Study on Implementation of Risk based Inspection using FMEA-FTA

Method on Ro-Ro Ship Bastiong-Sofifi Route

Bagus Gelis Pratama Putra

1

, Wasis Dwi Aryawan

2

and Yani Nurita Purnawanti

1,2

1,2

Department of Naval Architecture, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

3

Department of Ocean Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Keywords: Risk Based Inspection, FMEA-FTA, Ro-Ro Ship

Abstract: Routine checking is one of the preventions of ship accidents by ensuring that the condition of the ship is

feasible to carry out operational activities. The condition checking of the ship can be done in the form of a

ship survey or inspection. The survey process that was carried out less effectively resulted in less directed

inspection activities on the ships, so that the results of the inspection could not be on target. One method of

inspection carried out to obtain inspection results that are right on target is to use a Risk Based Inspection

(RBI) method. This method prioritizes the risk assessment of the equipments or parts to direct the inspection

activity process. By inspecting 20% of all parts, the risk of failure of the remaining 80% of the share can be

mitigated. The application of RBI to Ro-Ro Ships in Bastiong-Sofifi Trip can be carried out from previous

inspection data to produce optimum inspection and mitigation procedures. In this study, the RBI was carried

out based on the results of the calculation of the risk with the FMEA method. Whereas for inspection and

mitigation procedures carried out based on the results of the analysis using the FTA method.

1 INTRODUCTION

Cruise lines from Bastiong-Sofifi often experience

bad weather. Bastiong Harbor is a port located on

Ternate Island, while Sofifi port is a port located on

Halmahera Island. This cruise connects Ternate

Island and Halmahera Island. But lately BPPD North

Maluku reported that often occur in bad weather in

the shipping channel, so the potential event of an

emergency (BBC, 2018).

Accidents on North Maluku waters occur twice

according to emaritim.com in 2017. One of them is

the speedboat that goes to Ternate, which fires in

January. Then in November 2017 KM Karya Indah,

departing from Bacal Bacan Harbor, the destination

of Bastiong Harbor, Ternate, crashed into Kasiruta

Island in the waters of Tanjung Berek, West Bacan,

South Halmahera, North Maluku (Emaritim, 2017).

this incident needs to be examined for internal and

external causes.

Based on the events that occurred in the north

Maluku shipping channel, this ship accident

occurred on traditional ships and conventional ships.

Although it has adjusted the regulations issued by

the government and the classification bureau, vessel

accidents can still occur due to conditions that are

not predictable. Ship accidents that result in sinking

ships and falling casualties are the biggest risks that

must be avoided by ship operators.

Periodic condition checking is one of the

mitigations of ship accidents by ensuring that the

condition of the ship is feasible for operational

activities. Checking the condition of the ship can be

done in the form of a ship survey or inspection.

Inspection is checking the condition of the ship as a

whole and in detail on the condition of the ship.

One method of inspection carried out to obtain

inspection results that are right on target is to use a

Risk Based Inspection (RBI) method. This method

puts forward the risk assessment that exists in the

equipment or part to direct the inspection activity

process. By inspecting 20% of all parts, the risk of

failure of the remaining 80% of the part can be

mitigated (Drozyner et.al., 2012). Therefore, a study

of ro-ro ferry inspection on bastiong-sofifi routes in

northern Maluku waters with a risk-based method

needs to be carried out.

RBI offers a more focused and targeted approach

to inspection rather than constants. Although it

requires more effort to achieve this 'focus', the RBI

assessment applied to the 'design circle' can first see

areas that can be redesigned, thus creating a more

reliable unit with fewer checks and interventions

during the operational phase. The benefit of the

initial effort is that some checks may be done less

frequently, reducing downtime and possible

shutdowns (Llyod’s Register, 2017). RBI can be

done by combining the FMEA method (to obtain the

Putra, B., Aryawan, W. and Purnawanti, Y.

Study on Implementation of Risk based Inspection using FMEA- FTA Method on Ro-Ro Ship Bastiong-Sofifi Route.

DOI: 10.5220/0008542300730078

In Proceedings of the 3rd International Conference on Marine Technology (SENTA 2018), pages 73-78

ISBN: 978-989-758-436-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

73

value and level of risk) with the FTA method (to

detect the cause of failure) (Peeters, et.al., 2017).

2 RESEARCH DESCRIPTION

The purpose of this paper is to determine the

potential for frequent operational failures, risk

values, and causes of failure on the Ro-Ro Ferry

Ship on the Bastiong-Sofifi route so that the results

can later be used as a reference in risk-based

inspection and the making of mitigation procedures.

This research was carried out with the following

procedures:

2.1 Literature Study

Literature study is done to find sources relevant to

the topic of Risk Based Inspection on Ships. The

RBI in this case study was carried out with an

FMEA and FTA approach, so literature is also

needed. Literature is obtained from papers, journals,

previous research, opinions of experts, the internet

and others.

2.2 Data Collection and Inspection

Data Screening

Data was collected by the inspection data collection

ro-ro ships operating in the shipping lanes Bastiong-

Sofifi. The inspection data obtained an overall data

checks the parts of the ship in each month during the

period July 2017-June 2018.

2.3 Clustering of Mode of Failure

Clustering of inspection results is done by screening

and grouping data. This data grouping is done based

on the failure mode that occurs.

2.4 Risk Identification and Assessment

This identification and assessment is in accordance

with the Failure Modes and Effects Analysis

(FMEA) method. Risk identification and assessment

is carried out based on the value of the probability,

consequences and effectiveness of failure

prevention. The probability value is obtained based

on the inspection results of the ro-ro ship on the

Bastiong-Sofifi shipping line. The assessment of the

consequences and effectiveness of prevention is

based on expert judgment (IMCA, 2002).

After the assessment, a calculation and creation

of a risk values is carried out, whichever mode of

failure can be mapped which has the highest risk

level.

2.5 Identification of Causes of Failure

Identification of causes of failure is done in failure

modes that have the highest risk level. This

identification uses the FTA method. The results of

the identification of the causes of this failure can be

used as a reference in carrying out inspections,

mitigation, and prevention of subsequent failures.

3 RESULTS AND DISCUSSION

The Ro-Ro Ferry Vessels that often sail on the

airport-sized routes are between 000 GT to 111 GT.

In this study using inspection data from one of the

ships with the following main dimensions LOA 45.5

m, LBP 40.21 m, B 12 m, H 3.2 m, T 2.75 m with an

average speed of 9 knots.

Inspection data used is inspection data for 1 year

on the measured vessel for risk analysts.

3.1 Screening Phase

The result of this phase is the initial identification of

all inspection data on ships sailing on the Bastiong-

Sofifi route.

The purpose of the screening phase is to identify

any changes that have occurred and check whether

the previous risk assessment basis reflects

operational and technical conditions (DNV, 2016).

Stages in the screening phase are:

• Review of previous risk assessments

• Categorize changes that occur

• Perform analysis on changes occurring by

identifying how much influence the

changes to the operating system, then

calculate the level of risk.

From the screening phase, there were several

locations that experienced the most changes, namely

in the construction section.

3.2 Risk Identification and Assessment

Failure identification and risk assessment using the

FMEA method. In the previous procedure general

identification of all inspection data was carried out.

At this stage the FMEA method is carried out

through several stages (OpenAIS, 2015):

SENTA 2018 - The 3rd International Conference on Marine Technology

74

• Identify the potential and effects of failure on

components

• Identify the control process from the owner/

company

• Determine the rank of the occurance, Severity,

and Detectability using RPN (Risk Priority

Number)

The following is the result of identifying the

greatest damage that occurs most often and based on

the results of periodic inspections and their impacts

based on the assessment of the user / expert

judgement.

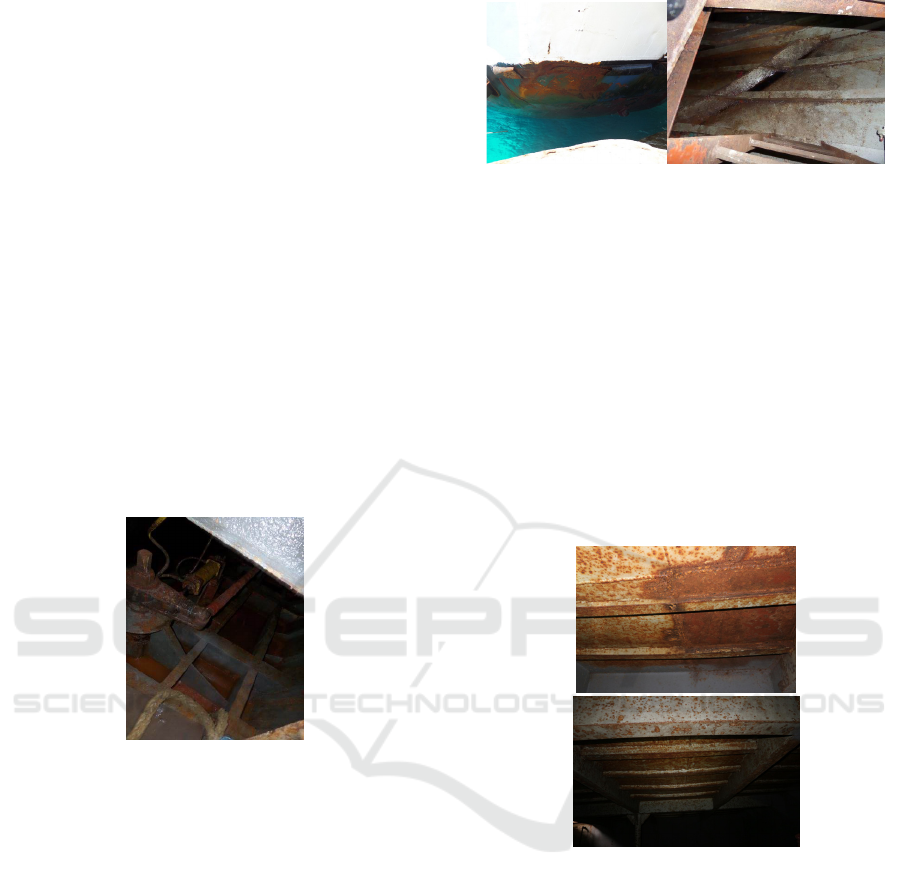

3.2.1 Construction of the Steering Wheel

In the steering room there are plate construction and

reinforcement. In this ship, corrosion is often found

in the plate and its construction as shown in Figure

1.

Figure 1: Plate and construction on steering room.

Based on data from periodic inspections, in the

steering room there is often a puddle from the

seepage of the steering shaft. If this corrosion

continues to occur it can have an impact on the

thinning of the plate and result in a hull in the hull of

the steering wheel. Prevention that has been carried

out is by draining the steering room if the puddle is

high enough.

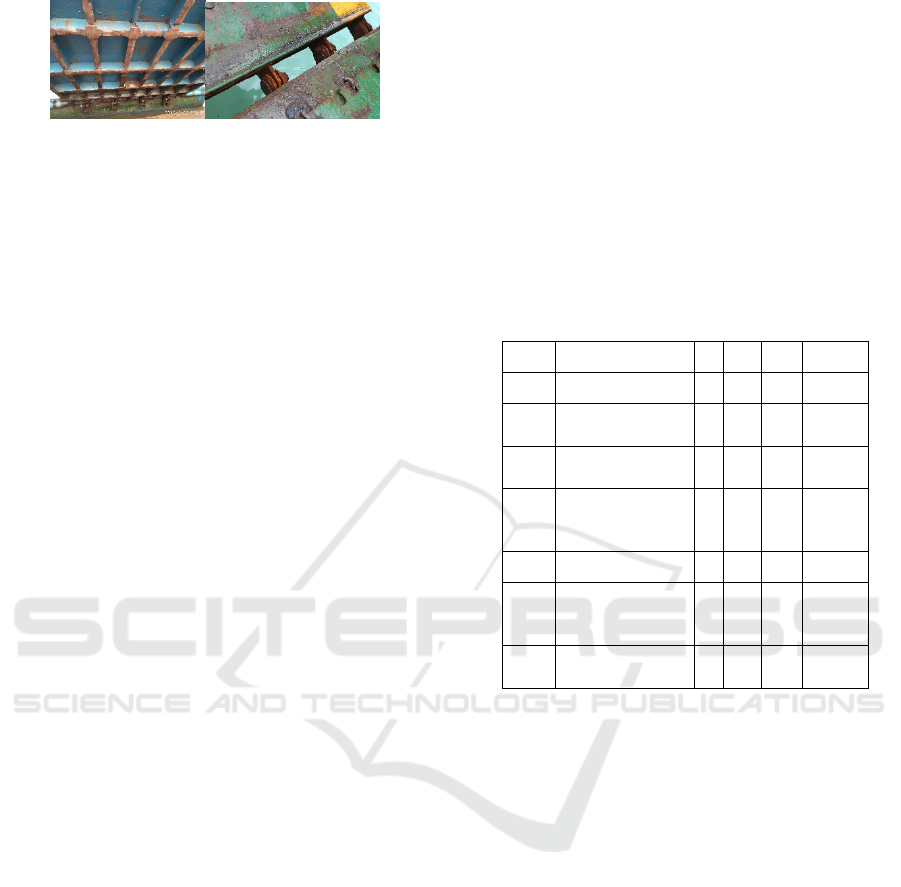

3.2.2 Side Plate and Side Stringer Hull

Corrosion occurs in the reinforcement and outer

plates on the side hull. In Fig 2 it can be seen that

the ship is experiencing corrosion on the side of the

hull and its reinforcement. Corrosion of the hulls

(inside) occurs due to seepage of water and air from

the outside. This seepage can occur because of a

crack on the side hull (Figure 2a).

Figure 2: (a) side hull (b) side stringer hull.

Crack on the side hull can occur due to corrosion

that forms naturally due to interaction with the

environment (sea water and air). If no

countermeasures are taken, there can be a leak on

the side hull of the ship.

3.2.3 Main Deck Plate

The next part of the vessel that has the potential to

fail is the plate and main deck construction as shown

in Figure 3. Corrosion in part is due to the lack of

care and there are indications there is a crack that

sea water and air can seep in until corrosion occurs

on the inner stiffener.

Figure 3: Main deck plate.

Corrosion in this section results in the thinness of

the main deck plate so that there is a possibility of a

break due to the inability of the structure to

withstand load loads.

3.2.4 Plates and Hinges on Rampdoor

Rampdoor is a very important part of the ferry ro-ro

vessel because the rampdoor is an access for loading

and unloading vehicles. Shows that corrosion also

occurs in the construction part of the rampdoor and

its hinges.

Study on Implementation of Risk based Inspection using FMEA- FTA Method on Ro-Ro Ship Bastiong-Sofifi Route

75

Figure 2: Plate and hinges on rampdoor.

Unmanageable corrosion can result in thinning of

plates on the rampdoor, and also the reduced

strength of the support on the rampdoor. This will

disrupt the operation because the hinges are broken

and the rampdoor can be separated from the original

position, so that it can disrupt the process of loading

and unloading the vehicle.

3.3 Risk Rating Determination

Determination of risk levels is done by calculating

event probability, impact score, and detectability

score (IMCA, 2002; OpenAIS, 2015). The

probability of occurrence is obtained from the input

data every month for one year. Then the impact and

detectability scores were obtained from the results of

the questionnaire and interview user expert (expert

judgment).

In this paper the risk assessment uses the FMEA

method FMEA is a simple method that is easy to

implement, can be used to improve the quality of

products and processes. This method focuses on

additional consequences and protection to reduce the

impact of failure.

The assessment in the FMEA method uses a

RPN (Risk Priority Number) where this RPN is a

multiplication of the probability of occurrence, the

value of the impact / consequence, and the value of

the detection carried out.

RPN = (S) x (D) x (O) (1)

Occurance (O) is an estimate of the probability

or chance that a cause will occur and produce a

failure mode that causes certain consequences.

Severity (S) is a subjective estimate or estimation

of how bad the end user will feel the consequences

of that failure.

Detectibility (D) is a subjective estimate of how

effectiveness and prevention or detection methods

are.

The RPN value of each potential problem can

then be used to compare the causes identified during

the analysis. In general, the RPN is between the

specified limits, corrective actions can be proposed

or done to reduce risk. When using a risk assessment

technique, it is very important to remember that the

RPN level is relative to a particular analysis (carried

out with a set of general rating scales and team

analysts that attempt to rank consistently for all

causes of problems identified during the analysis). In

this paper the rating uses the standard from IMCA

(The International Marine Contractors Association –

Guidance on FMEAs).

For that reason, an RPN in an analysis can be

compared to other RPNs in the same analysis, but

can be incomparable to the RPN in one analysis.

Table 1: Calculation of RPN.

No. Failure Modes O S D RPN

1 Side plate hull 6 8 7 336

2

Side plate hull

construction 6 8 7 336

3

Plate of steering

room 8 8 6 384

4

Constructions

of the plate of

steering room 8 8 6 384

5 Main deck plate 6 7 4 168

6

Plate and

hinges of

rampdoor 7 7 5 245

7

Rampdoor

construction 7 7 5 245

Table 1 shows that the highest RPN occurred in

the Plates and Toners failure modes in the steering

room with a total RPN 384. The steering wheel and

the enforcement of the steering room are located in

the same location (Figure 1) so that each other

affects each other. A high enough score for the

occurrence of events. This score is obtained from

inspection data that has been scaled according to

IMCA standard. Detectability has a lower score

because there is enough maintenance in this location

by way of draining stagnant water. Severity gets a

high score because the impact of this failure mode is

considered to be large enough that it can threaten

passenger safety in the event of a leak.

Other parts that have a large RPN are on the

reinforcement and side hull plates. In this section the

probability of moderate occurrence is based on the

results of the inspection. But for severity is quite

high because the failure mode on the side plate of

the hull can be fatal, namely a leak that can threaten

passenger safety. Preventive measures in the form of

checking have often been done but are less effective.

SENTA 2018 - The 3rd International Conference on Marine Technology

76

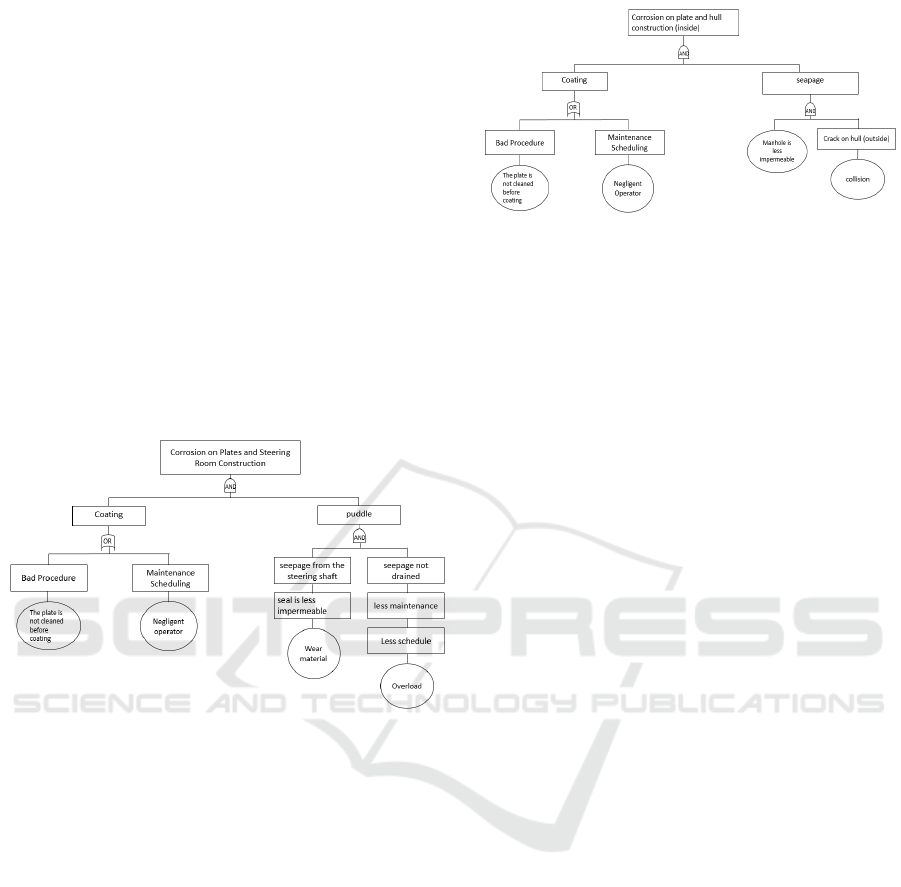

3.4 Identification of Causes of Failure

Identify the causes of this failure using the FTA

method. Fault Tree Analysis is an analytical tool that

graphically translates combinations of errors that

cause system failure. This technique is useful for

describing and assessing events in the system

(Haasl, et.al., 1981). This Fault Tree Analysis

method is effective in finding the core of the

problem by ensuring that an undesired event or loss

caused does not originate at one point of failure.

Fault Tree Analysis identifies the relationship

between causal factors and is displayed in the form

of an error tree involving a simple logic gate.

Identification of the causes of failure was carried

out in the two modes of failure with the highest RPN

in the Plates and steering wheel constructions as

well as on the plates and the side of the hull.

Figure 5: FTA of corrotion of the steering room

construction

Figure 5 shows that the cause of the corrosion of

the plate and construction in the steering room is the

presence of stagnant water and problems with the

coating. Stagnant water comes from seepage of

water from the steering shaft which is not

immediately drained. This water seepage occurs due

to the seal of the rudder stock which is less

impermeable due to the wear of the material.

Coating problems occur due to bad procedures or

there are problems with maintenance scheduling.

The bad procedure is that when the plates are being

coated, sometimes the operators have not cleaned

the remaining dirt on the plate first. While the

problem in maintenance scheduling can occur due to

negligence of officers who do not do the coating

according to the coating schedule.

Figure 6: FTA of corrotion of the hull construction

The cause of corrosion in ship side hull

construction is water seepage and coating problems

(Figure 6). Seepage of water comes from manholes

that are not impermeable and crack side hulls. The

Crack can occur due to collisions when docked at

the port.

4 CONCLUSIONS

• Based on FMEA analysis, potential operational

failures that often occur on Ro-Ro ferry vessels,

especially on Bastiong-Sofifi shipping lines, are

corrosion on plates and reinforcement in the

steering and side hulls which can have an impact

on vessel leakage which can threaten passenger

safety. This potential failure is classified as high

risk according to the standards of IMCA (The

International Marine Contractors Association) in

the assessment of the risk.

• Based on FTA analysis, the cause of the potential

failure is the presence of water seepage and

problems in coatings, as well as problems with

maintenance scheduling.

From these conclusions can be used as a

reference for further risk-based inspection, as

well as the making of mitigation procedures.

REFERENCES

BBC, 2018. Kapal tenggelam di Maluku Utara, 14 tewas.

bbc.com. Accessed on August 1

st

, 2018.

DNV, 2016. DNVGL-RP-G107: Recommended Practice

Efficient Updating of Risk Assessments. DNV GL AS.

Drozyner, Przemysia, E.Veith, 2012. Risk Based

Inspection Methodology Overview, Diagnostyka’27

82-88.

Emaritim, 2017. Kecelakaan Kapal Sepanjang Tahun

2017. Jakarta, emaritim.com. Accessed on August 1

st

,

2018.

Study on Implementation of Risk based Inspection using FMEA- FTA Method on Ro-Ro Ship Bastiong-Sofifi Route

77

Haasl, D.F., N.H. Roberts, W.E. Vesely, F.F. Goldberg,

1981. Fault Tree Handbook. Nuclear Regulatory

Commission. Washington.

IMCA, 2002. Guidance on Failure Modes & Effects

Analyses (FMEAs), IMCA M 166.

Lloyd's Register, 2017. Guidance Notes For The Risk

Based Inspection Of Hull Structures. Lloyd's Register.

London.

OpenAIS, 2015. FMEA And Hazard Analysis Report,

OpenAIS.

Peeters, J.F.W., Basten, R.J.I., Tinga, T., 2017. Improving

Failure Analysis Efficiency By Combining FTA And

FMEA In A Recursive Manner. Reliability

Engineering and System Safety 36-44. Elsevier.

SENTA 2018 - The 3rd International Conference on Marine Technology

78