Compressed Natural Gas Addition Effect on the Exhaust Emission of

Diesel Dual Fuel Engine based on Experiment

Nilam Sari Octaviani

1

, Semin

1

and Bambang Sudarmanta

2

1

Marine Engineering Department, ITS, 60111 Surabaya, Indonesia

2

Mechanical Engineering Department, ITS, 60111 Surabaya, Indonesia

Keywords: The Exhaust Emission, Diesel Dual Fuel Engine.

Abstract: Energy source availability and environmental effect from engine exhaust emission are attractive issue to be

discussed recently. Furthermore, these problem are related to alternative fuel energy supply and clean energy.

Natural gas is one of alternative fuel for internal combustion engine and this study will analyze the effect of

Compressed Natural Gas (CNG) addition on exhaust emission of diesel dual fuel engine single cylinder. The

formation of NOx, CO2 and CO will be investigated furthermore. To obtaine the data, the engine was tested

on 3 different speed, they are 1500, 1800 and 2200 rpm. The gas flow rate was varied from 0-3 liter/minute

on 0-4000 Watt of engine load. The experimental result indicated that the addition of CNG on diesel dual fuel

engine has a significant influance on NOx, SOx, CO2 and CO emissions. NOx, Sox and CO2 emissions of

diesel engine operated on dual fuel was lower than diesel engine operated on normal condition. However, the

CO emission showed the different condition. It can be concluded that the implementation of CNG on diesel

is a potential way to decrease the environmental effect of diesel engine combustion.

1 INTRODUCTION

Diesel engine is a type of internal combustion engine

that is often used in the world because it has the best

combustion efficiency, reliability, adaptability and

cost-effectiveness of other types of internal

combustion engines. Diesel engines also have high

reliability with relatively low operational costs.

Diesel engines are also used as the main engine of the

ship, using fossil fuel such as heavy fuel oil (HFO),

marine diesel oil (MDO) dan high speed diesel

(HSD). However, the emissions from combustion of

these fuels contain gases that are harmful to the

environment and human health.

In recent years, International Maritime

Organization (IMO) has implemented increasingly

stringent emission limits produced by ships. In IMO

Tier III, NOx emissions from ships should be reduced

by more than 75%. This forces machine

manufacturers and researcher to advance the steps for

reducing emissions while trying to maintain high

efficiency. Some techniques, especially proven in the

automotive field are reconsidered and evaluated for

their emission reduction potential. Several emission

reduction techniques have been carried out. However,

some of them are only able to reduce certain

emissions. For example, the application of Exhaust

Gas Recirculation (EGR) and Selective Catalytic

Reduction (SCR) on diesel engines can only reduce

NOx emission (Hussain, et.al, 2012; Komar, et.al,

2007). On the other hand, the application of natural

gas as an alternative fuel is one way to reduce ship

exhaust emissions, and the results of this research

show that it can reduce emissions of NOx, SOx, CO2

and PM simultaneously (Ohashi, 2015).

Natural gas is an alternative fuel with the main

constituent components of methane gas (CH4) with a

composition of 87-96% (Semin and Bakar, 2008;

Wei, 2016; Wang, et.al, 2016) and the remainder are

other components, such as ethane, propane , n-butane,

isobutane, n-pentaneane, isopentane, hexane, CO2,

nitrogen, O2, and little hydrogen content. Availability

of natural gas reserves is still abundant with relatively

cheaper price compared to gasoline and diesel, but its

utilization has not been done optimally (Semin and

Bakar, 2008; Wei, 2016; Wang, et.al, 2016; Arif and

Sudarmanta, 2015). And according to Wei et al

(2016) natural gas is environmentally friendly fuel

because it contains less carbon per unit of energy

compared to fossil fuels. In addition, natural gas also

generates less CO2 emissions within every mile of the

120

Octaviani, N., Semin, . and Sudar manta, B.

Compressed Natural Gas Addition Effect on the Exhaust Emission of Diesel Dual Fuel Engine based on Experiment.

DOI: 10.5220/0008376001200126

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 120-126

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

engine trip, thereby reducing the effect of greenhouse

effect caused by CO2 gas.

According to Semin et al (Ohashi, 2015; Semin and

Bakar, 2013), compressed natural gas (CNG) has been

widely developed as fuel for spark ignition engines,

however for diesel engines, CNG still needs a lot of

study and development. Base on Zoltowski (2014),

natural gas will be difficult to apply to diesel engines

because natural gas is a type of fuel with low cetane

number but high octan number. However Semin et al

(2008, 2016, 2016) explained that the natural gas can

be applied to diesel engines with dual fuel technology

where the engine is operated on lean burn combustion

with a small amount of diesel fuel. In dual fuel diesel

engines, natural gas acts as the main fuel and diesel fuel

acts as a pilot fuel.

Research and development of dual fuel diesel

engines is increasing every year, they are not only used

for experimental processes but also has been developed

in the field of industry and transportation (JFE, 2014;

Mehta, et.al, 2015; Semin, et.al, 2007; Ehsan and

Bhuiyan, 2009), the applications of natural gas as

alternative fuel are very promising in the

environmental and economic points of view even

though technically constrained on performance

degradation (Zoltoski, 2014; Ehsan and Bhuiyan,

2009).

The main purpose of this investigation is to validate

the effect of natural gas application on diesel engine,

specially exhaust gas emission. The main exhaust gas

emission will be investigated are NOx, CO and CO2.

2 LITERATURE REVIEW

2.1 Dual Fuel Concept

Nowadays, diesel engines come with various

developments, one of which is a dual fuel system. The

dual fuel system is a diesel engine system using dual

fuel (diesel and gas fuel) in the combustion process.

Diesel engines use a dual fuel system commonly

referred to as a dual fuel diesel engine. In two-fuel

diesel engines, gas acts as the main fuel while diesel

acts as pilot fuel.

The dual fuel engine working principle is the

combination of the conventional diesel engines and

otto engines. In a diesel engine, the air is compressed

in the combustion chamber until it reaches a certain

pressure and temperature then the fuel is injected into

the combustion chamber resulting in combustion.

While on the engine otto, fuel and air mixing first in

the fire room and then compressed below the point of

explosion and then there is combustion with the help

of spark plug which acts as pilot fuel (Heywood, 1998).

In dual fuel diesel engines, gas and air are mixing

when they enter the combustion chamber. Gas and air

that have been mixed then experience the compression

process. At the end of the compression process, when

the gases and air have been at a certain pressure and

temperature, a small amount of diesel fuel is injected

to cause the combustion process. The advantage of this

type of engine is, if there is a failure in gas fuel, the

engine can still work by switching dual fuel mode into

a conventional diesel engine mode that only rely on

diesel fuel. While the drawback is the engine is very

dependent on the availability of diesel fuel for dual fuel

diesel engine working system is still going on (Sahoo,

et.al, 2009).

2.2 Emission

2.2.1 Nitrogen Oxides (NOx)

NOX is one of the most detrimental emissions from

diesel engines and it is a grouped emission consisting

of nitrogen monoxide (NO) and nitrogen dioxide

(NO2). NO is the main component and usually

accounts for more than 90% of NOX emissions in

engine cylinders. The formation of NO in the

combustion zone is a chemical complex and two

distinct mechanisms are involved, namely, the

thermal mechanism (Zeldovich mechanism) and the

fast mechanism (Fenimore mechanism).

According to thermal mechanism, the formation

of thermal NO is strongly influenced by the in-

cylinder temperature and oxygen concentration. NO

formation occurs when temperatures above about

1800 K and formation rates increase exponentially

with an increase in in-cylinder temperature

(Heywood, 1998). According to a prompt

mechanism, formation the NO prompt is led by

intermediate hydrocarbon fragments from

combustion of fuel - specifically CH and CH2 -

reacting with N2 in the combustion chamber and the

resulting C-N species then continues through a

reaction pathway involving O2 to produce NO

(Hoekman and Robbins, 2012).

NO prompt is usually only formed under fuel-rich

conditions, where a number of hydrocarbons are

available to react with N2. The prompt NO has a

relatively weak temperature dependence compared to

thermal NO (Fenimore, 1971; Stiesch, 2003). Under

most conditions of combustion of diesel engines,

thermal mechanisms are believed to be the main

contributors to total NOx (Bowman, 1979; Fernando,

2006).

Compressed Natural Gas Addition Effect on the Exhaust Emission of Diesel Dual Fuel Engine based on Experiment

121

2.2.2 Carbon Monoxides (CO)

Carbon monoxide (CO) is a type of harmful emission

that is different from the engine and its function in the

availability of fuel in combustion and combustion

temperature in the cylinder, which controls the rate of

decomposition of fuel and oxidation (Heywood,

1998). Higher CO usually results from lack of

oxygen. However, large amounts of CO can also be

produced in fuel areas when the combustion

temperature is less than 1450 K (Kitamura, et.al,

2002).

2.2.3 Carbon Dioxides (CO2)

Carbon dioxide (CO2) is a product of hydrocarbon

fuels that are completely burned. The first

hydrocarbon fuel is oxidized to CO during the

combustion process. And then if the temperature in

the cylinder is high enough and in the presence of

oxygen, CO is oxidized to form CO2 in sequence.

Thus, the formation of CO2 is very dependent on the

in-cylinder temperature and oxygen concentration.

3 EXPERIMENTAL SET-UP

3.1 Fuel Properties

Compressed Natural Gas (CNG) is an alternative fuel

that can be used as a substitute for gasoline, diesel

fuel and propane / LPG. CNG is a gas with the main

composition is methane (CH4). In addition, propane,

butane, iso-butane and other gases are also contained

in small quantities. Usually the methane gas content

is more than 90-98% in natural gas, depending on the

location of the source and process of natural gas

processing.

Table 1: The Characteristic of Compressed Natural Gas

(Wei, 2016).

Properties Value

Density (kg/m

3

) 0,72

Flammability limits (volume % in air) 4,3-15

Flammability limits (Ø) 0,4-1,6

Autoignition temperature in air (

0

C) 723

Minimum ignition energy (mJ) 0.28

Flame velocity (ms-1) 0.38

Adiabatic flame temperature (K) 2214

Quenching distance (mm) 2.1

Stoichiometric fuel/air mass ratio 0.058

Stoichiometric volume fraction (%) 9.48

Lower heating value (MJ/kg) 45.8

Heat of combustion (MJ/kg air) 2.9

The addition of gas as fuel in diesel engines causes

the addition of new components and modifications to

several engine components. Tiwari (Tiwari, 2015),

conducted an experiment in converting diesel engines

into dual fuel engines using diesel and gas (CNG) fuel.

Some system components that need to be modified

include the cylinder head, spark ignition system and

cooling system. While the components that need to be

added to the modification process are selenoid valves,

diesel modulators, high / low pressure filters, the use of

low compression type pistons, dual fuel Electronic

Control Units (ECUs) and turbocharger air bypass

(TAB). The last is the addition of components to the

gas installation system so that it can be injected into the

combustion chamber.

Several studies on the conversion of diesel

engines fueled by diesel oil to dual fuel engines

(diesel and gas) have been carried out, both in

computational and experimental simulations

(Heywood, 1998; Sahoo, et.al, 2009; Semin, et.al,

2009; Tesfa, et.al, 2013). The conversion results have

an effect on the exhaust emission. This is due to

differences in the characteristics of the fuel used.

Table 2 shows the differences in properties between

gas and diesel fuel. It is the difference in property of

this fuel that causes the addition of natural gas in the

combustion chamber to affect the change in exhaust

emission in dual fuel engines.

Table 2: Physicochemical properties of natural gas and

diesel fuel (Sahoo, et.al, 2009).

Fuel Properties

Natural

Gas

Diesel

Low heating value (MJ/kg) 48.6 42.5

Heating value of stoichiometric

mixture (MJ/kg)

2.67 2.79

Cetane number - 52.1

Octane number 130 -

Auto-ignition temperature (

o

c) 650 180-220

Stoichiometric air/fuel ratio 17.2 14.3

Carbon content (%) 75 87

3.2 Engine Set-up

The engine used in the experiments is a single-

cylinder, four-stroke, water-cooled, direct injection

(DI) compression-ignition engine. Dimensions of the

engine are the bore D = 85 mm and stroke H = 87 mm.

The main specifications of the engine are presented in

Table 2. The shaft of the engine is coupled to the rotor

of an electric generator which is used to load engine

by receiving the field voltage. A calibrated burette

and a stopwatch were employed to measure the mass

flow rate of fuel.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

122

Table 3: Main Specification.

Engine Specification

Data

Engine type

Four stroke cycle,

Direct injection

Number of cylinder 1

Bore x Stroke 85 mm x 87 mm

Displacement 493 cc

Compression Ratio 18

Max. Engine speed at full load 2200 RPM

Continues Power Output 7.5 kW

Specific Fuel Consumption 171 gr/HP.h

Volume per injection 0.07 mL

Data retrieval is performed on diesel engines in

normal conditions and in fuel mode. The engine is

operated at 1800, 2000 and 2200 rpm with a variation

of the 0-4000 Watt electric load. In dual fuel systems,

the gas is injected into the intake manifold at 20ᵒ

BTDC at the exhaust stage or in conjunction with the

opening of the suction valve. While diesel fuel is

injected into the combustion chamber according to

the engine conditions, namely at 18ᵒ BTDC on the

compression stage. Gas fuel entering the combustion

chamber is regulated in 1-3 litre / minute variations.

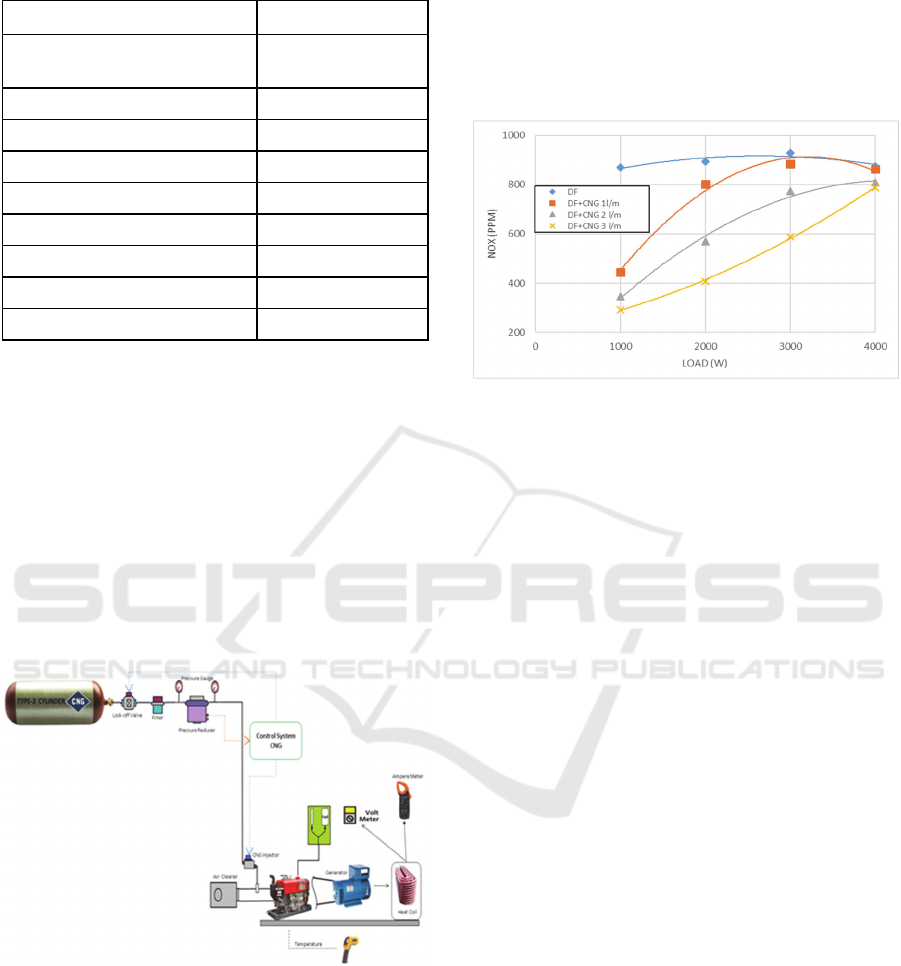

Experimental set-up of this study is presented on

Figure 1.

Figure 1: Experimental Engine Set-up.

4 DISCUSSION

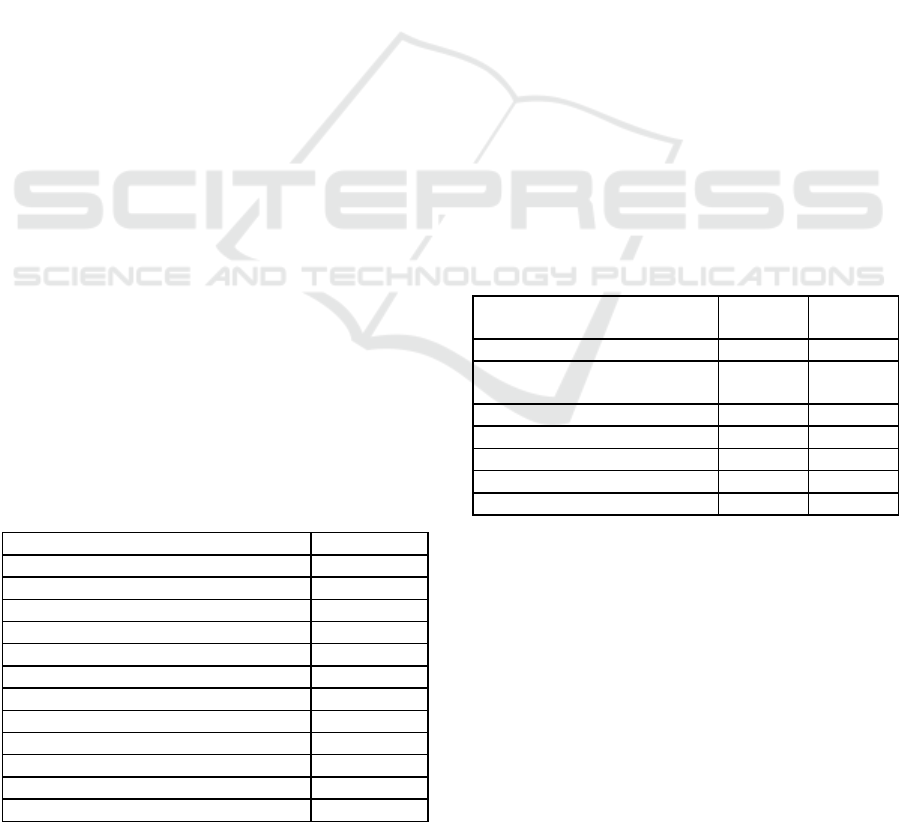

4.1 Nitrogen Oxide (NOx)

The addition of CNG to the diesel engine combustion

process affects the NOx emissions produced by the

engine. When the engine was operated in normal

mode using diesel fuel, NOx emissions generated

from the combustion process are as much as 871 ppm.

However, the amount gradually decreases as the CGN

is added to the combustion chamber. At 25% engine

load, the reduction of NOx as a result of adding a

number of CNG is between 50-65%.

Figure 2: Effect of CNG addition and engine load on NOx

Emission.

According to Figure 2, engine load also affects

NOx emission. When the engine was operated in

normal mode, the amount of NOx rise along with the

increase of engine load and it reaches the maximum

value when the engine operates on the 75% engine

load before finally returning down at maximum load.

On the other hand, when the engine operates in dual

fuel mode, NOx emissions generated increase with

the increasing of engine load. When engine operating

on dual fuel mode at 100% of engine load, the NOx

value is almost equivalent to the engine when

operating in normal mode.

The addition of CNG in the combustion process

increases the heat capacity of the air mixture, CNG

and diesel fuel in-cylinder which results in a

reduction in the average temperature at the end of the

compression step and during the overall combustion

process. Low combustion temperature affects the

decrease in NOx formation. At lower engine loads,

the resulting combustion temperature is very low so

that a decrease in NOx on the engine low load occurs

significantly

(Wei, 2016)

. This event is shown in

Figure 2. Longer ignition delay from combustion of

natural gas / diesel double fuel due to differences in

properties of both fuels and the poor quality of

combustion of natural gas caused by lean premix

conditions will reduce combustion temperature,

resulting in a reduction in NOx emissions

The effect of engine speed on the amount of NOx

can be seen in Figure 3. When the engine operates in

normal mode, NOx drops when the engine speed

increases. While dual fuel mode experiences the

opposite. On diesel engine operation, the increase in

Compressed Natural Gas Addition Effect on the Exhaust Emission of Diesel Dual Fuel Engine based on Experiment

123

engine speed, NOX formation time becomes reduced,

and hence NOX emissions decrease.

Figure 3: Effect of CNG addition and engine speed on NOx

Emission.

4.2 Carbon Monoxide (CO)

Figure 4 present the effect of CNG addition and

engine load on CO emission on diesel engine.

According to Figure 4, when diesel engine operated

normally, the CO emission generated from the

combustion process is 445 ppm. The amount going

down first, then increase when the engine load

increase from 50% to 75% of engine load and keep

increase during the increasing of engine load to

100%.

Opposite from diesel engine operation, on dual

fuel operation, the increasing of CNG quantity on

combustion chamber affect the increasing of CO

emission. The increasing of CO emissions occurs

between 400-600 times the amount of CO when

operating in normal diesel. However, this amount

gradually going down when the increasing of engine

load. The lowest CO emission of dual fuel mode

occurs when the engine operated on 75% engine load,

and then slowly increase at 100% engine load. The

amount of CO emission on normal diesel and dual

fuel operated almost equal when engine operates at

100% engine load.

Natural gas air mixture ignited by diesel fuel as a

pilot under dual fuel operation and the flames should

spread through the charge. The mixture in some areas

is too lean to maintain the propagation of fire. For

this, the local temperature drops and the CO oxidation

reaction freezes. This is the reason of CO emissions

increase under dual fuel operation.

Figure 4: Effect of CNG addition and engine load on CO

Emission.

4.3 Carbon Dioxide (CO2)

Figure 5: Effect of CNG addition and engine load on CO2

Emission.

The addition of CNG to the diesel engine combustion

process affects the CO2 emissions produced by the

engine as presented on Figure 5. When the engine

operates in normal mode using diesel fuel, CO2

emissions generated from the combustion process are

as much as 3.4%. However, the amount gradually

decreases as the CGN is added to the combustion

chamber. Under both engine operation, CO2 emission

increase when the engine load increase. The reduction

of CO2 in every engine load occur. The reduction of

CO 2 emission at 25%, 50%, 75% and 100% engine

load respectively are 11%, 5.1%, 6.1% and 3.3%.

CNG with the main constituent of methane gas

has one of the lowest carbon content among

hydrocarbons. CNG combustion has the potential to

produce lower CO2 emissions compared to diesel.

Under dual fuel mode, imperfect combustion is a

serious problem. Some fuels are not fully oxidized to

CO and dumped into the exhaust pipe, which can

reduce CO2 emissions.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

124

5 CONCLUSION

The effect of CNG addition has been investigated

above. According to data obtained, the conclusion of

this study are:

1. The NOx emission formed by high temperature

of combustion process. The addition of CNG on

dual fuel operation decrease the NOx emission.

The most reduction of NOx emission obtained

when engine operates at low load under dual

fuel operation. In the other hand, the increasing

of CNG quantity also affect the NOx reduction.

2. The CO emission formed because of incomplete

combustion of engine. The addition of CNG on

diesel operation affect the increasing of CO

emission. Under normal diesel operation, the

amount of CO going down firs and then increase

when the engine load increase. However, under

dual fuel operation the CO emission gradually

going down when the increasing of engine load.

3. The CO2 emission formed because of complete

combustion process. The addition of CNG on

diesel operation reduce CO2 emission. Under

both engine operation, CO2 emission increase

when the engine load increase

ACKNOWLEDGMENT

Firstly, the authors would like to thank and

acknowledge to the KEMENRISTEK DIKTI

Indonesia to provide research grants and support the

financials of this research. And furthermore, the

authors would like to be obliged to Department of

Marine Engineering, ITS for providing laboratory

facilities.

REFERENCES

Hussain J., Palaniradja K., Alagumurthi N., Manimaran R.,

2012. Effect of Exhaust Gas Recirculation (EGR) on

performance and emission characteristics of three

cylinder direct injection compression ignition engine,

Alexandria Engineering Journal, 51, 241-247.

C. P. Fenimore, 1971. Formation of nitric oxide in premixed

hydrocarbon flames, Symp. Combust. 13 (1) 373–380.

Arif A., Sudarmanta B., 2015. Karakterisasi performa

mesin diesel sistem dual fuel Solar-CNG tipe LPGI

dengan pengaturan start of injection dan durasi injeksi

CNG, Tesis Magister, Institut Teknologi Sepuluh

Nopember Surabaya.

C. T. Bowman, 1979. Kinetics of pollutant formation and

destruction in combustion, in: N.A. Chigier (Ed.),

Energy and Combustion Science (Student Edition One),

pp. 33–45 (Pergamon).

D. I. G. Stiesch, 2003. Modeling Engine Spray and

Combustion Processes: Springer Berlin Heidelberg.

Ehsan Md, Bhuiyan S, 2009. Dual fuel performance of

small diesel for application with less frequent load

variations, International Journal of Mechanical and

Mechatronics Engineering (IJMME), 9 (10), pp 30-39.

Heywood J. B., 1998. Internal Combustion Engine

Fundamental, New York: McGraw - Hill Book Co.

JFE Engineering, 2014. Dual Fuel Engine Gas Fuel

Conversion Technology, JFE Technical Report, 19.

K. Hoekman, C. Robbins, 2012. Review of the effects of

biodiesel on NOx emissions, Fuel Process. Technol. 96

(0) 237–249.

Komar I., Antonic R., Matic P., 2007. Selective Catalytic

Reduction as secondary methode to remove NOx from

diesel engine exhaust gas, IFAC Proceedings, 40 (17)

305-309.

Mehta R., Chauhan A.K., Patel J., Khatri M., Panchal D.,

2015. A study on dual fuel engine: Opportunities for

development of non polluting and efficient I.C. Engine,

International Journal of Engineering Science and

Innovative Technology (IJESIT), 4 (2) 420-424.

Ohashi I., 2015. Dual fuel marine engine (highly reliable

environmentally friendly engine), YANMAR Technical

Review.

S. Fernando, C. Hall, S. Jha, 2006. NOx reduction from

biodiesel fuels, Energy Fuel 20 (1) 376–382.

Sahoo B. B., Sahoo N., Saha U.K., 2009. Effect of engine

parameters and type of gaseous fuel on the performance

of dual-fuel gas diesel engine – A critical review,

Renewable and Sustainable Energy Reviews, 13, pp

1151-1184.

Semin and R.A Bakar., 2008. A technical review of

compressed natural gas as an alternative fuel for

internal combustion engines, American Journal of

Engineering and Applied Sciences, 1, 302-311.

Semin, Bakar R.A., Ismail A.R., 2007. Air flow analysis of

four stroke direct injection diesel engines based on air

pressure input and L/D ratio, Research Journal of

Applied Science, 2 (11), pp 1135-1142 (2007).

Semin, Bakar R.A., Ismail A.R., 2009. Green engines

development using CNG as an alternative fuel; A

review. American Journal of Environmental Science, 5

(3), 371-381.

Semin, Bakar RA, 2013. Simulation and experimental

method for the investigation of comressed natural gas

engine performance, International Review of

Mechanical Engineering (IREME), 7 (7).

Semin, Gusti A.P., Octaviani N.S., Zaman M.B., 2016.

Effect of new injector on the torue performance

characteristics of gas engine, International Journal of

Applied Engineering Research, 11 (11) 7462-7466.

Semin, Octaviani N.S., Gusti A.P., Zaman M.B., 2016.

Power performance characteristics investigation of gas

engine using new injector, International Journal of

Applied Engineering Research, 11 (11) 7462-7466.

Compressed Natural Gas Addition Effect on the Exhaust Emission of Diesel Dual Fuel Engine based on Experiment

125

Sun L., Liu Y.F., Zeng K., Yang R., Hang Z.H., 2015.

Combustion performance and stability of a dual fuel

diesel natural gas engine, Proc Inst. Mech Eng. D.J.

Automob. Eng. 229 (2), 441-453.

T. Kitamura, J. Senda, H. Fujimoto, 2002. Mechanism of

smokeless diesel combustion with oxygenated fuels

based on the dependence of the equivalence ratio and

temperature on soot particle formation, Int. J. Eng. Res.

3 (4) 223–248.

Tesfa B., Mishra R., Zhang Q., Gu F., Ball A.D., 2013.

Combustion and performance characteristics of CI

engine running with biodiesel, Energy, 51 (0), 101-115.

Tiwari A., 2015. Converting a diesel engine to dual fuel

engine using natural gas. International Journal of

Enrgy Science and Engineering, 1 (5), 163-169.

Wang Z., Zhao Z., Wang D., Tan M., Han Y., Liu Z., Dou

H., 2016. Impact of pilot diesel ignition mode on

combustion and emissions characteristics of a

diesel/natural gas dual fuel heavy-duty engine, Fuel

167, 248-256.

Wei L., P. G., 2016. A Review on Natural Gas/Diesel Dual

Fuel Combustion, Emissions and Performance. Fuel

Processing, 142, 264-278.

Zoltoski A., 2014. Investigation of combustion process in

dual fuel diesel engine, Journal of KONES Powertrain

and Transport, 21 (2)303-309.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

126