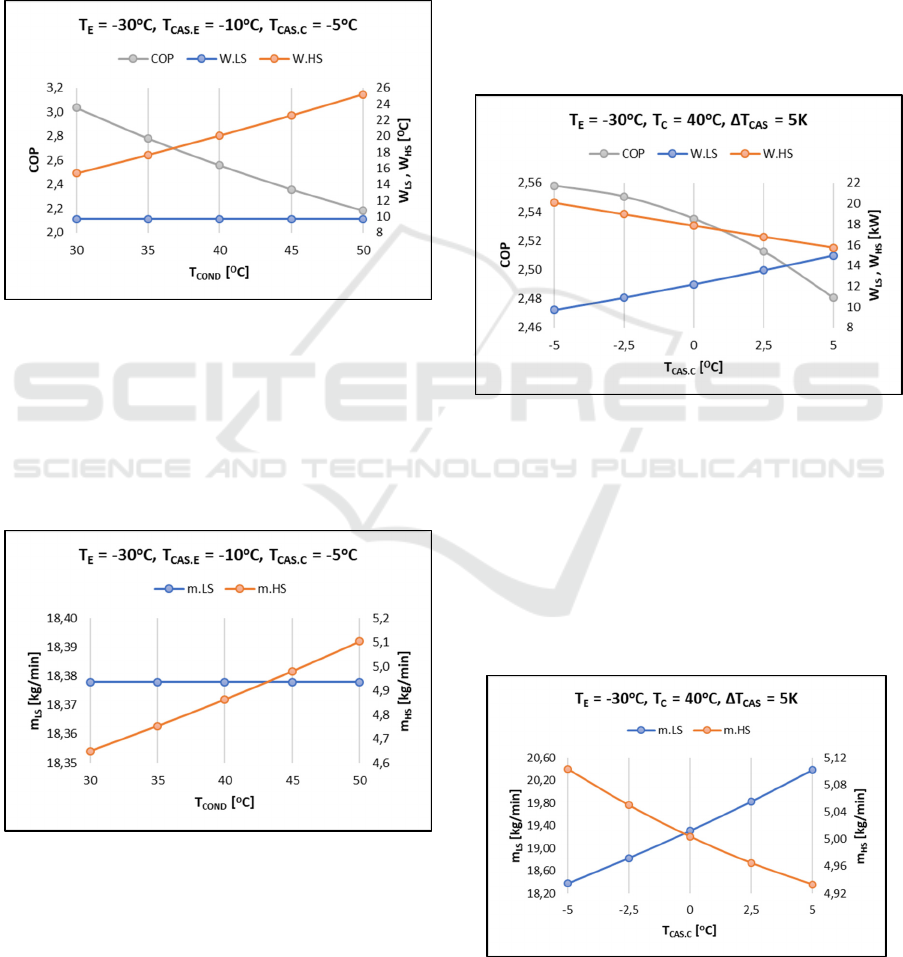

4.2 Effect of Condenser Temperature

The temperature of the condenser (T

C

) was varied

from 30

o

C to 50

o

C by holding the evaporator

temperature and the cascade condenser temperature at

the operating design parameters.

The effect of the condenser temperature changes

on the work required by the LTC compressor and the

HTC compressor has been analyzed (see Figure 5).

Figure 5: System performance and compressor work with

variations in condenser temperature.

As the condenser temperature increases, the work

required by the HTC compressor increases

significantly, while the COP of the cascade system

decreases significantly, while the condenser

temperature changes have no effect on the work

required by the LTC compressor.

Figure 6: Mass flow rate of refrigerant with variations in

condenser temperature.

Figure 6 shows the effect of changes in the

temperature of the condenser on the mass flow rate on

the LTC and the HTC.

The mass flow rate of refrigerant on the HTC

increases significantly as the condenser temperature

increases, while the mass flow rate of refrigerants on

the LTC is not affected by changes in condenser

temperature

4.3 Effect of Cascade Condenser

Temperature

The temperature of the cascade heat exchanger (T

CAS

)

has varied from 5

o

C to -5

o

C by keeping the

temperature of the evaporator and the condenser

temperature at the operating design parameters.

Figure 7: System performance and compressor work with

variations in cascade condenser temperature

The effect of changes in the cascade heat

exchanger temperature on the work required by the

LTC compressor and the HTC compressor illustrated

in Figure 7. The results show that as the cascade heat

exchanger temperature increases, the work required

by the LTC compressor increases, while the work

required by HTC compressor tends to decrease.

therefore, the cop of the cascade system decreases.

Figure 8: Mass flow rate of refrigerant with variations in

cascade condenser temperature.

SENTA 2018 - The 3rd International Conference on Marine Technology

174

The effect of the cascade condenser temperature

changes on the mass flow rate is shown in Figure 8.

As the cascade condenser temperature increases, the

mass flow rate on the LTC increases while the mass

flow rate on the LTC decreases.

5 CONCLUSIONS

In this study, thermodynamic analysis of the cascade

refrigeration system presents the use of Carbon

dioxide (CO

2

) on the LTC and Ammonia (NH

3

) on

the HTC. This analysis leads to the following

conclusions:

1. An increase in the temperature of the evaporator

produces an increase in the COP and decreases

both the work required by the compressor and

the mass flow rate.

2. An increase in condenser temperature results in

a decrease in COP and an increase in the mass

flow rate and work required by the compressor

on the HTC.

An increase in the cascade heat exchanger

temperature results in an increase in the mass flow

rate and work required by the compressor on the LTC

but decreases the mass flow rate and the work

required by the compressor on the HTC. Therefore,

the COP cascade system tends to decrease.

REFERENCES

Bansal, P. K. & Getu, H. M., 2008. Thermodynamic

analysis of an R744–R717 cascade refrigeration

system, Volume 31, p. 45–54.

Cengel, Y. A. & M. A. Boles, 2015. An Engineering

Approach. 8th ed. McGraw-Hill Education. New York.

Dopazo, J. A., Fernandez-Seara, J., Sieres, J., Uhia, F. J.,

2009. Theoretical analysis of a CO2–NH3 cascade

refrigeration system for cooling applications at low

temperatures, 29(8–9), p. 1577–1583.

EES., 2013. Engineering Equation Solver, s.l.: fChart

Software Inc.

Handayani, A., Alimin, A., Rustiah, W. O., 2014. Effect of

Storage at Low Temperature (Freezer -3oC) on Water

Content and Fat Content in Lemuru Fish (Sardinella

longiceps), 2(1), p. 64–75.

Jankovich, D. & Osman, K., 2015. A feasibility analysis of

replacing the standard ammonia refrigeration device

with the cascade NH3/CO2 refrigeration device in the

food industry, 19(5), p. 1821–1833.

Messineo, A., 2012. R744-R717 cascade refrigeration

system: performance evaluation compared with a HFC

two-stage system. s.l., s.n.

Rawat, K. S., Kshetri, R., Khulve, H., Pratihar, A. K., 2015.

Parametric study of R744-R717 cascade refrigeration

system, Volume 2.

Tsamos, K. M., Y. T. Ge., Santosa, I., Tassou, S. A.,

Bianchi, G., Mylona, Z., 2017. Energy analysis of

alternative CO2 refrigeration system configurations for

retail food applications in moderate and warm

climates, p. 822–8.

Thermodynamic Analysis of Cascade Refrigeration System using CO2 – NH3 Refrigerant for Fish Cold Storage Application

175