Study on Carbon Emission from Sludge Drying and Incineration

Process

Shasha Ji

*

Shanghai Urban Construction Design & Research Institute (Group) Co., Ltd., Shanghai, China

Keywords: Sludge, Drying and incineration, carbon emission

Abstract: In China, there is a lack of research on the carbon footprint of sludge treatment and disposal. This paper

studied the carbon emissions during sludge drying and incineration process In order to make the research

more practical, the carbon footprint of “ZhuYuan sludge incineration project” is calculated by the actual

measurement method and model estimation method. Using the model estimation method, the discharge

equivalent of CO

2

in the sludge incineration process is 1546.6~1709.9 kg CO

2

/t DS; Using the actual

measurement method, the discharge equivalent of CO

2

in the sludge incineration process is 3046.6 kg CO

2

/t

DS. The causes of the difference between the two methods were discussed. Finally, the optimization

strategy of reducing the carbon emission of the sludge drying and incineration process is put forward.

1 INTRODUCTION

It is estimated that by 2020, the amount of municipal

sludge will reach 6000~9000 million tons. The cost

of sludge disposal accounts for about half of the total

cost of sewage treatment. Sludge disposal and

management is one of the major challenges for the

global water industry (Zhou et al., 2013). The sludge

treatment process during sewage treatment has

become a major source of carbon emissions due to

its energy consumption and greenhouse gas

emissions. The carbon footprint is a new parameter

for the evaluation of the sludge technology route,

which reflects the possible greenhouse gases and

related climate changes that may be discharged

during the process of sludge treatment and disposal

(Brown et al., 2010).

In recent years, sludge drying and incineration

technology has shown explosive growth in China,

especially for some large cities with limited land

use. During the "13th Five-Year" period, all the new

construction projects of sludge treatment facilities in

the three major areas of Shanghai central urban area

were dry chemical incineration technology.

Sludge drying is designed to remove or reduce

the water content in the sludge. The removal process

is divided into two stages, namely, the vaporization

and evaporation process on the surface of the sludge

and the diffusion process of the water in the sludge.

It can reduce the sludge greatly, improve the sludge

calorific value, kill the harmful components and

create conditions for the utilization of resources.

Incineration is a complete combustion process,

especially suitable for large cities that are faced with

land restrictions. During the incineration process, the

combustible components in the sludge are rapidly

oxidized. The temperature required for complete

combustion is generally 760~820 ℃. One of the

main parameters of sludge incineration is the water

content of sludge. The sludge with solid ratio of

30%~50% could combustion without auxiliary fuel.

The sludge with solid ratio of 20%~30% needed to

add auxiliary fuel and pre-drying in the incinerator.

In addition, the low solid content will lead to the

increase of the flue gas treatment. Therefore, proper

solid ratio should be selected before incineration.

Another important parameter of sludge is the sludge

calorific value (Cao and Pawlowski, 2013).

At present, most of the research on carbon

footprint in China is mainly macroscopic. This paper

focuses on the carbon footprint research of sludge

treatment and disposal, and provides the basis for the

carbon emission reduction work of the sludge

industry.

Ji, S.

Study on Carbon Emission from Sludge Drying and Incineration Process.

DOI: 10.5220/0008188802730277

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 273-277

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

273

2 METHODOLOGY

2.1 Project Introduction

At present, “ZhuYuan sludge incineration project” is

the largest sewage sludge drying and incineration

project that has been operated in China. The scale of

this project is 150 t/DS, and the Sludge calorific

value is 13700 kJ/kg. The project mainly includes

sludge receiving and storage system, sludge drying

system, sludge incineration system, waste heat

utilization system, flue gas treatment system and

auxiliary system. The sludge is dried by indirect

drying method, and the heat source is steam. The

sludge is incinerated by fluidized bed incinerator.

2.2 Boundary of Research System

In the study of sludge life cycle assessment, it is

generally regarded as the starting point of life cycle

evaluation, and the scope of the study includes the

whole process from production, transportation,

recycling, and treatment to final disposal. This paper

focuses on the research on the disposal and disposal

parts. Along with the sludge itself entering the

system, it also includes auxiliary energy and other

raw materials; the output of the system is useful

products and recycled energy.

Sludge treatment processes and the disposal

route are presented in Figure 1. “Thickening” and

“Dewatering” process are finished in Waste water

treatment plant. “Drying” and “Incineration” process

are finished in Sludge treatment plants. Research

boundary is limited to sludge treatment plant.

Figure 1: Sludge treatment processes and disposal routes.

2.3 Carbon Footprint Method

The Carbon footprint is defined as the total amount

of greenhouse gases (GHG) produced to directly and

indirectly support human activities, usually

expressed in equivalent tons of carbon dioxide

(CO

2

). It is a common method to calculate the

impacts of human activities on Global Warming

(IPCC, 2006).

Although the study found many gases affecting the

climate system, only 6 major types of greenhouse

gases were included in the “Kyoto Protocol”,

including CO

2

, CH

4

, N

2

O, HFCs, PCFs and SF in

the carbon footprint assessment. As the

quantification of these gases cannot be directly

measured, they are estimated by calculating GHG

emissions of each processes involved in the studied

activities. The amount of each gas is then converted

with an emission factor in CO

2

equivalent (CO

2eq

)

according to their Global Warming Potential (GWP),

which showed in Table 1 (IPCC, 2006).

Table 1: Considered gases in carbon footprint and their

Global Warming Potential at 100 years (GWP

100

).

Formula

GWP

100

CO

2

1

CH

4

21

N

2

O

310

HFCs

124-14800

PCFs

7390-10300

SF

17200

GHG emission of sludge treatment can be divided

into direct part and indirect part:

Direct part: GHG emissions directly occurring

in sludge treatment and disposal.

Indirect part: GHG emissions caused by

electricity and fuel consumption during sludge

drying and incineration process.

2.4 Calculation Method

At present, the domestic calculation methods of

GHG emissions in sludge treatment and disposal

process are mainly divided into actual measurement

method and model estimation method.

The actual measurement method needs to

measure the relevant parameters of the emission

source or the operating equipment through the actual

testing method, and calculate the carbon emissions

by the measured data approved by the environmental

protection department. Most of calculations used

model estimation method. These studies are of great

guiding significance, but the results are largely

dependent on the hypothesis and scenario analysis.

In order to make the research more practical, the

carbon footprint of “ZhuYuan sludge incineration

project” is calculated by actual measurement method

and model estimation method.

Thickening

Dewatering

Drying

Incineration

Sludge

Waste water treatment plants

Sludge treatment plants

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

274

3 MODEL ESTIMATION

METHOD

3.1 Calculation Method of Drying

The carbon emission during the sludge drying

process is mainly energy consumption, and the

calculation method is as shown in Equation 1.

CO

2

=M1·(EC1·F

electric

+ EC2·F

natural gas

)

(1)

M1: The mass of water reduction during drying

EC1: Specific energy consumption (electric)

F

electric

: CO

2

emission factor (electric)

EC2: Specific energy consumption (natural gas)

F

natural gas

: CO

2

emission factor (natural gas)

3.2 Calculation Method of Incineration

Carbon emissions from sludge incineration include

Energy source CO

2

, Biogenic source CO

2

and

Alternative CO

2

, and the calculation method is as

shown in Equation (2) ~ (6).

CO

2

=M2·(EC3·F

electric

+ EC4·F

electric

)

(2)

M2: Dry sludge quality

EC3: Specific energy of Wet flue gas purification

system (electric)

EC4: Specific energy of SNCR (electric)

CO

2

=M2·CC·η1·44/12·

(3)

CC: Carbon content in sludge

η: Combustion carbon oxidation factor

CO

2CH4

=M2·F

CH4

·

(4)

F

CH4

: Emission factor of CH

4

CO

2N2O

=M2·F

N2O

·

(5)

F

N2O

: Emission factor of N

2

O

CO

2

=M2·Hv·η2·F

diesel

/Hvd

(6)

HV: Sludge calorific value

η2: Energy utilization rate

F

diesel

: CO

2

emission factor (diesel)

Hvd: Diesel calorific value

3.3 Estimation Result

In the model estimation method, the calculation

parameters of sludge drying and incineration process

are shown in Table 2. In the drying stage, due to the

different use of equipment and the actual operation,

it causes difference in energy consumption, and

there is still such a situation in the incineration stage,

that is, different flue gas treatment equipment and

different working conditions will lead to the

different energy consumption of the wet scrubbing

tower and the SNCR system (Liu et al., 2013).

The discharge equivalent of CO

2

in the sludge

incineration process is 1546.6~1709.9 kg CO

2

/t DS,

and the emission equivalent of the energy source

CO

2

is 737.7~988.0 kg CO

2

/t DS, and the emission

equivalent of the biological source CO

2

is 1432.5 kg.

Alternative CO

2

comes from the energy produced by

the sludge incineration. This part of the energy can

be used to compensate for the consumption of the

system (Showed as Table 3).

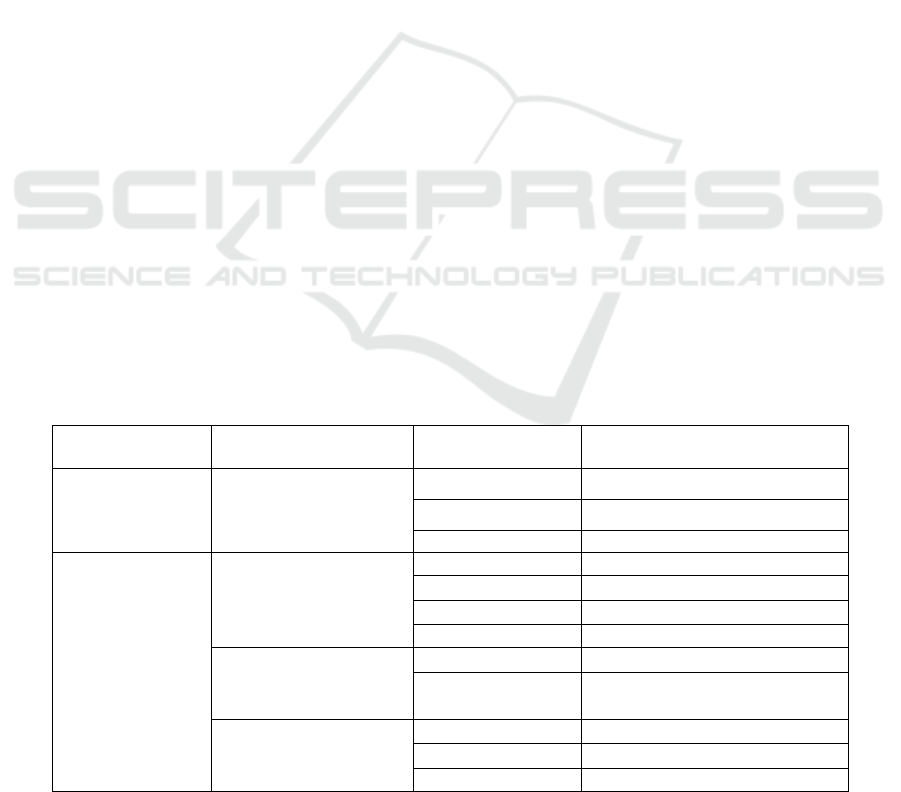

Table 2: Calculation parameters of GHG emission.

Unit

Category

Parameter

Value (Ministry of environmental

protection)

Drying

Energy source CO

2

M

2.5 kg

EC1

100-200 kWh/m

3

EC2

2750 kJ/kg

Incineration

Energy source CO

2

CC

36%

η1

95%

EC3

6~19 kWh/t DM

EC4

40~50 kWh/t DM

Biogenic source CO

2

F

CH4

24.25 g CH

4

/t DM

F

N2O

990 g N

2

O/t DM

Alternative CO

2

Hv

13700 kJ/kg

Hvd

43.0 TJ/Gg

η2

70%

Study on Carbon Emission from Sludge Drying and Incineration Process

275

Table 3: GHG emission.

Unit

Emission type

Emission value (kg)

GWP

CO

2

eq (kg CO

2

/t DS)

Drying

Energy source CO

2

t

684.9~916.9

1

684.9~916.9

Incineration

Energy source CO

2

49.8~71.1

1

49.8~71.1

Biogenic source CO

2

1125.1

1

1125.1

Emission of CH

4

0.024

21

0.504

Emission of N

2

O

0.99

310

306.9

Alternative CO

2

-710.6

1

-710.6

4 ACTUAL MEASUREMENT

METHOD

4.1 Energy Source CO

2

The energy source CO

2

emission from “ZhuYuan

sludge incineration project” mainly includes the

consumption of power, light diesel, activated carbon,

NaOH and Ca(OH)

2

. The specific value was showed

in Table 4. The discharge equivalent of energy

source CO

2

is 1891.96 kg CO

2

/t DS.

It is necessary to explain that the energy

generated by the sludge incineration is not sufficient

to support the drying of the sludge, so the external

energy is needed to fill the dry energy gap, and the

steam from the “Waigaoqiao power plant” is used in

this project.

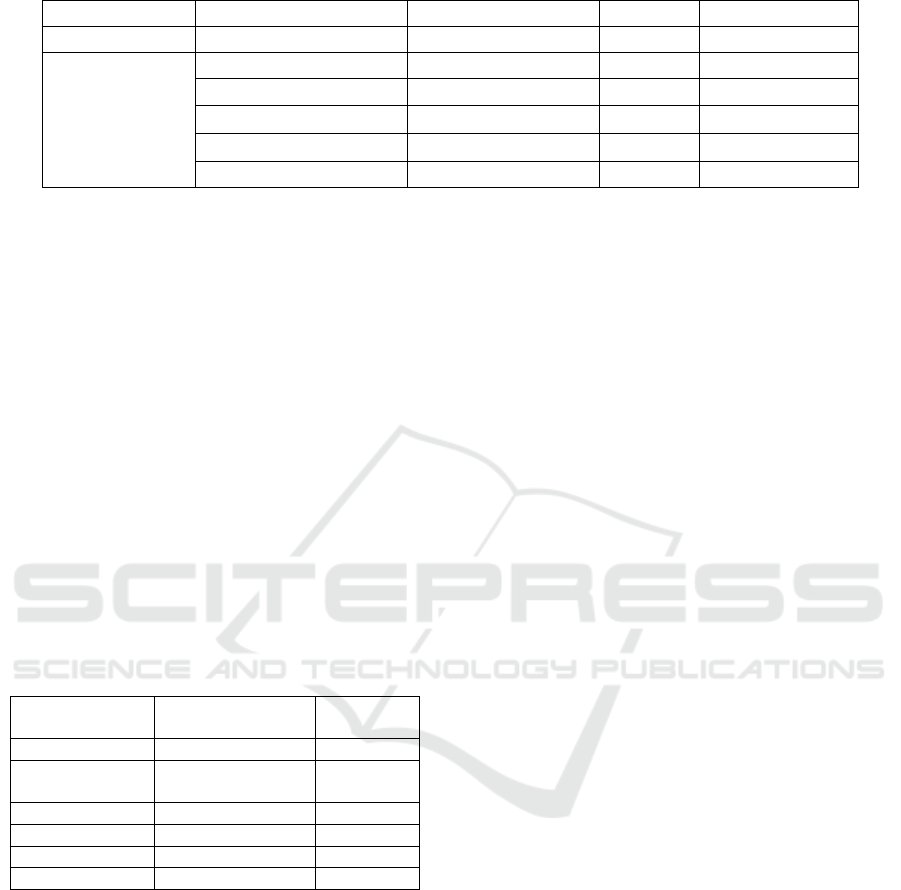

Table 4: Energy source CO

2

emission.

Entry

Consumption

CO

2

eq (kg

CO

2

/t DS)

Power

578.97 kWh/t DS

537.28

External steam

(used for drying)

996.14 kWh/t DS

924.42

light diesel

124 kg/t DS

394.20

activated carbon

1 kg/t DS

6

NaOH

17.86 kg/t DS

20.90

Ca(OH)

2

9.41 kg/t DS

9.17

4.2 Biogenic Source CO

2

The average carbon content in dehydrated sludge

was 32%, and the average carbon content in fly ash

was 1.1% after burning. According to the estimated

method proposed by the IPCC (2006), the CO

2

emission of biological source was 1154.6 kg CO

2

/t

DS.

4.3 Alternative CO

2

Energy produced by the sludge incineration is all

self-used, one part is used for primary air heating in

incinerator and the other is used in the waste heat

boiler to produce steam to drying sludge, so it is no

longer included in the emission statistics.

5 METHOD COMPARISON

Using the model estimation method, the discharge

equivalent of CO

2

in the sludge incineration process

is 1546.6~1709.9 kg CO

2

/t DS; Using the actual

measurement method, the discharge equivalent of

CO

2

in the sludge incineration process is 3046.6 kg

CO

2

/t DS. It can be seen that there are large

differences in the calculation of CO

2

emission

equivalents by different methods. The main reasons

are as follows: 1. The power consumption in the

actual measurement method is the total power

consumption of the entire engineering operation

facility, which is greater than the power

consumption of the specified equipment in the

model estimation method; 2. The specific energy

consumption in the model estimation is greatly

affected by the assumptions, equipment and working

conditions, and there is a big difference with the

actual operating conditions. 3. The energy available

for sludge incineration after model incineration

depends on the assumed utilization value. For the

estimation, this is also quite different from the actual

use value of the energy in the measured method.

6 OPTIMIZATION SUGGESTION

Through analysis, it can be seen that the energy

source CO

2

emissions in the dry process and the flue

gas treatment process account for a large proportion.

Drying process is one of the most important links of

CO

2

emissions. The energy consumption of the

sludge drying technology is related to the dry form.

Therefore, the selection of a dry process with lower

energy consumption can effectively reduce CO

2

emissions.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

276

The energy consumption of drying is still related

to the type of heat source chosen. From the

perspective of reducing carbon emissions, when the

flue gas temperature is high enough and transport

distance is relatively short, it is preferable to use

waste heat flue gas of large-scale industrial and

environmental protection infrastructure, such as

waste incinerator, power station, chemical facilities,

etc.

In addition, the energy utilization rate of the

incineration system should be increased, which can

increase the value of Alternative CO

2

.

ACKNOWLEDGEMENTS

Thanks for the support of scientific research project

of Shanghai science and Technology Commission

(18XD1422700).

REFERENCES

Brown, S., Beecher, N., Carpenter, A., 2010. Calculator

tool for determining greenhouse gas emissions for

biosolids processing and end use. Environ. Sci.

Technol. 44, 7.

Cao, Y., Pawlowski, A., 2013. Life cycle assessment of

two emerging sewage sludge-to-energy systems:

Evaluating energy and greenhouse gas emissions

implications. Bioresour. Technol. 127, 81–91.

IPCC, 2006. Guidelines for national greenhouse gas

inventories.

Liu, B., Wei, Q., Zhang, B., Bi, J., 2013. Life cycle ghg

emissions of sewage sludge treatment and

disposaloptions in tai lake watershed, china. Sci. Total

Environ., 447, 361–369.

Ministry of Environmental Protection. Guidelines for Best

Available Techniques for Sewage Treatment Plant

Sludge Treatment and Disposal Preparation of

research report [R].

Zhou, Y.Z., Zhang, D.Q., Le, M.T., Puah, A.N., Ng, W.J.

2013. Energy utilization in sewage treatment—A

review with comparisons. J. Water Clim. Chang 4, 1.

Study on Carbon Emission from Sludge Drying and Incineration Process

277