Formulation of Moringa oleifera Leaf Extract in Lotion and Gel as

Sunscreen

Nining Sugihartini

1

, M. Alif Fajri

2

, Desty Restia Rahmawati

3

1

Departement of Pharmaceutical Technology, University of Ahmad Dahlan, Jln. Prof. Dr. Soepomo, Janturan, Umbulharjo,

Yogyakarta, Indonesia

2

Pascasarjana of Pharmacy University of Ahmad Dahlan, Jln. Prof. Dr. Soepomo, Janturan, Umbulharjo, Yogyakarta,

Indonesia

3

Faculty of Pharmacy University of Ahmad Dahlan, Jln. Prof. Dr. Soepomo, Janturan, Umbulharjo, Yogyakarta, Indonesia

Keywords: Moringa oleifera, leaf extract, gel, lotion, sunscreen

Abstract: Moringa oleifera leaf extract has an antioxidant activity so it can be used to protect the skin. The aim of this

study is to determine the extract specification and formulation in lotion and gel as sunscreen agent. Moringa

oleifera leaf extract was obtained by maceration method using ethanol 70%. The extracts were identified for

chemical content and specification test of extract. After that, extract was formulated into gel and lotion. The

evaluation of gel and lotion includes physical characteristics (spreadability and adhesivity) and the value of

Sun Protection Factor. The result showed that Moringa oleifera leaf extract contained alcaloids, flavonoids

and poliphenols. The value of moisture content, ash content, acid soluble ash, and β-caroten were 5.75%,

0.19%, 0.16%, and 0.46%, respectively. The IC

50

of antioxidant activity was 516.28. The value of Sun

Protection Factor of the 5% octyl metoxycinnamate solution, gel (contain 5% extract), and lotion (contain

5% extract) were 33.25, 34.75, 24.98, and 25.89, respectively. The lotion and the gels have a strong

sunscreen activity and meet the requirements of physical properties for preparations.

1 INTRODUCTION

Moringa oleifera contains ß-carotene, protein,

vitamin C, calcium and potassium that can be used

as natural antioxidant (Krisnadi, 2013). In addition,

other studies have also shown that moringa leaves

contain phenolic compounds, flavonoids and

carotenoids (Vongsak et al., 2013 and Jayawardana

et al., 2015). Based on the content of active

ingredients, moringa leaves have various properties

such as antioxidants, antimicrobials, natural food

preservatives, and anti-inflammatory (Jayawardhana

et al., 2015; Singh et al., 2009).

Indonesia as a tropical country has a high

intensity of sunlight, so one part of the body that was

affected by the condition is the skin. The skin, as

one of the body's protective organs, can undergo an

excessive dryness (Rawlings et al., 2000).

Therefore, it needs a certain dosage form that can be

used to protect and to maintain the moisture of skin.

Antioxidant and anti-inflammatory properties of

moringa leaves are expected to protect the skin from

free radicals that are caused by sunlight or other

factors.

A previous study have shown that moringa leaf

extract can be applied in topical form for the

prevention and treatment of oxidative and anti-aging

stress diseases (Atif et al., 2013). A research by

Sugihartini et al. (2016) showed that a 3%

concentration of extract in cream was able to

improve skin smoothness. The increasing

concentration of extract in cream will increase SPF

value. This study will focus on the formulation of

extract in the form of lotion and gel preparation with

an extract concentration of 3%. The evaluations of

dosage form will consist of physical properties of

the preparation and the SPF value.

2 MATERIALS AND METHOD

2.1 Materials

Moringa oleifera leaves was obtained at Yogyakarta,

Indonesia. The ingredients for lotion and gel were

154

Sugihartini, N., Fajri, M. and Rahmawati, D.

Formulation of Moringa oleifera Leaf Extract in Lotion and Gel as Sunscreen.

DOI: 10.5220/0008241001540158

In Proceedings of the 1st Muhammadiyah International Conference on Health and Pharmaceutical Development (MICH-PhD 2018), pages 154-158

ISBN: 978-989-758-349-0

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

vaseline album (Brataco, Indonesia), stearic acid

(Brataco, Indonesia), cetyl alcohol (Brataco,

Indonesia), thrietanolamin (Brataco, Indonesia),

dimeticon (Brataco, Indonesia), methyl paraben

(Brataco, Indonesia), propylene glycol (Brataco,

Indonesia), ethanol 0% (pharmaceutical grade),

ethanol 35% (pharmaceutical grade), etanol 70%

(pharmaceutical grade), and aquadest. The

instruments that was used were oven (Binder, ED

115/Esv 00-17289), rotary evaporator (Heidolph,

Germany), analitical balance (Wiggen Hauser),

waterbath (Memert, Germany), pH meter (WTW

82362 Weilheim, Germany), termometer,

sentrifugator (PLC-series), vacuum pump (Rotary

Vane), viskometer Rheosys Merlin VR, freeze dryer

(Virtis, United States), the equipment of adhesivity,

the equioment of spreadability and glassware (Pyrex,

United States).

2.2 Methods

2.2.1 Extraction of Moringa oleifera Leaf

Extract of leaves Moringa oleifera leaves was

obtained by using maceration method. The

maceration method was performed with a ratio of

1:40. The 10 grams of dried sample powder was

extracted by using of 400 mL ethanol 70%

pharmaceutical grade for 72 hours at room

temperature. After that, it was filtered with filter

paper and vacuum pump. The extract was

evaporated by using rotary evaporator and was

continued by using waterbath until dry (Vongsak et

al., 2013).

The extract of moringa leaf was obtained by

maceration method with ethanol 70%. This is based

on research results of Vongsak et al. (2013) which

indicates that the nutritious compounds of phenolic

and flavonoids as antioxidants can be maximized by

using the methods. This study will be identify the

specific and non-specific parameters of moringa leaf

extract.

2.2.2 Specification of Extract

The levels of β-carotene in moringa leaf extract was

determined by using High Performance Liquid

Chromatography. The extracts were also identified

for their chemical content, the extract specification

test included water content, total ash content, acid

soluble ash content.

2.2.3 Formulation of Moringa oleifera

Extract in Lotion and Gel

The composition of lotion and gel that was used in

this study are presented in Table 1 and 2.

The preparations of lotion and gel were

performed by using fusion principle. The water-

soluble and oil-soluble parts was were soluted in

water and then heated at a temperature of 70°C.

Then, the second mixture (water phase) was

gradually added into the first mixture (oil phase) at

70°C and was homogenized. The extract of moringa

was added when it was cold (Munson, 1991).

2.2.4 Evaluation of Physical Characteristic

• Adhesivity test

The gel or lotion was weighed 0.25 g and then was

placed between two glass objects. One kilogram of

load was put on the upper side of glass objects to

give a tension for 5 minutes. After that, the glass

object were put on the tool that had 80 grams of

load. The time was needed for two glass objects

separated after the load of 80 grams release was

noted (Putra and Setyawan, 2014).

• Spreadability test

The gel or lotion was weighed 0.5 g and then was

placed in the middle of a circular glass. The other

glass was placed on the upper side of it for 1 minute.

The diameter of lotion or gel was measured. One

hundred grams of load was placed on the glass for 1

Table 1: The Formulation of Moringa oleifera leaf

extract in lotion.

Composition Weight (g)

Stearic aci

d

4,00

Cetyl alcohol 4,00

Triethanolamine 2,00

Gl

y

cerin 2,00

Meth

y

l

p

a

r

a

b

en 0,20

Propyl

p

araben 0,03

Extract of moringa 3%

Aquadest Add 100

Table 2: The Formulation of Moringa oleifera leaf

extract in gel.

Composition Weight (g)

Carbopol 1

Triethanolamine 0,05

Glycerin 2

Pro

p

y

lene

g

l

y

col 1

Meth

y

l

p

araben 0,03

Extract of morin

g

a 3%, 6%

Aquadest 100

Formulation of Moringa oleifera Leaf Extract in Lotion and Gel as Sunscreen

155

minute and then the diameter of gel or lotion was

measured until getting a constant one (Astuti et al.,

2010).

• The measurement of pH

The pH values of lotion and gel were determined by

using pH meter after 500 mg of gel or lotion was

soluted in 5 ml of distilled water (Naibaho et al.,

2013).

• The measurement of Viscosity

The viscosity of lotion or gel was measured by

using Viscosimeter Rheosys Merlin VR.

2.2.5 The Measurement of Sun Protection

Factor Value

The values of Sun Protection Factor (SPF) of the gel

and the lotion were determined based on a set

method by Bambal et al. (2011). A total of 1 gram of

sample was added to Erlenmeyer and then was

added with ethanol up to 100 ml. The solution was

sonicated for 5 minutes and then the mixture was

filtered. A total of 10 ml of first filtrate was

discarded. Furthermore, filtrate was taken as much

as 5 ml and then was added ethanol up to 50 ml.

Five ml of the solution was taken and was added

with ethanol to 25 ml. The spectral absorbance was

read by using spectrophotometer at 290-320 nm with

a wavelength interval of 5 nm. The SPF value was

calculated based on the equation (1):

SPF

spectrophotometric

(1)

2.2.6 Data Analysis

The data were analysed by ANOVA test to find the

level of differences between the formulas.

3 RESULT AND DISCUSSION

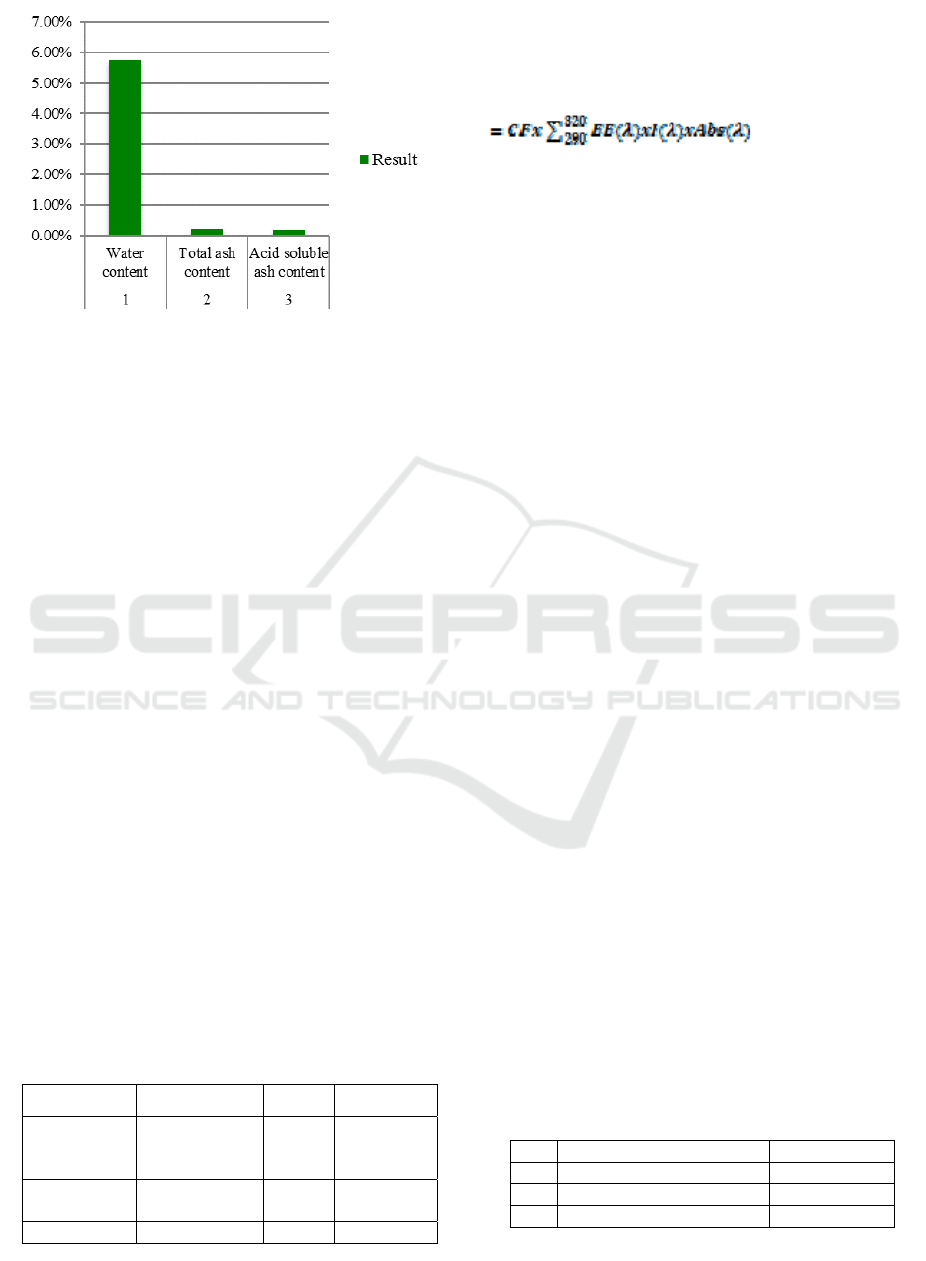

The extract obtained in this study was evaluated for

water content, total ash and acid soluble ash content

as presented in Figure 1. The total ash content and

acid soluble ash content of moringa leaf extract

fullfilled the requirement (≤0.20%) based on Herbal

Pharmacopoeia (year). The extracts were also

evaluated for their chemical content including

alkaloids, flavonoids and polyphenols as presented

in Table 3.

The extract was also analysed for the level of β

carotene as active substance in the extract. The

extract potency was evaluated based on antioxidant

activity by calculating IC

50

and SPF values. The

result of the assay of β-carotene, IC50 and SPF

values was presented in table 4.

The test results show that IC

50

was 516.28. This

means that the antioxidant activity of moringa leaf

extract was weak. However, the extract has a high

SPF value of 33.25 which means it has a strong

sunscreen activity. The step after the extract

specification was formulation of extracts for the

preparation of lotions and gels. The preparations

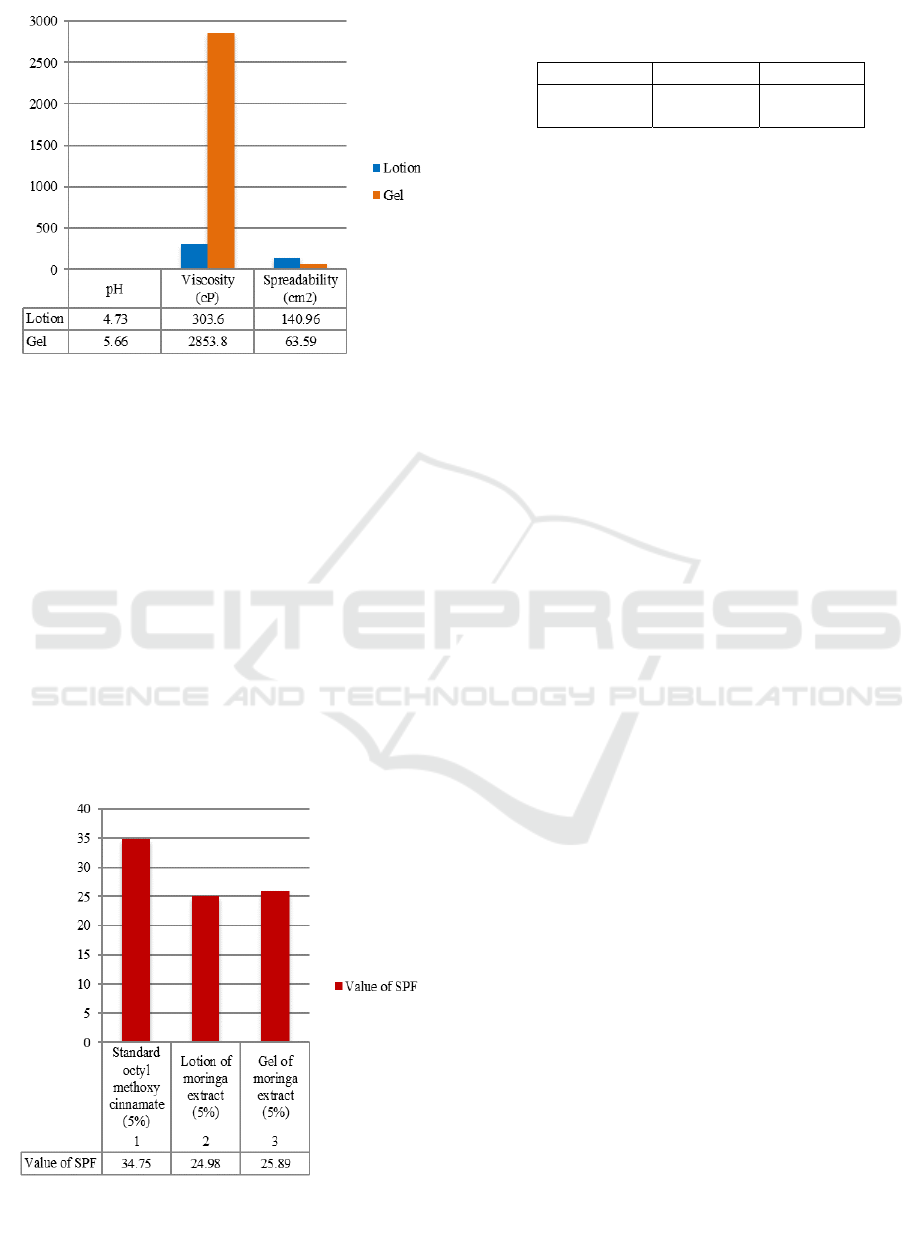

were then evaluated for physical properties as

presented in Figure 2 and table 5. The test results

show that all the preparations also met the

requirements of pH, viscosity, adhesivity and

spreadability.

The test results show that the pH values of the

lotion (4.75) and the gel (5.66) met the requirements

of pH of the skin preparation that are between 4.5 to

Table 3: Result of identification of chemical content on

moringa extract.

Test Reagen Result Evidence

Alkaloid HCL 2N,

Dragendorf

and maye

r

+ There was

sediment

Flavanoid Ethanol 70%,

amonia

+ Yellow

Pol

yp

henol FeCL

3

+ Green dar

k

Table 4: The number of β carotene, IC

50

and SPF value

of

extract moringa.

No Test Result

1. The number of β karoten 0,024 mg/ml

2. The value of IC

50

516,28

3. The value of SPF 33.25±0.98

Figure 1: Result of water content, total ash content

and acid soluble ash content in the extract of

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

156

6.5 (Swastika et al., 2013). Otherwise, it will cause

irritation. The viscosity of the lotion (303.6 cP) was

lower than gel (2,853.8 cP) which resulted in a

thinner consistency. It also increased the lotion’s

spreadability and decreased its adhesivity (Vicky et

al., 2016; Latifah et al., 2016). The lotion and the

gel met the requirements of adhesivity, that is at

least 4 seconds, spreadability, that is between 5-7

cm

2

(Ulaen et al., 2012; Garg et al., 2002).

The potencies of lotion and gel of moringa leaf

extract as a sunscreen agent were evaluated based on

SPF values as presented in Figure 3. The results

show that, at concentration of 5%, both gel and

lotion have a strong activity as sunscreen although

the values were lower than the standard octyl

methoxycinnamate. The existing sunscreen activity

may be due to the presence of active ingredients

such as alkaloids, flavonoids and polyphenols that

are able to absorb the sunlight.

4 CONCLUSION

Moringa leaf extract contains alkaloids, flavonoids

and polyphenols and meets the requirements of

moisture content, ash content and acid soluble ash

content. The extract has a weak antioxidant activity

but a strong activity as a sunscreen. Similarly, when

it has been formulated in the preparation forms, of

lotion and the gel have a strong sunscreen activity

and meet the requirements of physical properties of

preparations.

ACKNOWLEDGEMENT

This study was supported by PUPS LPP grant in

2017.

REFERENCES

Astuti, I.Y., Hartanti, D.,Aminiati A., Majalah Obat

Tradisional, 15, 94-99 (2010).

Atif, A., Akhtar, N., Mumtaz, A.M., Khan.M.S.,

Iqbal,F.M and Zaidi.S., 2013, In Vivo Skin Irritation

Potential of a Cream Containing Moringa oleifera

Leaf Extract, American Journal of Pharmacy and

Pharmacology, 7(6) : 289-293.

Garg A, Aggarwal ID, Garg S, Sigla AK, 2002 An Update,

Pharmaceutical Technology 84.

Jayawardana B.C, Liyanage R, Lalantha N, Iddamalgoda

S,Weththasinghe P, 2015, Antioxidant and

antimicrobial activity of drumstick (Moringa oleifera)

leaves in herbal chicken sausages, Food Science and

Technology, 64: 1204-1208.

Krisnadi, A.D., 2013, e-book Kelor Super Nutrisi. Blora:

Kelorina.com.

Latifah F, Sugihartini N, Yuwono T 2016 Trad. Med.

Journal 21(1): 1.

Naibaho, D.H., Yamkan, V.Y., Weni, Wiyono, Pengaruh

Basis Salep Terhadap Formulasi Sediaan Salep

Ekstrak Daun Kemangi (Ocimum sanctum L.) pada

Table 5: The result of evaluation of physical

characteristic of gel and lotion.

Test Lotion Gel

Adhesivity

(

minute

)

>10 >10

Figure 2: The result of evaluation of physical

characteristic of gel and lotion.

Figure 3: The values of SPF of standard, lotion, and gel.

Formulation of Moringa oleifera Leaf Extract in Lotion and Gel as Sunscreen

157

Kulit Punggung Kelinci yang Dibuat Infeksi

Staphylococcus aureus. Jurnal Ilmiah Farmasi, 2(2)

(2013).

Putra, A.D., Setyawan, E.I., Media Farmasi, 11(2), 137

(2014).

Singh B.N., Singh B.R., Singh R.L., Prakash D., R.

Dhakarey, Upadhyay G., Singh H.B., 2009, Oxidative

DNA damage protective activity, antioxidant and anti-

quorum sensing potentials of Moringa oleifera, Food

and Chemical Technology, 47: 1109-1116.

Swastika, A., Mufrod, Purwanto., Trad Med Journal,

18(3),132-140 (2013)

Ulaen, Selfie PJ, Banne, Yos S, Ririn A. Pembuatan Salep

Anti Jerawat dari Ekstrak Rimpang Temulawak

(Curcuma xanthorrhiza Roxb.). JIF. 2012;3 (2): 45-9.

Vicky AK, Sugihartini N, Yuwono T 2016 Proc. Int. Conf.

of CONFAST 2016 Conference series: International

Conference on Industrial Biology (Yogyakarta) 1746

(1) (AIP Conference) p 10.1063

Vongsak, B., Sithisarn, P., Mangmool, S.,

Thongpraditchote, S., Wongkrajang, Y., Gritsanapan,

W. 2013.Maximizing total phenolics, total flavonoids

contents and antioxidant activity of Moringa oleifera

leaf extract by the appropriate extraction method.

Industrial Crops and Products, 44: 566-571.

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

158