The Application of Analytic Hierarchy Process to Select Load out

Method

Silvianita

1

, Diar Eka Satria Prabowo

2

and AgroWisudawan

1

1

Ocean Engineering Department, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

2

Graduate Student of Ocean Engineering Department, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia

Keywords: Analytic Hierarchy Process, Load out, Offshore Platform.

Abstract: In the construction of an offshore platform, one of the most important is the process of loadout. Loadout is

the process of moving an offshore building from yard to top barge by moving the structure horizontally or by

lifting method. The loadout process can be done in several ways by considering various factors both geometry

and structure weight, as well as the availability of equipment needed during the loadout process. The Multi-

Criteria Decision Making (MCDM) is a method of decision making to determine the best alternative from a

number of alternatives based on certain criteria. This paper will discuss the best load out method for marine

structures namely skidding, dolly and lifting method. The AHP results are derived from the expert judgments

involve in marine structures. The Skidding method is the main priority with a weight of priority 0.521, then

the Lifting method with a weight of priority 0.287 and Dolly method with a weight of priority 0.192.

1 INTRODUCTION

Construction of offshore platforms was built in an

offshore fabricator. In the construction of an offshore

platform, one of the important things is the process of

loadout. Loadout is the process of moving an offshore

building from yard to top barge by moving the

structure horizontally or by lifting method (DNV.GL,

2017).

This process includes a fairly critical stage

because the stability of the barge must be carefully

calculated after the structure is a load on it

(Chakrabarti, 2005). The load out process can be done

in several ways by considering various factors both

geometry and structure weight, as well as the

availability of equipment needed during the load out

process. One of the factors that is very important in

the selection of load out methods is economic factors

(Silvianita, et.al, 2016).

The Multi-Criteria Decision Making (MCDM) is

a method of decision making to determine the best

alternative from a number of alternatives based on

certain criteria. Analytical Hierarchy Process (AHP)

is the most popular method in Multicriteria Decision

Making Method (MCDM). The AHP method is one

of the most popular pair wise comparison methods

used for decision making in Multi-Criteria Decision

Making (MCDM). The AHP has been successfully

applied in many areas to select the best alternatives

(Silvianita, et.al, 2009; Shafiq and Silvianita, 2010;

Silvianita and Kurian, 2013; Silvianita, et.al, 2018;

Silvianita and Kurian, 2012, 2016).

2 BASIC THEORY

2.1 Loadout

Loadout is an activity to move the marine structures

in the form of platforms, jackets, modules or other

structures to the top of the barge to be transported to

the site where the structure will be installed.Based on

the method of moving the activity, process load out is

divided into three types, namely (Silvianita, et.al,

2009) :

a. Skidding Method

Loadout activity with the skidding method is done by

moving the structure onto the barge by placing the

structure above the skid way. The structure is then

tied with steel (sling) on the side of the barge.

b. Dolly (Trailer Method)

Loadout activity by this method is done by moving

the structure using dolly (trailer). The advantages of

Silvianita, ., Prabowo, D. and AgroWisudawan, .

The Application of Analytic Hierarchy Process to Select Load out Method.

DOI: 10.5220/0008376101270131

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 127-131

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

this method lies in the ease of the process and the

small chance of failure.

c. Lifting Method

Loadout activity with lifting method is carried out by

lifting the structure by using several cranes which are

then transferred to the barge.

2.2 Multi Criteria Decision Making

(MCDM)

Multi-criteria decision making (MCDM) is a

decision-making technique from several alternative

options. Inside this MCDM contains elements of

attribute, objective, and purpose. There are two

categories of Multi-criteria decision making

(MCDM), there are:

a. Multiple Objective Decision Making (MODM)

Multiple Objective Decision Making (MODM)

concerns design issues, where optimization

mathematical techniques are used, for very large

numbers of alternatives (up to infinity) and for

answering what and how many questions.

b. Multiple Attribute Decision Making (MADM)

Multiple Attribute Decision Making (MADM),

concerning the issue of election, where

mathematical analysis is not too much needed or

can be used for selection only for a small

number of alternatives. The Analytical

Hierarchy Process (AHP) method is part of the

MADM technique.

2.3 Analytical Hierarchy Process

Analytical Hierarchy Process (AHP) is a method of

decision making with many criteria developed by

Thomas L. Saaty by compiling several complex

criteria into a structured and systematic hierarchy.

The purpose of AHP is to calculate the overall score

by combining the weights of various decision

elements. The working principle of AHP is to form a

problem structure (Saaty, 2003).

2.3.1 Basic Principles AHP

There are three basic principles in the AHP method,

namely as follows (Saaty, 2003, 2008):

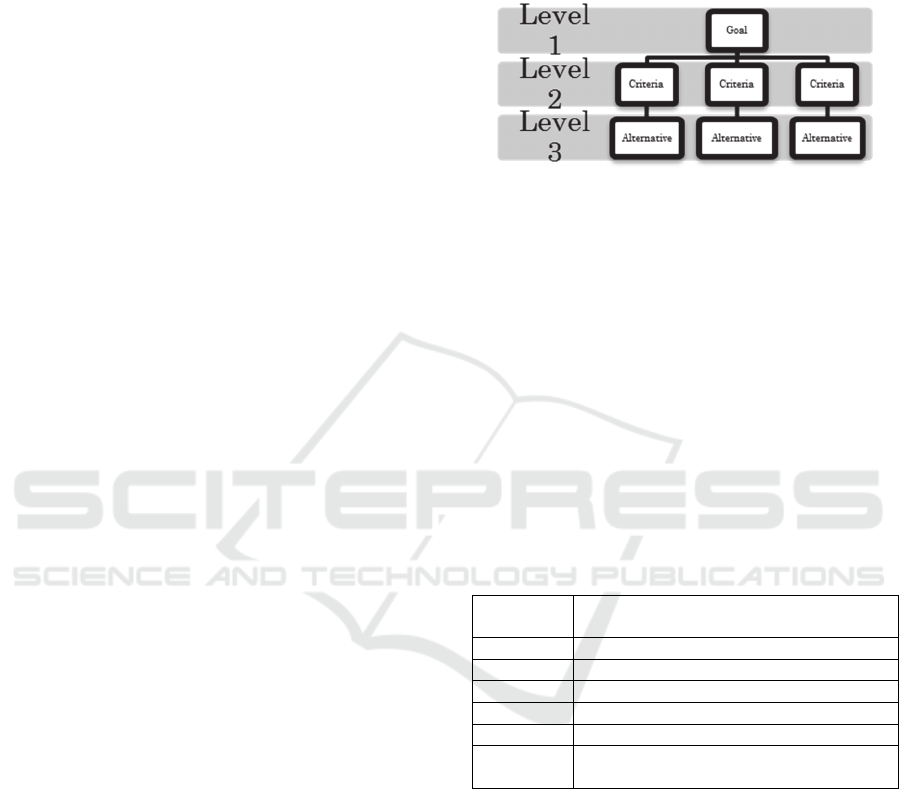

1. Decomposition

After the problem is defined, decomposition needs to

be done, which is to divide the problem into smaller

parts. The division process will produce several levels

of problems. That is why the process of analysis is

called hierarchy. In the hierariki's basic structure, the

details of the relationship are displayed in a chart that

is divided into 3 (three) levels. Level 1 is the goal of

the hierarchy. Level 2 is a criterion in getting that

goal. Level 3 is an alternative choice of these goals.

The basic structure of the hierarchy can be seen in

Fig.1.

Figure 1: Basic Structure of Hierarchy.

2. Comparative Judgment

This assessment is the main point of the AHP method

because it affects the priority of elements. The results

of this assessment can be observed better if displayed

in the form of Pairwise Comparison Matrix. namely a

pairwise comparison matrix that contains the level of

decision making preferences for alternatives based on

existing criteria. The scale used to express the level

of preference is the Saaty scale, where scale 1 shows

the level of "equally important", scale 3 shows

"moderate importance", scale 5 shows "importance”,

scale 7 shows "very important importance" and scale

9 shows the level of "extreme importance".

Table 1: Saaty’s Scale.

Level of

Importance

Definition

1 As important as others

3 Moderate importance compared to others

5 Kuat pentingnya dibanding yang lain

7 Very strong importance compared to others

9 Extreme importance than others

2,4,6,8

The values between two assessments are

close together

3. Synthesis of Priority

From each Comparison Matrix, the eigenvector value

is useful for obtaining local priorities. Because the

Pairwise Comparison Matrix is available at each

level, global priorities can be obtained by

synthesizing between these local priorities.

4. Consistency Test

The consistency test is done in each paired matrix

(pairwise comparison) to check whether the judgment

is consistent or not. Measurement of consistency of a

matrix is based on maximum eigen value. Thomas L.

Saaty has proven that the consistency index of an

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

128

ordered matrix can be obtained by the following

equation:

𝐶𝐼

𝜆

𝑛

𝑛1

(1)

Where:

CI = Consistency ratio

λ_max = Maximum eigen value of matrix

n = matrix size

If CI is zero, the pairwise comparison matrix is

consistent. The limit of inconsistency has been

determined by Thomas L. Saaty by using the

Consistency Ratio (CR). CR (Consistency Ratio) is a

comparison between the consistency index value (CI)

with the Random Index (RI) value. RI (Random

Index) obtained from an experiment by the Oak Ridge

National Laboratory was later developed by the

Wharton School. The RI value depends on the order

matrix n and can be seen in Table 2. Thus, the

Consistency Ratio (CR) can be seen in the following

equation:

𝐶𝑅

𝐶𝐼

𝑅𝐼

(2)

Where:

CI = Consistency Index

RI = Random Index

Table 2: Random Index Value (RI).

n 1 2 3 4 5 6 7 8

RI 0.0 0.0 0.58 0.9 1.12 1.24 1.32 1.41

n 9 10 11 12 13 14 15

RI 1.45 1.49 1.51 1.48 1.56 1.57 1.59

If the pairwise comparison has a CR value smaller

or equal to 0.1, then inconsistencies may be accepted,

otherwise the assessment needs to be repeated.

2.3.2 Steps for AHP Implementation

The steps in the application of AHP are as follows

(Saaty, 1990):

1) Define the problem and determine the desired

solution.

2) Create a hierarchical structure that begins with a

general purpose, followed by selected criteria

and alternatives.

3) Create a pairwise matrix depicting the relative

contribution or influence of each element to a

goal or criterion that is above the level.

Comparisons are made by choice or judgment of

decision makers by assessing the importance of

an element over other elements.

4) Normalize the data by dividing the value of each

element in the matrix in pairs with the total value

of each column.

5) Calculating the eigenvector value and testing its

consistency, if inconsistent then the data

retrieval (preference) needs to be repeated. The

eigenvector value in question is the maximum

eigen vector value obtained.

6) Repeat steps 3, 4 and 5 for the entire hierarchy

level.

7) Calculates eigen vectors from each paired

comparison matrix. Eigenvector vector is the

weight of each element.

8) Test the consistency of hierarchy. If it does not

meet with CR ≤0,1 then the assessment should

be repeated again.

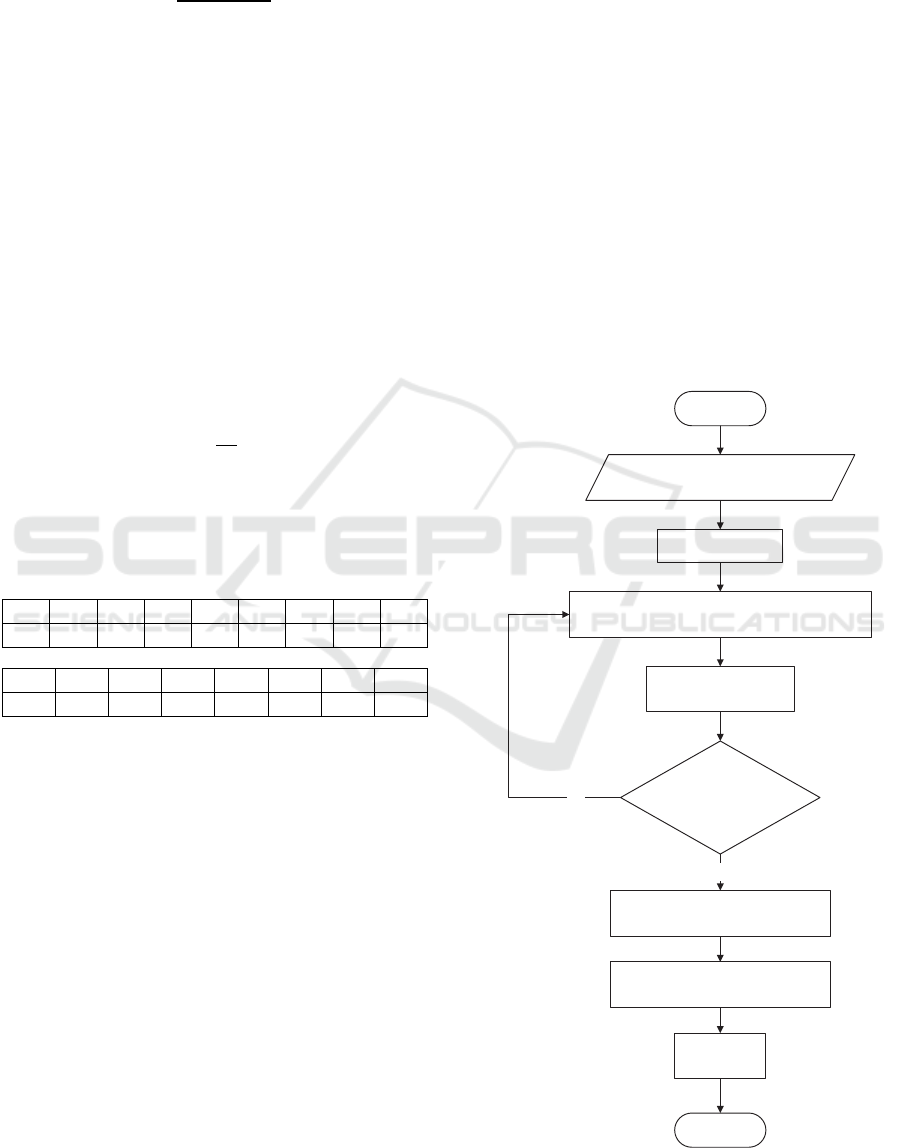

3 RESEARCH METHODOLOGY

Start

Literature Study and

Finding Data Information

Input Data

Make a Matrix Pairwise Comparison for every

criteria based on AHP’s Scale

Normalization Matrix

for Every Criteria

Consistency Criteria

CR < 10%

No

Yes

Calculate Value of Each

Alternative

Decide Alternative Rank

Conclusion

Finish

Figure 2: Research Methodology.

The Application of Analytic Hierarchy Process to Select Load out Method

129

4 RESULTS AND DISCUSSIONS

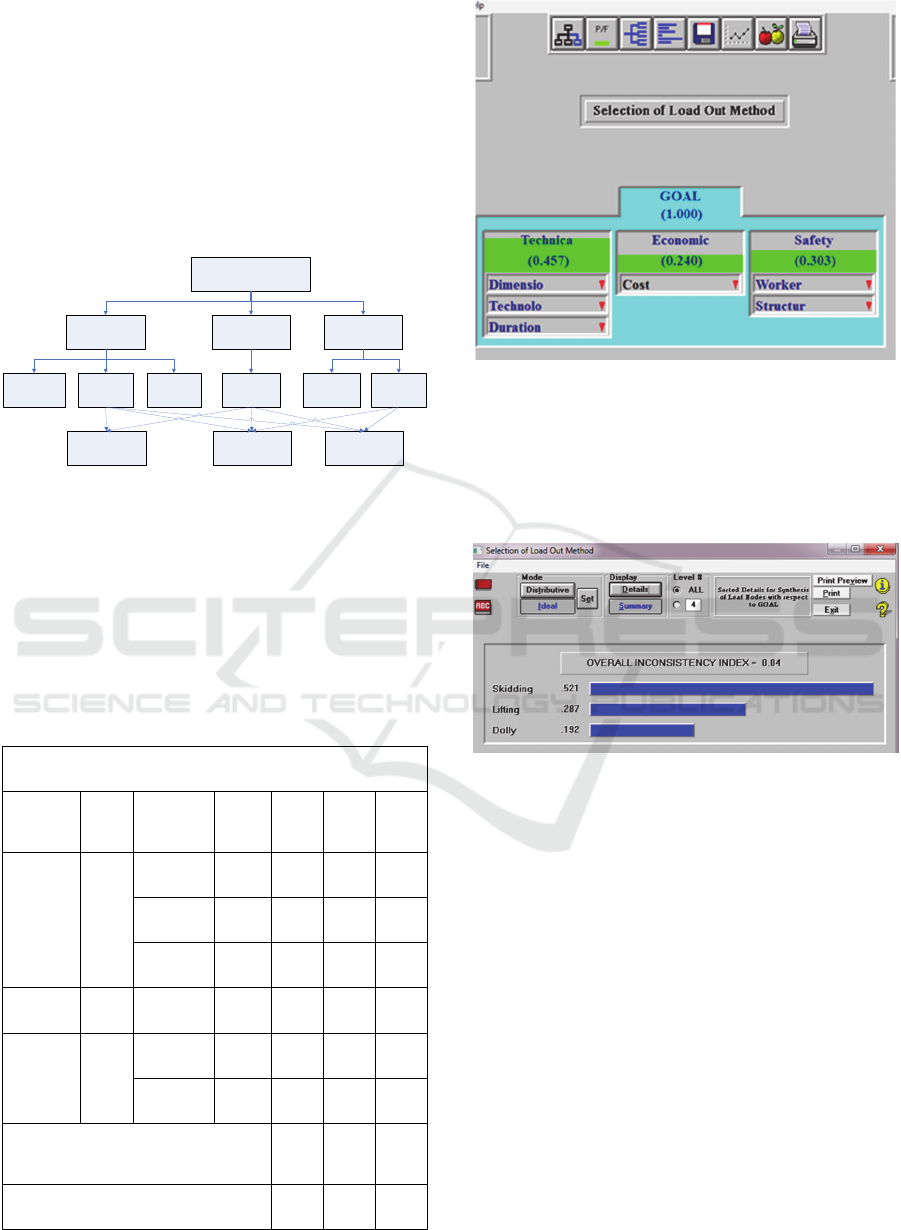

4.1 Hierarchy Selection of Loadout

Method

The Analytical Hierarchy Process Method (AHP) has

four levels: first level is the goal, the second level is

the criterion, the third level is the subcriteria and the

fourth level is the alternative. The structure of the

hierarchy can be seen in Figure 3.

The Selection of Loadout

Method

Technical Economical Safety

Dimension of

the Structure

Technology CostDuration StructureWorker

Skidding Lifting Dolly

Figure 3: The hierarchy of Selection Load out Method.

4.2 Pairwise Comparison at Criteria

Level

The data for criterion priority assessment is obtained

from the expert judgment using Saaty’s Scale of

AHP. The results of the calculations are shown in

table 3.

Table 3: AHP Output on Selection of Load out Method.

Selection of Load Out Method

Critical

Factor

Priority Sub Factor Priority Skidding Dolly Lifting

Technical 0.457 Dimension 0.340 0.249 0.066 0.025

Technology 0.054 0.041 0.005 0.009

Duration 0.006 0.006 0.009 0.048

Economical 0.240 Cost 0.240 0.169 0.051 0.020

Safety 0.303 Worker 0.248 0.020 0.047 0.181

Structure 0.055 0.033 0.013 0.009

Priority of Maintenance on the Basis of

Consequences

0.521 0.287 0.192

Ranking 1 2 3

Figure 4: The Hierarchy using Expert Choice Software.

Fig 4 shows the hierarchy structure develop using

Expert Choice Software. The Expert Choice Software

gives the local and global priority. Fig 5 shows the

weight of priority of the best load out method is

Skidding with 0.521.

Figure 5: The weight priority of Load out Method.

5 CONCLUSIONS

From the analysis that has been done, it can be taken

some conclusions as follows:

1. The criteria and subcriteria to select the best

load out method using AHP are consisting of :

a. Technical (dimensions of the structure,

technology, and duration).

b. Economical (cost)

c. Safety (worker and structure)

2. The best alternative of load out process based on

expert judgements are:

a. Skidding method with a weight of 0.521

b. Lifting method with weight of 0.287

c. Dolly method with a weight of 0.192

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

130

REFERENCES

DNV.GL, 2017. Marine Warranty Wizard. ed: Noble

Denton Marine Services.

K. M. F. Silvianita, V. J. Kurian, 2012. Development of a

Framework for Safety Assessment of Mobile Mooring

System, 8th Asia Pacific Structural Engineering and

Construction Conference 2012 (APSEC 2012) & 1st

International Conference on Civil Engineering

Research (ICCER 2012), Surabaya, Indonesia.

M. F. K. Silvianita, Kriyo Sambodho, Nur Syahroni, Yeyes

Mulyadi, Muhammad Zikra, 2016. Investigation of

Risk Based Decision Making for Mobile Mooring

System," Applied Mechanics and Materials, Vol. 836,

pp. 233-238.

M. F. K. Silvianita, Kurian V John, 2012. Risk Based

Decision Making of Mobile Mooring System, presented

at the International Conference on Statistics in Science,

Business and Engineering 2012, Langkawi, Malaysia.

M. F. K. Silvianita, Suntoyo, Dirta Marina Chamelia, 2018.

Methodology for Investigation of Risk Based

Maintenance (MIRBA) for Mobile Mooring System,

Research Journal of Apllied Sciences, vol. 13, pp. 26-

33.

M. F. K. Silvianita, V.J. Kurian, 2013. Decision Making for

Safety Assessment of Mobile Mooring System, Jurnal

Teknologi, vol. 61, pp. 41-52.

N. Shafiq, Silvianita, 2010. Prioritizing the Pipeline

Maintenance Approach using Analytical Hierarchical

Process, International Review of Mechanical

Engineers, pp. 346-352.

R. D. P. Silvianita, Dirta Marina Chamelia, Wimala L

Dhanistha, 2016. Time and Cost Analysis of Jacket

Structure Loadout Using Skidding, International

Conference, Coastal Planning for Sustainable Marine

Development, CITIES 2016, Surabaya, Indonesia.

S. Chakrabarti, 2005. Handbook of Offshore Engineering:

Elsevier Ltd.

S. N. Silvianita, Khamidi M.F, Sadiq A, 2009. Performing

Sensitivity Analysis of Pipeline Risk Failure Using

Analytical Hierarchy Process, in International

Conference on Asian and Pacific Coast, Singapore.

T. L. Saaty, 1990. How to Make A Decision: The Analytical

Hierarchy Process, European Journal of Operational

Research.

T. L. Saaty, 2003. Fundamentals of Decision Making and

Priority Theory with the Analytic Hierarchy Process

Vol 6. USA: Pittsburg University.

T. L. Saaty, 2008. Decision Making with the Analytic

Hierarchy Process, International Journal of Servies

Sciences Volume 1, No. 1, pp. 83-98.

The Application of Analytic Hierarchy Process to Select Load out Method

131