Application and Challenge of Flow Improver for the Development of

Heavy Oil and Waxy Crude

Fusheng Zhang

1,2*

, Baoshan Guan

1,2

, Guoliang Liu

1,2

, Xuening Li

1,2

, Zhuoyan Zhu

1,2

and Huimin Su

1,2

1

Research Institute of Petroleum Exploration and Development, PetroChina, No.20 Xueyuan Road, Beijing 100083, China

2

Key Laboratory of Oilfield Chemistry, CNPC, No. 20 Xueyuan Road, Beijing 100083, China

Keywords: Heavy oil, Waxy crude, Development , Flow improver, Application

Abstract: This paper outlined the composition of some flow improvers and their applications in long-distance pipeline

transportation in China, thereafter compared the effectiveness of using oil-based and water-based viscosity

reducers in both low-viscosity and high-viscosity heavy oil wells in China. At the end, this paper summarized

challenge in the research of viscosity reducer for the heavy oil formation drive.

1 INTRODUCTION

Generally speaking, the production of crude oil has

three stages: formation drive, wellbore lifting and

pipeline transportation. According to its viscosity,

crude oil can be classified as conventional oil, heavy

oil, extra heavy oil and bitumen (Li et al., 1990).

The conventional crude oil in China normally

features high wax content (Wang,1995), high pour

point and viscosity, and poor flow. Because of high

resin and asphaltene content, heavy oil, extra heavy

oil and bitumen generally have even higher viscosity

and poorer flow. In order to improve the flow of

crude oil meanwhile ensure safety in production,

heating is commonly used in the production of heavy

oil. Flow improvers are generally believed to have

the potential to greatly improve the flow of crude oil;

furthermore, they could be far more energy-efficient

and economic.

After years of arduous work, Scientists

worldwide have made great progress in the research

of flow improvers (Barasha et al., 2018; Pranab and

Moumita, 2014; Hafiz and Khidr, 2007; Zhang et al.,

2014; Khidr, 2011; Deshmukh and Bharambe, 2009;

Nassar, 2008; Du et al., 2012; Ahmed et al., 2014), a

series of which were developed and proved to be

suitable for the pipeline transportation and wellbore

lift of crude oil. Flow improvers have been widely

used in pipelines and wellbores (Bai et al., 2016; Qin

et al., 2012; Luo et al., 2015; Liu et al., 2017; Jiang et

al., 2013; Ma et al., 2017), and moreover brought

forth substantial economic and social benefits.

In reservoir conditions, for conventional crude oil,

its flow is generally good, which poses little problem

to formation drive, water flooding is used. In

comparison, for heavy oil, extra heavy oil and

bitumen, because its flow is poor, thermal technology

is mainly used to solve the difficulties of formation

drive. For normal heavy oil, water flooding is used,

but the oil recovery of water flooding is only 5-25%,

the main reasons is the higher viscosity of normal

heavy oil, so the study of viscosity reducer for

normal heavy oil has great significance to improve

oil recovery of its water flooding.

2 APPLICATION OF FLOW

IMPROVER IN CRUDE OIL

PIPELINE

To combat flow loss in pipeline transportation, for

conventional crude oil, heating combined with flow

improvers are commonly used; while for heavy oil,

extra heavy oil and bitumen, heating is commonly

used.

2.1 Composition of China's Crude Oil

Transported by Some Pipelines

China's onshore oil pipeline has a total length of over

23,400 kilometers (Zhang, 2016). Pipelines are the

main means of transportation for crude oil,

accounting for over 80%. For some major oil

Zhang, F., Guan, B., Liu, G., Li, X., Zhu, Z. and Su, H.

Application and Challenge of Flow Improver for the Development of Heavy Oil and Waxy Crude.

DOI: 10.5220/0008185900770082

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 77-82

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

77

pipelines of China, crude oil has high wax, resin and

asphaltene content, which brings about great

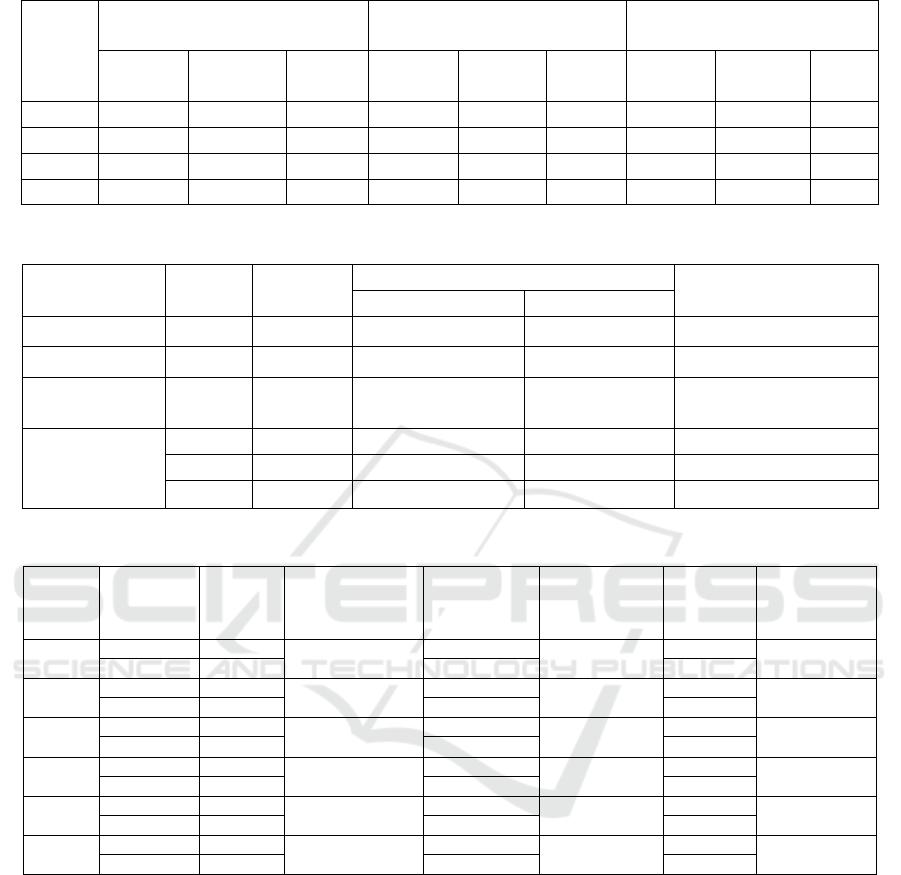

challenges for pipeline transportation (Table 1).

2.2 Application Results in Crude Oil

Pipeline

Based on studies of pour point depressing

mechanisms (Zhang and Wang, 1995), flow

improvers (Zhang et al., 1999a; Zhang et al., 1999b;

Cao and Li, 2004; Li et al., 1989; Wang, 2013; Li,

2010; Dang et al., 1996; Bi, 1992) was developed and

has demonstrated good adaptability and modification

results for crude oil transported by some pipelines

such as Luning, Zhongluo and Pulin et al. in China

(Table 2).

Table 2 shows that flow improvers produced

good pour point depression and viscosity reduction

results. With treatment of 10-100mg/kg, pour point

dropped 12℃-23℃, and viscosity dropped 16%-98%.

Through its applications in the pipelines, we have

seen great savings in fuels and transportation costs,

and moreover significant economic and social

benefits. On the other hand, operational safety and

adaptability of pipeline transportation have been

improved.

Table1: Some pipeline parameters and composition of transported crude oil in China.

Pipeline

Pipeline length

/km

Design throughput

/10

4

ton/y

Wax

/%

Resin and asphaltene

/%

Luning

652.6

2000

20.60

23.70

Zhongluo

290.1

500

24.59

6.81

Pulin

241.9

350

21.40

8.00

Weijing

226.4

350

30.80

9.90

Donghuang

251.1

1000

18.30

21.60

Donglin

171.3

1000

19.10

20.80

Mahuining

270.0

470

17.90

20.10

Huage

438.8

300

22.60

11.80

Kushan

476.0

1000

8.84

6.47

Dongxin

93.0

540

19.60

21.50

Hongjing

210.1

350

14.80

13.27

Table 2: Effect of flow improvers on some pipeline's crude oils in China

Pipeline

Dosage

/mg/kg

Pour point /℃

Pour point

reduction

/℃

Viscosity(30℃) /mPa.s

Viscosity

reduction

/%

Before

treatment

After

treatment

Before

treatment

After

treatment

Luning

40

24

5

19

935

300

68

Zhongluo

50

33

13

20

1172

60

95

Pulin

50

33

15

18

763

19

98

Weijing

50

37

23

14

1720

119

93

Donghuang

50

17

4

13

396

334

16

Donglin

50

23

3

20

408

314

23

Mahuining

100

18

-5

23

1716

①

41

①

97

Huage

100

33

15

18

2365

②

256

②

89

Kushan

11

1

-11

12

293

③

32

③

89

Dongxin

10

27

10

17

2418

④

476

④

80

Hongjing

50

33

22

11

192

⑤

48

⑤

75

Note: ①8℃; ②20℃; ③2℃; ④20℃; ⑤35℃

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

78

3 APPLICATION OF VISCOSITY

REDUCERS IN HEAVY OIL

WELLBORE LIFTING

According to the characteristics of heavy oil in China

and based on studies of viscosity reduction

mechanisms (Zhang and Wang,1995), both oil-based

and water-based viscosity reducers were developed

and used in the wellbore lifting of heavy oil (Zhang et

al.,1999c).

3.1 The Application of Oil-based

Viscosity Reducers in Wellbore

Lifting

Oil-based viscosity reducer is composed of the

macromolecule polymers containing the strong polar

groups. The groups with strong polarity in its

molecules and those in the molecules of resin and

asphaltene form hydrogen bonds, which have good

viscosity-reducing effect for heavy oil. Therefore,

oil-based viscosity reducers are suitable for the

production of heavy oil with low water content and

low viscosity. Viscosity of some heavy oil with low

viscosity was significantly reduced, results are

shown in Table 3.

Table 3 shows that dosage of 250-300mg/kg, the

viscosity of above-mentioned heavy oil dropped

46%-91%.

In the early production stage of Block 104-5, oil

production were well under expectation. Great

production improvements were achieved after the

treatment of oil-based viscosity reducers, as shown in

Table 4.

Table 4 shows that after the treatment of oil-based

viscosity reducers in Block 104-5, both oil

production time and rates were increased. Production

improvements were obvious that daily oil production

rate increased from 20 tons to 230 tons.

3.2 The Application of Water-based

Viscosity Reducers in Wellbore

Lifting

Water-based viscosity reducer is composed of

surfactants and emulsion stabilizers. It is able to turn

an oil-water system into an O/W emulsion, reducing

the viscosity of heavy oil by over 90%.

In the wellbore lifting process, the viscosity

reducer can be used alone by injecting into the

bottomhole or with steam stimulation. The viscosity

reduction effect is shown in Table 5.

Water-based viscosity reducer was used in a

number of oil wells in Wa-38 block of Xinglongtai

oil production plant at Liaohe. The application results

are shown in Table 6.

Table 6 shows that both production days and

production rates of Wa38 block increased

significantly. According to the statistical data from

15 Wells provided by the oil production plant,

accumulative incremental reached 35,870 tons, and

return on investment is as high as 26:1.

Table 3: Viscosity-reducing effect of oil-soluble viscosity reducer for some heavy oils.

Oil sample

Dosage

/mg/kg

Viscosity (40℃) /mPa.s

Viscosity reduction /%

Before treatment

After treatment

104-5 Block,

Jidong

Oilfield

106-5

300

5500

1100

80.0

104-5

300

1600

448

72.0

109-6

300

910

490

46.2

109-7

300

1230

650

47.2

Namazhuang Huabei oilfield

250

1513

123

91.0

Erlian oilfield

300

2620

360

86.3

Kelamayi

300

2300

460

80.0

Application and Challenge of Flow Improver for the Development of Heavy Oil and Waxy Crude

79

Table 4: Application results in Block 104-5 of Jidong Oilfield.

Well

number

Production efficiency

/%

Time of continuous production

/d

Production

/ton/d

Before

treatment

After

treatment

Incre-

ment

Before

treatment

After

treatment

Incre-

ment

Before

treatment

After

treatment

Incre-

ment

104-6

40

94

54

110

254

144

3.7

4.4

0.7

109-6

43

96

53

81

118

37

5.5

8.3

2.8

111-6

97

98

1

119

129

10

8.4

9.5

1.1

111-7

96

97

1

44

200

156

10.4

10.7

0.3

Table 5: Effect of water-based viscosity reducer for some heavy oils.

Oil sample

Dosage

/mg/kg

Oil :Water

/w:w

Viscosity /mPa.s

Viscosity reduction

/%

Before treatment

After treatment

Shengli oilfield

100

6:4

59600 (60℃)

30 (30℃)

>99.95

Jidong oilfield

100

6:4

22750 (40℃)

50 (40℃)

99.80

Kelamayi

oilfield

100

6:4

12050 (30℃)

44 (30℃)

99.60

Wa 38 Union,

Liaohe oilfield

100

7:3

77600 (50℃)

50 (30℃)

>99.94

150

7:3

77600 (50℃)

49 (30℃)

>99.94

200

7:3

77600 (50℃)

55 (30℃)

>99.93

Table 6: Application results in Wa-38 Block of Liaohe oilfield.

Well

number

Steam

cycle

/round

Recovery

water

/%

Increment of

water recovery

/%

Oil

production

/ton

Increment of

oil production

/ton

Production

time

/day

Increment of

production

time

/day

3542

2

45.9

8.1

2283

1780

148.3

83.1

3

54.0

4063

231.4

37430

1

47.5

77.5

2069

404

168.1

25.6

2

125.0

2473

193.7

37435

2

35

29.0

1761

247

243.7

5.0

3

64

2008

148.7

3124

5

27.7

58.5

1824

1476

137.5

65.8

6

86.2

3300

203.3

36432

2

37.8

35.5

2064

80

179.5

31.7

3

73.8

2144

211.2

3743

2

29.9

25.2

470

1143

58.5

137.4

3

55.1

1613

195.9

4 VISCOSITY REDUCER FOR

HEAVY OIL FORMATION

DRIVE

For conventional crude oil with the low in-situ

viscosity, water flooding is mainly used as formation

drive. For heavy oil with high viscosity, thermal

recovery is used, which includes steam stimulation,

steam flooding, in-situ combustion and SAGD. For

heavy oil with low viscosity, water flooding is used.

In terms of heavy oil, those that can be developed

by water flooding accounts for 30.1% of total

reserves and 18% of total production. Because of the

thickness of oil and the heterogeneity of reservoir,

water flooding in normal heavy oil reservoirs could

only yield 5-25% final oil recovery.

In an effort to improve oil recovery factor of

water flooding in heavy oil reservoirs, most

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

80

researchers home and abroad previously focused

their studies on alkaline flooding, polymer flooding,

surfactant flooding and combination flooding etc.

Their theoretical research has some merits (Liao and

Tang, 2018; Qu, 2013; Tang et al., 2012; Zhou, 2017;

Chen, 2013; Jin et al., 2005), besides some

technologies proposed were put into field tests. In

No.3 oil production plant of Dagang oilfield in China,

a small-scale field test using viscosity reducer was

implemented. Due to the failure for the small

molecule viscosity reducers to form stable O/W

emulsions under low in-situ shear rate, incremental

oil production was found to be nominal.

Studies show that the key to improving water

drive recovery factor in heavy oil reservoirs is to

enlarge swept volume. Reducing viscosity of heavy

oil and raising viscosity of displacement phase are

effective ways to achieve this. Now that there is no

research conducted home or abroad on heavy oil

water flooding EOR technologies that could reduce

heavy oil viscosity meanwhile raising displacement

phase viscosity under low in-situ shear stress. This

could possibly be achieved by macromolecular

viscosity reducers according to the theory of

molecular design. The synergism could greatly

improve the recovery factor of water flooding in

heavy oil reservoirs. Therefore, macromolecular

viscosity reducer is one of the key technologies to

replace water flooding in the near future. It is of great

significance to water flooding EOR of heavy oil and

has a promising prospect and range of applications.

5 CONCLUSIONS AND

PROPOSALS

Flow improver which has good pour

point-depressing and viscosity-reducing effects for

the waxy crude oil, had been used in Luning,

Zhongluo and Pulin, et al. pipelines and improved

safety and adaptability in operations.

Oil-based viscosity reducer which has good

viscosity reducing effect for heavy oil with low

viscosity, had used to wellbore lifting of low

viscosity heavy oil. While water-based viscosity

reducer which has good viscosity reducing effect on

heavy oil with high viscosity, had used to wellbore

lifting of extra heavy oil.

More research needs to be diverted to and focused

on viscosity reducers for formation drive, including

studies of viscosity reducing mechanisms, evaluation

system and molecular structure design.

REFERENCES

Ahmed, N. S., Nassar, A. M., Nasser, R. M., et al., 2014.

Novel terpolymers as pour point depressants and

viscosity modifiers for Lube oil. Petroleum Science

and Technology, 32(6): 680-687.

Bai, W. H., Zhang, X. Q., Gu, H., et al., 2016. Selection

and pilot test of an oil based viscosity reducer .

Advances in Fine Petrochemicals, 17(6): 32-34.

Barasha, D., Rohit, S., Arnab, M., et al., 2018. Synthesis

and evaluation of oleic acid based polymeric additive

as pour point depressant to improve flow properties of

Indian waxy crude oil. Journal of Petroleum Science

and Engineering, 170: 105-111.

Bi, M. H., 1992. Development and application of CE crude

pour point depressant. Oil-Gas Field Surface

Engineering, 11(4): 44-46.

Cao, D. F., Li, Q. P., 2004. The Application of new flow

improver in Hongjing oil pipeline. Oil & Gas Storage

and Transportation, 23(3): 28-32.

Chen, J. J., 2013. Improving the development effectiveness

of water flooding in heavy oil reservoir. Complex

Hydrocarbon Reservoirs, 7(1): 38-40, 57.

Dang, J. P., Shen, J. J., Zhang, J. F., 1996. The synthesis

and application of GY-2 oil depressant. Oil & Gas

Storage and Transportation, 15(12): 12-15.

Deshmukh, S., Bharambe, D., 2009. Evaluation of effect of

polymeric pour point depressant additives on Indian

waxy crude oil. Petroleum Science and Technology,

27(18): 2097-2108.

Du, T., Wang, S., Liu, H. et al., 2012. The Synthesis and

characterization of methacrylic acid ester-maleic

anhydride copolymer as a Lube oil pour point

depressant. Petroleum Science and Technology, 30(2):

212-221.

Hafiz, A.A., Khidr, T.T., 2007. Hexa-triethanolamine

oleate esters as pour point depressant for waxy crude

oils. Journal of Petroleum Science and Engineering,

56(4): 296-302.

Jiang, K., Hou, J. R., Liu, B. X., et al., 2013. Experimental

study on viscosity reduction by emulsification of Fuyu

heavy oil. Oilfield Chemistry, 30(2): 259-262.

Jin, F. Y., Pu, W. F., Ren, Z. G., et al., 2005. Experimental

study of viscosity reduction by water flooding for

heavy oil. Special Oil and Gas Reservoirs, 12(6):

95-97.

Khidr, T. T., 2011. Pour Point Depressant Additives for

Waxy Gas Oil. Petroleum Science and Technology, 29:

19-28.

Li, J. M., 2010. Huage mixing conveying oil thixotropy

petroleu and natural gas. Xi'an: Xi'an Shiyou

University.

Li, J., Zhang, F., Zhang, Y. L., 1989. Experiment on

transporting crude oil by Maling-Huianbao-Zhongning

pipeline using flow improving chemicals. Oilfield

Chemistry, 6(1): 50-57.

Li, P. J., Zhang, S., He, Y. T., 1990. Classification of crude

oil. Oil & Gas Storage and Transportation, 9(1):74-77.

Liao, H., Tang, S. F., 2018. Experimental research on

emulsification and viscosity reducing of deep

Application and Challenge of Flow Improver for the Development of Heavy Oil and Waxy Crude

81

ultra-heavy oil with high bitumen content. Natural Gas

and Oil, 36(2): 64-67, 95.

Liu, W. M., Kang, F., Luo, Z. C., et al., 2017. High waxy

crude oil pour point depressant synthesis and

performance research on Halahatang oilfield. Applied

Chemical Industry, 46(4): 641-645.

Luo, Y. T., Li, B. G., Qin, B., 2015. Development of

oil-soluble viscosity reducer for pipeline transportation

of Shengli heavy oil. Petroleum Processing and

Petrochemicals, 46(4): 467-471.

Ma, Y. Z., Fu, Y. R., Fu, L. X., et al., 2017. Development

and application of fluorocarbon oil pour point

depressant. Xinjiang Oil & Gas, 2: 83-85.

Nassar, A. M., 2008. Synthesis and evaluation of viscosity

index improvers and pour point depressant for Lube oil.

Petroleum Science and Technology, 26(5): 523-531.

Pranab, G., Moumita, D., 2014. Study of the influence of

some polymeric additives as viscosity index improvers

and pour point depressants: Synthesis and

characterization. Journal of Petroleum Science and

Engineering, 119: 79-84.

Qin, B., Luo, Y. T., Li, B. G., et al., 2012. The relationship

between structure and performance of oil-soluble

viscosity of heavy oil. Chemical Engineering of Oil &

Gas, 41(5): 499-503.

Qu, C. X., 2013. Study on Mechanism and Heavy Oil

Recovery Enhanced by Chemical Flooding. Qingdao:

China University of Petroleum (East China).

Tang, M. G., Pei, H. H., Zhang, G. C., et al, 2012. Present

situation and development trend on chemical flooding

of conventional heavy oil. Fault-Block Oil & Gas

Field, 19(1): 44-48.

Wang, B.,1995. Paraffin characteristics of waxy crude oils

in china and the methods of paraffin removal and

inhibition. International Meeting on Petroleum

Engineering, SPE 29954.

Wang, J., 2013. Research on flow improver in Dongxin

pipeline. Beijing: China University of Petroleum.

Zhang, C. Q., Gao, C. C., Gao, F. F., et al., 2014. Synthesis

of comb bipolymers and their pour point depressing

properties. Petroleum Science, 11(1)1: 155-160.

Zhang, F. S., Wang, B., 1995. Studies on the mechanism

involved in pour point depression and viscosity

reduction by some pour point depressant and viscosity

reducer. Oilfield Chemistry, 12(4): 347-352.

Zhang, F. S., Wang, B., Xie, H. Z., et al., 1999a.

Application of pour point depressants for crude oil in

long distance pipeline transportation of china. Oilfield

Chemistry, 16(4): 368-371.

Zhang, F. S., Wang, B., Xie, H. Z., et al., 1999b. Synthesis

of BEM-3 Flow improver and its industrial application

in Luning pipeline. Speciality Petrochemicals, 4: 6-8.

Zhang, F. S., Xie, H. Z., Dong, L. J., 1999c. The

application of pour point depressant/viscosity reducer

in production and transportation for crude oil.

Speciality Petrochemicals, 6: 28-30

Zhang, J. S., 2016. Leakage and risk control of crude oil

transportation pipeline. Modern Occupational Safety, 7:

72-74.

Zhou, F., 2017. Experimental study and application of

emulsifying viscosity reducer in Liaohe oilfield.

Petrochemical Industry Application, 36(1): 78-83.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

82