Formulation of Sechium edule Extract Effervescent Granule with the

Variation of Citric Acid, Tartrate Acid and Sodium Bicarbonate

Ina Ba’dia Grajang and Iis Wahyuningsih

Faculty of Pharmacy, Universitas Ahmad Dahlan, Jl. Prof. Dr. Soepomo, Janturan , Kota Yogyakarta, Indonesia

Keywords: Effervescent granules, extract, Sechium edule.

Abstract: The Sechium edule fruit is traditionally proven to contain antiulcer. Thus, it is necessary to develop dosage

formulations. An effervescent granule is chosen as an alternative form of drug delivery, considering its

dosage preparation may apply simply within a short amount of time. This study aims to discover the

composition of the mixture of citric acid, tartrate acid, and sodium bicarbonate met the physical test

requirement for effervescent granule. Effervescent granules are made by wet granulation technique (the

mixture of alkali-acid) by <25% of relative humidity on 20-25

o

C temperature. There are three effervescent

granule formulas, consisting a different portions composition of citric acid, tartrate acid, and sodium

bicarbonate: formula I = (2.5 :5:15); formula II = (2.25:4.5:16.88); and formula III = (2:4:18). Physical test

on granules consists of flow rate test, moisture content, time of dissolution, pH and organoleptic. Following

trials performed on Formulas I, II, and III of effervescent granule, the granules flow time of each formula

are:1.48;1.53;1.48 seconds moisture content: 3.40; 3.62; 3.50%, time of solubility : 4.37; 4.25; 3.65 minutes,

pH: 6.62; 6.54; 6.59, and likeness survey: (Colour=1.93; 1.90;2,0.Scent=2.0; 1.93; 2.07. Flavour=1.76; 2.06;

2.13). Those three formulas met the good physical test requirement, except on the moisture content.

Formula III go the most preference on colour, scent and taste.

1 INTRODUCTION

Sechium edule is one of the plants used for

traditional medicine. Sechium edule has many

potentials as a drug to treat some diseases; one of

them is as an antiulcer (Kamble et al., 2008). The

fruits and leaves of Sechium edule contain saponins

and flavonoids. Besides that, the fruit also contains

alkaloids and tannins, while the leaves contain

flavonoids and polyphenols (Gandhu et al., 2012).

The fruit also contains saponins, alkaloids and

tannins, while the leaves contain saponins,

flavonoids and polyphenols (Pratiwi, 2011). The

active ingredients in the contents of Sechium edule

that function as antiulcer are the tannin, flavonoid,

and alkaloid compounds contained in the skin and

fruit of Sechium edule (Hagerman, 2000).

In Rofifah's research (2016), the extract of the

Sechium edule has antiulcer effect at the dose of 300

mg/kg BW when administered to a rat. Converted

into a human the dose, it equals 3.360 mg for single

use. With such a large dose of use, it is necessary to

develop a formulation to produce an appropriate

dosage form acceptable to the patient. Effervescent

granules are chosen as an alternative dosage form

because of the advantages of these dosage forms.

First, they are easy to use; the preparation of the

solution with the right dosage of the drug can be

done in fast, convenient time. Second, it can provide

a refreshing delicious sensation because of

carbonate, which can help improve the taste (Allen,

2002).

Effervescent granule processing is generally

derived from the acid combination of citric acid-

tartaric acid rather than just one acid because the use

of single acid alone would be difficult. When using

only citric acid, it will produce a mixture of

adhesives and difficult for granulation. When only

tartrate acid is used, the resulting granule will easily

lose its strength, easy to clot and will produce a fast

effervescent reaction (Ansel, 1989). Sodium

bicarbonate is used as the alkali reaction and acts to

neutralize the citric acid and tartaric acid and can

produce foam and liberate carbon dioxide gas and is

completely soluble in water (Pulungan et al., 2004).

The acid mixture (citric acid-tartaric acid) and alkali

(sodium bicarbonate) in effervescent granule extract

of the Sechium edule aims to provide sparkle or taste

54

Grajang, I. and Wahyuningsih, I.

Formulation of Sechium edule Extract Effervescent Granule with the Variation of Citric Acid, Tartrate Acid and Sodium Bicarbonate.

DOI: 10.5220/0008239300540060

In Proceedings of the 1st Muhammadiyah International Conference on Health and Pharmaceutical Development (MICH-PhD 2018), pages 54-60

ISBN: 978-989-758-349-0

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

effects such as soda drinks that take place quite

rapidly and produce a clear solution (Pulungan et al.,

2004). Therefore, the drug given in the form of an

effervescent granule with a mixture of citric acid,

tartaric acid and sodium bicarbonate will provide a

refreshingly delicious taste sensation (Ansel, 1989).

The objective of this research is to find out the

composition of citric acid, tartrate, and sodium

bicarbonate mixture which meets the physical

requirement of effervescent granule extract of

squash fruit (Sechium edule).

2 MATERIALS AND METHOD

2.1 Materials

The materials used in this research are Sechium

edule obtained from farmers’ group of Mount

Sindoro, Parakan, Temanggung, Central Java,

ethanol 96%, ethanol 70%, HCl 2 N, ammonia,

Mayer reagent, FeCl

3

, citric acid, tartaric acid,

sodium bicarbonate, lactose, aspartame, and PVP.

2.2 Methods

2.2.1 Preparation of Sechium edule Extract

One kilogram of Sechium edule crude simplicia

granules was performed by maceration using 96%

ethanol solvent of 5 L stirred with intermittent

shaking for 3 hours at 400 rpm for 72 hours (3 days).

The maceration results are evaporated over the

waterbath at 50-60°C until a thickened extract is

obtained, then placed in a dark container and stored

in a cool place for further use. The evaluations of the

extract of the Sechium edule include:

• Calculation of yield of the extract: the extract

yield of the Sechium edule is calculated by

comparing the initial weight of the simplisia

and the final weight of the extract produced.

• Organoleptic extract of Sechium edule:

organoleptic test includes the observation of

colour, smell, taste and consistency of the

extract.

• The moisture content of Sechium edule

extract: the moisture content of the extract was

tested using a Halogen Moisture Analyzer

with heating at 105

o

C for 15 minutes, the

percentage content of the sample will be

automatically listed. Good moisture content

does not exceed 10% (Depkes RI, 2000).

• Identification of flavonoids, alkaloids, and

tannins: this identification was performed by

tube test method using the appropriate

reagents for the class of compounds to be

tested i.e. flavonoids, alkaloids, and tannins.

Ammonia vapour reagents are used for the

examination of flavonoids (Robinson, 1995).

Mayer reagent is used to detect alkaloid

compounds and then observe the presence or

absence of precipitation (Mojab et al., 2003).

The FeCl

3

reactor is used for the examination

of polyphenols (tannins) by observing the

colour of the result solution (Sri et al., 2014).

2.2.2 Making Effervescent Sechium edule

Granule

Effervescent granules were made using a wet

granulation method. Separated between acidic

components and alkalic components. Effervescent

granules are made under special conditions of 25%

relative humidity at 20-25°C (Siregar, 2007). All

ingredients on the formula were sieved with a sieve

mesh size 50 and dried earlier in the oven for 1 hour

then weighed according to the formula. The acid

mixture consisted of dry extract of Sechium edule,

citric acid, tartaric acid, aspartame, lactose and PVP,

dripped with 96% ethanol to form a mass that can be

clenched, sieved with sieve mesh size 14, dried in an

oven at 50 °C for 3 hours. Dry granules are sifted

back with sieve mesh size 16. The alkalic

components (Sodium bicarbonate mixed with

residual lactose, and residual PVP) were dripped

with 96% ethanol to form a mass that can be

clenched, sieved with mesh no. 14, dried in an oven

at 50 ° C for 3 hours. Dry granules are sieved back

with mesh sieves size 16. Acid components and

alkalic components are mixed in special room

conditions (temperature 20-25

0

C with 25% relative

humidity (RH)) until they became homogeneous.

The mixture was packed in an airtight container. The

granules obtained were evaluated. The organoleptic

examination includes examination of colour, flavour

and taste. The formulation of granule can be seen in

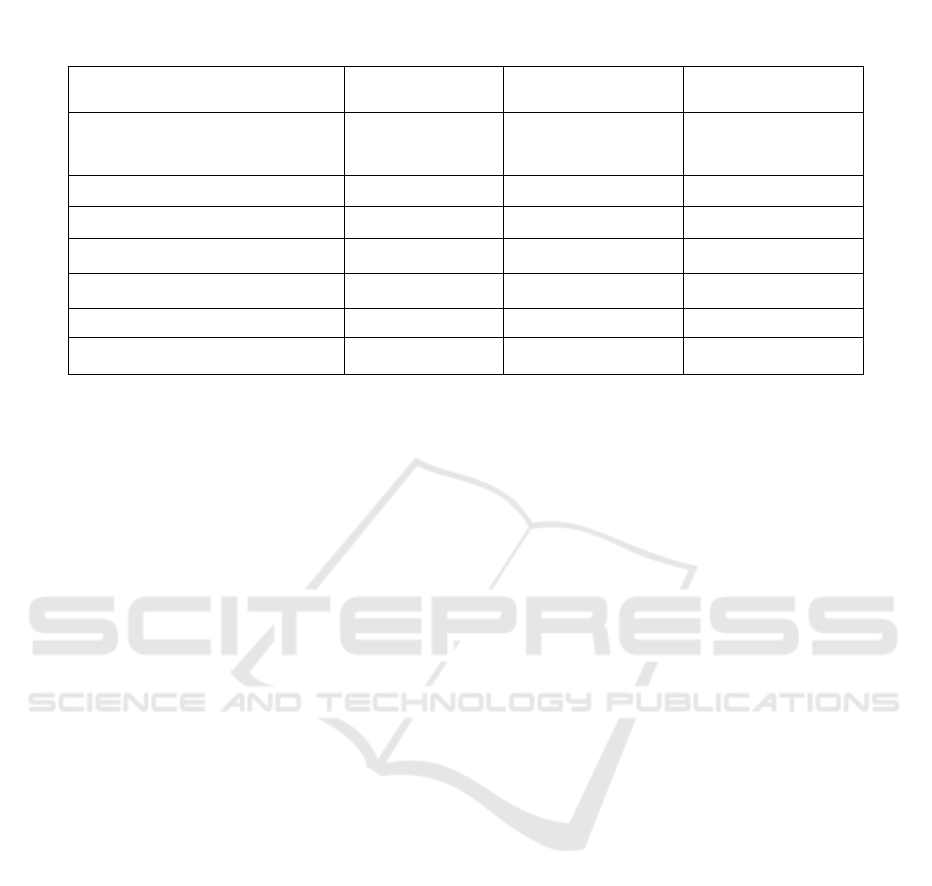

Table 1.

Formulation of Sechium edule Extract Effervescent Granule with the Variation of Citric Acid, Tartrate Acid and Sodium Bicarbonate

55

2.2.3 Physical Characteristics of Effervescent

Granules Abstract

• Effervescent granule flow time test

Weighed a total of 50 g, mass of granules were

inserted into the flowmeter. The time required for

the granules to flow through the lid of the funnel

opening was recorded. Testing was done five times.

Good flow time requirement <10 g/ sec (Voigt,

1995).

• Effervescent granule moisture content

Five gram mass of granules inserted into the

moisture balance tool at 105

0

C for 15 minutes. After

15 minutes, the percentages (%) of water levels will

automatically displayed on the tool display. The

requirements of good effervescent moisture content

granules levels are 0.4-0.7% (Fausett et al., 2000).

• Soluble time of effervescent granule

The effervescent granules weighed 5 g was then

inserted into 200 mL of water. Time recording is

required until the granules dissolve. Requirements

for good effervescent granule time of less than 5

minutes result in a clear solution (Siregar, 2007).

• pH of granule effervescent

The effervescent solution was prepared by weighing

5 g of mass of granules dissolved in 200 mL of

water. pH meter calibration was performed by first

using buffer solution of pH 4.0 and pH 7.0. Once

calibrated, the electric pH meter was dipped into

effervescent solution that no longer have gas

bubbles. the pH value obtained was noted. The pH

of effervescent solution is said to be good if the pH

is close to neutral i.e. 6-7 (Widayanti et al., 2012).

• Hedonic test

Hedonic test was administered to 30 panel lists age

17 years and above, healthy and had no disorder

around the mouth that can affect the taste. They had

been instructed not to consume food or drink prior to

the test that could affect the assessment. They were

asked to taste and assess the taste, smell and colour

of the 5 g effervescent granule samples which had

been diluted with 200 mL water. The panellists were

expected to fill in the provided questionnaires.

2.3 Data Analysis

The result of granule physical characteristics test

was statistically analyzed using one way ANOVA.

This was followed by LSD test with 95% confidence

level to know the significant difference between test

result formula.

3 RESULT AND DISCUSSION

3.1. Simplicia and Sechium edule Extract

The Sechium edule are dried in the sun for 1 day and

continued to be dried in the oven at 50°C for 2 days

to reduce the moisture content. The use of the oven

as a dryer means that the dried Sechium edule are

evenly dried and the drying time is faster because it

Table 1: Effervescent granule formulation of Sechium edule (@ 50 g)

Ingredients Formula I (g) Formula II (g) Formula III (g)

Dried Sechium edule extract

(Viscousextract:Lactose (1: 5))

20.16 20.16 20.16

Citric Acid 2.5 2.25 2

Tartaric acid 5 4.5 4

Sodium bicarbonate 15 16.88 18

Polyvinyl pyrrolidone (PVP) 1.5 1.5 1.5

Aspartame 2 2 2

Lactose ad 50 g 3.84 5.43 4.68

Note :

F I: Mixtures Citric acid, tartaric acid, and sodium bicarbonate: (2.5 g: 5 g: 15 g)

F II: Mixture Citric acid, tartaric acid, and sodium bicarbonate: (2.25 g: 4.5 g: 16.88 g)

F III: Mixture Citric acid, tartaric acid, and sodium bicarbonate: (2 g: 4 g: 18 g)

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

56

is not affected by weather conditions and protected

from UV damage (Sulistyani and Eka, 2011). The

powder of simplicia obtained from 20 Kg of squash

is 1000 g of crude simplicia powder.

The Sechium edule extract is prepared by

maseration method. The solvent used in this study

was 96% ethanol because the content of the active

substance of the Sechium edule had a good solubility

in ethanol (Firdous et al., 2012). The maceration was

performed with a ratio of 1000 g of simplicia of

Sechium edule and 5 L of ethanol 96% per 1 time

maceration. From the extract that was obtained thick

extract 194.626 g from 1000 g of simplicia with

yield of extract 19.463%. The result of organoleptic

examination of Sechium edule extract is dark

brownish green colour extract, unique smell of

aromatic extract, bitter extract flavour and slightly

thickened extract form.

The identification of the compounds contained in

the extract of the Sechium edule is done by tube test.

The tests include flavonoids, alkaloids, and tannins.

Flavonoid test obtained positive results by passing

the extract that has been dripped on filter paper with

ammonia vapour. Filter paper turns yellow due to

flavonoid reaction with ammonia vapour to form salt

and a kinoid structure on ring B that will create

double bonds that conjugated longer so that it will

increase the colour intensity (Robinson, 1995). In

the alkaloid test, positive result of alkaloid with

Mayer’s reagent was characterized by turbidity and

formed a little white precipitate. The nitrogen in the

alkaloids reacts with the K

+

metal ions from the

tetraiodomerkurat (II) potassium to form the

potassium-alkaloid complex precipitation (Marliana,

2005). In the tannin test, a positive result was

obtained by adding the FeCl

3

reagent to form a

blackish-green colour. The formation of blackish-

green colour on the extract after being added with

FeCl

3

is because tannin will form complex

compounds with Fe

3+

ions (Mangunwardoyo et al.,

2008).

3.2. Granulation

Formulation of effervescent granule extract of

Sechium edule with a mixture of citric acid, tartaric

acid, sodium bicarbonate and other excipients of the

three formulas is a modified obtained from the trial

results. Manufacture of effervescent granules with

wet granulation method has the advantage of making

a simple, quick and homogeneous granule produced

(Parikh, 2005). Effervescent granules are prepared

by separating the acid and the alkali components to

prevent reaction between acid-base components

when mixed in wet conditions (Parikh, 2005). Citric

acid and tartaric acid act as the source of acid,

sodium bicarbonate as the alkali source, PVP as the

binder, aspartame as the sweetener, and lactose as

the filler. All the processes were performed; both

formulations and physical properties of effervescent

granules were performed in a special room with RH

of 25% and temperature of 20-25

o

C (Siregar, 2007).

3.3. Physical Properties of Effervescent

Granule Extract of Sechium edule

Effervescent granules were tested for their physical

properties using methods such as flow time test,

moisture content test, soluble test, pH test, and

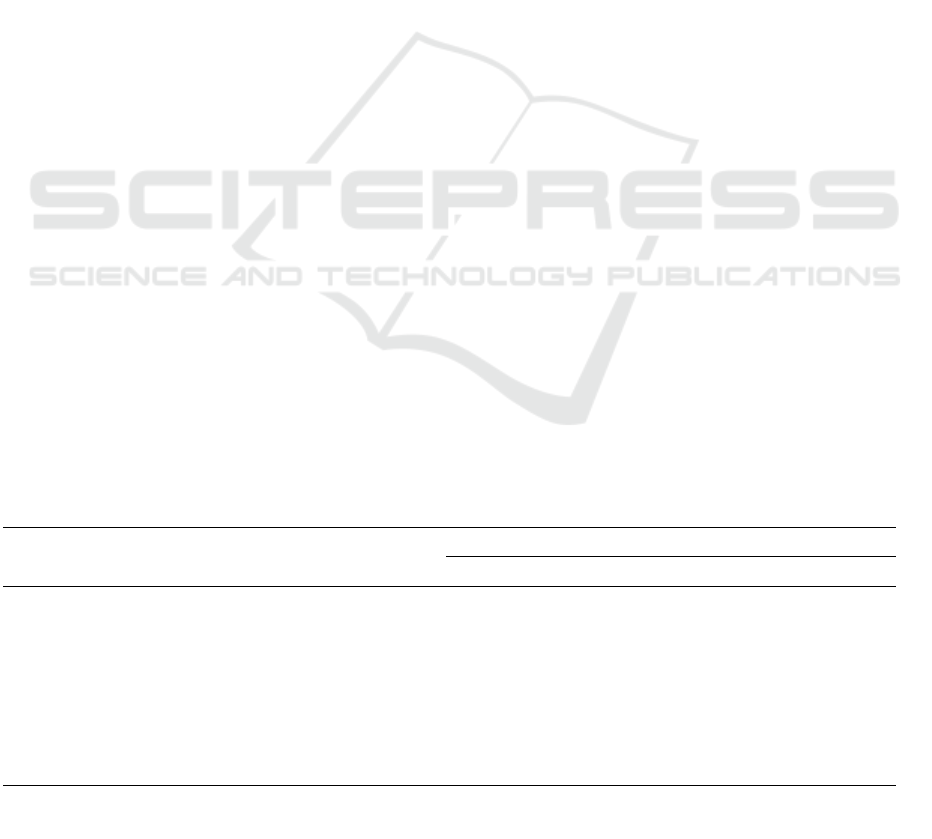

Hedonic test. The test results can be seen in Table 2.

The flow time of effervescent granule extract of

Sechium edule from F I is shorter compared to F II

and F III. This is due to F I that produced

effervescent granules with larger particle size

compared to other formulas (determined based on

visual observations since they are not measured).

Table 2: Physical properties of granul effevescent extract of Sechium edule

No Test Parameter

Value (X ± SD)

Formula I Formula II Formula III

1 Granule flow time (seconds)

1.47±0.20 1.53± 0.14 1.48 ± 0.10

2 Granule water content (%)

3.40 ± 0.34 3.62 ± 0.44 3.50 ± 0.63

3 Granule soluble time (minutes)

4.37 ± 0.12 4.25 ± 0.08 3.65±0.55*

4 pH value

6.62 ± 0.04 6.54 ± 0.08 6.59 ± 0.05

5 Hedonic test

Colour

1.93 ± 0.78 1.90 ± 0.71 2.00 ± 0.69

Scent

2.00 ± 0.79 1.93 ± 0.74 2.07 ± 0.91

Taste

1.77 ± 0.77 2.07 ± 0.74 2.13 ± 0.63

Description: * There is a difference with FI

Formulation of Sechium edule Extract Effervescent Granule with the Variation of Citric Acid, Tartrate Acid and Sodium Bicarbonate

57

According to Ansel (1989), one molecule of water

per citrate acid molecule determines powder

formation, whereas according to Voigt (1984),

enlargement of particle size can generally improve

flow characteristic or powder glide power.

Differences in the concentration of citric acid and

tartaric acid (1:2) used can affect the effervescent

granular flow characteristic. The higher the acid

concentration used, the better the flow characteristic

(Widayanti et al., 2012). The flow time is influenced

by the shape, size, porosity, density, and particle

frictional forces and experimental conditions.

Tartaric acid has a greater density than citric acid so

that granules containing tartrate acid will have

greater density. Large densities show large

molecular weights that will flow more easily due to

greater gravity (Anshory et al., 2007). According to

Mohrle (1980), citric acid has a specific density

value of 1.665 mg/mL, while tartaric acid has a

specific density value of 1.7598 mg/mL. The

statistical analysis of the three distributed formulas

is 0.930 and the homogeneous data is 0.086. The

result of statistical test shows that the three

effervescent granule formulations that have been

made have an average granule flow time which is

not significantly different and less than 10 seconds.

These results show that citric acid, tartaric acid, and

sodium bicarbonate in the formula have no

significant effect on granule flow time.

The moisture content of FI, FII, and FIII of

effervescent granules in this study has not fulfilled

the requirements of good effervescent granule water

content i.e. 0.4-0.7% (Fausett et al., 2000). The

moisture content was not achieved because of the

limitations in the room where the effervescent

produced has high relative humidity, causing the raw

material from the effervescent to react quickly.

Despite efforts to reduce the relative humidity of the

room, room control can only reach 29% with a

temperature of 29

o

C, whereas the room relative

humidity for the preparation of effervescent

preparations is 25% with a temperature of 20-25

o

C

(Siregar, 2007).

This limitation makes the granules absorb

moisture from the environment so that moisture

content in the effervescent granule becomes high.

Although the effervescent granule materials have

been dried in the oven, effervescent granules

produced cannot reach moist moisture of 0.4-0.7%.

It is possible to achieve moisture content balance

between the effervescent granule materials and the

humidity of the manufacturing chamber (Budi and

Lisa, 2007). The non-fulfilment of the effervescent

granular moisture content will affect the flow

characteristic and the dissolution rate (Widayanti et

al., 2012). The ability of sodium bicarbonate to

absorb moisture during storage is less than citric

acid and tartaric acid, so the moisture contained in

sodium bicarbonate is less than the moisture

contained in citric acid and tartaric acid. Thus, the

greater the amount of sodium bicarbonate used in

the production of effervescent granules will further

decrease the moisture content of effervescent

granules produced.

The nature of citric acid that is hygroscopic also

has the potential to absorb water vapour in the air.

Sodium bicarbonate is not hygroscopic and at room

temperature that has a moist content of less than 1%

(Lindberg et al., 1992). From the statistical test

obtained, the average of granule moisture content of

the three formulas is not significantly different.

The soluble time of FI, FII, and FIII of

effervescent granules in this study fulfilled the

requirement of good soluble time i.e. less than 5

minutes. The process of dissolution of effervescent

granules begins with the penetration of water into

the effervescent granules. The presence of water

penetration into the effervescent granules will

produce acid and alkali reactions that will produce

CO

2

gas. In the presence of CO

2

gas, the process of

breaking the granules will be faster and indirectly

accelerate the process of dissolving granules in

water.

The binder used in this study was PVP 3%. PVP

has hydrophilic properties that will facilitate the

penetration of water into the effervescent granules,

which will accelerate the dissolution of effervescent

granules in the water. According to Rizal and Widya

(2014), the citric acid contains water when reacting

with sodium bicarbonate containing carbon dioxide

gas then it will produce sodium citrate, water and

carbon dioxide gases three times faster that can help

solubility. This is supported by Nugroho (1999) who

states that the presence of carbon dioxide gases

produced help solubility without involving manual

stirring on condition that all components are highly

soluble in water. Based on a study conducted by

Hayu (2015), the combination of citric acid and

tartaric acid had a significant effect on the dissolving

time of the effervescent tablets made. The higher the

tartaric acid in the tablet, the higher the solubility

(quick to dissolve). This occurs because citric acid

has lower solubility than tartaric acid, and tartaric

acid can react with sodium bicarbonate which can

accelerate the solubility of effervescent tablets.

According to Mandagi et al. (2015), the greater the

concentration of sodium bicarbonate and the smaller

percentage of citric acid in the effervescent formula,

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

58

the faster the soluble time in water. Otherwise, the

less sodium bicarbonate, the greater percentage of

citric acid in the formula the longer the granule

dissolves in water. This is because sodium

bicarbonate acts as a destroyer of effervescent

granules in water so that it can dissolve completely

without stirring and when sodium bicarbonate reacts

with water it carbonates (Dwijayanti, 2009). Alkali

effect is greater than the acid mixture effect. Thus it

is predicted that the base is more dominant in

determining the effervescent granule soluble time.

Comparing soluble time between F I and F III, there

was a significant difference due to differences in the

composition of citric acid, tartaric acid and sodium

bicarbonate.

The pH test needs to be done because if the

effervescent solution that is formed is too acidic it

can irritate the stomach whereas if it has too much

alkaline it will have bitter taste and bad taste. pH

values of F I, F II, and F III of effervescent granules

in this study are qualified as good pH values,

ranging from 6.54 to 6.62. The pH of effervescent

solution is said to be good if the pH is close to

neutral i.e. 6-7 (Widayanti et al., 2012). The

statistical results show that the three formulas have

different granule pH values not significant.

The hedonic test is a test method used to measure

the level of preference of a product using a rating

sheet (Singh-Ackbarali and Maharaj, 2014).

Assessment categories consist of 4 levels namely (1)

do not like; (2) somewhat like; (3) like, and (4) like

very much. To know whether there is a difference

between treatments an analysis of variance needs to

be done seen from the value of F arithmetic

compared with the value of F table. If the value of F

arithmetic > F table then the treatment is very

different (significantly different). Considering that

the difference level is significant, the test was

continued with DMRT (Duncan Multiple Rating

Test) method to know which treatment is the same

or different (Itsagusman, 2013). The hedonic test

was seen from 3 hedonic test parameters (colour,

scent, and taste). The results of the tests indicate that

the highest hedonic average score belongs to

formula III in terms of colour (2.0), scent (2,07), and

taste (2.13). The results of the analysis of the

organoleptic colour, smell, and taste test varieties

showed no significant differences between formulas

I, II, and III. The conclusion of hedonic test for the

colours, aromas, and flavours of these three formulas

is that they have an average score of 2 which means

they are in the category of "somewhat like". This

means that based on the general panellist’s response

on the three formulas of effervescent granules they

are less attracted to the colour, the smell of

effervescent granule drink, and that the taste of

effervescent granule drink extract of Sechium edule

on the three formulas is too sweet. These results

show that required the modification of effervescent

granule formula is required to produce health drinks

that is acceptable to the people.

4 CONCLUSIONS

The formula that produces the best effervescent

granules of the best Sechium edule extract is formula

III whose composition of the mixture of citric acid,

tartaric acid, and sodium bicarbonate is 2: 4: 18.

This best formula has physical properties of flow

time of 1.48 seconds, water content of 3.50%,

soluble time 3.65 minutes, pH 6.59, and has the

highest degree of preference (colour 2.0, aroma 2.07,

and taste 2.13).

ACKNOWLEDGEMENTS

This study was supported by Kemenristek Dikti

Republik Indonesia.

REFERENCES

Allen, V.L., 2002, The Art, Science and Technology of

Pharmaceutical Compounding, 2nd Ed, 99-101,

American Pharmaceutical Assosiation, Washingtong

D.C.

Ansel, H.C., 1989, Introduction to Pharmaceutical

Dosage Form, translated by Farida Ibrahim, Pengantar

Bentuk Sediaan Farmasi, Edisi IV, Indonesia

University Press, Jakarta.

Anshory, H., Syukri, Y., dan Malasari, Y., 2007,

Formulasi Tablet Effervescent dari Ekstrak Ginseng

Jawa (Tlinum panicukatum) dengan Variasi Kadar

Pemanis Aspartam, Jurnal Ilmiah Farmasi, Vol. 4 No.

I.

Budi, A.S.L., dan Lisa, N., 2007, Optimasi Natrium Sitrat

dan Asam Fumarat sebagai Sumber Asam dalam

Pembuatan Granul Effervescent Ekstrak Temulawak

(Curcuma xanthorrhiza Roxb) secara Granulasi

Basah., Majalah Farmasi Indonesia, 18(1), 21-28.

Depkes RI, 2000, Parameter Standar Umum Ekstrak

Tumbuhan Obat. Departemen Kesehatan Republik

Indonesia, Jakarta.

Dwijayanti, R., 2009, Pemanfaatan Natrium Alginat

sebagai Fortifikasi Serat dalam Pembuatan Minuman

Serbuk Effervescent Bercitarasa Jeruk Lemon, Skripsi,

Fakultas Perikanan dan Ilmu Kelautan Institusi

Pertanian Bogor.

Formulation of Sechium edule Extract Effervescent Granule with the Variation of Citric Acid, Tartrate Acid and Sodium Bicarbonate

59

Fausett, H, Gayser C. and Dash AK., 2000, Evaluation of

Quick Disintegrating Calcium Carbonate Tablets. in:

Jurnal AAPS PharmScitech.

http://www.pharmscitech.com. accessed date 27

Agustus 2016.

Firdous, S.M., Sravanthi, K., Debnath, R., dan Neeraja,

K., 2012, Protective Effect of Ethanolic Extract and its

Ethylacetate and N-butanol Fractions of Sechium

edule Fruits Againts Carbon Tetrachloride Induced

Hepatic Injury in Rats, Int J Pharm Sci, 4(1): 354-359.

Gandhu, S., Syed, F.H., Gone, S.K., Bodavula, S.S.R.,

2012., Anti-Ulcer Activity of Sechium edule Ethanolic

Fruit Extract., The Pharma Innovation Journal., ISSN

2277-7695., Vol. 1 No. 5.

Hagerman, A.E., 2002, Tannin Chemistry.

http://www.users.muohio.edu/hagermae/tannin.pdf (20

September 2015).

Hayu, T.S., 2015, Formulasi Tablet Effervescent

Antioksidan Ekstrak Kulit Manggis (Garcinia

mangostana L.) dengan Kombinasi Asam Sitrat-Asam

Tartrat, Naskah Publikasi, Fakultas Farmasi

Universitas Muhammadiyah Surakarta, Surakarta.

Itsagusman, 2013, Pengujian Organoleptik, Modul

Penanganan Mutu Fisis (Organoleptik), Program Studi

Teknologi Pangan Universitas Muhammadiyah

Semarang.

Kamble, M.B., Dumbre, R.K., Rangari, V.D., 2008,

Hepatoprotective Activity Studies of Herbal

Formulations. Int J Green Pharm, 2:147-51.

Lindberg, N., Engfors, H., Ericsson, T., 1992, Encylopedia

of Pharmaceutical Technology, Effervescent

Pharmaceutical in Swarbricck, J., Boylan, J.C., Vol 5,

45-71, Marcel Dekker, Inc., New York.

Mandagi, R., Gregoria, S.S.D., Erny, N., Lucia, M., 2015,

Formulasi Granul Effervescent Sari Buah Pala

(Myristica fragrans H.), Cocos E-Journal, Vol. 6

No.2.

Mangunwardoyo, W., Ismaini, L., and Endang, S.H.,

2008., Analisis Senyawa Bioaktif dari Ekstrak Biji

Picung (Pangium edule Reinw)., Segar., Berita

Biologi, 9(3).

Marliana, S.D., Suryanti, V., Suyono., 2005, Skrining

Fitokimia dan analisis kromatografi lapis tipis

komponen kimia buah labu siam (Sechium edule Jacq.

Swartz.) dalam ekstrak etanol, Biofarmasi, 3(1):26-

31.

Mojab, F., Kamalinejad, M., Ghaderi, N., dan Vahidipour,

H.R., 2003, Phytochemical Screening of Some Species

of Iranian Plants, Iranian Journal of Pharmaceutical

Research, pp. 77-82.

Mohrle, R., 1980, Effervescent Tablet, in Lieberman,

H.A., Lachman, L., (eds),

Pharmaceutical Dosage

Form, Tablet, Vol. I, 284-362, Warner Lambert

Company, Morris Pliains, New Jersey.

Nugroho, S., 1999, Penambahan komponen berprotein

pada minuman serbuk effervescent, Skripsi, Fakultas

Teknologi Pertanian, IPB, Bogor.

Parikh, D.M., 2005, Handbook of Pharmaceutical

Granulation Technology. Taylor & Francis Group.

London, pp. 212-216.

Pratiwi, S.I.R., 2011, Karakterisasi Simplisia dan Uji

Aktivitas Antioksidan FEkstrak n-Heksan, Etil Asetat,

dan Etanol Herba Labu Siam (Sechium edule

(Jacq)Sw.) dengan metode DPPH. Skripsi. Fakultas

Farmasi Universitas Sumatra Utara, Medan.

Pulungan, H.M., Suprayogi, dan Yudha, B., 2004,

Effervescent Tanaman Obat. Trubus Agrisarana,

Surabaya.

Rizal, D., dan Widya, D.R.P., 2014, Pembuatan serbuk

effervescent miana (Coleus (L) benth): Kajian

konsentrasi dekstrin asam sitrat terhadap karakteristik

serbuk effervescent, Jurnal Pangan dan Agroindustri,

Vol.2 No.4.

Robinson, T., 1995, Kandungan Organik Tumbuhan

Tinggi, translated by Padmawinata K, 191-213.

Rofifah, D.S., 2016, Aktivitas Anti-Ulser Ekstrak Etanol

Buah Labu Siam (Sechium edule) Terhadap Ulkus

Peptikum Lambung Tikus Wistar, Skripsi, Fakultas

Farmasi Universitas Ahmad Dahlan.

Singh-Ackbarali, D., dan Maharaj, R., 2014, Sensory

Evaluation as a Tool in Determining Acceptability of

Innovative Products Developed by Undergraduate

Students in Food Science and Technology at The

University of Trinidad and Tobago, Journal of

Curriculum and Teaching, 3 (1), 10-27.

Siregar CJP., 2007, Teknologi Farmasi Sediaan Tablet

Dasar-Dasar Praktis. Penerbit EGC. Bandung. Hlm.

275, 277-280.

Sri, R.I., Silvia, R.Y., 2014, Pengaruh Perbandingan

Pelarut Etanol-Air Terhadap Kadar Tanin pada

Sokletasi Daun Gambir (Uncaria gambir Roxb), Sagu

Vol.13 No.1 : 1-7.

Sulistyani, N., dan Eka, K., 2011, Aktivitas Antifungi

Ekstrak Etanol Batang Binahong (Anredera cordifolia

(Tenore) Steen.) terhadap Candida albicans serta

Skrining Fitokimia, Jurnal Ilmiah Kefarmasian,

Vol.1,No.2,51-62.

Voigt, R., 1984, Buku Pelajaran Teknologi Farmasi,

translated by Soendani Noeromo, Universitas

Indonesia, Jakarta.

Voigt, R., 1995, Buku Pelajaran Teknologi Farmasi,

translated by Soendani N.S., UGM Press, Yogyakarta.

Widayanti, A., Naniek, S.R., and Dwi, O., 2012,

Optimasi Konsentrasi Asam Sitrat dan Asam Tartrat

(1: 2) sebagai Sumber Asam Ditinjau dari Sifat Fisik

Granul Effervescent Sari Buah Mengkudu (Morinda

citrifolia L), Farmasains,

Vol.1 No.6.

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

60