Mechanical Properties Analysis of Slats Inter-lay Joint Gap of

Bamboo Laminates for Fishing Boat Construction

Heri Supomo

1

, Eko Budi Djatmiko

2

, Achmad Zubaydi

1

and Setyo Nugroho

3

1

Department of Naval Architecture, Faculty of Marine Technology, Institut Teknologi Sepuluh Nopember (ITS), Jl. Arief

Rahman Hakim, Surabaya, Indonesia

2

Department of Ocean Engineering, Faculty of Marine Technology, Institut Teknologi Sepuluh Nopember (ITS), Jl. Arief

Rahman Hakim, Surabaya, Indonesia

3

Department of Sea Transportation, Faculty of Marine Technology, Institut Teknologi Sepuluh Nopember (ITS), Jl. Arief

Rahman Hakim, Surabaya, Indonesia

Keywords: Laminated Bamboo Slats, Fishing Boat Construction, Bamboo Slats Interlay Joint Gap, Mechanical

Properties.

Abstract: Today, the use of laminated bamboo as a ship construction material is increasing. With the limited length of

bamboo stems, it is not possible to make a component of a ship construction without a blade connection. This

bamboo slat interlay joint gap greatly determines the mechanical properties of the bamboo laminate formed.

Thus, the bamboo slat interlay joint gap needs to be examined so as to obtain a minimum limit that meets the

requirements of the construction strength of the Indonesian classification bureau (BKI). This writing will

focus on the effect of Bamboo slat interlay joint gap as a function of the thickness of the blade (t) on tensile

strength, flexural strength and modulus of elasticity. These three mechanical properties are a requirement in

determining the strength of a ship's construction material. The bamboo material studied for the construction

of a fishing vessel is bamboo ori (Bambusa Arundinacea). The testing standards used are ASTM D3500 (Pull)

and ASTM D3043 (Flexure). In accordance with the results of specimen testing and the requirements of BKI

vol: vii 2013, the mechanical properties of tensile strength, flexure strength and modulus of elasticity that

fulfill the conditions are the specimen with a variation of slats interlay joint gap ≥10t.

1 INTRODUCTION

Solid wood is the main raw material in traditional

fishing boats in Indonesia, but now the availability of

solid wood is increasingly difficult to obtain. The

scarcity of solid wood is caused by uncontrolled

illegal logging, according to the Ministry of Forestry

of the Republic of Indonesia, forest destruction in

2012 reached more than 1.08 million hectares per

year (Wibowo & Gintings, 2010). On the other hand,

to obtain wood that meets construction standards, it

takes a very long time, as well as the time of planting,

so that it can be used as raw material for construction

of fishing boats that take around 30-40 years

(Budyatmojo, 2013). Therefore, an alternative

material is needed for wood substitution which has

several criteria for its application: a short regeneration

period, renewability and a more practical processing

(Supomo, 2016).

Figure 1: Bamboo forests in Mojokerto district.

To provide alternative solutions, laminated

bamboo can be used as a consideration for solid wood

replacement materials for the construction of fishing

vessels. Bamboo is a type of grass plant that has a

relatively very fast regeneration rate and shorter

harvesting age compared to other types of solid wood

126

Supomo, H., Djatmiko, E., Zubaydi, A. and Nugroho, S.

Mechanical Properties Analysis of Slats Inter-Lay Joint Gap of Bamboo Laminates for Fishing Boat Construction.

DOI: 10.5220/0008543501260133

In Proceedings of the 3rd International Conference on Marine Technology (SENTA 2018), pages 126-133

ISBN: 978-989-758-436-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(Khotimah & Sutiono, 2014). For more details, the

availability of bamboo can be seen in Figure 1, which

is one of the bamboo forests in Mojokerto, East Java.

Utilization of bamboo as an alternative fishing boat

construction is carried out The use of bamboo as an

alternative fishing boat construction is done by using

special gluing techniques into one unit which is called

laminated bamboo (Sharma, et al., 2015).

Several studies on the mechanical properties of

laminated bamboo with various types of bamboo have

been written. From the results of their research it has

been proven that bamboo is a very good material for

construction (Sharma, et al., 2015; Huang, et al.,

2017; Jakovljević, et al., 2017; Nurdiah, 2016;

Sharma, et al., 2015). In addition there are several

studies that have produced several outcomes in the

form of bamboo strength standards for building

construction. Some of these writings include: (Raj &

Agarwal, 2014; Gatóo, et al., 2014; Xiao, et al.,

2010). However, related to the bamboo interlay joint

gap bar, this has never been tested and there is no

standard that can be called for the application of

laminated bamboo for construction. So there is no

guidence to apply the blade connection between

layers in bamboo laminate.

Variation testing of bamboo slats interlay joint

gap needs to be tested for its effect with mechanical

properties. The distance of the inter-layer blade joints

greatly determines the strength and size of the fishing

vessel construction components. Blade connections

are very necessary because besides bamboo it has

advantages: easy to cultivate, sustainable, renewable,

high producability, besides that bamboo also has a

limited length of stem (Supomo, et al., 2015).

The length of betung bamboo stems (Dendro

Calamus Asper) which can be used as construction

material is between 9m to 12m. While the type of

bamboo ori (Bambusa Arundinacea), the length of the

stem that can be used for construction is only 6m to

8m. To make laminated bamboo, the bamboo blades

used must be perfectly straight. The perfect alignment

of the blade can only be obtained if the length is about

2m, width (25-30) mm and thickness (3-5) mm. Thus

to make construction components - especially fishing

vessels made from bamboo laminate, it is necessary

to connect the blades to each layer (Supomo, et al.,

2018).

With a minimum limitation of tensile strength and

flexural strength - in accordance with BKI regulations

2013 regarding small vessels L ≤ 24m, the influence

of blade joints between layers on bamboo laminate

material needs to be tested and analyzed. So that the

results of this study will be able to provide a reference

in fabricating fishing boat components.

2 METHOD

2.1 Preparation of Bamboo Slats

The basic material used in this study is bamboo Ori

(Bambusa Arundinacea). This is because this type of

bamboo is very abundant in terms of availability. To

facilitate the fabrication process, the bamboo to be cut

down must have several criteria, namely: the age of

bamboo is at least 3 years, bamboo stems are sought

as straight as possible without extreme curves.

Besides that bamboo sticks also have water content

below 50% (Khotimah & Sutiono, 2014; Sharma, et

al., 2015; Jakovljević, et al., 2017; Sá Ribeiro, et al.,

2016).

Selected bamboo stalks then cut to a length of 2m,

divided into sections with a width of blades (3-4) cm.

Bamboo that has been cleaved is then preserved by

immersion in a tub containing a mixture of clean

water and 25% borax solution, 20% salt and 10%

Ureum. The preservation process is carried out for a

minimum of 7 days. This soaking is done so that the

bamboo material that is ready to be used for the test

material is free from destructive pests. Bamboo is

then left in the open without being exposed to direct

sunlight for two days for the drying process (Huang,

et al., 2017; González & Gutiérrez, 1995). This

bamboo blade illustration can be seen in Figure 2.

Figure 2: Bamboo slats before flattening.

The next process is thick leveling using a Single

Planar Auto engine. In this process the bamboo slats

should be leveled up and down. Bamboo blades are

then cut into 500 mm lengths for tensile test

specimens and 700 mm for bending test specimens.

The cutting process can use a jig saw or disc saw

machine manually. Bamboo blades that have been cut

500 mm and 700 mm are then flattened on each side

Mechanical Properties Analysis of Slats Inter-Lay Joint Gap of Bamboo Laminates for Fishing Boat Construction

127

with hand planar tools. This process is carried out so

that the bamboo blades are really precise, both left

and right and top-down so that the final dimensions

of the slats can be obtained with sizes (500 x 30 x 5)

mm and (700 x 30 x 5) mm. Bamboo skin and fine

powder left as a result of the fabrication process is

very resistant to the adhesive, so before being formed

into laminated bamboo boards, it must be cleaned

using a knife or cutter and scouring paper. For more

details, bamboo blades that have been plannered and

ready to be laminated can be seen in Figure 3.

Figure 3: The Flattened Bamboo slats.

2.2 Preparation of Test Specimens

Bamboo blades that have been flattened on all sides

are then arranged so that the size of the thickness

matches the standard. To do the tensile and flexure

tests on this laminated bamboo, the arrangement is

done with variations of slats interlay joint gap. This is

intended to obtain the level of influence of interlay

joint gap on the tensile strength and flexure of

laminated bamboo. Blade interlay joint gap are made

with 5 variations: 1t, 3t, 5t, 8t, 10t, where t: thick

bamboo slats.

Figure 4: Bamboo laminate board.

Laminated bamboo boards for tensile tests

measuring 500 x 250 x 28 (mm) and for bending tests

have a size of 700 x 250 x 28 (mm). Laminated beams

that have been arranged are then cut back in

accordance with the variation of the bamboo slat

intersection distance between layers. This laminated

bamboo board picture can be expressed in Figure 4.

After the arrangement of the bamboo blades is in

accordance with the specimen testing design, the next

step is to glue them with epoxy polyamide marine use

EWA135. The process of gluing and pressing

bamboo laminates takes 3 hours to get laminated

bamboo with perfect adhesion. The laminate board is

then cleaned from the rest of the sticking paper and

excess adhesive using a planar machine and

sandpaper. Finally, the laminate bamboo board is

formed into test specimens with dimensions that refer

to ASTM D3043 standard for tensile testing and

ASTM D3500 for bending test. The total number of

specimens for all tests is 5 (blade joint variation) x 4

(test) x 2 pieces (pull & flexure) = 40 pieces. For more

details the size and shape of the test specimen can be

selected in Figure 5 (tensile) and Figure 6 (flexure).

Figure 5: Dimension of the specimen for tensile test.

Figure 6: Dimension of the specimen for flexure test.

2.3 Testing

Specimens that have been prepared are then tested

according to the mechanical properties required by

BKI. This tensile and flexural testing process uses

UTM (Universal Testing Machine). Tests were

carried out to find out the strength of each material

with a variety of bamboo slats interlay joint gap

which is a multiple of bar thickness (t). From the

tensile test, a load vs strain graph is produced, while

in flexural testing, a load vs deflection graph is

created.

Tensile and bending tests were carried out in

accordance with the standards of ASTM D3500 and

D3034 using UTM (Universal Testing Machine) with

the specifications described in Table 1. Figure 7

SENTA 2018 - The 3rd International Conference on Marine Technology

128

shows the tensile strength test of Bambusa

Arundinacea using UTM. For this flexural test, the

application of a load of 20 kN and 2 mm / minute is

applied. Figure 8 illustrates the flexural strength test

on the same material also using UTM.

Table 1: Process Used to Evaluate Tensile and Flexure

Strength.

Mechanical

Properties

Capacity Cross head

speed

(mm/min)

Tensile UTM

MFL/UFD.20kN up

to 200 kN

2 - 3

Flexure

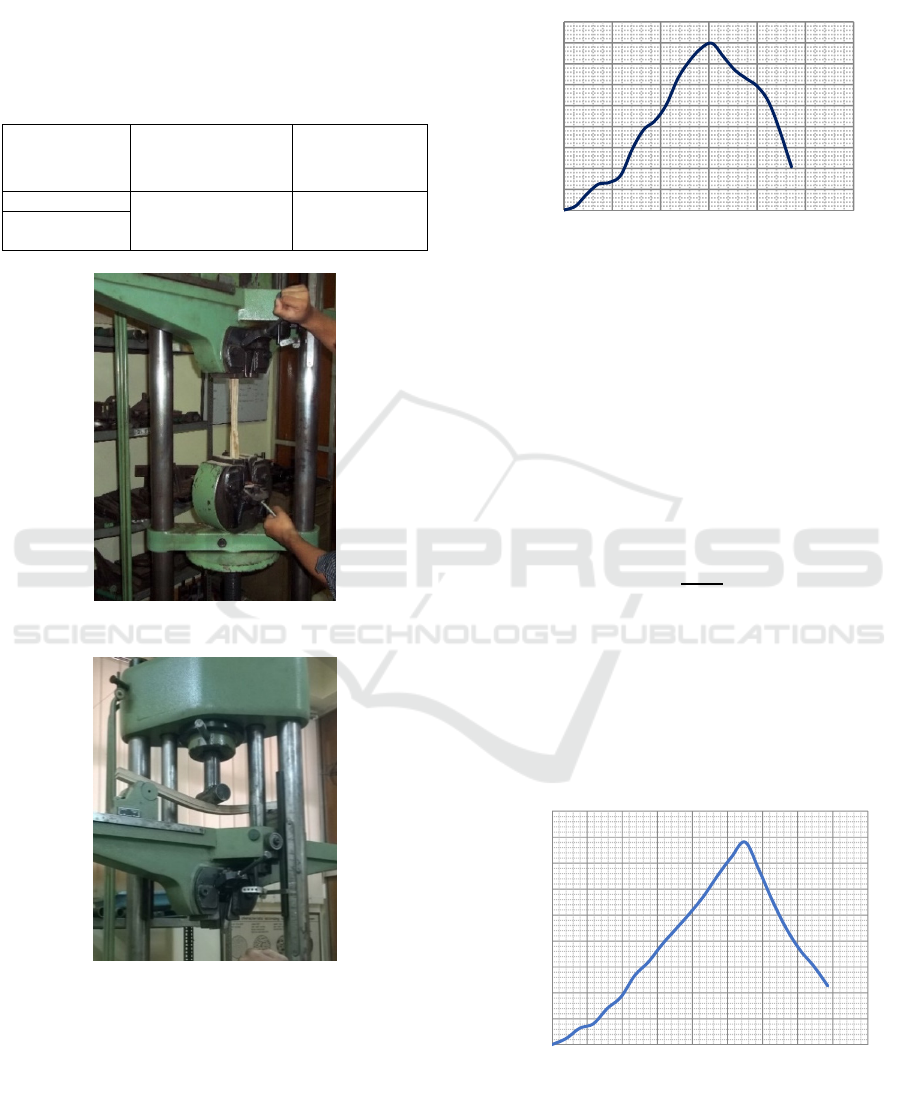

Figure 7: Tensile Test Process.

Figure 8: Flexure test process.

Tensile testing results for each specimen with

bambbo slats interlay joint gap variations is a graph

of load vs. elongation. This curve must be converted

into a graph tensile strength vs. strain. This

conversion graph of (5t) variation of bamboo slats

interlay joint gap can be seen in Figure 9. According

to the graph, it can be explained that for variation (5t)

the tensile strength is close to the value of 40MPa

with a strain of 15%. All test pieces will be calculated

and illustrated by the curve.

Figure 9: Graph of tensile test results (specimen with

variation of slats interlay joint gap 5t).

As for flexure testing, the graph obtained is a load

vs. deflection curve. Each coordinate point on the test

results diagram needs to be calculated using the

ASTM D3034 standard formula. The MOR value is

obtained from the calculation of the flexural strength

of the bamboo laminated beam that is given a

centered load (P) in the middle of the span (L) using

the formula:

3

2

(1)

Where the MOR is the Flexure strength of the

laminated beam tested (Mpa), the length of the span

of the beam L (mm), the width of the beam b (mm)

with the height of the beam h (mm). The centered load

given to the beam is represented by P (N). From this

calculation, a graph of variation joint (8t) is obtained

and can be shown in Figure 10.

Figure 10: Graph of Flexure test results (specimen with

slats interlay joint gap variation of 8t).

0

5

10

15

20

25

30

35

40

45

0 5 10 15 20 25 30

Tensile Strength (MPa)

Strain [%]

0

10

20

30

40

50

60

70

80

90

0 5 10 15 20 25 30 35 40 45

Flexure Strength (MPa)

Deflection [mm]

Mechanical Properties Analysis of Slats Inter-Lay Joint Gap of Bamboo Laminates for Fishing Boat Construction

129

From tensile and flexure graphs for all test

specimens, then tabulated and taken the maximum

mechanical properties of each test specimen. Each

tensile and flexure values are then grouped according

to the variation of slats interlay joint gap starting from

(t) up to (10t).

In addition to the modulus of elasticity (MOE)

bamboo laminated will be calculated according to the

formula ASTM D3034. This is intended to obtain the

MOE value perpendicular to the bamboo fiber that

meets the regulatory requirements.

2.4 Analysis of Test Results

The tensile, flexural strength and modulus of

elasticity (MOE) values were then averaged for all the

results of the laminated bamboo specimens. The

average value of all testing within a variation of the

bamboo slats interlay joint gap of 1t, 3t, 5t, 8t and 10t.

This mean value is then displayed in the graph of the

tensile, flexure strength, and modulus of elasticity.

Furthermore, it is matched with the curve trend in

each graph, compared to the BKI vol permit limit: vii,

2013 regarding L Small Ship ≤ 24 m as a requirement

for fishing vessel construction material.

3 RESULT AND DISCUSSION

3.1 Tensile Strength

From the results of tensile testing with variations of

slats interlay joint gap (t) up to (10t), with each

amounting to 4 specimens, the average values are as

shown in Table 2. It can be seen the tensile strength

value of each bamboo slats interlay joint gap

variation, then be analyzed to determine the

relationship between tensile strength and joint gap

variation. This variation is a multiple of the thickness

of the blade (t). The level of correlation greatly

determines the test results.

Table 2: The Average Value of Tensile Testing Results.

Specimen

No.

Interlay Joint Gap - (Mpa)

t 3t 5t 8t 10t

1 19.44 27.87 42.51 61.43 72.67

2 17.63 33.54 47.33 62.25 73.80

3 20.57 31.58 45.13 66.17 73.19

4 19.12 24.79 44.63 60.58 78.11

Average

19.19 29.44 44.90 62.61 74.44

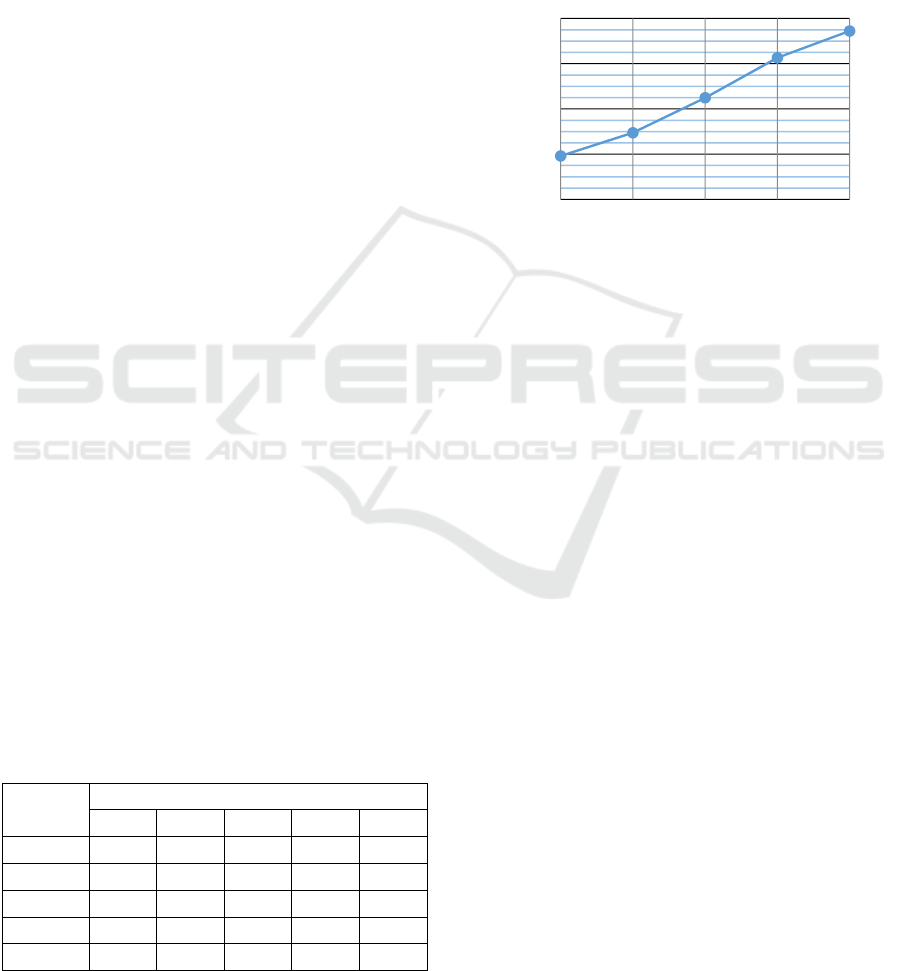

In Figure 11 it can be seen that there is an increase

in the average value of a significant tensile strength

from the variation of the joint gap interlay 3t to 5t.

Whereas from 8t to 10t, it increased but slightly

sloping. Even so, in Figure x9 it can be explained

from the graph that the average tensile strength value

is increasing along with the addition of bamboo slats

interlay joint gap. Based on Figure 1, the tensile

strength after the 10t variation always increases until

reaching the maksimum value of bamboo laminated

without interlay joint.

Figure 11: Tensile strength vs slats interlay joint gap.

Thus, according to Figure 11, it can be stated that

the longer the bamboo blade joint distance on a

laminated bamboo material, the higher the tensile

strength produced. Whereas the shorter the bamboo

blade connection distance in a laminated bamboo

material, the lower the tensile strength produced. The

magnitude of the tensile strength value is one of the

requirements for the use of material for the

construction of a fishing boat, according to the

Indonesian classification bureau regulations.

3.2 Strain

Although strains are not a basic requirement for

material properties that must be fulfilled according to

BKI, this is very influential on changes in shape when

the vessel receives more load. Therefore in the

process of strain testing must be considered in

applying bamboo laminate as a fishing boat

construction material.

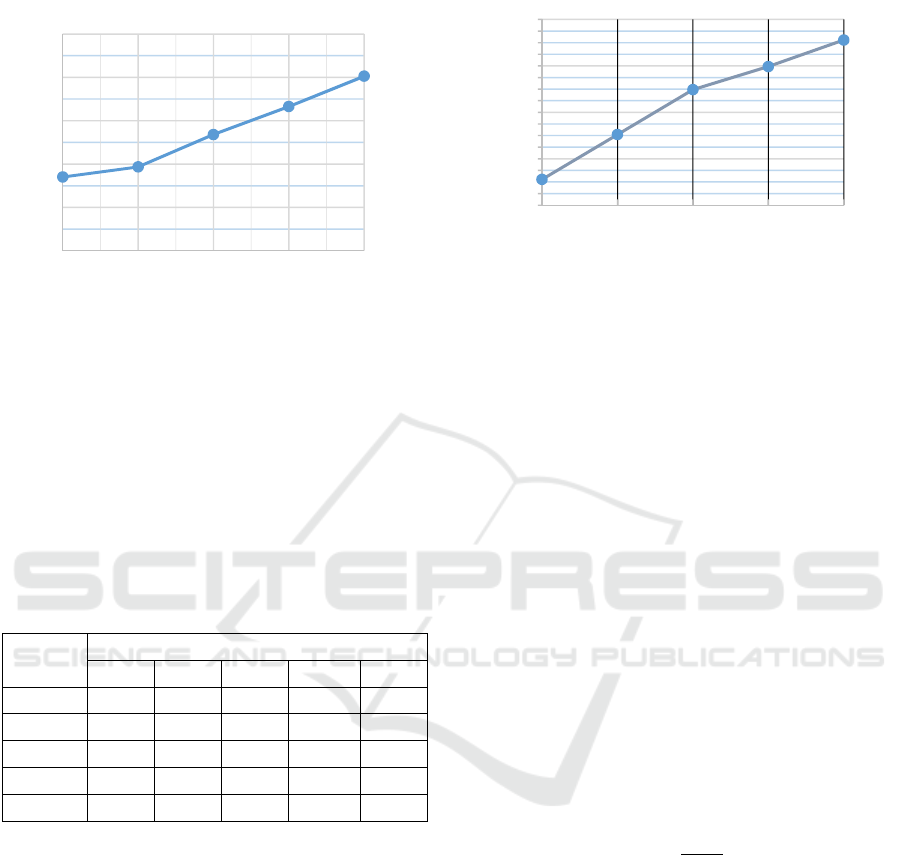

In accordance with the results of the tensile test

experiment, the average value of the strain as

illustrated in Figure 12 are carefully obtained. In the

strain chart it can be said that with the variation of

slats interlay joint gap (t) to (3t), the addition of the

strain value is very small. However, starting from

variations (5t) to (10t) these values increase

significantly. Thus, by increasing slats interlay the

joint gap, the bamboo lamination material will be

more stable to accept the load without experiencing

0

20

40

60

80

t 3t5t8t10t

Average Tensile Strength (MPa)

Bamboo slats interlay joint Gap

t: Slats thickness

SENTA 2018 - The 3rd International Conference on Marine Technology

130

damage. The characteristics of the bamboo blade

laminated strain will complement other properties as

a consideration to be used to make a fishing vessel.

Figure 12: Strain Comparison Chart of Connection gap.

3.3 Flexure Strength

Tabulation of the average value of flexure testing

with variations in bamboo blade connection distance

can be seen in Table 3. From this value, an analysis

was then performed to determine the effect of

bamboo blade connection gap between layers in

flexure testing.

Table 3: The Average Value of Flexure Test Results.

Specimen

No.

Interlay Joint Gap - MPa (t: Slats thickness)

t 3t 5t 8t 10t

1 10.800 30.672 55.296 62.640 70.416

2 12.096 33.264 51.840 58.320 74.736

3 10.800 28.080 42.336 56.160 66.960

4 10.800 29.808 49.680 61.776 72.576

Average

11.124 30.456 49.788 59.724 71.172

Furthermore, the flexure strength average value in

Table 2 is plotted in graphical form to determine the

effect of blade interlay joint distance with flexure

strength of bamboo lamination. So the graph of the

relationship between flexure strength and the

variation of slat interlay joint gap can be seen in

Figure x11.

According to the curve in Figure 13, it can be said

that the increase in slides interlay joint gap will

increase the flexure strength value. Gradient increase

in flexure strength from variation (t) to (5t) can be

thought to be extreme (mean: 19.332 MPa), whereas

from (5t)to (10t), the addition of flexure strength is

somewhat reduced (average: 9.936 MPa). If the slats

interlay joint gap is added continuously, then there is

a possibility that flexure strength will also increase

until it equals the strength value of flexure bamboo

lamination without connection (= 111.56 MPa).

Figure 13: Flexure strength versus slats interlay joint gap.

3.4 Modulus of Elasticity

Modulus of elasticity (MOE) is one of the mechanical

properties of fishing vessel construction materials

required by BKI. Therefore, in making bamboo blade

lamination, the joint gap must be carefully monitored

so that the elasticity of the bamboo laminate material

meets the requirements of BKI.

In accordance with the experiments that have been

carried out (tensile and flexure tests), the modulus

elasticity value has been calculated for each slats

interlay joint gap variation (t) to (10t). In the tensile

test, MOE value is done in direction of parallel to

bamboo fiber, whereas for flexure test, the value of

MOE is perpendicular to the bamboo fiber path. In

making the construction of a fishing vessel made

from bamboo laminate, the MOE that needs to be

considered is perpendicular to the direction of the

bamboo fiber. The calculation of the MOE value is

using the equation :

4

8

(2)

MOE (GPa) is the elastic modulus of laminated

bamboo beams perpendicular to its fiber (Gpa), P (N)

is the maximum load, while the spacing of L (mm), I

is the moment of inertia from the cross section of the

tested specimen, while deflection is denoted δ ( mm).

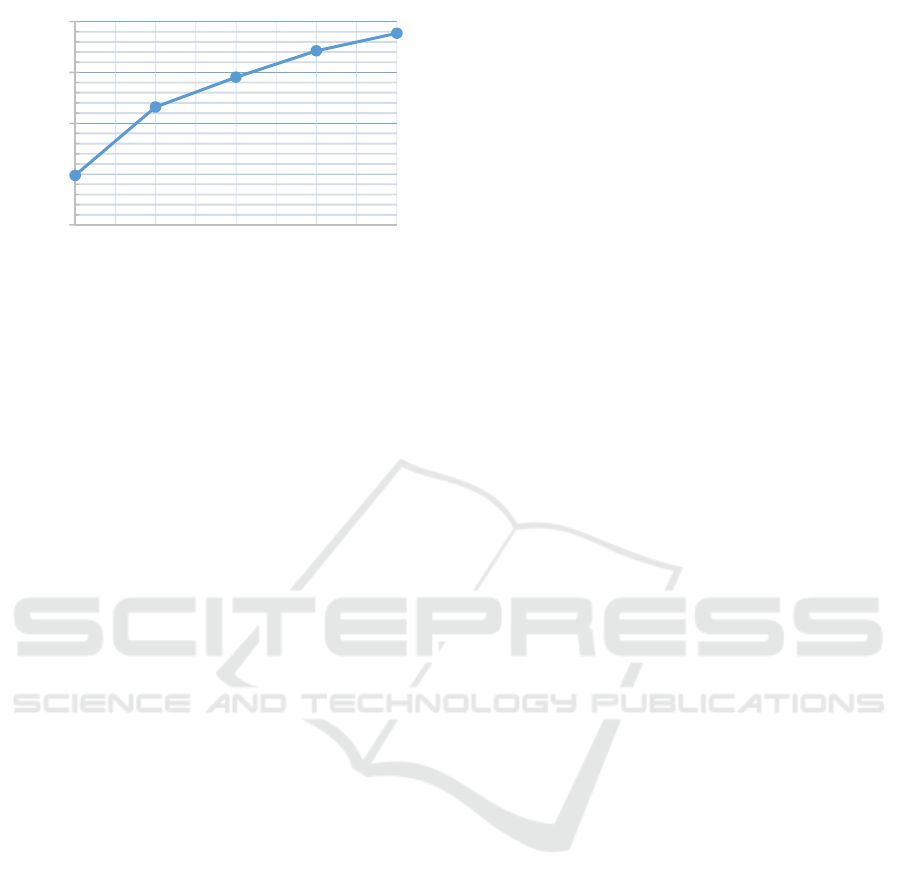

From the value of this calculation, the MOE value

and its correlation with the slats interlay joint gap

factor are obtained graphs as shown in Figure 14.

0

10

20

30

40

50

t 3t5t8t10t

Strain (%)

Bamboo slats interlay joint Gap

0

20

40

60

80

t 3t 5t 8t 10t

Flexure Strength (MPa)

Bamboo slats interlay joint Gap

Mechanical Properties Analysis of Slats Inter-Lay Joint Gap of Bamboo Laminates for Fishing Boat Construction

131

Figure 14: MOE versus slats interlay joint gap.

In the variation between (t) to (3t), the MOE value

has increased dramatically by 6.72GPa. However,

starting from variations (5t) to (10t), the increase was

rather gradual, ie. an average of 2.42 GPa. MOE

values that meet BKI requirements are ranging from

variations of 5t to 10t. However, this still has to be

considered with other mechanical characteristics and

provisions.

3.5 Material Requirements for Ship

Construction

According to BKI in 2013 concerning Small Vessels

≤ 24, plywood or laminate used as a whole

construction material must have tensile strength

greater than 42.169 MPa, whereas based on the test

results, the tensile strength that meets the

requirements is bamboo slats interlay joint gap

variation of 5t, where the tensile strength is 44,244

MPa. So for the tensile strength value, which meets

BKI regulations as a fishing vessel construction

material is a variation of ≥(5t).

As for the flexure strength required is the Strong

Class III, which is a minimum of 71,098 Mpa. In

accordance with the test results, flexure strength

values that meet the minimum requirements are (10t)

variation, which is 71.172 MPa. So that for the

flexure strength value, which meets the requirements

of BKI so that it can be used as a ship construction

material is the variation of (10t).

The modulus of elasticity required in the rules of

classification is 6.68 Gpa. Based on the results of

testing with a variety of bamboo-slats interlay joint

gap (3t), this test gives MOE results of 11.59 Gpa.

However, each of these test results cannot stand alone

as a precondition for fishing vessel construction

material. These three mechanical properties as a

whole must meet the minimum limits stated in the

BKI rules.

Thus, based on the results of testing in this study,

bamboo slats interlay joints gap that can be accepted

as requirements for fishing vessel construction

materials, according to BKI vol rules: vii 2013, is a

variation of ≥10t, (t: thickness of bamboo slat).

4 CONCLUSIONS

Based on the results of testing, analysis and

discussions that have been carried out, the following

conclusions can be drawn:

Bamboo lamination material is very limited by

the size of the blade naturally, so that a

connection is needed to make a component of

ship construction with a certain size.

In laminated bamboo, tensile strength, flexural

strength and modulus elsticity are directly related

to bamboo slats interlay joint gap, where the

longer the connection distance, the greater the

tensile strength, flexural strength and MOE.

Based on the minimum material stress in

accordance with BKI vol: vii, 2013 concerning

Small Vessels, 24 meters, each mechanical

properties that meet the requirements are: tensile

strength = 42.169 MPa, strong flexure = 71.098

MPa, and MOE = 6.86 GPa. From the results of

testing the laminated bamboo with variations in

blade joint spacing, which meets the regulations

as a fishing vessel construction material is slats

inter-lay joint gap > (10t).

ACKNOWLEDGEMENTS

A big thank you to some students who have been

diligently helping this research. To my wife and 3

children, I express my highest appreciation for the

moral support with patience until the completion of

this writing and also all supporting in which has been

given so that this research can be completed without

significant constraints.

REFERENCES

Budyatmojo, W., 2013. Penegakkan Hukum Tindak Pidana

Illegal Loging (Antara Harapan dan Kenyataan).

Yustisia. Yogyakarta.

Gatóo, A. et al., 2014. Sustainable Structures: Bamboo

Standards and Building Codes. Proc. Inst. Civ. Eng. -

Eng. Sustain.

0

5

10

15

20

t 3t 5t 8t 10t

Modulus of Elasticity (GPa)

Bambbo Slats interlay joint gap (xt)

SENTA 2018 - The 3rd International Conference on Marine Technology

132

González, T. & Gutiérrez, J. A., 1995. “Bamboo

preservation at the Costa Rican National Bamboo

Project,”. The Vth International Bamboo Workshop

and the IVth International International Bamboo

Congress. Ubud, Bali, Indonesia.

Huang, Z., Sun, Y. & Musso, F., 2017. Assessment of

Bamboo Application in Building Envelope by

Comparison with Reference Timber. Construction and

Building Materials.

Jakovljević, S., Lisjak, D., Alar, Ž. & Penava, F., 2017. The

Influence of Humidity on Mechanical Properties of

Bamboo for Bicycles. Construction and Building

Materials.

Khotimah , H. & Sutiono, 2014. Analisis Kelayakan

Finansial Usaha Budidaya Bambu. Jurnal Ilmu

Kehutan.

Nurdiah, E. A., 2016. The Potential of Bamboo as Building

Material in Organic Shaped Buildings. Social and

Behavioral Sciences.

Raj, A. D. & Agarwal, A. B., 2014. Bamboo as a Building

Material. Journal of Civil Engineering, Envireonment

and Technology.

Sá Ribeiro, R. A., Sá Ribeiro, M. G., Sankar, K. & Kriven,

W. M., 2016. Geopolymer-Bamboo Composite – A

Novel Sustainable Construction Material. Constr.

Build. Mater.

Sharma, B., Gatóo, A., Bock, M. & Ramage, M., 2015.

Engineered Bamboo for Structural Applications.

Construction and Building Materials.

Sharma, B., Gatóo, A. & Ramage, M. H., 2015. Effect of

Processing Methods on the Mechanical Properties of

Engineered Bamboo. Construction and Building

Materials.

Supomo, H., 2016. Studi Penggunaan Bambu sebagai

Material Alternatif untuk Bahan Pembuatan Kapal

Ikan dengan Metode Cold Press Planking System,

Program Pasca Sarjana ITS. Surabaya.

Supomo, H., Djatmiko, E. B. & Zubaydi, A., 2018.

Analysis of the Adhesiveness and Glue Type Selection

in Manufacturing of Bamboo Laminate Composite for

Fishing Boat Building Material. Appl. Mech. Mater.,

Volume 874, p. 155–164.

Supomo, H., Manfaat, D. & Zubaydi, A., 2015. Flexural

Strength Analysis of Laminated Bamboo Slats

(Bambusa Arundinacea) for Constructing a Small

Fishing Boat Shells. Trans. R. Inst. Nav. Archit.

Wibowo, A. & Gintings, A. N., 2010. Degradasi dan Upaya

Pelestarian Hutan. In: Membalik Kecenderungan

Degradasi Sumber Daya Lahan dan Air. Badan

Penelitian dan Pengembangan Pertanian. Jakarta.

Xiao, Y., Zhou, Q. & Shan, B., 2010. Design and

Construction of Modern Bamboo Bridges. J. Bridg.

Eng.

Mechanical Properties Analysis of Slats Inter-Lay Joint Gap of Bamboo Laminates for Fishing Boat Construction

133