Research and Analysis on Performance of Purified Air Conditioning

Mingming Sun

Zhejiang DunAn Artificial Environment Co., Ltd., Hangzhou, China

Keywords: purified air conditioning; purification efficiency; energy consumption

Abstract: In order to study the performance of purified air conditioning, the author designed an air conditioning with

purification function. On the basis of the original air conditioning, honeycomb activated carbon filter and

precious metal room-temperature catalytic filter are added to the purified air conditioning. We have

analysed the purification performance, refrigeration performance and power consumption of the conditioner,

which provides references for the design and energy consumption analysis of purified air conditioner.

1 INTRODUCTION

Indoor environment refers to the small space made

of natural or artificial materials, and it is a small

environment which is relatively separated from the

external environment. The architectural indoor

environment is the most important and most

common. A lot of chemical composite materials are

used during the modern interior decoration, such as

man-made sheet, wallpaper, paint, composite

ceiling, furniture and interior soft decoration. These

elements emit a large number of poisonous and

harmful gaseous pollutants continuously, including

formaldehyde, benzene, xylene and VOCs (Volatile

Organic Compounds). With the development of

economy and people's living standard, urban

residents spend more than 80% of their time indoors.

IAQ (Indoor Air Quality) affects not only the

comfort and health of human body, but also the

working efficiency of indoor personnel prominently.

A study by Harvard University shows that air quality

in office has a significant impact on work efficiency.

Good air quality helps to improve the ability to

thinking, understanding, memorizing, learning and

decision-making. The study found that people in the

office with a good ventilation condition and a low

concentration of pollutants were 61 percent more

efficient than in a traditional office. With the

improvement of healthy and environmental

awareness, the indoor air pollution has aroused great

attention in China (GB/T 18801-2015, 2015).

Relevant information from the WHO (World

Health Organization) showed that the number of

deaths due to indoor environmental pollution was

about 2.8 million per year all over the world (GB/T

18883-2002, 2002).

The American Cancer Society studies founds that

indoor air pollution had an great direct link with

urban residents' health, and that more than 4%

diseases in the world had a direct relationship with

indoor pollution. It also indicated that the number of

deaths from asthma attacks caused by indoor air

pollution was more than 300 thousand every year,

40% of which are children (Guo, 2012).

In such a grim situation of air pollution, people

attach more and more importance to problems

related to IAQ. China's environmental protection

industry is also taking advantage of development.

The indoor air purification device began to rise,

comprising air purifier, purified household air

conditioner, purified central air conditioner, fresh air

unit and so on. At present, the main purification

technology for treating gaseous pollutants on the

market is activated carbon adsorption, which

belongs to physical adsorption. This technology has

low purification efficiency and short service life. It

needs to be replaced after a period of use, increasing

after-sales costs and maintenance costs.

In this study, the purified air conditioning unit

has been developed independently. And the

experimental research and performance comparison

are carried out mainly aiming at air purification

capacity, service life, and energy consumption.

264

Sun, M.

Research and Analysis on Performance of Purified Air Conditioning.

DOI: 10.5220/0008188602640267

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 264-267

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 INTRODUCTION OF PURIFIED

AIR CONDITIONING

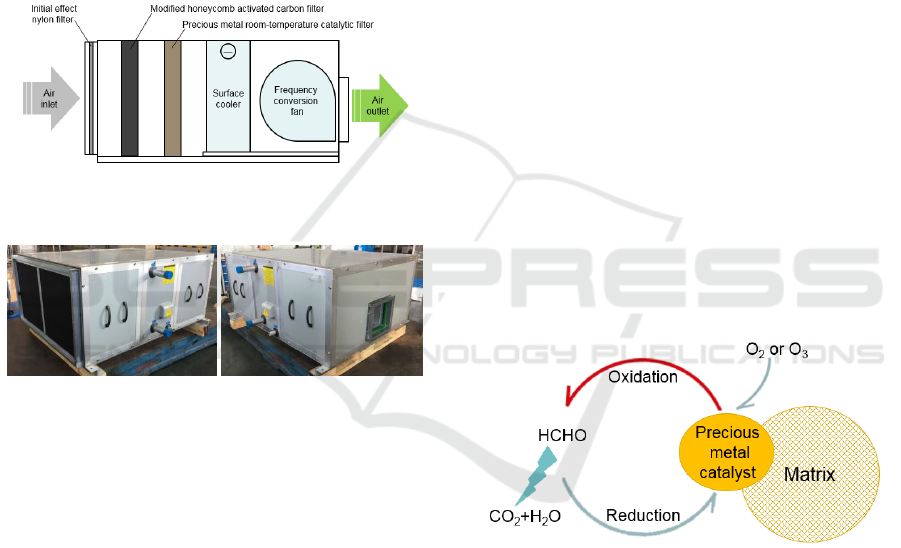

The purified air conditioning unit adds air

purification function section, compared with original

air conditioning unit. The unit mainly includes the

panel, air inlet, air outlet, initial effect nylon filter,

modified honeycomb activated carbon filter,

precious metal room-temperature catalytic filter,

surface cooler, water tray, frequency conversion fan

and so on. The design air volume is 2000m

3

/h, the

cooling capacity is 11.6kW, and the external

pressure is 120Pa.The structure of the unit is shown

in the following chart (Figure 1 and 2).

Figure 1: Structure diagram of purified air conditioning

unit.

Figure 2: Appearance diagram of purified air conditioning

unit.

2.1 Modified Honeycomb Activated

Carbon Filter

Modified honeycomb activated carbon material uses

honeycomb activated carbon composites as matrix,

and its purification ability is improved by chemical

modification. This material combines physical and

chemical adsorption, with high purification

efficiency and low desorption capacity. Compared

with conventional activated carbon particle and

activated carbon fabric, this material has the

advantages of long purification life. The material is

integrated, so its strength is greater and it is harder to

break and leak powder. The material has through-

hole structure, which makes the resistance very

small. The modified honeycomb activated carbon

material can effectively remove benzene and other

TVOCs, abnormal flavor and odor.

2.2 Precious Metal Room-temperature

Catalytic Filter

Precious metals generally refer to metals such as

gold, silver, platinum, palladium, rhodium, iridium,

osmium and ruthenium (JG/T 294-2010, 2012).

Gold, platinum, palladium and other precious metals

have good chemical stability and catalytic activity,

and they have excellent performance for catalytic

decomposing formaldehyde at room temperature.

Precious metals are not used as purifying

materials directly, but as materials for purification

by loading on carriers. There are two forms of

carrier: one is the ceramic honeycomb, also called

cordierite, the other is the metal honeycomb

winding, like Fe-Cr-Al heat-resistant steel (Jin et al.,

2007).

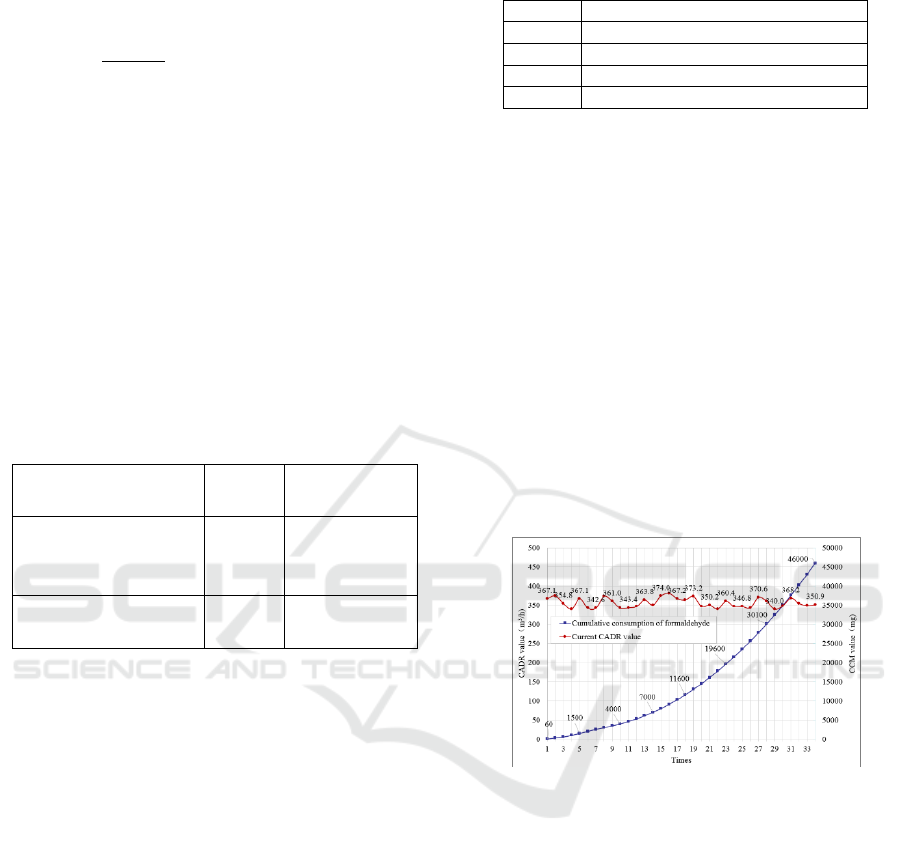

The precious metal room-temperature catalytic

material is supported by ceramic honeycomb, whose

surface is loaded with precious metal material. At

room temperature, the material can decompose

formaldehyde to CO

2

and H

2

O under the action of

precious metal catalysts, as shown in the Figure 3.

The purification efficiency of precious metal room-

temperature catalytic material is very high and

thorough, without secondary pollution. Because the

material plays the role of chemical catalysis, the

purification effect of material is long-lasting and

durable.

Figure 3: Principle diagram of precious metal room-

temperature catalysis.

3 EXPERIMENTAL METHODS

AND RESULTS

3.1 Primary Purification Efficiency

Primary purification efficiency is the ratio of the

difference between the pollutant concentration of

upstream and downstream to the pollutant

concentration of windward, as shown equation

below. In reference to JG/T294-2010 Test of

Research and Analysis on Performance of Purified Air Conditioning

265

Pollutant Cleaning Performance of Air Cleaner

(Shao et al, 2016), the test of primary purification

efficiency is carried out at the air tunnel test system.

(1)

P — the primary purification efficiency.

C

1

—the pollutant concentration of upstream

C

2

— the pollutant concentration of downstream.

The experimental conditions are that the ambient

temperature is 23±2, the relative humidity is

50±10%, and the concentration of the upper air side

is 3S±0.1S (S is the concentration limit specified in

GB/T 18883-2002 Indoor Air Quality Standard

(Zhang et al., 1999). The concentration limit of

formaldehyde is 0.10mg/m

3

and that of TVOC is

0.60mg/m

3

.). The primary purification efficiency of

formaldehyde and TVOC are tested on the

purification function section. The results are shown

as Table 1.

Table 1: Results of the primary purification efficiency.

Project

Test

Results

Standard

Requirements

Primary purification

efficiency of

formaldehyde

76.6%

≥50%

Primary purification

efficiency of TVOC

62.3%

≥50%

The primary purification efficiency of

formaldehyde is 76.6% and that of TVOC is 62.3%.

According to JG/T294-2010, the primary

purification efficiency should be more than 50%,

and the above two items are much higher than the

standard values.

3.2 CADR and CCM Values of

Formaldehyde

The Clean Air Delivery Rate (CADR value) is a

parameter of the purification capacity for the target

pollutant, indicating the rate of air purifier to provide

clean air.

The Cumulate Clean Mass (CCM value) is a

parameter of cumulative purification capacity for the

target pollutant. It indicates the total mass of the

target pollutant when the CADR converges to 50%

of the initial value. In reference to GB/T18801-2015

Air Cleaner (Zhu and Xiao, 2012), there are four

levels of CCM value in Table 2.

Table 2: Evaluation of CCM value.

Grade

CCM value

F1

300 mg ≤ CCM < 600 mg

F2

600 mg ≤ CCM < 1000 mg

F3

1000 mg ≤ CCM < 1500 mg

F4

1500 mg ≤ CCM

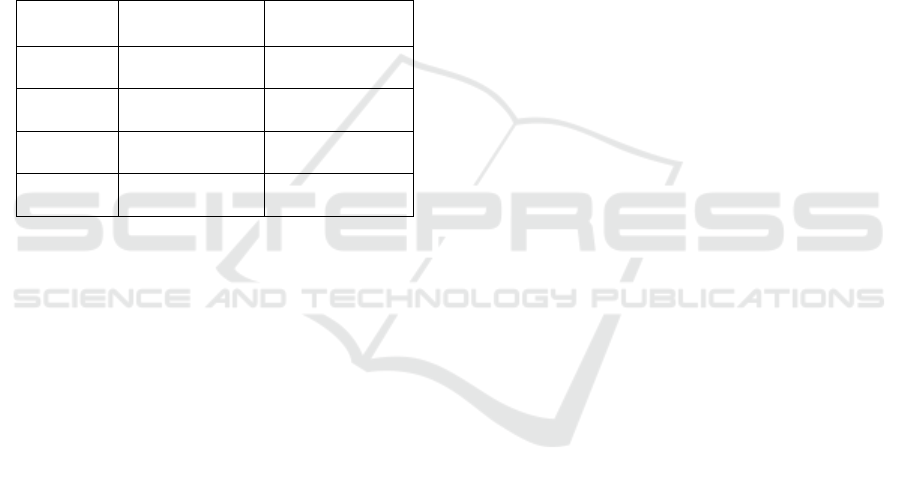

The tests of CADR and CCM are carried out in

the environment cabin test system under the same

conditions as in the previous section. According to

the gradual incremental injection method prescribed

in GB/T18801-2015, the CADR values of

formaldehyde were tested when the cumulative

injection volume reached 300mg, 600mg, 1000mg,

1500mg, 2100mg, 2800mg, 3600mg, 4500mg,

5500mg……, respectively. Originally planned, the

test would be finished when the CADR value of

formaldehyde dropped to 50% of the initial value.

However, the CADR value remained at a stable level

during the test, because of the steady purification

performance of the product. The test was carried out

for 4 months, and the CADR value of the product

was still not significantly reduced, so the test was

terminated. The results are shown as Figure 4.

Figure 4: Test results of CADR and CCM values of

formaldehyde.

The square points in the diagram represent the

total amount of formaldehyde treated after each

incremental injection, and the last value is the CCM

value of formaldehyde. The round points represent

the CADR values of formaldehyde tested after each

incremental injection.

The initial CADR value of formaldehyde is

367.1 m

3

/h and it is 350.9 m

3

/h when the test ends.

The final CADR value is 95.6% (much higher than

50%) of the initial value, without significant decline

keeping between 340 and 380 m

3

/h. During the

whole lifetime test, the total formaldehyde is 46g,

which is 30 times higher than that of the F4 level in

GB/T 18801-2015. The corresponding CCM of F4

level is 1.5g.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

266

3.3 Cooling Capacity and Energy

Consumption

In order to study the effect of purification function

on the performance of air conditioning units, we test

the cooling capacity and power consumption of the

units, through frequency conversion controlling the

air volume at 2000 m

3

/h and the external pressure at

120Pa. The experimental conditions are that the air

dry-ball-temperature is 27, the air wet-ball-

temperature is 19.5, the inlet-water-temperature is

7, and the temperature difference between the inlet

and outlet water is 5. The results are shown as

Table 3.

Table 3: Test results of cooling capacity and energy

consumption.

Project

Unit without

Purifying Filters

Unit Installed

Purifying Filters

Air

volume

1951 m

3

/h

1970 m

3

/h

External

pressure

121 Pa

122 Pa

Cooling

capacity

12154 W

12222 W

Input

power

301 W

355 W

Under the same conditions of air volume and

external pressure, after installed the purifying filters,

the cooling capacity of the air conditioning unit is

basically unchanged and the energy consumption is

increased by 17.9%.

4 CONCLUSIONS

The purified air conditioning unit adds air

purification function section to the original common

air conditioning unit, including modified honeycomb

carbon filter and precious metal room-temperature

catalytic filter. It can purify formaldehyde, TVOC

and other gaseous pollutants and provide

comfortable, healthy, clean air. At the same time,

there is a certain increase in resistance and energy

consumption of the unit. The concrete results are as

follows:

1) The air purification function section has high

purification effect on formaldehyde and TVOC. The

primary purification efficiency of formaldehyde is

76.6%, and that of TVOC is 62.3%. Both are higher

than the standard values 50%.

2) The initial CADR value of formaldehyde is

367.1 m

3

/h. The final CADR value is 367.1 m

3

/h,

which is much higher than 50% of the initial value.

3) The purification performance of the air

purification functional section is stable, so it has

long purification life, low replacement frequency

and low running cost. During the whole lifetime test,

the total formaldehyde is 46g, which is 30 times

higher than that of the F4 level in GB/T 18801-2015.

And the final CADR value is 95.6% (much higher

than 50%) of the initial value, without significant

decline keeping between 340 and 380 m

3

/h. The

CCM value of formaldehyde is far greater than 46g.

4) Compared with the common air conditioning

unit, under the same conditions of air volume and

external pressure, the cooling capacity of the air

conditioning unit installed the purifying filters is

basically unchanged and the energy consumption is

increased by 17.9%

REFERENCES

GB/T 18801-2015 Air Cleaner [S]. Beijing: China

Standard Press, 2015.

GB/T 18883-2002 Indoor Air Quality Standard [S].

Beijing: China Construction Industry Press, 2002.

Guo, S. B., 2012. Central Air Conditioning System

Purification Technology [D]. Taiyuan: Taiyuan

University of Technology.

JG/T 294-2010 Test of Pollutant Cleaning Performance of

Air Cleaner [S]. Beijing: China Standard Press, 2012.

Jin, J. M., Bao, W. F., Wu, J. Q., Zhang, D. M., 2007.

Supporter Materials and Noble Metal Catalyst [A].

Shanghai Powder Metallurgy Conference [C].

Shanghai, 2007:190-195.

Shao, Z. Y, Tang, X. C., Han, B. S., 2016. Research on

Air Purification Technology of Central Air-

conditioning [J]. Central Air-conditioning Market,

6(6): 68-70.

Zhang, G. Q., Shang, S. P., Xu, F., 1999. Indoor Air

Quality [M]. Beijing: China Construction Industry

Press.

Zhu, X. W., Xiao, G. M., 2012. The Research Progress of

Precious Metal Catalysts [J]. Chemical Time Journal,

12 (26): 27-32.

Research and Analysis on Performance of Purified Air Conditioning

267