The Effect of Increased Level of Avocado (Persea americana Mill.)

Seed Starch as Binding Agent on Physical Properties of the Liquorice

Extract (Glycyrrhiza glabra Linn.) Lozenges

Landyyun Rahmawan Sjahid, Anneke Lionie Kumala Satki, Inding Gusmayadi

Fakultas Farmasi dan Sains, Universitas Muhammadiyah Prof. DR. HAMKA, Jakarta

Keywords: Avocado seed starch, Lozenges, Liquorice Extract.

Abstract: The utilization of avocado (Persea americana Mill.) seed has not been optimal even though it is known to

be high in starch and can be used as a binder for formulation of the lozenges. The purpose of this study was

to determine the effect of increased level of avocado (Persea americana Mill.) seed starch as a binding

agent on the hardness and friability of liquorice (Glycyrrhiza glabra Linn.) extract lozenges using wet

granulation method. The lozenges were made from four formulas based on different avocado seed starch

concentrations of 5, 10, 15, and 20%. Evaluations of the lozenges included visual test, weight uniformity,

size uniformity, hardness, friability and disintegration time. The result of hardness and friability test was

analyzed with one-way ANOVA with 95% confidence level (α = 0.05) followed by the Tukey HSD. It

showed that 15% and 20% concentration of avocado seed starch meet the hardness specification of the

lozenges with value 11,09 Kgf and 13,30 Kgf, respectively. The formula using 20% concentration of

avocado seed starch meets the requirement of lozenges friability with value 0,45%. It can be concluded that

the increased concentration of avocado starch as binder for the lozenges can increase the hardness and

reduce the friability of the lozenges.

1 INTRODUCTION

Avocado (Persea americana Mill.) is a fruit that is

commonly consumed as food and beverage

ingredient. However, avocado seed is often

considered not useful and is usually only disposed as

a waste. An avocado seed contains carbohydrates

consisting of 32.5% amylose and 67.5%

amylopectin (Builders et al., 2010). Amylopectin

can form aggregates through the bonding process

between particles, so it can be used as a binder of

tablets (Kartika et al., 2012). Builders et al. (2010)

stated that granules made with avocado seed starch

as a binder have higher mechanical strength

compared to granules made with corn starch.

Based on these advantages, this study was

conducted to determine the effect of increased level

of avocado (Persea americana Mill.) seed starch as

a binder on lozenges. From this, it is expected to

produce a good lozenges that has a hardness value of

10-20 Kgf in order to be soluble slowly in the mouth

(Lachman et al, 1986). The active substance used in

this study used is liquorice (Glycyrrhiza glabra

Linn.) extract that has antibacterial activity against

Streptococcus mutans, a bacteria that causes dental

caries (Chaiya et al., 2013; Ajagannanavar et al.,

2014).

2 MATERIALS AND METHOD

2.1 Materials

The materials that are used in this research are tablet

compression machine (Rimek), oven (Memmert),

hardness tester, friability tester, tap density tester,

disintegration tester, granule flow tester, blender

(Philips), vacuum rotary evaporator (Eyela), sieve

shaker, pH meter (LaMotte), microscope (Yakumi),

Furnace (Barnstead Thermolyne), analytical balance

(Ohaus), Liquorice powder (Herbal Anugrah Alam-

Yogyakarta), ethanol 70%, Avocado seed, sucralose

(JK Sucralose Inc), Mannitol (SPI Pharma-USA),

magnesium stearate, aerosil (Cabot-China), sodium

metabisulfite, aquadest dan FeCl

3,

Iodium, HCl

(p)

.

Sjahid, L., Satki, A. and Gusmayadi, I.

The Effect of Increased Level of Avocado (Persea americana Mill.) Seed Starch as Binding Agent on Physical Properties of the Liquorice Extract (Glycyrrhiza glabra Linn.) Lozenges.

DOI: 10.5220/0008239000390043

In Proceedings of the 1st Muhammadiyah International Conference on Health and Pharmaceutical Development (MICH-PhD 2018), pages 39-43

ISBN: 978-989-758-349-0

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

39

2.2 Methods

2.2.1 Preparation The Liquorice Extract

Liquorice powder is macerated with 70% ethanol for

three days. The macerate was then evaporated using

a rotary evaporator to obtain a viscous extract. The

characteristics of the extract were examined by the

organoleptic test, pH measurement, ash content and

chemical compound identification.

2.2.2 Isolation of Starch From Avocado Seed

The skin of avocado seed was peeled and washed,

then mashed using a blender with the addition of 1:

1 water. Then filtered to take starch from the tissue.

The filtrate was left for 12 hours to obtain starch

deposits. When the sediment has been formed, the

water was removed, then washed with clean water

and re-deposited for three times, then deposited

again with 3000 ppm Na

2

S

2

O

5

solution, according

to the treatment of the fourth immersion. The starch

deposits was dried in an oven at 50ºC. The dried

starch was ground and then sieved through the

number 60 sieve.

2.2.3 Avocado Seed Starch Characterisation

The test included organoleptic test, amylum

identification (Departemen Kesehatan Republik

Indonesia, 2014), ash content and weight loss on

drying (Departemen Kesehatan Republik Indonesia,

2008).

2.2.4 The Preparation of Liquorice Extract

Lozenges

Granules are prepared according to the formulas in

Table 1. Mannitol, sucralose and liquorice extract

were crushed slowly to make them homogeneous

and added with the mucilage of avocado seed starch

gradually. Then it was crushed and added with

aquadest (F1 = 11 mL, F2 = 8 mL, F3 = 2 mL, F4 =

0 mL) to form a mass of banana breaking which then

sieved with the number 14 sieve. The result was

dried in an oven with temperature ± 50ºC for ± 24

hours. Dry granules were sieved with the number 18

sieve and then added with magnesium stearate and

aerosil. The quality of the granules were examined,

the characteristics included compressibility, flow

properties, weight loss on drying and particle size

distribution.

3 RESULT AND DISCUSSION

3.1 Liquorice Extract Characterisation

The results of the organoleptic test showed that the

extract of liquorice had the black viscous liquid,

dark brown coloured, aromatic odor and sweet taste.

The sweet taste is due to the presence of

glycyrrhizin, which 50 times sweeter than sugar

(Nitalikar et al. 2010). The pH of liquorice extract

was 5.52. This liquorice extract contained 3.8% of

ash content. The results of phytochemistry screening

showed that liquorice extract was positively contain

flavonoids and tannins which have been known to

have antibacterial activity against Streptococcus

mutans, the bacteria that cause dental caries (Chaiya

et al., 2013).

3.2 Avocado Seed Starch

Characterisation

Starch obtained in the form of fine powder had light

brown colour, tasteless and odorless. Identification

test for starch with iodine 0.005 N solution showed

positive results. Weight loss on drying of 8.00% and

ash content of 0.94%. That value obtained is higher

than the Builder et al. (2010) requirement which sets

the weight loss on drying and ash content of avocado

seed starch by 7,81 ± 0,35% and 0,42 ± 0,10%

respectively. The ash content of the starch indicated

the presence of mineral content. In this case, the

habitat of the avocado plant in Indonesia may affect

the mineral content in the plant.

3.3 Granule Evaluation Results

The weight loss on drying of the granules from each

formula were below the Voigt (1995) requirement

with 5%, indicated that the water content of the

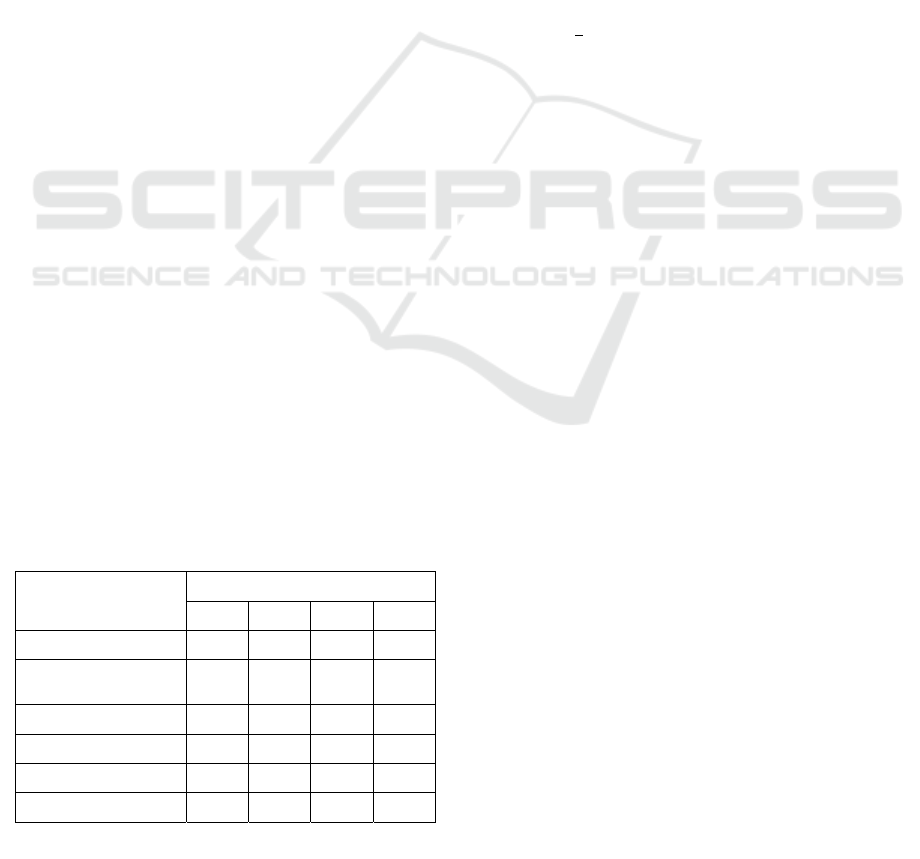

Table 1: The liquorice extract lozenges formula

Ingredients

Formula (%)

F1 F2 F3 F4

Liquorice Extract 2 2 2 2

10% Avocado seed

starch mucilage

5 10 15 20

Sucralose 0,2 0,2 0,2 0,2

Mg Stearate 3 3 3 3

Aerosil 0,25 0,25 0,25 0,25

Mannitol a

d

100 100 100 100

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

40

granules was quite low (table 2). Granules with low

water content have a good flowability because the

moisture content is also low. High moisture in

granules can increase the risk of sticky tablets on die

and punch tablet compression machine. The flow

time and the angle of repose of each formula showed

excellent flow properties. Each formula produced

granules with 26º - 28º angle of repose, indicated

that the granules have excellent flow properties

(Table 2). Compressibility test from all formulas

was appropriate with the requirements needed, with

the percent of compressibility value below 10%.

This result which shows that the granule mass can be

reduced in volume when given pressure

(Hadisoewignyo and Fudholi 2013). From the results

of flow time testing, the angle of repose and

compressibility (table 2), it can be concluded that the

granules of each formula have excellent flow

properties. Good granular flow properties can affect

the granule filling process from the hopper to the die

which will affect the uniformity of the tablet weight.

In this study, the average values of particle size

of the granules from F1 to F4 were 763.53 μm;

756.23 μm; 751.04 μm and 748.04 μm, respectively.

According to Siregar (2010), the more massive and

more spheric particles show better flow properties,

compared with the smaller one. Particles with size

>250 μm generally flow well, while the particle with

the size <100 μm flow slower, because the effect of

cohesion and adhesion that is greater in smaller

particles which reduces the granular flow capability

(Hadisoewignyo and Fudholi 2013).

3.4 Liquorice Extract Lozenges

Evaluation

The tablet appearance of each formula did not

show any differences, all formulas produced the

same tablet that have round form, light brown

coloured, sweet taste, flat and smooth surface. Taste

is an essential factor in the preparation of the

lozenges because it will be dissolved in the mouth

for a long period (± 30 minutes), so it should

produce a pleasant taste inside the mouth (Lachman

et al., 1986).

The weight uniformity test result (table 3)

described that all formulas fulfilled the requirements

set by Departemen Kesehatan Republik Indonesia

(1979), that tablets with more than 300 mg are

required not to be allowed more than 2 tablets that

have a 5% weight deviation from the average weight

of the tablet and there is no single tablet that has a

10% weight deviation of the average weight of the

tablet. The excellent flow properties of the granules

can produce uniform tablet weights. From the result

of tablet size uniformity test, it can be stated that the

tablets of each formula have met the requirements,

the tablet diameter is no more than three times and

not less than 1

1

/

3

of the tablet thickness (Departemen

Kesehatan Republik Indonesia 1979). Good granular

flow properties and punch stability produced a

uniform tablet size during the tablet compression

process.

The result of the hardness test (table 3) showed

that there was an increase in the hardness of the

tablet as the concentration of the binder was also

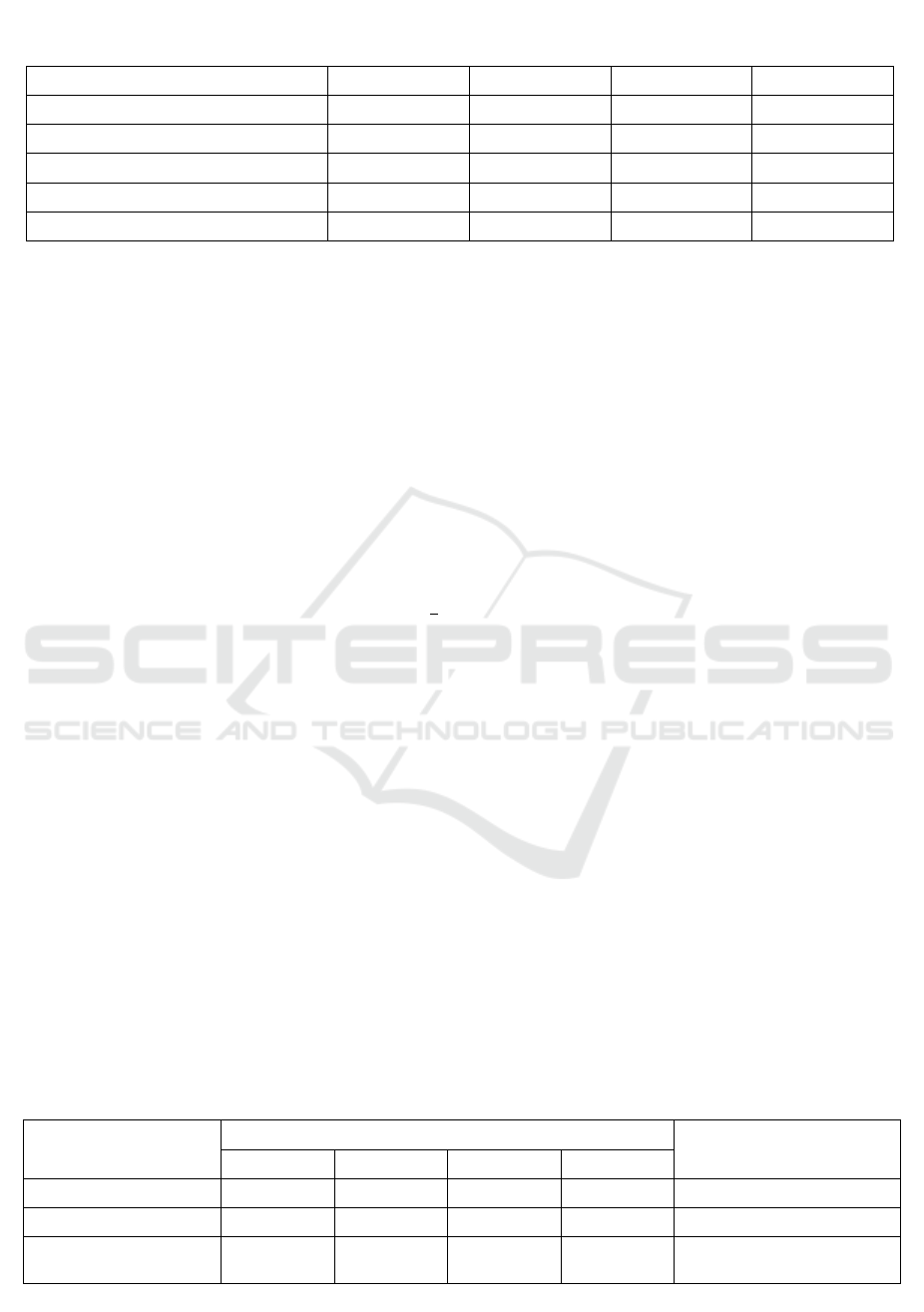

Table 2: Granules evaluation

Evaluation F1 F2 F3 F4

Weight Loss on Drying (%) 2,38±0,03 2,82±0,03 2,20±0,04 2,79±0,05

Flow time (second) 4,34±0,26 4,26±0,26 4,54±0,26 4,50±0,23

Angle of Repose (

o

) 28,23±1,41 28,34±1,55 28,24±0,57 26,83±0,75

Compressibility (%) 3,65±0,58 4,66±1,55 3,99±1,00 2,99±1,72

Weight uniformity diameter (μm) 763,53 756,23 751,04 748,04

Table 3: Hardness, friability, and disintegration time evaluation of liquorice lozenges

Evaluation

Results

Requirement

(Lachman et al. 1986)

F1 F2 F3 F4

Hardness (Kgf) 7,44±0,28 9,04±0,63 11,09±0,44 13,30±0,29 10-20 kgf

Friability (%) 5,76±0,39 3,04±0,63 1,13±0,16 0,45±0,03 0,8 – 1,0%

Disintegration Time

(minute)

14,13±0,07 21,10±0,03 24,38±0,06 33,03±0,51 ±30 menit

The Effect of Increased Level of Avocado (Persea americana Mill.) Seed Starch as Binding Agent on Physical Properties of the Liquorice

Extract (Glycyrrhiza glabra Linn.) Lozenges

41

leveled up. The addition of avocado seed starch in

the form of 10% mucilage by 15% (F3) and 20%

(F4) as a binder produced lozenges that suitable with

the hardness requirement of lozenges which is 10-20

kgf (Siregar 2010). The addition of the binder can

affect the hardness of the tablet because the binder

forms an internal matrix during the wet granulation

process. The higher the binding concentration, the

liquid bridges between solid particles that are

formed are getting stronger. During the drying

process, there is a crystallization of the binder,

forming a solid bridge that gets stronger and

increases the strength of the granule. It will produce

harder tablet during the pressing process. In addition

to the binder, the compression pressure provided

during the pressing process can also affect the tablet

hardness.

The result of the friability test (table 3) of the

tablet found that F3 and F4 were close to the tablet

friability requirement set by Lachman et al. (1986)

which is 0.8-1%, while F1 and F2 were not suitable.

Tablet friability test was carried out to determine the

ability of the tablet to withstand the effects of

mechanical shocks during the manufacturing,

packing and distribution process (Lachman et al.

1986). The higher the binding concentration, the

lower the friability percent of the tablet. The

cohesive properties of the binder can reduce the

friability of the tablet because the cohesiveness can

bind small particles and form more extensive and

stronger aggregates, so that during the compression

process can produce a tablet that is strong and

resistant to shock. In addition, the friability of the

tablet can also be caused by the amount of water

added during the granulation process. In F1, the

amount of water added to form a banana breaking

mass was much than F2, F3 and F4. The more

amount of water added to the granule mass, the

higher the tablet friability will be produced.

The disintegration time test was carried out using

the disintegration tester. This measurement does not

describe the actual condition in the mouth.

Therefore, the purpose of this test was only to know

the condition of the lozenges when in contact with

water. The lozenges were designed to dissolve

slowly in the mouth, so that they are not destroyed

due to contact with water and are expected to

dissolve in ± 30 minutes (Lachman et al., 1986).

From the result of the test, F4 was suitable with

these requirements. Disintegration time is affected

by the hardness of the tablet, the harder the tablet,

the longer it will take to be broken.

4 CONCLUSION

Based on the results, this study showed that the

lozenges that meet the requirements of hardness and

disintegration time was F4, with the use of 20%

avocado seed starch as a binder. Whereas in the

friability test, F3 and F4 had closer friability

requirements of common lozenges. It can be

concluded that from higher avocado seed starch

concentration used as a binder, it will also generate

more hardness and disintegration time, and lower the

friability as well.

REFERENCES

Ajagannanavar SL, Battur H, Shamarao S, Sivakumar V,

Patil PU, Shanavas P. 2014. Effect of Aqueous and

Alcoholic licorice (Glycyrrhiza glabra) Root Extract

Against Streptococcus mutans and Lactobacillus

acidophilus in Comparison to Chlorhexidine: An In

Vitro Study. Journal of International Oral Health. 6(4):

29-34.

Builders P F, Nnurum A, Mbah C, Attama A, Manek R.

2010. The Physicochemical and Binder Properties of

Strach from Persea americana Miller (Lauraceae).

Strach. 62. 309-320

Chaiya A, Saraya S, Chuakul W, Temsiririrkkul R. 2013.

Screening for Dental Caries: Preventive Activities of

Medicinal Plants against Streptococcus mutans.

Mahidol University Journal of Pharmaceutical

Science. 40(1):9-17

Departemen Kesehatan RI. 1979. Farmakope Indonesia.

Edisi III. Badan Pengawas Obat dan Makanan.

Jakarta. Pp. 6-7, 9, 720

Departemen Kesehatan RI. 2008. Farmakope Herbal

Indonesia. Edisi I. Departemen Kesehatan Republik

Indonesia. Jakarta. Pp. XXVI, 169, 171, 174

Departemen Kesehatan RI. 2014. Farmakope Indonesia.

Edisi V. Badan Pengawas Obat dan Makanan. Jakarta.

Pp. 57-58, 69-71, 1002, 1126

Hadisoewignyo L, Fudholi A. 2013. Sediaan Solida.

Pustaka Pelajar. Yogyakarta. Pp. 121, 143

Kartika D H. Mutmainah, Mufrod. 2012. Pengaruh

Peningkatan Konsentrasi Pati Biji Alpukat (Persea

americana Mill.) Sebagai Pengikat Terhadap

Karateristik Fisik Granul dan Tablet Ekstrak Akar

Alang-Alang (Imperata cylindrica Linn.). Majalah

Obat Tradisional 17(2): 22-26

Lachman L, Lieberman H A, Kanig J L. 1986. The Theory

and Practice of Industry Pharmacy. Third Edition. Lea

& Febiger. Philadelphia. Pp. 296-300, 315-317, 332,

333

Nitalikar MM, Munde KC, Dhore BV, Shikalgar SN.

2010. Studies of Antibacterial Activities of

Glycyrrhiza glabra Root Extract. International Journal

of Pharmatech Research.

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

42

Siregar C. 2010. Teknologi Farmasi Sediaan Tablet Dasar-

Dasar Praktik. Penerbit Buku Kedokteran EGC.

Jakarta. Pp. 35, 145, 159, 172, 184, 193, 204-215, 505,

508

Voigt R. 1995. Buku Pelajaran Teknologi Farmasi. Gadjah

Mada University Press. Yogyakarta. Indonesia. Pp.

51, 160, 169, 507

The Effect of Increased Level of Avocado (Persea americana Mill.) Seed Starch as Binding Agent on Physical Properties of the Liquorice

Extract (Glycyrrhiza glabra Linn.) Lozenges

43