Thrust Analysis and Type of Kaplan Series and B Series Torque

Propeller on Monohull, Catamaran, and Trimaran Vessels with

Variations in Number of Blade using Computational Fluid Dynamic

Berlian Adietya, Deddy Chrismianto, Jatie Erlangga and Harno

Naval Architecture Department, Diponegoro University, 50275 Semarang, Indonesia

Keywords: Propeller, Monohull, Catamaran, Trimaran, CFD.

Abstract: One part of the propulsion system is a propeller. The choice of a good driving device will affect the force of

the ship. One way of selecting a ship propulsion is the selection of the propeller type as well as providing

new variations of the propeller to produce the maximum thrust force. Kaplan series and B Series are the

most widely used blade type propellers on ships. The purpose of this study was to determine the optimum

thrust value and the lowest torque from the variation of the monohull, catamaran and trimaran propeller

vessels. Variations made are adding the number of blades to 4 and 5. The model was simulated using the

computational fluid dynamic method on the Ansys CFX software. The results of this study indicate that the

monohull propeller K6 60 Series pitch ratio 0.7 has the greatest thrust value of 333797 N. For catamaran

ships, propeller K4 60 Series pitch ratio 0.6 has the greatest thrust value of 61986.4 N. For trimaran ships,

propeller K4 60 Series pitch ratio 0.6 has the greatest thrust value of 0.8727 N.

1 PRELIMINARY

Propeller efficiency is influenced by several things

including the shape of the ship's hull and the ship's

propulsion system itself.

In determining the optimal ship propulsion

system, propeller design planning is an important

aspect that needs attention. Ship propeller design is

also considered for ship operational needs in terms

of its economy (Hartono, 2008). Propeller is one

aspect that must be planned properly to achieve the

purpose of the ship's function in achieving speed.

The speed of the ship cannot be separated from the

good propeller design in order to get the optimal

thrust produced by propeller motion (Nurul, 2013).

Seen from its function, monohull, catamaran, and

trimaran vessels must have a good propulsion

system to produce optimal thrust values in the

propeller. Thrust is the driving force that results

from the lifting force on the back of the propeller

that moves and is in line with the movement of the

ship. One of the requirements that need to be

considered in the propeller design to get maximum

thrust is the number of blades (Trimulyono, 2015).

The greater the value of the blade area ratio, the

greater the thrust force (Bangkit et.al, 2016). The

previous Kaplan series type propeller design is the

addition of the propeller end plate (Andilolo, 2017).

In this study, the propeller planning made is to

do variations in the number of blade added. Blade

area ratio is the ratio between the blade area of the

propeller and the full rotation area of the blade tip or

commonly referred to as A0 (Bangkit et.al, 2016).

While the pitch ratio is the axial distance round the

propeller.

The study conducted is to do variations on the

existing propeller model. Variations made include

increasing the number of propeller blade to 4 and 5

blade.

The limitation of the problem in this study is to

only analyze the thrust and torque values of the

variation of the propeller model. This study also

ignores the factors and conditions of fluid flow from

the ship's hull and only analyzes the flow

distribution behind the propeller. The shape of the

propeller hub was also ignored in this study.

Propeller variation model will be analyzed using

computational fluid dynamic method. In this study

do not do the cost analysis calculation.

The purpose of this study was to obtain the

greatest thrust value and torque from the variation of

the propeller model that was carried out. This study

is expected to provide benefits in the development of

shipping technology, especially in the field of ship

Adietya, B., Chrismianto, D., Erlangga, J. and Harno, .

Thrust Analysis and Type of Kaplan Series and B Series Torque Propeller on Monohull, Catamaran, and Trimaran Vessels with Variations in Number of Blade using Computational Fluid

Dynamic.

DOI: 10.5220/0008373000210028

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 21-28

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

21

propulsion. In addition, this study can be used as a

reference source in terms of consideration of the

selection of propellers that are appropriately applied

to ships and can also be a reference for propeller

producers to innovate propeller products to be

produced.

2 METHOD

2.1 Data Collection

The data needed for this study are the data of the

main size of monohull, catamaran and trimaran ship

propellers.

Table 1: Main Size Propeller B-Series.

Tipe B Series

Number of blade 4

Diameter 0,8 meter

Blade Area Ratio 0,70

Pitch 0,8

Angle of Rake 0

Propeller Rotation 0 rpm

2.2 Modelling and Variation

Modelling of the Kaplan Series propeller is based on

data from the main size of the propeller and the

addition of variations to the propeller. In this study

the parameters used are as follows:

• Constantly Parameter:

1. Main Size from ship propeller.

• Unconstantly Parameter

1. Number of blade 4 and 5

2. Rpm 600, 900, and 1000

3. Propeller type B-Series and Kaplan

Table 2: Shows Data on 12 Variations of the Kaplan

Series Propeller Model.

Model Number of Blade Rpm Propeller Type

Monohull 1 4 600 B-Series

Monohull 2 4 600 Kaplan

Monohull 3 5 600 B-Series

Monohull 4 5 600 Kaplan

Catamaran1 4 1000 B-Series

Catamaran2 4 1000 Kaplan

Catamaran 3 5 1000 B-Series

Catamaran 4 5 1000 Kaplan

Trimaran 1 4 900 B-Series

Trimaran 2 4 900 Kaplan

Trimaran 3 5 900 B-Series

Trimaran 4 5 900 Kaplan

2.3 Model Simulation

Analysis of variations in propeller models using the

Computational Fluid Dynamic method on the Ansys

CFX software. This method has often been used to

analyze fluid flow especially in thrust analysis and

torque propeller in previous studies.

2.4 Study Sites

This research was conducted at the hydrodynamic

laboratory, Department of Naval Architecture,

Faculty of Engineering, Diponegoro University,

Semarang.

3 RESULTS AND DISCUSSION

3.1 Model Making Stage

In making a propeller model, the main size of the

propeller is used as the initial data entered in the

PropCad software. Variations that will be applied to

the propeller are also modeled in this software. Then

a 3D propeller model will be produced along with

propeller geometry data. Here are the results of the

visualization of the propeller model from PropCad

software.

Figure 1: Propeller on Software Prop Cad.

After modelling the PropCad software, it was

repeated using Solidwork software to improve the

model. The propeller model made is 16 models with

variations in the number of blade, blade area ratio

and pitch ratio as well as 1 model with the addition

of nozzle kort. The following are the results of

visualization modelling using solidwork software.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

22

Figure 2: Propeller on Software Solidwork.

3.2 Simulation of Computational Fluid

Dynamics

The propeller model created in Solidwork software

then exported in the iges format to be imported into

the Ansys CFX software. The steps of propeller

simulation on Ansys CFX software include:

1. Geometry

2. Mesh

3. Setup

4. Solution

5. Result

3.2.1 Geometry Stage

At this stage the model entered must be solid. The

next step is to make a tubular fluid domain. The size

of the fluid domain is adjusted to the propeller

model to be analyzed.

Figure 3: Geometry Stage Visualization.

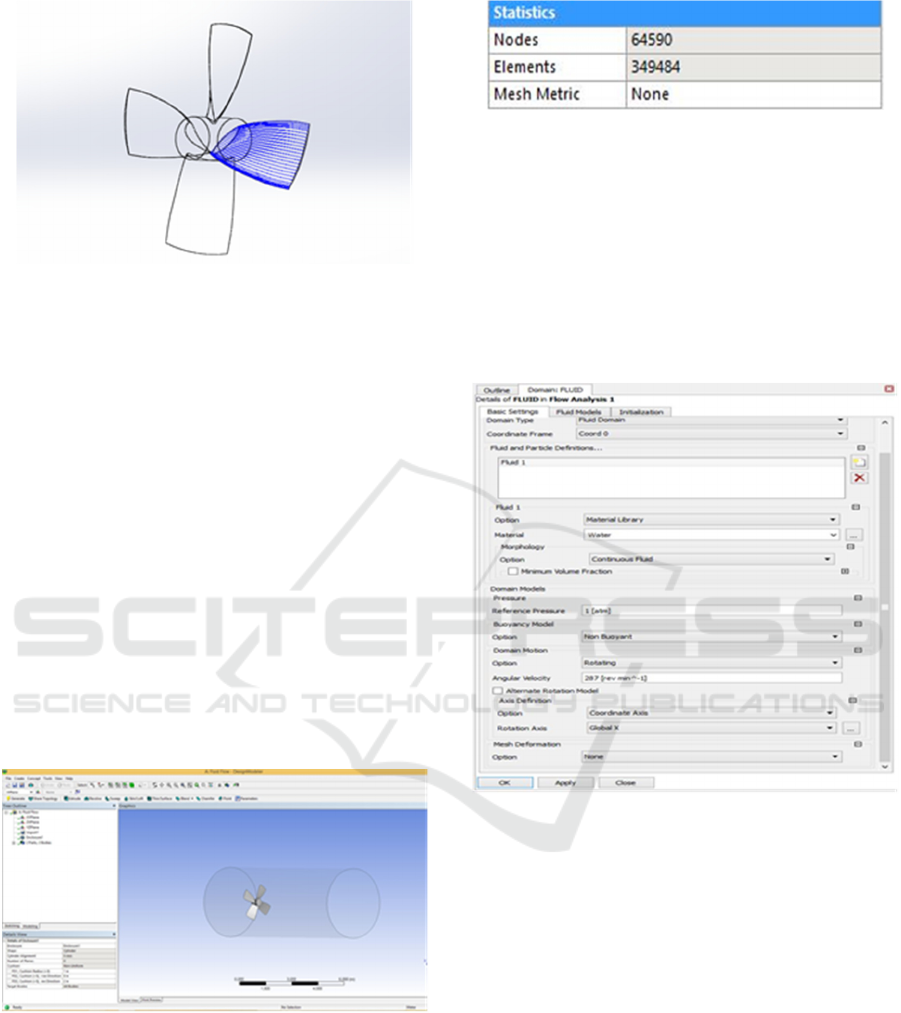

3.2.2 Mesh Stage

After the fluid domain is formed, the next is

meshing the model. The initial step in meshing is to

determine the size of the element used. The smaller

elements that are made running time are longer and

the file capacity is greater.

Figure 4: Meshing result statistics.

3.2.3 Setup Stage

In the setup stage data input will be used for

computational fluid dynamic simulations. The initial

step at this stage is to create a default domain.

Domains created include domains for fluids and

propellers. The next step is making boundaries.

Boundaries made include inlet, outlet and wall in the

domain fluid.

Figure 5: Default domain.

The next step is making initialization. The menu

is almost the same as the boundary. The final step is

the determination of the solver which one of its

functions determines the unit for measures in the

simulation process and control solver.

3.2.4 Solution Stage

The solution phase is a running calculation process

in the form of literacy from the basic equation of

computational fluid dynamic.

Thrust Analysis and Type of Kaplan Series and B Series Torque Propeller on Monohull, Catamaran, and Trimaran Vessels with Variations in

Number of Blade using Computational Fluid Dynamic

23

Figure 6: Convergence Running Model.

3.2.5 Result Stage

At the result stage the running results can be known.

The amount of thrust and torque can be obtained as

well as the model and flow visualization can be

displayed.

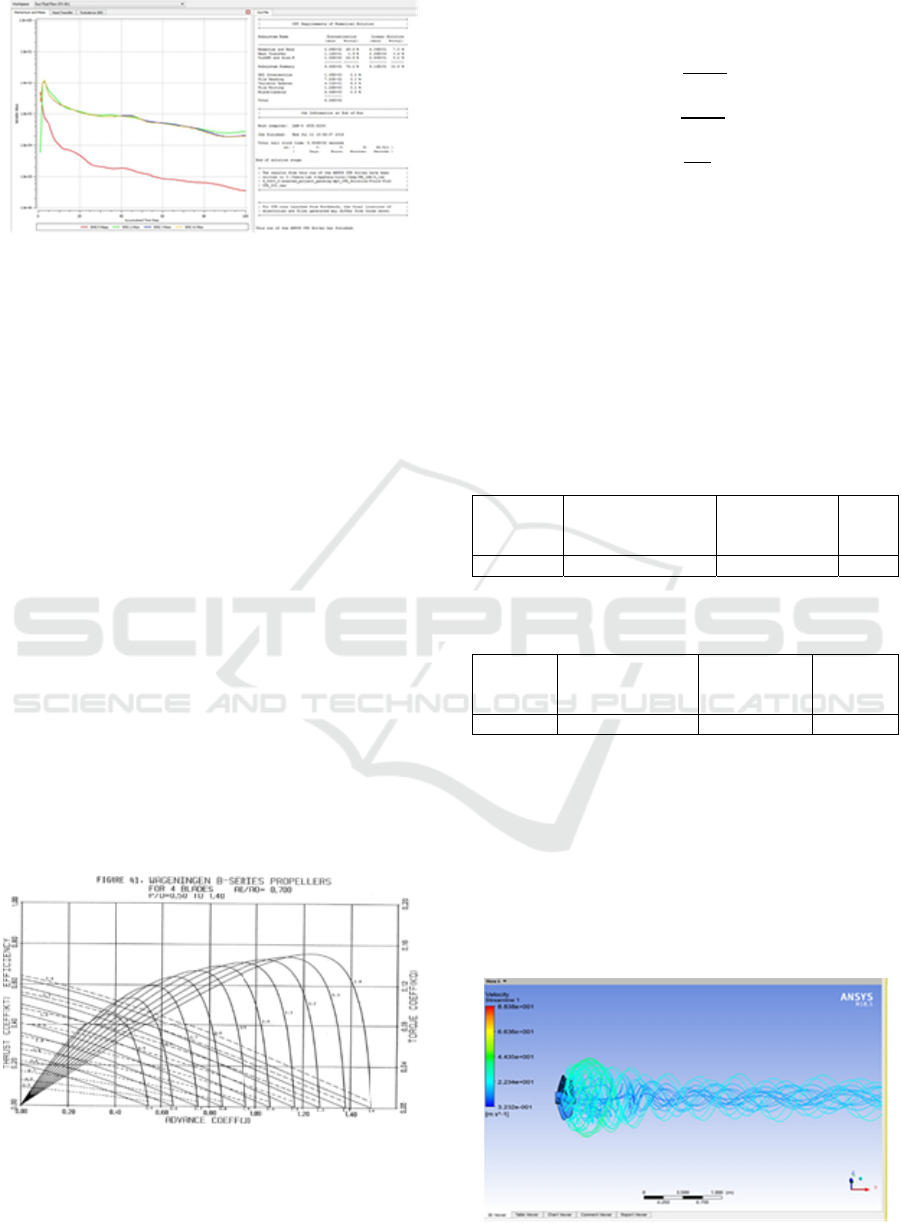

3.3 Propeller Validation

In this study the validation used was the result of

previous research. The main size of the propeller and

the main size of the ship in this study are the same as

previous studies. Validation is used to determine the

right boundary condition at the setup stage, so that it

can be used to analyze the propeller model analyzed

in this study.

Validation references for propellers use the

Wageningen B-Series graph. The propeller model

used is the Wageningen B4 70 Series type. The

maximum error for validation between

computational fluid dynamic and calculation results

is 5%.

In general, the characteristics of the ship

propellers in the open water test conditions are as

presented in the KT-KQ-J diagram.

Figure 7: Diagram Kt-Kq-J B4-70 (Bernitsas, 1981).

Mathematical calculations to find thrust and

torque are using the formula obtained from the

calculation of Wageningen B-Series. Equation

models for ship propeller performance

characteristics are as follows:

4

(1)

(2)

(3)

Where KT is the propeller thrust coefficient, KQ is

the propeller torque coefficient, J is the advance

propeller coefficient, Va is the advance (fr / s)

velocity, D is the propeller diameter (ft), n is the

propeller rotation (rev / s), T is the thrust propeller

(lbf), Q is the torque propeller (lbf / ft) and ρ is the

type of fluid.

The results of thrust and torque calculations on

computational fluid dynamic simulations and

mathematical calculations using Wageningen B-

Series charts are as follows:

Table 3: Thrust Propeller Validation (Wibowo et.al, 2017).

Rotation

Speed

(rpm)

The Calculation

Thrust Results

(N)

The CFD Result

(N)

Error

(%)

287 123006,49 122713,00 0,23

Table 4: Validation Torque Propeller (Wibowo et.al,

2017).

Rotation

Speed

(rpm)

The Calculation

TorqueResult

(Nm)

CFD

Simulation

Results (Nm)

Error

(%)

287 39646,94 40196,4 1,38

From the results of computational fluid dynamic

calculations compared to the results of mathematical

calculations of propellers using the Wageningen B-

Series graph, the margin of error is below 5%. This

means that the setup parameters in the computational

fluid dynamic calculation are quite accurate. Then

the setup parameter will be used in this study.

3.4 Results Analysis

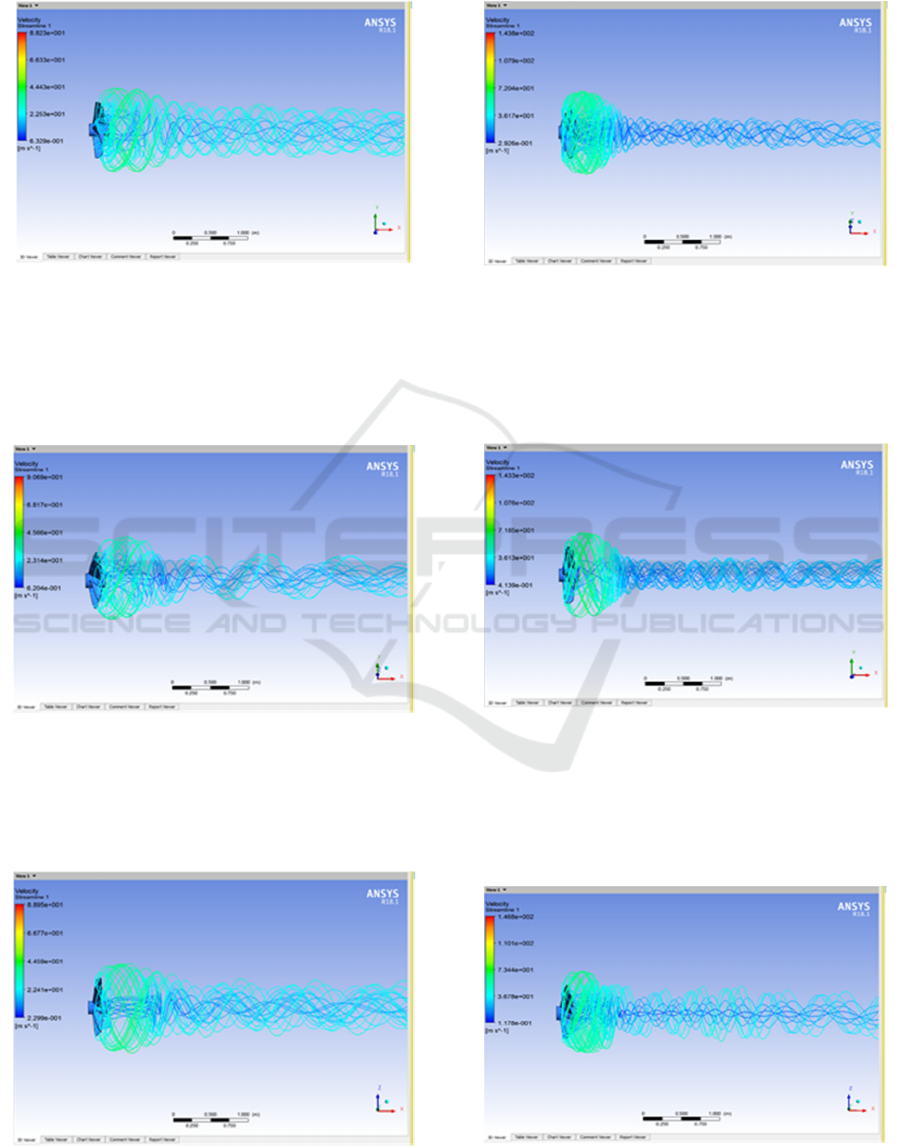

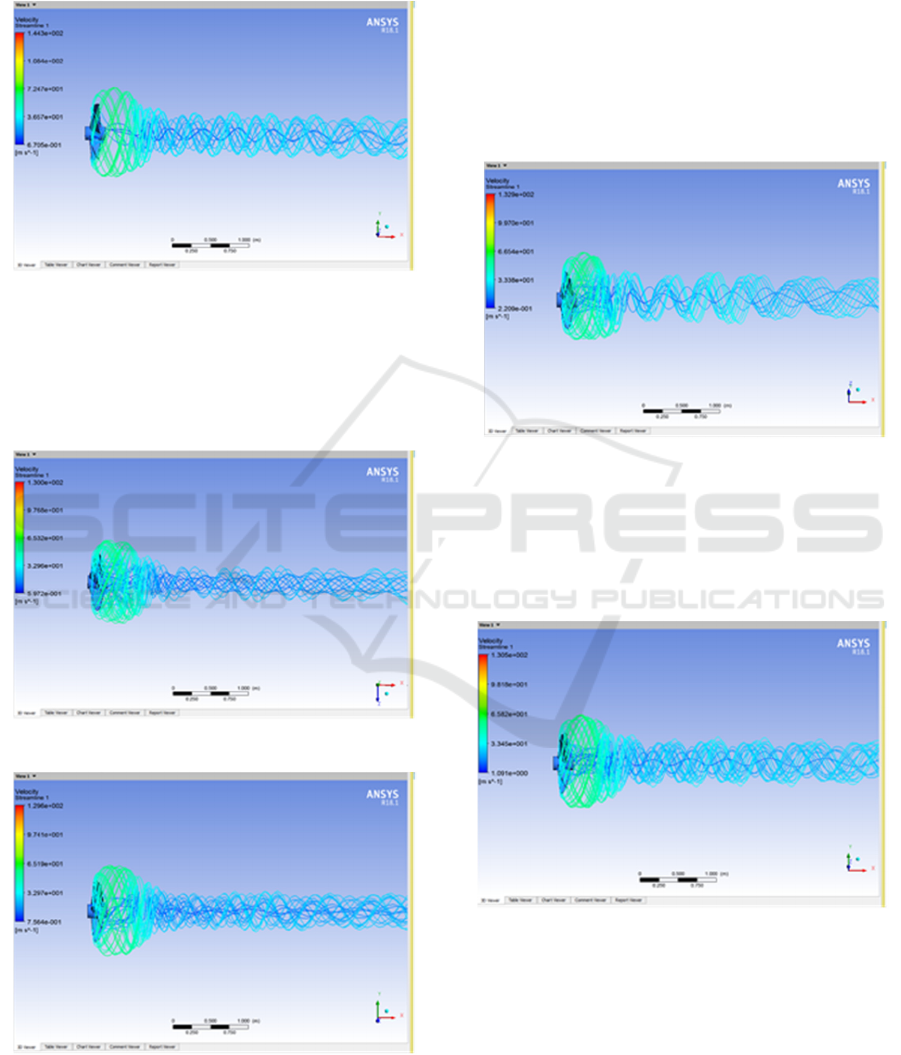

Figure 8: Result Streamline Monohull 1.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

24

In the streamline model Monohull 1 has a less stable

and constant fluid flow. Fluid flow is less smooth

and turbulence is quite high in front of the propeller.

Figure 9: Result Streamline Monohull 2.

In the streamline model Monohull 2 has a stable

and constant fluid flow. Fluid flow is quite smooth

and turbulence is smaller than before especially the

area in front of the propeller and along the flow is

quite low.

Figure 10: Result Streamline Monohull 3.

In the streamline model Monohull 3 has a fluid

flow that is less stable and not constant. The fluid

flow is less smooth and the turbulence in front of the

propeller is quite high.

Figure 11: Result Streamline Monohull 4.

The streamline Monohull 4 model has a stable

and constant fluid flow. Fluid flow is smooth enough

and turbulence is quite low along streamlined flow.

Figure 12: Result Streamline Catamaran 1.

The streamlined propeller model of Catamaran 1

has a fairly stable and fairly constant fluid flow.

Fluid flow is still quite smooth but the emergence of

turbulence is very large especially in the front area

of the hub.

Figure 13: Result Streamline Catamaran 2.

In the streamlined propeller model of Catamaran

2, the fluid flow starts to become unstable but is

quite constant. Fluid flow is still quite smooth, but

the emergence of turbulence starts large especially in

the propeller hub area.

Figure 14: Result Streamline Catamaran 3.

Thrust Analysis and Type of Kaplan Series and B Series Torque Propeller on Monohull, Catamaran, and Trimaran Vessels with Variations in

Number of Blade using Computational Fluid Dynamic

25

The streamlined propeller model of Catamaran 3

has an unstable and not constant fluid flow. Fluid

flow is not smooth enough and turbulence is quite

large in front of the hub.

Figure 15: Result Streamline Catamaran 4.

In the stream lined propeller model of Catamaran

4, the fluid flow is still stable and fairly constant.

Fluid flow is still quite smooth but the emergence of

turbulence is quite low in the hub propeller and

along the streamline.

Figure 16: Result StreamlineTrimaran 1.

Figure 17: Result Streamline Trimaran 2

In the streamlined propeller model of Trimaran 1 has

an unstable but constant flow of fluid. Subtle fluid

flow and turbulence are still quite large in the front

area of the hub propeller, but turbulence begins to

decrease along the streamline flow.

In the streamlined propeller model of Trimaran 2

has a fairly stable and fairly constant fluid flow.

Fluid flow is still quite smooth. Turbulence is quite

large in the front area of the hub propeller, as well as

turbulence as long as the streamline flow begins to

decrease.

Figure 18: Result Streamline Trimaran 3.

In the streamlined propeller model of Trimaran 3

has an unstable and not constant fluid flow. Less

smooth fluid flow and turbulence begin to decrease

in the front area of the hub propeller, and turbulence

along the streamline flow is quite low.

Figure 19: Result StreamlineTrimaran 4.

In the streamlined propeller model of Trimaran 4

has a fluid flow that starts quite stable and is quite

constant. Fluid flow is quite smooth and turbulence

is still quite large in the front area of the hub

propeller but low along the streamline flow.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

26

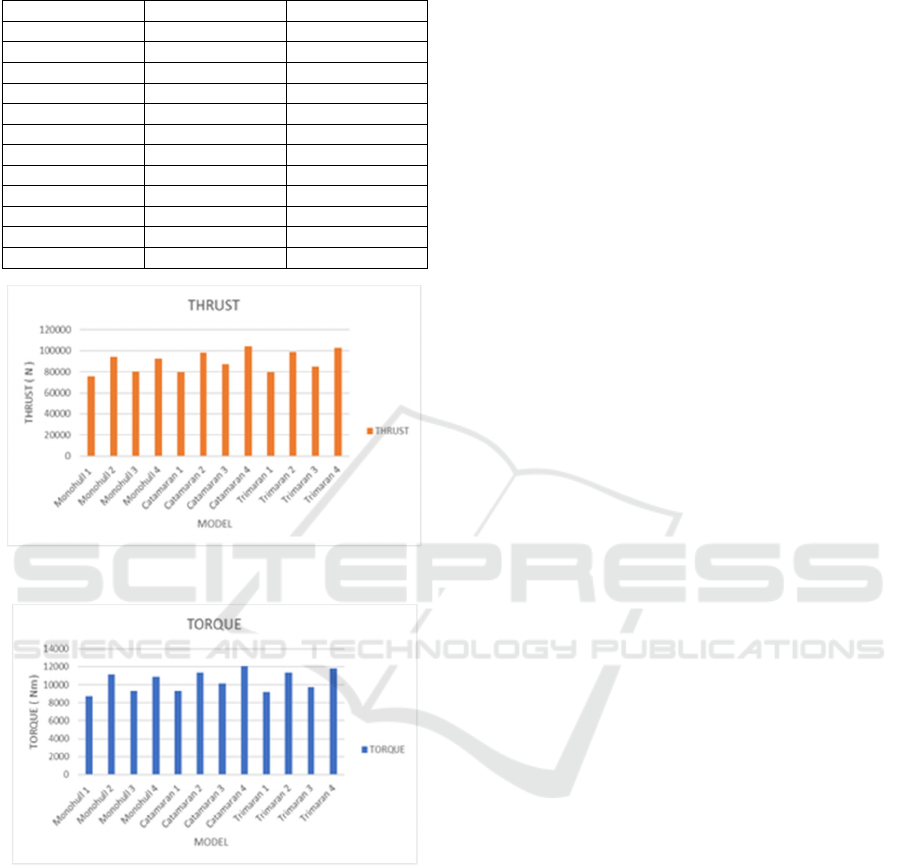

Table 5: Result of Thrust, Torque, and Efficiency of 16

Variation Propeller Model.

Model Thrust (N) Torque (Nm)

Monohull 1 75706 8745,81

Monohull 2 94624 11171,7

Monohull 3 80239 9300,41

Monohull 4 92666,6 10894,8

Catamaran1 79483 9267,26

Catamaran2 98143,9 11370,1

Catamaran3 87012 10136,2

Catamaran4 104105 12062,7

Trimaran1 79307,1 9193,42

Trimaran2 99067,6 11338,3

Trimaran3 84823,1 9771,13

Trimaran 4 102802 11779,4

Figure 20: Diagram of Thrust Propeller Value.

Figure 21: Diagram of Torque Propeller value.

3.5 Discussion

Based on the data in Table 5 and the Graphs in

Figures 20 and 21 show that the largest Thrust Value

for monohull vessels is obtained from the monohull

2 model, namely 70 Series K4 propellers that have

thrust of 94624 N.

The lowest Torque value for monohull vessels is

obtained from monohull 1 model, namely 70 Series

B4 propeller which has a torque of 8745.81 Nm.

The biggest Thrust value for Catamaran ships is

obtained from Catamaran 4 model, namely 70 Series

K5 propellers that have a thrust of 104105 N.

The lowest Torque value for Catamaran ships is

obtained from the Catamaran 1 model, namely the

70 Series B4 propeller which has a torque of

9267.26 Nm.

The biggest Thrust value for Trimaran ships is

obtained from Trimaran 4 models, namely 70 Series

K5 propellers which have a thrust of 102802 N.

The lowest Torque value for Trimaran ships is

obtained from the Trimaran 1 model, namely the 70

Series B4 propeller which has a torque of 9193.42

Nm.

Based on table 5 shows that the increasing

number of blade in the variations carried out will

increase thrust propeller. The greater the value of

Rpm or propeller rotation, the greater thrust will

result.

4 CONCLUSION

Based on the results of the calculation and

computational fluid dynamic simulation are

obtained, that is:

1. The Monohull 2 model, the K4 70 Series

propeller can be used as an alternative choice for

monohull ship propellers because it has

maximum thrust value.

2. Catamaran 4 model and Trimaran 4, K5 70

Series propeller can be used as an alternative

choice for Catamaran and Trimaran ship

propellers because they have maximum thrust

value.

REFERENCES

A. Trimulyono, 2015. Analisa Efisiensi Propeller B-Series

dan Kaplan Pada Kapal TugBoat ARI 400 HP Dengan

Variasi Junlah Daun , KAPAL, vol. 12, pp. 112–120.

G. P. Wibowo, D. Chrismianto, 2017. D. T. Perkapalan,

and U. Diponegoro, Analisa Nilai Thrust Optimum

Propeller B4-70, KA4-70 dan AU4-59 Pada Kapal

Tugboat Pelabuhan Paket-II 2X1850HP Dengan

Variasi Sudut Rake Menggunakan CFD, J. Tek.

Perkapalan, vol. 5, no. 1, pp. 27–37.

H. Nurul, 2013. Analisa Pengaruh Energy Saving Device

Pada Propeller Dengan Metode CFD. Semarang:

Tugas Akhir, Jurusan Teknik Perkapalan, UNDIP.

Hartono, 2008. Design Ekonomis Untuk Propeller Kapal,

TEKNIK, vol. 29, no. 3.

M. M. Bernitsas, 1981. KT, KQ and Efficiency Curves for

the Wageningen B-Series Propeller, Michigan.

Thrust Analysis and Type of Kaplan Series and B Series Torque Propeller on Monohull, Catamaran, and Trimaran Vessels with Variations in

Number of Blade using Computational Fluid Dynamic

27

P. Bangkit, S. Budi, D. Chrismianto, and G. Rindo, 2016.

Analisa Performance Propeller Tipe B-Series pada

Kapal Selam Midget 150M Dengan Variasi Skew

Angle dan Blade are Ratio (AE/AO) Menggunakan

Metode CFD, J. Tek. Perkapalan, vol. 4, no. 4, pp.

725–737.

Y. Rahardian Andilolo, 2017. Studi Kasus Kinerja

Propeller Kaplan Series Akibat Pengurangan Diameter

dan Penambahan End Plate dengan Metode CFD, J.

Tek. Perkapalan, vol. 5, no. 1, pp. 205–213.

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

28