Effect of Heating Rate on Interlaminar Shear Strength Property of

Carbon Fiber-reinforced Composite with High-pressure Microwave

Curing

Guiming Liu

1

, Lihua Zhan

1, 2*

, Chenglong Guan

1

, Guangming Dai

1

and Ziqiang Li

1

1

School of Mechanical and Electrical Engineering, Central South University, Changsha, Hunan 410083, China

2

Light Alloys Research Institute, Central South University, Changsha, Hunan 410083, China

Keywords: Composite, High-presure microwave, CFRP, Heating rate, ILSS, Fracture surface

Abstract: Microwave curing has been deemed to be a rapid and cost-effective technology for curing carbon

fiber-reinforced composite. In this study, a set of devices about high-pressure microwave curing were built

with a real-time temperature measurement and control system of microwave input. Under a given

high-pressure microwave curing process, different heating rates were applied to the carbon fiber-reinforced

plastic (CFRP) laminates. The effect of heating rate on the curing quality was studied by interlaminar shear

strength (ILSS), the void content of composite samples was observed by optical digital microscope(ODM)

and the fracture surface of composite samples in these tests was inspected by scanning electron microscope

(SEM). The results showed that the heating rate had a significant effect on the ILSS of CFRP laminates. The

ILSS of CFRP laminates decreased and the void content increased with the increasing heating rate under

high-pressure microwave curing. There were a large amount of hackles among carbon fibers when the

heating rate was less than 6 °C/min. When the heating rate was 6 °C/min under high-pressure microwave

curing process, the total time could be saved 28.85%, and the ILSS of sample was basically consistent with

the value of sample in standard thermal curing.

1 INTRODUCTION

Carbon fiber reinforced plastics (CFRP) is widely

used in various engineering application due to their

characteristics of high mechanical properties, low

density and flexible process ability. (Wisnom, 1999;

Al-Saleh and Sundararaj, 2011; Gibson, 2010).

Microwave processing can be considered as an

alternative cost-effective route for curing CFRP

composite due to its rapid and volumetric heating

capabilities. Because of the specific heating

mechanism, microwave curing offers many

remarkable advantages over traditional thermal

curing, including energy saving, low operating costs,

high heating efficiency, increased throughput,

shortened processing time and improved processing

control. (Thostenson and Chou, 1999; Zhou et al.,

2003; Mijovic and Wijaya, 1990). Therefore, a series

of devicies about high-pressure microwave curing

need to be built to realize relate heating rate.

Meanwhile, it is important to understand the effect

of heating rate on the interlaminar shear strength

(ILSS) of CFRP laminates to choose the suitable

heating rate.

There were many researchers who had great

interest in microwave curing of composites because

of its fast curing compared with the conventional

thermal processing. (Thostenson and Chou, 1999;

Bogdal et al., 2003; Thostenson and Chou, 2001;

Fang and Scola, 1999). The main reason was that the

electromagnetic radiation generated in microwave

processing could penetrate the surface of the

material and induce volumetric curing via rapid

dielectric-related heat generation in the molecular

level of the resin. (Jacob et al., 1995; Li et al., 2014;

Li et al., 2018). For this different way of curing

composites, some researchers studied the effect of

temperature profiles of microwave curing on

mechanical properties of CFRP lamanates. Xiang

Hang et al studied the effects of different heating

rate on the mechanical properties of CFRP laminates

with microwave curing only at 0.1 MPa pressure.

(Hang et al., 2017). However, curing pressure was

one of the most significant factors in the process of

Liu, G., Zhan, L., Guan, C., Dai, G. and Li, Z.

Effect of Heating Rate on Interlaminar Shear Strength Property of Carbon Fiber-reinforced Composite with High-pressure Microwave Curing.

DOI: 10.5220/0008186701270133

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 127-133

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

curing forming of CFRP laminates. In previous

works, the curing pressure was not less than 0.4MPa

and if the curing pressure was too low, the

composite could have plenty of voids that seriously

affected mechanical propertise of CFRP in autoclave,

which was consistent with microwave curing. (Li et

al., 2014b; Li et al., 2015; Chen et al., 2017).

Xiaoping Chen et al studied a novel method for

curing CFRP laminate by high-pressure microwave.

(Chen et al., 2016). Compared with traditional

autoclave curing, the high-pressure microwave was

able to save energy significantly, by which the

mechanical properties of CFRP laminate specimens

were enhanced in the same curing processing curve.

Although a lot of scholars have done plenty of

researches on the microwave curing of composite

materials, there were few reports on effect of

different heating rate on the ILSS about CFRP

laminate with high-pressure microwave curing.

In this study, a set of devices about high-pressure

microwave curing were built, and a real-time

temperature measurement and real-time control

system of the microwave input power were equipped.

Furthermore, the effect of heating rate on the curing

quality was studied by the ILSS and the fracture

surface of composite samples in these tests was

inspected by scanning electron microscope (SEM) in

order to improve curing efficiency and save energy

consume as well.

2 EXPERIMENTAL

2.1 Materials

The material for the experiment was the the

T800/X850 carbon fiber reinforced plastics prepreg

(purchased from Commercial Aircraft Co., Ltd.,

China). The CFRP prepreg was stored at -12 °C in a

sealed contain, the physical properties of CFRP

prepreg were shown in Table 1.

Table 1: The basic physical parameters of composite.

Name

Ply

Thickness/mm

Density/Kg

.

m

-3

Fiber

volume/%

Value

0.191~1.195

1570

65

The designed CFRP laminates dimension was

200 mm (length) ×200 mm (width) ×1.91 mm

(thickness), and the thickness was approximately

1.82~1.85 mm after curing.

2.2 High-pressure Microwave Curing

Equipment

In order to obtain the high-pressure microwave

curing platform, the microwave feeding problem

under high-pressure was solved by combining the

fracture antenna with the pressure partition, and the

high-pressure microwave curing was realized.

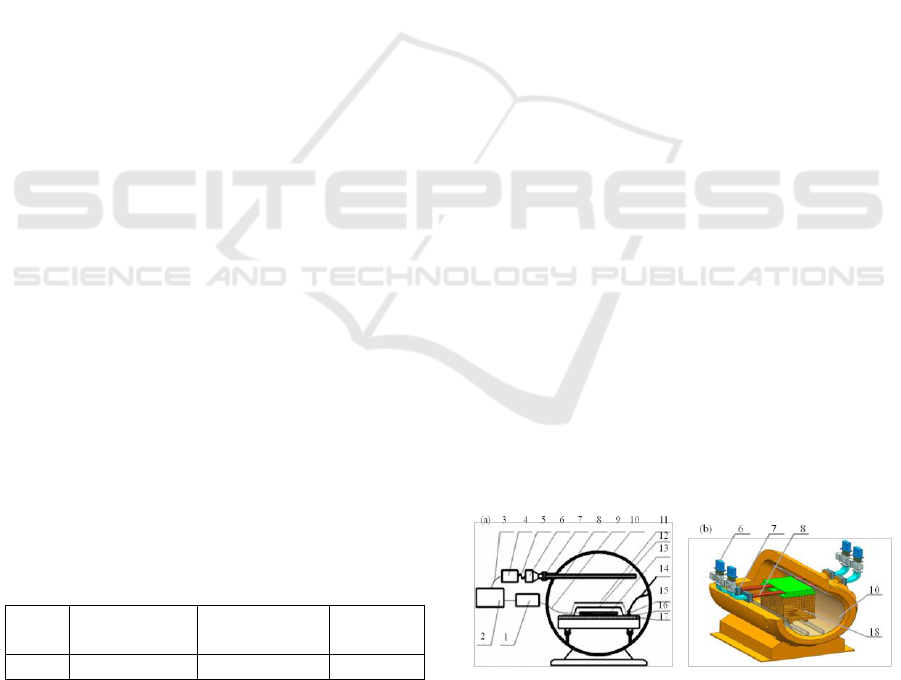

Figure 1 showed the high-pressure microwave

curing experimental platform which was mainly

composed of two parts: the pressure system and the

microwave generator. The uniform microwave was

generated by the microwave generator (6) through

confined glass (7) and the crack antenna (8) in the

resonant cavity of the closed autoclave. According to

preset curing process, the CFRP laminate on the top

of transparent wave shelf (17) was heated under the

action of microwave and the pressure was exerted

through the vacuum pressure system in the inside of

autoclave as well. A temperature measuring head

was embedded in the CFRP laminate, one end of the

temperature transmission line (9) was connected

with the temperature measuring head, and the other

end was led to the data acquisition instrument (1).

The power of the microwave generator was linearly

adjustable within the range of 0~4000 W and the

frequency of the microwave generator was 2.45 GHz.

Based on temperature feedback and timely

adjustment of microwave power, the curing of the

CFRP laminate according to the predetermined

temperature curve could be realized. There were

metal cavity in autoclave and iron oxide (Fe

2

O

3

) as

good wave absorbing materials in device interface to

make sure that microwave leakage was less than 1

mW. The microwave curing equipment was built

inside the traditional autoclave. The highest pressure

could reach 1.5 MPa and the maximum temperature

could reach 300 °C. And the preset curing process

could be realized by the automatic control system of

microwave power.

Figure 1: Schematic diagram of the structure of

high-pressure microwave curing equipment (a) device

module diagram (b) equipment structure diagram; (1) data

acquisition instrument, (2) PLC control system, (3)

connects cables, (4) microwave power control module, (5)

power transmission cable , (6) microwave generator, (7)

confined glass, (8) slot antenna, (9) temperature

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

128

measurement optical fiber, (10) autoclave, (11) vacuum

bag, (12) air flat, (13) wave absorbing part, (14) vacuum

tube, (15) quick connect, (16) sealing adhesive tape, (17)

through wave shelf plate, (18) microwave cavity.

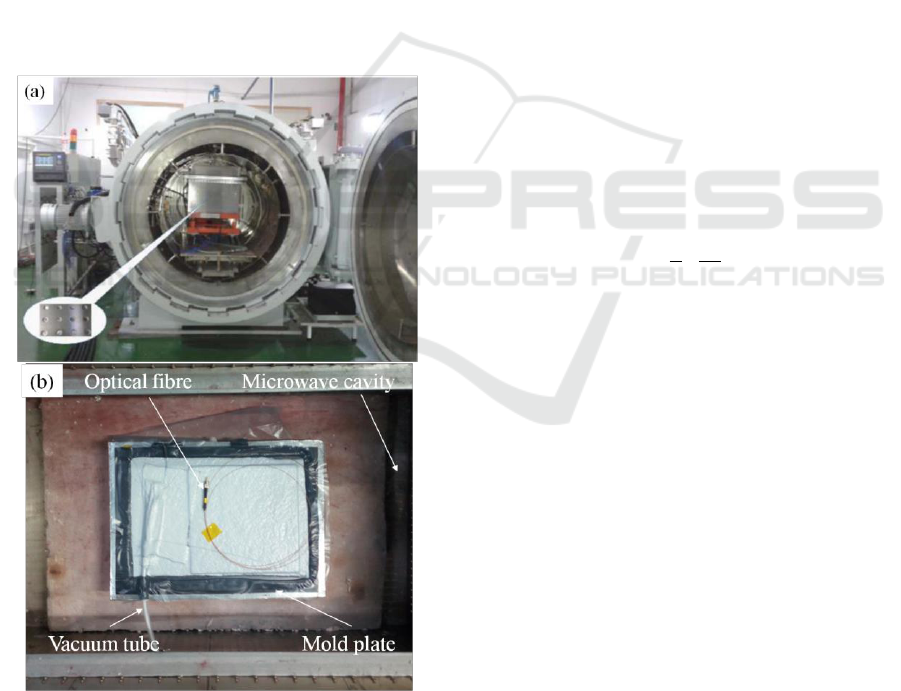

2.3 Preparation of CFRP Laminates

According to the requirements for the design size,

hand layup of unidirectional composite laminates

was conducted. A glass plate that could penetrate

through the microwave was chosen as the mold plate.

The specimens for interlaminar shear strength test

were heated and cured in the microwave cavity, as

shown in Figure 2. In order to study the influence of

different heating rate on the ILSS of the CFRP

laminate, five kinds of heating rate were chosen: 2.0,

4.0, 6.0, 8.0, 10.0 °C/min. The pressure of 0.1 MPa

in the vacuum bag was kept and the pressure of 0.6

Mpa considered as high-pressure could be provided

in the microwave curing cavity. Otherwise, the dwell

time was 100 min at 180 °C and the cooling rate was

2 °C/min.

Figure 2: Photograph of (a) high-pressure microwave

curing equipment and (b) the curing specimen of CFRP

laminates.

2.4 Characterization Techniques

2.4.1 Void Content

The void content was observed using the optical

digital microscope (ODM, model: OLYMPUS

DS

500). To calculate the void content, the samples

from different location of laminate were prepared

and then ground and polished to get a scratch-free

surface. The micrographs of samples were obtained

under the optical digital microscope. The void

content was calculated as an average value from at

least 20 micrographs.

2.4.2 Mechanical Property Test

The ILSS of the CFRP laminate was the most

important, the most common and the most

concerned indicator after curing. To assess the

effects of microwave on the mechanical property of

the composite laminates, the inter-laminar shear

strength test (ASTM JC/T 773-2010) was employed

for mechanical property evaluation. These tests were

carried out on the CMT5105 tensile testing

apparatus (Sansi Taijie Co., Ltd., China) at room

temperature. The size of the sample was 20 mm

(length) ×10 mm (width) ×2 mm (thickness). Each

group of parallel specimens was not less than 5. The

inter-laminar shear strength τ

m

(MPa) of the

composite samples was determined according to

Equation (1):

3

4

ILSS

F

bh

(1)

Where F was the failure load or maximum load

(N), b was the sample width (mm) and h was the

specimen thickness (mm).

2.4.3 SEM Characterization

To study the bonding condition between the fiber

and the resin in each specimen after interlaminar

shear strength test, the SEM (Model: TESCAN

MIRA3 LUM, USA) was employed to study the

surface microstructure of the specimens.

3 RESULTS AND DISCUSSION

3.1 Void Content Analysis

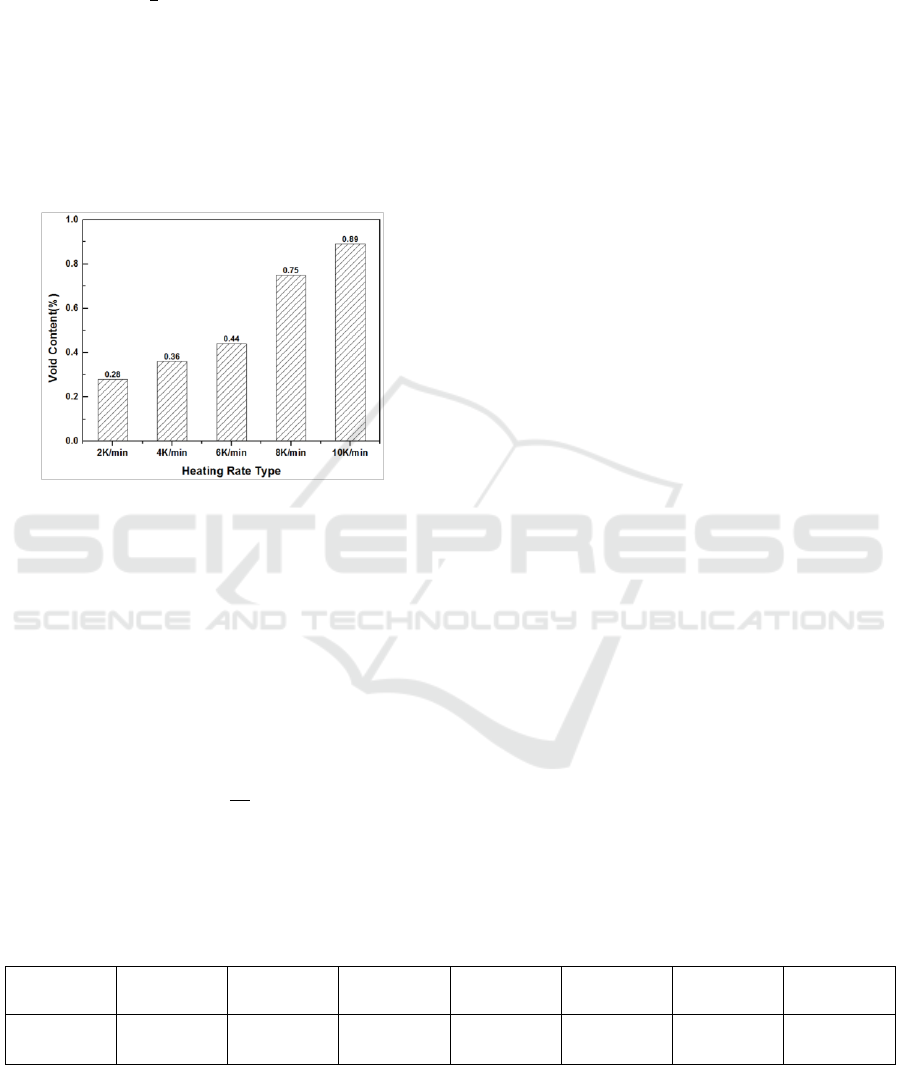

Figure 3 shows the quantitative relationship between

the heating rate and the void content of specimens in

high-pressure microwave curing. It can be seen that

the void content of sample increases from 0.28% to

0.89% as the value of heating rate rises from

2 °C/min up to 10 °C/min, which can illustrate that

Effect of Heating Rate on Interlaminar Shear Strength Property of Carbon Fiber-reinforced Composite with High-pressure Microwave

Curing

129

the void content of sample has been increased by

68.54%. Especially, when the heating rate is less

than 6 °C/min, the value of the void content changes

slightly, while the void content increases obviously

when the heating rate is more than 6 °C/min. From

the concrete value of view, the value of the void

content is 0.44% at the heating rate of 6 °C/min.

Contrastively, the value of the void content is 0.75%

at 8 °C/min, which has been increased by 41.3%.

Hence, it can illustrate that the void content of CFRP

laminates increases with increasing heating rate

under high-pressure microwave curing.

Figure 3: The void content of CFRP laminates at different

heating rate.

To understand the effect mechanisam of the

heating rate on void content of composites under

high-pressure microwave curing, assuming that the

composite pregreg is a kind of porous grid structure,

which is composed together by reinforcing

carbon-fibers and resin fluid with the saturation

wetting viscosity, (Amico and Lekakou, 2000).

Darcy’s law Equation (2) can be used to describe the

phenomenon:

K

VP

(2)

where V is the velocity vector of resin flow, K is the

fiber permeability,

is the resin viscosity,

P

is

a pressure gradient that along the thickness of the

resin. It can be seen that the velocity of resin flow

was proportion to the pressure gradient and fiber

permeability, and inversely proportion to the

viscosity of resin. There are pressure gradient of 0.6

MPa in CFRP laminates under high-pressure

microwave curing, which can almost ensure that the

excess resin and internal gas were excluded out of

the laminate and the compactness degree of fibers

had been improved. However, the difference of

value of void content still exists in CFRP laminates.

This is probably due to the change of the resin flow

in the initial stage of curing process. Firstly, a higher

heating rate can result in a more uneven temperature

distribution in CFRP laminates in microwave curing,

which can lead to an uneven level of viscosity

distribution in CFRP laminates. Hence, this

phenomenon can cause a hindrance on the resin flow

and resin impregnation of carbon fiber surfaces.

Secondly, when the heating rate is too high under

high-pressure microwave curing, there are no

enough time to ensure the resin impregnating carbon

fiber surfaces. Therefore, a higher heating rate bring

a negative effect on interfacial adhesion of carbon

fiber and resin matrix, and further result in

difference in void content of sample.

3.2 Interlaminar Shear Strength

Analysis

Autoclave curing is one of the main curing

techenology of carbon fiber-reinforced composites.

The recommended satandard autoclave curing

process is that the heating rate is 1.5 °C/min, the

dwell time is 150 min at 180 °C, the cooling rate is

2.0 °C/min, and the curing pressure is 0.6 MPa. The

mean value of the ILSS of CFRP laminates is 98.47

MPa, as shown in Table 2.

Microwave curing can be seen a rapid curing

technology, but the effect of heating rate on the ILSS

of CFRP laminates under high-pressure microwave

curing was not clear.

Table 2: The value of interlaminar shear strength in satandard autoclave curing.

Sample

number

Test piece 1

Test piece 2

Test piece 3

Test piece 4

Test piece 5

Test piece 6

Average

value

Sample

result(MPa)

94.67

99.29

100.5

97.31

100.89

98.15

98.47

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

130

Figure 4: The mean value of ILSS of CFRP laminates at

different heating rate under high-pressure microwave

curing.

Figure 4 shows the mean value of the ILSS of

CFRP laminates at different heating rate under

high-pressure microwave curing. It can be seen that

the ILSS of the CFRP decreases from 102.37 MPa

to 84.62 MPa decreases by 17.34% as the value of

heating rate rises from 2 °C/min up to 10 °C/min.

which shows that the heating rate has a significant

influence on the ILSS of CFRP laminates. What’s

more, the ILSS of sample is almost basically

consistent with satandard autoclave curing when the

value of the heating rate increases from 2 °C/min up

to 6 °C/min. However, the mean value of the ILSS

of CFRP laminates sharply decline when the heating

rate is more than 6 °C/min. So it means that the

ramp rate of microwave curing cannot be too high

since the ILSS of the CFRP laminates may be

influenced. In fact, when the heating rate is

6 °C/min, the ILSS of CFRP laminates is 95.30 MPa,

which is slightly reduced by 3.21% compared with

standard thermal curing. Contrastively, when the

heating rate is 8 °C/min, the ILSS of CFRP

laminates is only 86.35 MPa which is reduced by

12.3% compared with standard thermal curing.

Therefore, it can be seen that the heating rate has a

significant effect on the ILSS of CFRP laminates

under high-pressure microwave curing. Furthermore,

the value of ILSS of CFRP laminates decline and

the void content of specimen rises with inrease of

heating rate in high-pressure microwave curing.

To further investigate the effect mechanism of

heating rate on the ILSS of the specimens, the SEM

micrographs of the fracture surface of tested sample

at different heating rate are shown in Figure 5.

Delamination usually occurs under shear load,

resulting in the formation of overlapping white

patches on the surface of the fracture, which is

called hackles. (Xie and Sun, 2003). The

enhancement effect of the ILSS of CFRP laminates

in microwave curing may be well attributed to the

improvement effect on interfacial bonding of the

carbon fibre–polymer matrix. But a higher heating

rate has a negative effect on the ILSS of CFRP

laminates.

Figure 5: SEM micrographs of (a) heating rate of

2 °C/min (b) heating rate of 4 °C/min (c) heating rate of

6 °C/min (d) heating rate of 8 °C/min (e) heating rate of

10 °C/min.

Figure 5 shows the sample micrograph after

interlaminar shear strength test at different heating

rates. When the heating rate is low, the carbon fiber

is full filled with hackles. Moreover, it can be seen

that adhesive resin and hackles show a downward

trend with the increase of heating rate under

high-pressure microwave curing. This is because a

higher heating rate cause a hindrance on the resin

flow and resin impregnation of carbon fiber surface,

and then make interfacial adhesion of carbon fiber

and resin matrix weaken, which can explain the

value of ILSS of CFRP laminates reduces with the

increase of heating rate. Figure 5(a) ~ Figure5(c)

show a large amount of hackles among fibers,

accordingly, the value of the ILSS of CFRP

laminates is relatively high. However, Figure 5(d)

and Figure 5(e) show a small amount of hackles

among fibers, accordingly, the value of the ILSS of

CFRP laminates is low. What’s more, when the

heating rate is less than 6 °C/min, there is a large

amount of hackles among carbon fibers.

Contrastively, there is a small amount of hackles

among carbon fibers when the heating rate is more

Effect of Heating Rate on Interlaminar Shear Strength Property of Carbon Fiber-reinforced Composite with High-pressure Microwave

Curing

131

than 6 °C/min. In other words, hackles distributing

among adjacent fibers decrease with heating rate

increases under high-pressure microwave curing,

which is consistent with the results of macroscopic

mechanical tests. Therefore, with increase of heating

rate under high-pressure microwave curing, the

resin flow and resin impregnation of carbon fiber

surface were hindered in a certain extent. This

phenomenon causes the void contet decrease and

brings a negative effect on interfacial adhesion of

carbon fiber and resin, which causes difference of

the ILSS of CFRP laminates in macroscopic

mechanical property and difference of hacles in

microcosmic fracture surface.

It can be seen that when the heating rate is

6°C/min under high-pressure microwave curing

process, the ILSS of CFRP laminates is 95.30 MPa

and the void content of samples is 0.44%, whose

value is basically consistent with value of sample in

standard thermal curing, which can meet the need of

engineering application of composites. In addition,

the way of microwave curing is different with

thermal curing because of selective heating of

microwave heating, which can reduce energy

consumption compared with thermal curing.

Furthermore, the heating rate of 6 °C/min is

recommended under high-pressure microwave

curing, the heating time is only 25 min and the total

time could be saved by 28.85%, so this heating rate

can improve curing efficiency and reduce energy

consumption.

4 CONCLUSIONS

According to the analysis results obtained by ODM

and SEM technologies, the heating rate had a

significant influence on the void content of sample

and the ILSS of CFRP laminates under

high-pressure microwave curing. The void content

of sample increased with the increasing heating rate

under high-pressure microwave curing. The ILSS of

CFRP laminates tended to decrease and hackles

distributing among adjacent fibers decreased with

increase of the heating rate. Specially, when the

heating rate was more than 6 °C/min, the ILSS of

CFRP laminates decreased sharply. In the heating

rate of 6 °C/min process under high-pressure

microwave curing, the total time could be saved by

28.85%, and the ILSS of sample was basically

consistent with the value of sample in standard

thermal curing, which could be provided in

reference for the later microwave curing application

of composites.

ACKNOWLEDGEMENTS

This work is supported by the National Key Basic

Research Program of China (Grant No.

2014CB46502) and the Fundamental Research

Funds for the Central Universities of Central South

University ( 2018zzts473 ).

REFERENCES

Al-Saleh, M. H. and Sundararaj, U., 2011. Review of the

mechanical properties of carbon nanofiber/polymer

composites. Compos Part A: Appl S, 42: 2126-2142.

Amico, S. and Lekakou, C., 2000. Mathematical

modelling of capillary micro-flow through woven

fabrics. Composites Part A: Applied Science and

Manufacturing, 31(12): 1331-1344.

ASTM JC/T 773-2010. Standard test method for

short-beam strength of polymer matrix composite

materials and their laminates.

Bogdal, D., Penczek, P., Pielichowski, J., et al, 2003.

Microwave assisted synthesis, crosslinking, and

processing of polymeric materials. In: Bogdal D,

Penczek P, Pielichowski J, et al. (eds) Liquid

chromatography/FTIR microspectroscopy/ microwave

assisted synthesis. Berlin, Heidelberg: Springer pp,

194-263.

Chen, X. P. and Zhan, L. H., et al, 2017. Effect of cure

pressure on microstructure and interlaminar shear

strength properties of carbon fiber–reinforced plastics

with microwave curing. High Performance Polymers,

1-10.

Chen, X. P. and Zhan, L.H., et al, 2016. A novel method

for curing carbon fiber reinforced plastics by

high-pressure microwave. Fibers and Polymers,

17(12): 2143-2152.

Fang, X. and Scola, D. A., 1999. Investigation of

microwave energy to cure carbon fiber reinforced

phenylethynyl-terminated polyimide composites,

PETI-5/IM7. J Polym Sci Pol Chem, 37: 4616-4628.

Gibson, R. F., 2010. A review of recent research on

mechanics of multifunctional composite materials and

structures. Compos Struct, 92: 2793-2810.

Hang, X. and Li, Y. G., et al, 2017. Effects of temperature

profiles of microwave curing processes on mechanical

propertise of carbon fibre-reinforced composites.

Journal of Engineering Manufacture, 231: 1332-1340.

Jacob, J., Chia, L. and Boey, F., 1995. Thermal and

non-thermal interaction of microwave radiation with

materials. J Mater Sc, 30: 5321-5327.

Li, S. J. and Zhan, L. H., et al, 2014b. The influence of

cure pressure on microstructure, temperature field and

mechanical properties of advanced polymer-matrix

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

132

composite laminates. Fiber and Polym, 15:

2404-2409.

Li, S. J., Pu, Y. W. and Zhan, L. H., 2015. Effect of

mandrel structures on co-curing quality for polymer

composite hat-stiffened structures. Fiber and Polym,

116: 1898-1907.

Li, Y., Li, N. and Gao, J., 2014a. Tooling design and

microwave curing technologies for the manufacturing

of fiber reinforced polymer composites in aerospace

applications. Int J Adv Manuf Tech, 70: 591–606.

Li, Z. Q. and Zhan, L. H., et al, 2018. Kinetics modeling

of T800/epoxy resin composites based on microwave

curing process. Acta Materiae Compositae Sinica, 05:

1-7.

Mijovic, J. and Wijaya, J., 1990. Review of cure of

polymers and composites by microwave energy.

Polym. Compos, 11 (3) : 184-191.

Thostenson, E. T. and Chou, T. W., 2001. Microwave and

conventional curing of thick-section thermoset

composite laminates: experiment and simulation.

Polym Composite, 22: 197-212.

Thostenson, E. T. and Chou, T.W., 1999. Microwave

processing: fundamentals and applications. Compos.

Part A Appl. Sci. Manuf, 30 (9) :1055-1071.

Wisnom, M., 1999. Size effects in the testing of

fibre-composite materials. Compos Sci Technol, 59:

1937-1957.

Xie, F.J. and Sun, J.W., 2003. Failure analysis of

engineering materials [M]. Beijing: Machinery

Industry Press, 287.

Zhou, S. and Hawley M.C., et al, 2003. A study of

microwave reaction rate enhancement effect in

adhesive bonding of polymers and composites.

Compos. Struct, 61 (4) : 303-309.

Effect of Heating Rate on Interlaminar Shear Strength Property of Carbon Fiber-reinforced Composite with High-pressure Microwave

Curing

133