The Preservation of Liposomes During Air Drying Using a Matrix

Containing Maltodextrin and HPMC

Raditya Weka Nugraheni

1, 2*

, Helmy Yusuf

1

, Dwi Setyawan

1

1

Department of Pharmaceutics, Airlangga University, Jalan Dharmawangsa Dalam, Surabaya, Indonesia

2

Faculty of Health Sciences, University of Muhammadiyah Malang, Jalan Bendungan Sutami, Malang, Indonesia

Keywords: Liposomes, Air drying, Maltodextrin, HPMC, DDA

Abstract: This study used maltodextrin as a protectant to stabilize liposomes during air drying and Hydroxypropyl

Methyl Cellulose (HPMC) as solid dispersion matrix that could provide a barrier to the coalescence of

liposomes. The purpose was to optimize the composition of the matrix to protect liposomes. The liposome

suspension was prepared with the thin-film hydration method using three lipid components with the molar

ratio of SPC:DDA:Chol = 9:3:1. The maltodextrin was dissolved in water and used in the experiment as the

hydration liquid. The formulations included maltodextrin and HPMC with 4 (four) different ratios. Then,

they were air-dried at the same condition (40ºC for 120 hours). The solid products were characterized using

Powder X-Ray Diffraction (PXRD), Differential Scanning Calorimetry (DSC), and Scanning Electron

Microscopy (SEM). The PXRD analysis showed that all of the formulations developed in this study had an

amorphous structure. However, the formulations showed peak splitting in the DSC analysis. The differences

in the crystalline lamellar thickness of maltodextrin might be the cause of these results during the air drying.

The successful preservation of liposomes was analyzed using SEM photomicrography. Compared with the

other formulations, F2MO3 created the best protection for liposomes. The inclusion of HPMC as a

dispersion matrix into the liposome formulation potentially inhibits crystal formation during the drying

process and, therefore, provides better protection for the lipid bilayer.

1 INTRODUCTION

Liposome has particular advantages in vaccine

delivery, especially when cationic lipid components

are included in its formulation as a lipid bilayer

(Agger et al., 2008). One of the most potential

cationic lipids is DDA (dimethyl dioctadecyl

ammonium bromide) (Kaur et al., 2014). The use of

DDA in liposome formulations is still complicated

because it involves stability issues. First, due to its

physical instability, DDA is not suitably used as a

single lipid constituent (Kett et al., 2015). Second,

the electrostatic repulsion caused by its positive

charge is not sufficient to prevent the physical

aggregations of liposomes (Kallerup et al., 2015).

This research offers strategies to enhance the

stability of liposomes by adding sugars and

dispersing matrix, i.e., hydroxypropyl

methylcellulose (HPMC), into the developed

formulation. The role of sugar, e.g., maltodextrin,

and HPMC is to provide the glassy amorphous

matrix to inhibit the recrystallization of the

components in the formulations (Corveleyn &

Remon, 1996; Ingvarsson et al., 2011; Yu, 2001). To

prove the hypothesis, this research evaluated the

physical behavior of these components during the

drying process. Air drying is preferable because it is

simpler (i.e., it does not need special equipment) and

cheaper compared with the alternatives, namely

freeze-drying and spray-drying process.

2 MATERIALS AND METHOD

2.1 Materials

For the components of the liposomes, this research

used Dimethyl-dioctadecyl ammonium (Sigma

Aldrich, Singapore) and soy phosphatidylcholine S-

Nugraheni, R., Yusuf, H. and Setyawan, D.

The Preservation of Liposomes During Air Drying Using a Matrix Containing Maltodextrin and HPMC.

DOI: 10.5220/0008238600150018

In Proceedings of the 1st Muhammadiyah International Conference on Health and Pharmaceutical Development (MICH-PhD 2018), pages 15-18

ISBN: 978-989-758-349-0

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

15

100 (Lipoid GmBh, Germany). The addition of

cholesterol (Sigma-Aldrich, Singapore) to the

formulations was expected to provide a membrane

stabilizer. Maltodextrin (Sigma-Aldrich, E:13-17)

was used as a lyoprotectant to stabilize the

liposomes during the air-drying process. HPMC

15000 (Metolose 90SH-15000SR, Shin-Etsu, Japan)

functioned as a dispersion matrix to increase the

mass of the end product. This research chose

methanol (analytical grade, Merck) as a solvent to

facilitate the mixing of liposomal ingredients.

2.2 Methods

The liposomes were prepared with the thin-film

hydration methods. The membranes consisted of

SPC, DDA, and cholesterol dissolved in methanol.

The molar ratio of the constitutive elements of the

lipid bilayer was SPC:DDA:Cholesterol = 9:3:1. The

lipid phase was then evaporated in a vacuum

condition at 45°C for 60 minutes using a rotary

evaporator (Büchi, Germany). The process left a thin

film on the evaporator wall. Afterward, the

hydration procedure started using the pre-warmed

solution of maltodextrin (5 mL) in various

concentrations (Table 1). The hydration process was

carried out at a temperature of 50°C for 10 minutes.

The appearance of white-milky suspension indicated

a successful formation of liposomes. Then, the

liposome suspensions were sonicated for 5 minut es.

The HPMC powder was weighed according to the

details in Table 1 and dispersed in 5 mL of purified

water to form HPMC gel. The liposome suspensions

were added to the HPMC gel, mixed until

homogeneous, and divided into the vials for drying.

The characterizations of the solid products by

XRD, DSC, and SEM were carried out according to

Nugraheni et al. (2017). The condition of the XRD

analysis was as follows: Cu as an anode, Kα filter, a

generator set to 40 kV/30 mA, and room

temperature. The study was carried out at a 2theta

Table 1: The formulations of liposomes

Formulation Codes Maltodextrin

Concentrations

HPMC Concentrations Maltodextrin:HPMC

(Weight ratio)

F2MO1 5% 2.5% 2:1

F2MO2 10% 2.5% 4:1

F2MO3 5% 7.5% 2:3

F2MO4 10% 7.5% 4:3

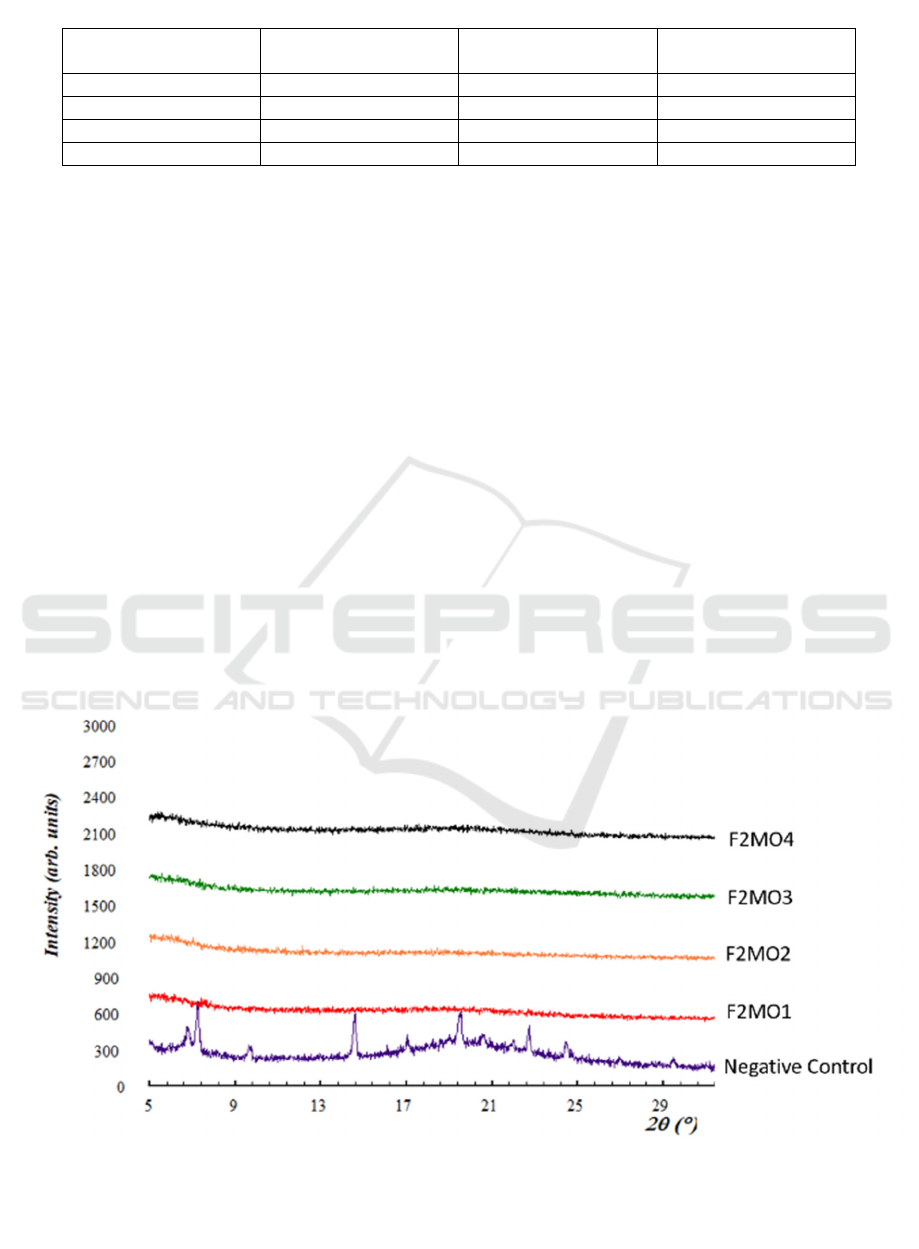

Figure 1: The X-Ray Diffraction pattern of samples containing different concentrations of maltodextrin and

HPMC (as seen in Table 1). The negative control (purple) was dried lipid components without maltodextrin

and HPMC.

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

16

range of 5 to 40°. Meanwhile, in the DSC thermal

analysis, the samples were placed in aluminum

crucibles and scanned from 30°C-300°C with a

heating rate of 10°C/min. The morphology of the

liposomes in the solid gel was analyzed with SEM.

The portions of the dried product were scattered and

glued onto 25-mm diameter plates, which were

attached to the SEM specimen mounts. The

specimens were sputter-coated with a 5-nm layer of

Au-Palladium.

3 RESULTS AND DISCUSSION

The solid systems of all formulations were relatively

amorphous. Compared with the negative control,

there was nearly no high-intensity peak detected in

the X-Ray diffractogram pattern analysis (Figure 1).

The amorphous system is the ideal condition

because it can preserve the liposomes in the

formulations. This physical feature is necessary

because the crystalline components can damage the

integrity of the bilayer membrane and cause ruptures

on it (Li et al., 2016). The X-Ray diffractogram of

all formulations also strongly confirmed the role of

vitrification mechanism to preserve the liposomes

during drying (Ingvarsson et al., 2011).

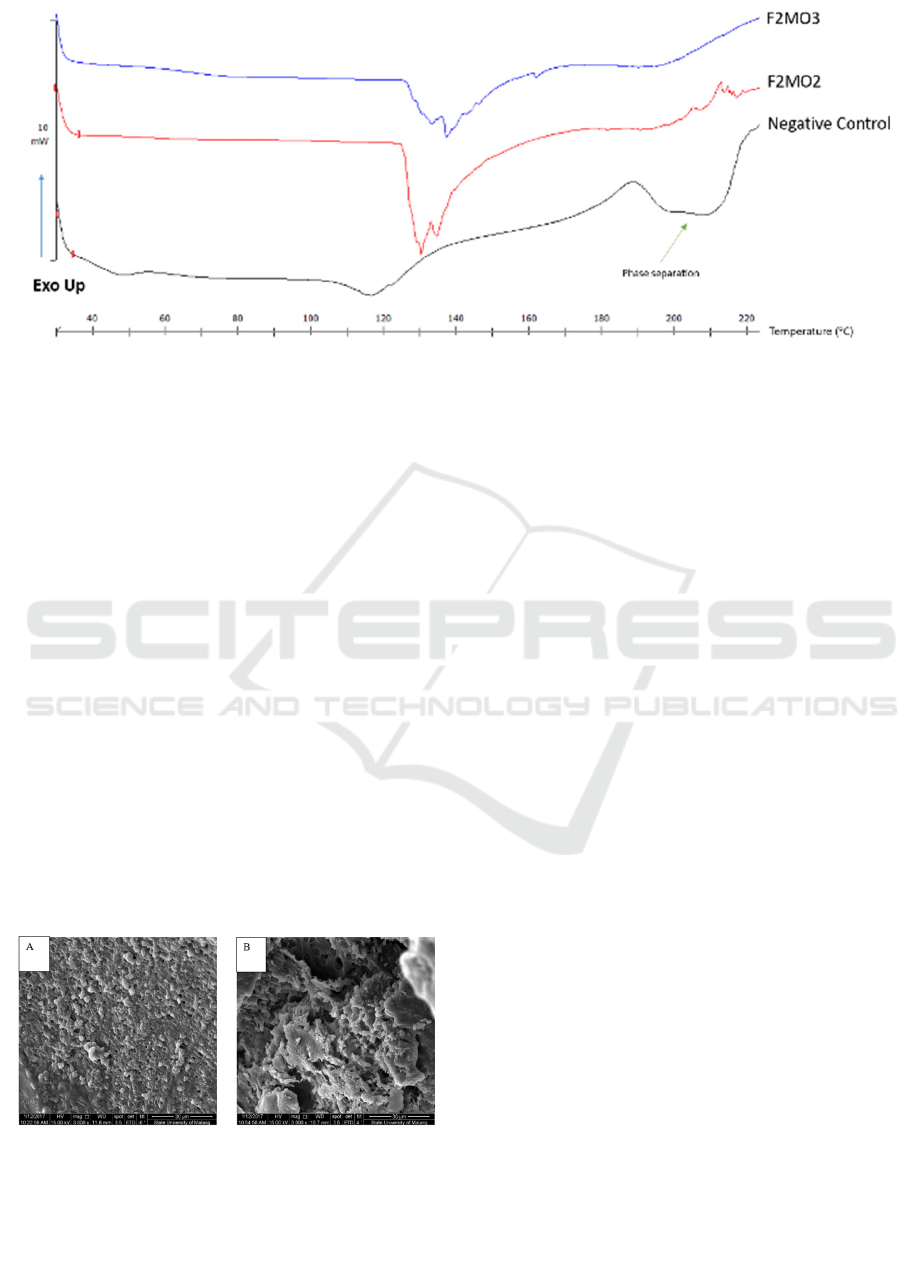

Contrary to Nugraheni et al. (2017) in which the

liposome formulations from maltodextrin were

freeze-dried, the DSC profiles in this research

exhibited endothermic peak splitting at 120-150⁰C

(Figure 2). These results imply the heterogeneity of

the samples. The different melting points of the

crystal with a different lamellar thickness in the

polymer were probably the cause of the endothermic

peak splitting (Montanheiro et al., 2016). The

reorganization or recrystallization of amorphous

material in thermal treatment, e.g., heating during

the air-drying process, might be responsible for this

phenomenon (Pereira et al., 2016).

Compared with the other formulations, F2MO3

and F2MO2 were more homogeneous (Figure 2).

The phase separation for samples containing neither

Maltodextrin nor HPMC occurred at 120-180⁰C.

This finding shows that both components are crucial

in the formulations.

The SEM photograph (Figure 3) of the sample’s

surface changed when the maltodextrin increased.

The increase of maltodextrin in the formulations

containing the same amount of HPMC produced

more porous and rougher surface. The porosity of

the matrix is essential to facilitate the rehydration of

the samples (Yusuf et al., 2017). F2MO3 produced a

Figure 2: The DSC thermogram pattern of samples containing different concentrations of maltodextrin and

HPMC (as seen in Table 1). The negative control (black) was dried lipid components without maltodextrin and

HPMC.

Figure 3: The different SEM microphotographs,

indicating that the increase of maltodextrin in

formulations containing the same amount of

HPMC produces a different surface profile. (A)

F2MO3, (B) F2MO4.

The Preservation of Liposomes During Air Drying Using a Matrix Containing Maltodextrin and HPMC

17

smoother surface than F2MO4, which would

accommodate the preservation of liposomes in the

matrix.

Yusuf et al. (2017) have created several

formulations with different disaccharides, but the

resultant crystallinity profile was unfavorable

because the phase separations still occurred in the

results. However, this research developed the

formulations using amorphous oligosaccharide. The

finding shows that F2MO3 is the formulation that

meets the desired physical characteristics. The high

HPMC-maltodextrin ratio inhibits molecular re-

arrangement and, thereby, provides better protection

for the liposome vesicles.

4 CONCLUSIONS

The inclusion of Maltodextrin and HPMC as a

dispersion matrix into the liposome formulations

potentially inhibits crystal formation during the

drying process and, consequently, provides better

protection for the lipid bilayer in liposomes.

REFERENCES

Agger, E.M., Rosenkrands, I., Hansen, J., Brahimi, K.,

Vandahl, B.S., Aagaard, C., Werninghaus, K.,

Kirschning, C., Lang, R., Christensen, D., Theisen,

M., Follmann, F., & Andersen, P., 2008. Cationic

Liposomes Formulated with Synthetic Mycobacterial

Cord factor (CAF01): A Versatile Adjuvant for

Vaccines with Different Immunological Requirements.

PLOS ONE 3, e3116.

https://doi.org/10.1371/journal.pone.0003116

Corveleyn, S., & Remon, J.P., 1996. Maltodextrins as

lyoprotectants in the lyophilization of a model protein,

LDH. Pharm. Res. 13, 146–150.

Ingvarsson, P.T., Yang, M., Nielsen, H.M., Rantanen, J.,

& Foged, C., 2011. Stabilization of liposomes during

drying. Expert Opinion on Drug Delivery 8, 375–388.

https://doi.org/10.1517/17425247.2011.553219

Kallerup, R.S., Madsen, C.M., Schiøth, M.L., Franzyk, H.,

Rose, F., Christensen, D., Korsholm, K.S., & Foged,

C., 2015. Influence of trehalose 6,6′-diester (TDX)

chain length on the physicochemical and

immunopotentiating properties of DDA/TDX

liposomes. European Journal of Pharmaceutics and

Biopharmaceutics 90, 80–89.

https://doi.org/10.1016/j.ejpb.2014.10.015

Kaur, R., Henriksen-Lacey, M., Wilkhu, J., Devitt, A.,

Christensen, D., & Perrie, Y., 2014. Effect of

Incorporating Cholesterol into DDA: TDB Liposomal

Adjuvants on Bilayer Properties, Biodistribution, and

Immune Responses. Molecular Pharmaceutics 11,

197–207. https://doi.org/10.1021/mp400372j

Kett, V., Yusuf, H., McCarthy, H., & Chen, K.H., 2015.

Liposomal delivery system. US Patent Document

Li, J., Hu, M., Xu, H., Yu, X., Ye, F., Wang, K., Luan, X.,

Li, L., & Zhang, D., 2016. Influence of type and

proportion of lyoprotectants on lyophilized

ginsenoside Rg3 liposomes: Lyophilized ginsenoside

Rg3 liposomes. Journal of Pharmacy and

Pharmacology 68, 1–13.

https://doi.org/10.1111/jphp.12489

Montanheiro, T.L. do A., Passador, F.R., Oliveira, M.P.

de, Durán, N., Lemes, A.P., Montanheiro, T.L. do A.,

Passador, F.R., Oliveira, M.P. de, Durán, N., &

Lemes, A.P., 2016. Preparation and Characterization

of Maleic Anhydride Grafted Poly (Hydroxybutyrate-

CO-Hydroxyvalerate) – PHBV-g-MA. Materials

Research 19, 229–235. https://doi.org/10.1590/1980-

5373-MR-2015-0496

Nugraheni, R.W., Setyawan, D., & Yusuf, H., 2017.

Physical Characteristics of Liposomal Formulation

Dispersed in HPMC Matrix and Freeze-Dried Using

Maltodextrin and Mannitol as Lyoprotectant.

Pharmaceutical Sciences, 23, 285–292.

https://doi.org/10.15171/PS.2017.42

Pereira, G.C., Rzatki, F.D., Mazzaferro, L., Forin, D.M.,

Barra, G.M. de O., Pereira, G.C., Rzatki, F.D.,

Mazzaferro, L., Forin, D.M., & Barra, G.M. de O.,

2016. Mechanical and Thermo-Physical Properties of

Short Glass Fiber Reinforced Polybutylene

Terephthalate upon Aging in Lubricant/Refrigerant

Mixture. Materials Research 19, 1310–1318.

https://doi.org/10.1590/1980-5373-mr-2016-0339

Yu, L., 2001. Amorphous pharmaceutical solids:

preparation, characterization and stabilization.

Advanced Drug Delivery Reviews 48, 27–42.

https://doi.org/10.1016/S0169-409X(01)00098-9

Yusuf, H., Nugraheni, R., Mulyadi, N.A., Setyawan, D., &

Rosita, N., 2017. Phase behavior of dried–DDA

liposomal formulation dispersed in HPMC matrix in

the presence of saccharides. Int J PharmTech Res 10,

50–56.

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

18