Construction Design of Assembly Module Based on Recycling and

Application Simulation in Architecture

Juan Zhang

1*

, Qingling Zhu

1

and Wenjie Wan

2

1

College of Architecture and Art, North China University of Technology, Beijing, China

2

Beijing General Municipal Engineering Design & Research Institute Co., Beijing, China

Keywords: Prefabricated building module; recyclable; structural design; green performance evaluation

Abstract: This research is based on the concept of material resource recyclability, with the modular module unit as the

carrier, the monomer size, structure, material selection of the module unit, its structural form and application

feasibility in residential buildings, etc. In this aspect, the adaptive design methods under different

construction forms, environmental characteristics and use requirements are discussed. Under the condition

of introducing energy-saving technology, the green efficiency evaluation and simulation analysis were

further carried out on its application method. It will have a customized module unit with high efficiency,

flexible use and recyclability, and dock with multiple functional spaces to effectively cope with many

problems in the construction and renewal of urban construction in China. In order to provide theoretical

basis and reference basis for relevant design practice in the future.

1 INTRODUCTION

In recent years, China's national economy has

changed from extensive to intensive growth.

Therefore, various problems such as overpopulation,

traffic congestion, housing difficulties,

environmental degradation, and resource shortages

in urban construction and renewal are urgently

needed to be resolved.

In the context of the era of sustainable building

design and informationization of building

industrialization, this paper discusses the structural

design method of assembled modular unit at the

beginning of design, which is conducive to the

recycling of materials. Deepening design,

construction, material selection, and the

configuration of multiple monomers. Taking the

residential building type as the research carrier, the

design analysis and application simulation are

carried out to form a feasible design method suitable

for different application types and construction

conditions. Furthermore, the application prospects of

the fabricated modular unit body in architectural

design and its feasibility to solve practical problems

are proposed and demonstrated. It is expected to

provide theoretical basis and effective reference for

future research and project practice in related fields.

2 BASIC DIMENSIONS,

CONSTRUCTION AND

MATERIAL SELECTION OF

THE MODULE UNIT

At the beginning of the design, the size, construction

method and material selection of the module unit

body should be considered based on the feasibility

of the recyclability of various material components

(Gao, 2005) and the disassembly and reorganization

of the module unit as a whole.

2.1 Unit Size

In order to make the module unit applicable to

various types of buildings, the common dimensions

of various buildings should be referred to to obtain

the appropriate dimensions of the unit body.

Compared to public buildings, the size of the home

is more stringent. Therefore, we mainly refer to the

residential building room parameters when

determining the basic dimensions of the module unit

body. At the same time, due to the structural

characteristics, the assembled steel structure

building modulus can also be considered. In

summary, we use 600 mm as the modulus to

250

Zhang, J., Zhu, Q. and Wan, W.

Construction Design of Assembly Module Based on Recycling and Application Simulation in Architecture.

DOI: 10.5220/0008188302500254

In The Second International Conference on Materials Chemistr y and Environmental Protection (MEEP 2018), pages 250-254

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

determine the frame size of the module unit body in

the basic dimensions of 2.4 m, 3 m, 4.8 m three

dimensions.

The spatial plane can be enlarged horizontally by

a plurality of components or a combination of a

plurality of cells. The 3.2 m rod piece can be used

vertically, and the adjustable height can be adjusted

to 2.5 to 3 meters. Walls, doors and windows are

also 600 mm, and the plates are spliced and

assembled to form suitable dimensions.

2.2 Structural Design

The structural system of the modular unit usually

includes two types of skeletonless systems and

skeleton systems (Figure 1). Among them, the

skeleton-free system is suitable for low-rise, multi-

storey, and 18-story high-rise buildings; the skeleton

system can be divided into hollow frame, platform

frame, cylinder structure and other different frame

forms, usually with light panels for wall

circumference. (Ma et al., 2018) The components

are light in weight.

a. Skeletonless system b. Skeleton system

Figure 1: Schematic diagram of modular unit structure.

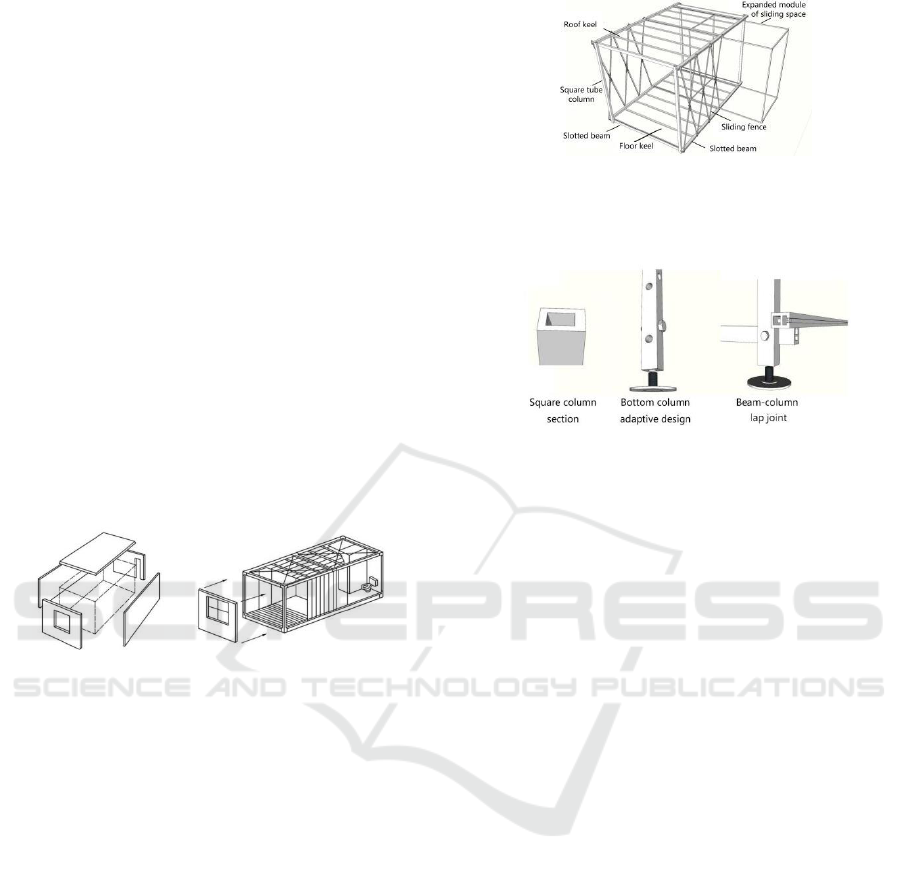

Taking the skeleton system as an example, the

module unit body is composed of prefabricated

standard members such as columns, beams, keels,

and telescopic components, as shown in Figure 2 .

The column is a hollow square column, and bolt

holes are formed at both ends of the column, and are

connected to the beam by bolts. The beam is a

grooved section with multiple sets of bolt holes at

both ends. (Wang, 2015) The connection of different

positions is selected to meet the different depth and

surface width of the single element (Figure 3). The

height of the floor surface of the unit body can be

adjusted through a plurality of sets of openings. The

combination of the unit body and the site is more

abundant, which is beneficial to lighting, ventilation,

moisture proof and heat insulation.

Figure 2: Schematic diagram of the modular unit body

structure design.

Figure 3: Module unit beam and column connection

diagram.

When a plurality of monomers are combined, the

monomers may be superposed as individual

structural units, or may be connected by beams or

column members.

2.3 Material Selection

In terms of materials, it can be flexibly selected

according to the use and use environment. For

example, the materials in the northern area are

mainly made of heat-insulating and sturdy thick wall

boards. In the south, the wall structure of fences is

used, and the materials are permeable and moisture-

proof. With the continuous development and

application of new products, such as nano materials,

intelligent environmental feedback materials, etc.,

the module unit body will be given more powerful

functions and possibilities.

3 FABRIC CONFIGURATION

BETWEEN MODULAR UNITS

AND ITS DESIGN

APPLICATION

As a basic construction unit, the module unit body

can be built into a frame of a certain scale by means

of interconnection and combination, forming a

stable and firm structure, and is easy to install,

Construction Design of Assembly Module Based on Recycling and Application Simulation in Architecture

251

disassemble and reassemble. It can be used flexibly

in many types of buildings.

3.1 Basic Unit Combination of Module

Unit

In the combined application, since the module

monomer can be self-contained structural system,

the mechanical constraints in the combined

connection are small. For the case where the number

of superimposed layers is too high and the

mechanical properties are complicated, an auxiliary

support can be formed by adding a main structure.

According to the type of building, spatial scale,

etc., the combination of unit bodies can include the

following types: series, superimposed, overlapping,

intersecting, parallel, misaligned, diagonal, upright,

standing, etc. ,As shown in Figure 4. Further, the

plurality of cells can be connected as a whole by

paralleling and superimposing, and the

corresponding device system can be configured.

Figure 4: Schematic diagram of unit cell combination.

3.2 Application Type of Module Unit

In the form of application, it is possible to use single

use, combined use, mixed structure, attachment

operation, addition, space placement and the like

(Figure 5). The independent application of the

module unit is suitable for small-sized, single-

function building types, such as single-family

apartments, retail stores, etc.; through the

composition of the monomer can get a larger use

area and more space, such as: multi-storey hotels,

Multi-storey buildings such as collective

dormitories, office buildings, restaurants, exhibition

halls, and warehouses.

Figure 5: Application form of the module unit.

4 INFORMATIZATION AND

INTELLIGENT PROMOTION

UNDER THE CONCEPT OF

RECYCLABILITY: TAKING

RESIDENTIAL BUILDINGS AS

AN EXAMPLE

Introducing the BIM information technology

platform into the whole cycle of the construction

industry has become a major trend in the industry.

The introduction of BIM technology in the design

stage of the fabricated modular unit can accurately

record the data of each component and reduce the

deviation between the design link and the

construction link. Thereby saving construction costs

and enhancing the recycling rate of components

after module assembly, use and disassembly. At the

same time, it can refer to the Internet thinking,

establish the network leasing, sales and recycling

mode of the assembled modular unit, and combine

the networking and the use of big data to make the

construction and application system of the modular

unit body more powerful and precise. (Xu et al.,

2018) Thereby improving the ability to update

research and development, and improving the

operational feasibility of recycling.

In the study, we take residential architecture as

an example to explore several feasible application

modes of modular unit in adapting to future urban

development.

4.1 Design and Application of

“Symbiotic Community” in Urban

Center

First, we create a square pillar and beam based on

9*9 meters, set up the floor and traffic space on each

9-meter frame, and determine the area where the

vertical traffic core is located, thus obtaining the

basic framework of the building. . In the large

frame, the overlapping and accumulating of the

corresponding spaces are carried out according to

the specific requirements and the modular

construction principle, and an overlapping staggered

growth organic building body with a certain

withdrawal from each layer is formed, as shown in

Figure 6 and Figure 7.

Figure 6: Architectural frame combination.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

252

Figure 7: Space combination of modular unit buildings.

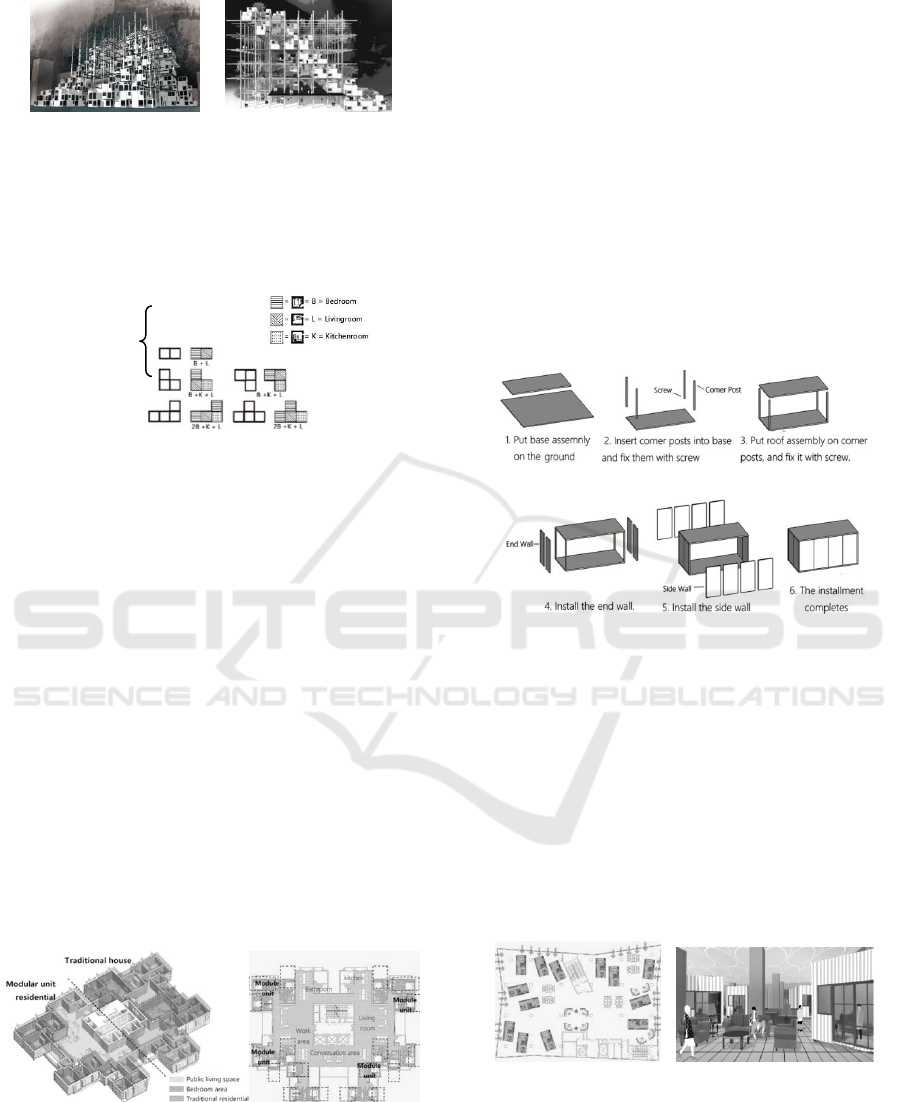

The spatial organization of the family can be

configured independently according to the needs of

the household population, forming a corresponding

plane combination, as shown in Figure 8.

· single-

apartmen

· Couples’ house

· Family of three

Figure 8: Plane combination diagram of unit module.

4.2 Design and Application in the

Renovation of Traditional

Residential Buildings

As the lifestyle of modern cities changes, to the

same extent, traditional dwellings are no longer able

to meet the needs of dwellings, and these buildings

will gradually be replaced by high-rise buildings.

We tried to keep each bedroom space, do modular

unit processing, and combine the living space,

kitchen and other functional spaces to get more open

functional space, while the independent bedroom did

not damage the privacy of the house. The shared

space effectively promotes neighborhood

communication, paying homage to the social

environment of traditional architecture while

preserving the convenience of modern architecture,

as shown in Figure 9.

Figure 9: Space and plan views of the modular unit in

traditional residential.

4.3 Insertion and Space Remodeling in

Existing Buildings

For some buildings to be demolished or unfinished

buildings, in addition to the fate of dismantling, is

there any other way to extend its life? We still take

the module body of 3*3 meters as the customized

module unit, or promote it according to other

required mode units, and introduce the original

building space, as shown in Figure 10. They are like

long-legged rooms, which are effectively combined,

increased, decreased, and moved according to

different needs in a free frame space, forming a new

experience of old building renovation and resource

utilization.

Figure 10: Constructed ways of the modular unit.

Those unfinished and modern buildings to be

demolished only need to dismantle its basic

maintenance structure, retain the original building's

frame and core space such as traffic nuclear, pantry,

bathroom and other necessary space, and then

increase or decrease according to people's needs. A

certain functional space, which meets people's

production and living needs, promotes

communication between neighbors, and gains a

wider and more comfortable sharing space.as shown

in Figure 11.

Figure 11: Reconstruction of the module unit in the

abandoned building.

Construction Design of Assembly Module Based on Recycling and Application Simulation in Architecture

253

5 CONCLUSIONS

Gathering the advantagess of all types of modern

industrial buildings, the generation and organization

of customized modular units retains the original

architectural construction model, which takes

advantage of the construction of blocks and large-

scale buildings, and promotes architectural design

and material applications. A more industrialized

point of view, thus proposed a more generalized

building structure system and a new concept of

urban construction.

The building is no longer a container that is fixed

in three dimensions. It is a winged tourist who can

move freely with the frame inside the site, go where

it should go, and move with the owner's migration.

Due to the adaptability of the modular unit, it is

better able to adapt to the environment and needs, so

that the building resources can be recycled.

Therefore, the exploration and research of the

architectural design of the modular unit body will

not only be a new attempt in the future living space,

but also a new discussion of the future office space.

ACKNOWLEDGEMENTS

This research was financially supported by the

National Natural Science Foundation of China(

Project No: 51608008)

REFERENCES

Gao, W., 2005. Temple University's modular housing-

modular design and construction, [J], residential

area,.z

Ma, S. H., Guo, X. Y., 2018. Research on "container

housing" of modular building, [J], Zhang Yuqing.

Architecture and Culture.

Wang, W., 2015. Feasibility Analysis of Modular

Building Market,[J], Industry and Technology Forum.

Xu, W., Wang J. H., He W., 2018. Foreign Modular

Construction and Practice Research, [J], Huazhong

Architecture.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

254