Optimize IoT for Operating Wastewater Treatment Plant

based on Visualizing User’s Thinking

J C Chen

*

, Y J Lin

and Z H Tsai

Department of Environmental Engineering and Science, Fooyin University, 151

Jinxue Rd., Dailiao Dist., Kaohsiung City, 83102, Taiwan (R.O.C.)

Corresponding author and e-mail: J C Chen, pl007@fy.edu.tw

Abstract. Sewer system is the major facility of avoiding improper disposal of wastewater. As

expanding wastewater treatment into rural areas, the supervision and the operation will be

more difficult. The fast innovation of IoT in sensor, wireless communication and s mart

control is gaining more and more expectation of IoT to be the next-generation option of

control system in wastewater treatment plant. At present IoT technology is moving rapidly

and its market is very competitive. There are still many uncertainties while making the

decision of upgrading control system to IoT. After all using IoT is an investment, the fault of

choosing an unpopular product and then losing support before long should be avoided. This

study shares the experiences how to identify the needs of IoT based on visualizing user's

thinking and then propose an optimal design of IoT to operating a wastewater treatment plant.

1. Introduction

Right now we face a tough situation that water pollution induced by untreated wastewater is

threatening the sustainable development in the downstream area of river. But so far the supervision

about WWTPs is weak and most of them are far behind the art of AI technology. The improper

disposal due to disorder management or chaotic operation still often happens. Although IoT is able to

extend networks connectivity and computer capability to every device in our living [1], but I do not

mean to suggest the manager of WWTPs immediately upgrading their system to IoT because of huge

diversity from their technologies and prices yet. After all using IoT is an investment, the risk due to

choosing an unpopular product and then losing support before long should be avoided.

By using IoT, Chen et al. [2] made a useful forecasting function of IoT by a neural network to

minimize losses in an emergency. In Zaragoza, Spain, a smart water management model developed

by Robles et al. [3] showed water management company a way to access a wider global market via

adopting IoT in decision support, monitoring and water governance of a pumping system. Artificial

intelligent in IoT will convert the monitoring records into valuable information, e.g. the timing and

supply of critical device [4]. At present IoT technology is moving rapidly and the market is very

competitive [5]. However people still have controversy over the anticipation that the management of

WWTPs will enter the era of IoT. Is it necessary to promote the control system of WWTP to IoT?

For seeking the truth we visited several wastewater treatment plants in the South Taiwan, interviewed

managers and operators form 8 WWTPs and visualized their decision making.

444

Chen, J., Lin, Y. and Tsai, Z.

Optimize IoT for Operating Wastewater Treatment Plant based on Visualizing User’S Thinking.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 444-452

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

This study uses Evaluation Grid Method (EGM) to perform an in-depth interviews that is able to

clearly visualize the user’s cognition as an Evaluation Hierarchical Map [6-7]. Since Sanui modified

Kelly’s repertory grid technique to create this approach, EGM has been successfully employed in

numerous product designs and service designs [8-10].

2. Methods

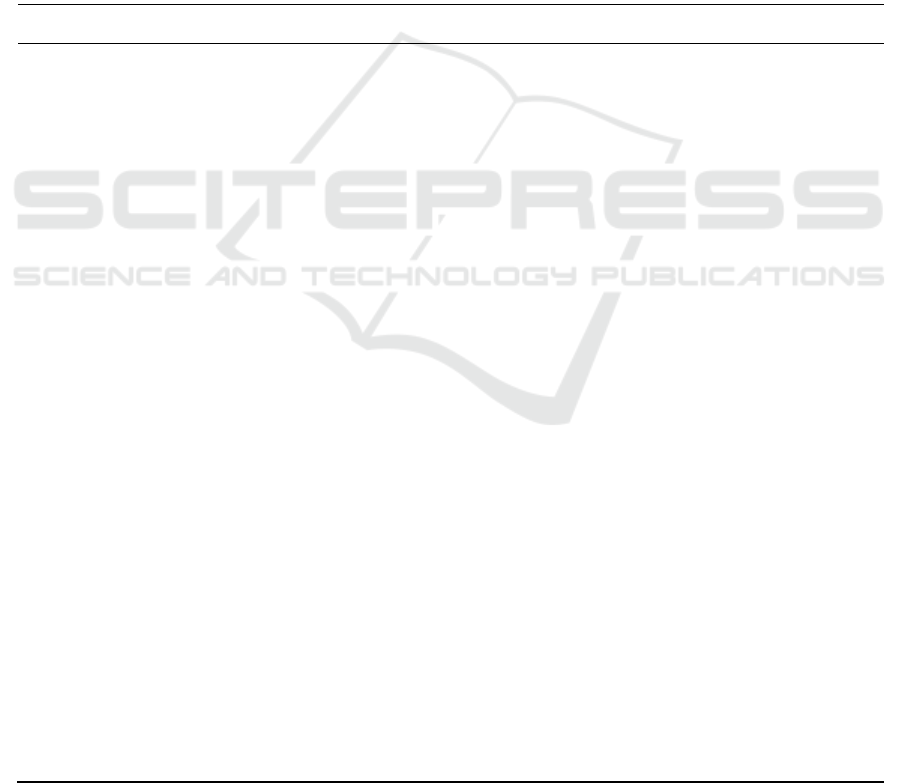

A schematic overview of the methodology employed was displayed in Figure 1. On April 8, 2017,

we invited 42 experts composed of managers and operators coming from 10 WWTPs to join a

meeting of discussing what kind of smart control they need. First we made a simply explain to these

experts what this meeting is for, and then arrange all experts to take a field trip before sharing vision

each other. This meeting derived a series of analysis at upgrading each device of WWTP to smart

control and summarized their importance as Table 1.

The quality and quantity of information elicited from an interview relies on the personal ability of

an interviewer. For this concern, we created a conceptual IoT for WWTP. In Taiwan almost every

adult owns a smart phone with 4G or WiFi wireless communication. So smart phone become the first

thing existing in the list of IoT we proposed. An App coding by Ruby-on-Rails (RoR) which

connects with the monitoring database running at MySQL server, manipulates the state of visual

relay in InduSoft© and power relay in distance to remote control the device, and supports user smart

services such as device’s knowledge, operating discipline, emergence response, etc. was created to be

the interview material. We spent 3 months to cooperate with an interdisciplinary teams composed of

8 engineers with the expertise of wastewater, sensor, automatic control, and software. This App

successfully promotes the interaction between interviewer and respondent during searching the

attractiveness of IoT in the following in-depth interviews. Moreover some potential functions, e.g.

artificial intelligent to detect the emerging disorder of machine, modelling the operation of engine by

adding sensor of noise, vibration, and electric, were also included into the scope of conceptual IoT

we proposed during interview.

Figure 1. The schematic diagram of research methodology.

2.1. In-depth interview

Manager who has the power of dominating the budget of operating WWTP is of critical to offer

valuable experiences to this study. We visited 8 wastewater treatment plants in the South Taiwan.

Expert meeting on system analysis

Identify the demand of smart control system for WWTP

Create the conceptual IoT for WWTP

In-depth interview with managers

In-depth interview with operators

Construct evaluation hierarchical map

Optimization of IoT for operating WWTP

Optimize IoT for Operating Wastewater Treatment Plant based on Visualizing User’S Thinking

445

Each manager of these plants has been interviewed at least twice or more times. They were asked to

determine their first impression, “satisfied/dissatisfied” or “most preferred/least preferred,” over the

IoT we proposed. Then the discussion during interview will ladder up to identify the abstract reasons

(e.g. value judgment) and ladder down to form concrete features (e.g. objective and concrete

understanding). Such an in-depth interview could make the respondent much more time to confirm

each evaluation item.

Operator will be in the closest relationship with IoT in WWTP. Basically IoT is a tool designed

for assisting operator to serve their duty more efficient if the operator was willing to use it. This

study invited more than 50 new operators to participate our in-depth interview. Discussions were

focused on how they feel the help including machine knowledge, operating discipline, emergence

response through APP we provided. Each operator was interviewed at least twice. After repeated in-

depth interview, we extracted their original feelings while operating WWTP with the aid of IoT, and

then extended to infer their abstract reasons and concrete features about the service supported by IoT.

Eventually each personal evaluation hierarchical map was done as the structure of three-layer

hierarchy

Table 1. The analysis at upgrading each device of WWTP to smart control.

Device

Demand to smart control

Unit

priority

(1~5)

Water pump

Automatic control by water level

Most units

5

Grit chamber

Automatic control by sand thickness

Pumping station, primary clarifier

1

Clay washer

Operation linked with sand pump

Pumping station

3

Mechanical screen

Operation linked with flow rate

Inlet channel

2

Valve/gate

Automatic operation

Most units

3

Scraper

Automatic calibration, Automatic operation

Primary clarifier, final settling tank, sludge

thickening tank

3

Deodorizer

Automatic control by odour concentration

Primary clarifier,

aeration tank

4

Ventilating system

Staff security by operating with gas detector

Primary clarifier,

aeration tank

5

Blower

Adjust air supply by detecting DO

Aeration tank,

sand filter

5

De-foaming

system

Operation by detecting the nozzle pressure

Aeration tank

2

Recycling

Sludge system

Automatic waste sludge by F/M ratio

Aeration tank

2

Aeration system

Detect the oxygen profile

Aeration tank

5

Sludge pumping

Operating by grit/sludge thickness

final settling tank,

sludge thickening tank

5

Scum pump

Automatic control by detecting scum

Final settling tank

4

Feeding pump

Automatic adjust the feeding rate

Sedimentation, filtration, chemical treatment

4

Screw pump

Detect bearing noise

Sludge thickening tank

2

Boiler

Monitoring the digestion state

Sludge digester

5

Dewatering

machine

Detect the shift

Sludge dewatering

5

Conveyor

Detect system’s noise

Sludge dewatering

2

Polymer

preparation

Maintain the concentration of polymer

Aeration tank,

4

PS Priority at ranking 5 is the most importance

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

446

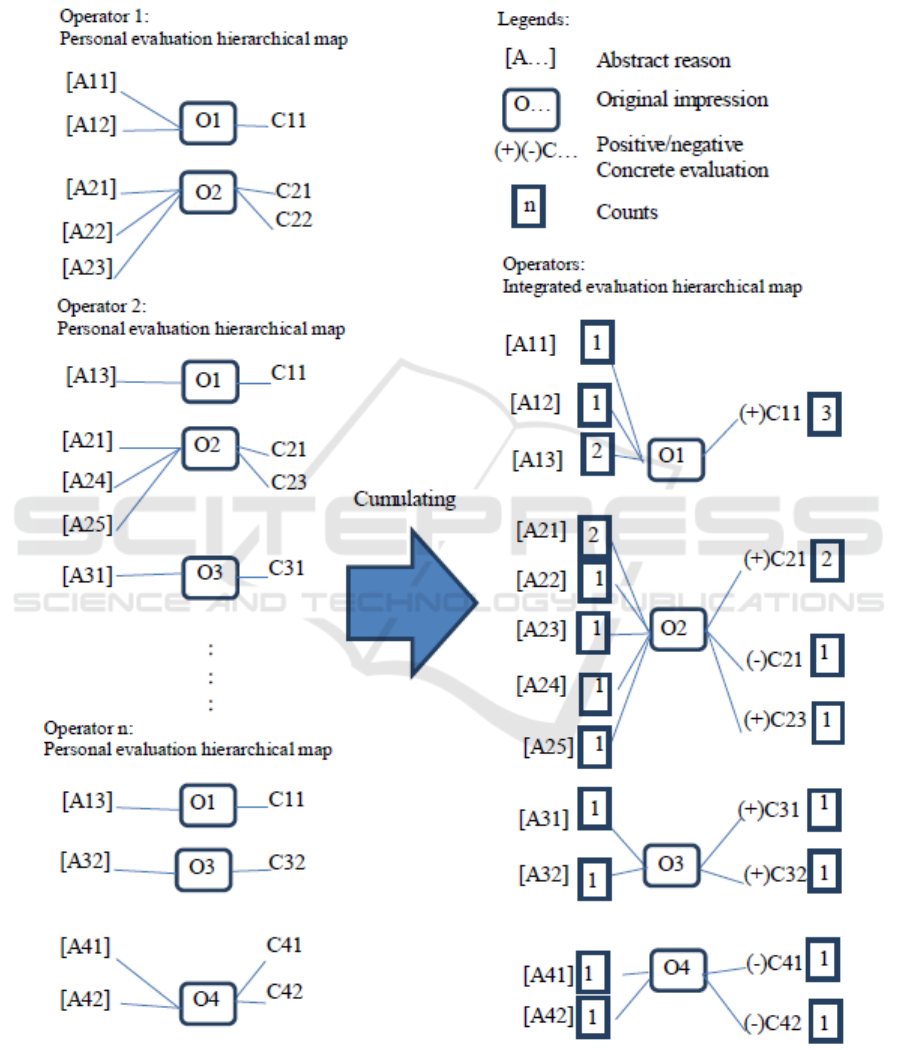

2.2. Evaluation grid method

In this study, we performed the following steps to extract the information from dialog with managers

and operators. Then we adopted EGM to establish a map with three-layer hierarchical structure that

comprises abstract reasons, original impressions, and concrete evaluations (Figure 2).

Figure 2. The process of forming evaluation hierarchical map.

Optimize IoT for Operating Wastewater Treatment Plant based on Visualizing User’S Thinking

447

2.3. Integrated evaluation hierarchical map

Overall EGM provides a method for analyzing product attractiveness factors and eliminates the

potential influence of subjectivity from few decision makers. Then we compile the personal

evaluation hierarchical maps of all the participants and calculate the number of overlapped

evaluations to plot an integrated evaluation hierarchical map. Such a visualization of user’s thinking

does effectively systemize data obtained from in-depth interview and accurately interpret the needs

during optimization of IoT designed for operating WWTP.

3. Results and discussion

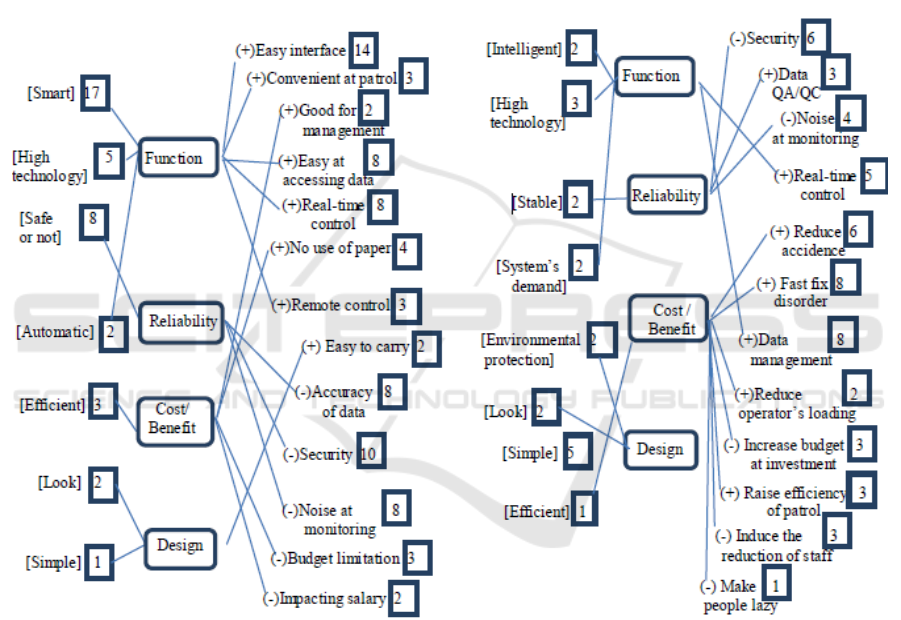

Four original impressions including “Function”, “Reliability”, “Cost/Benefit”, and “Design” are

extracted from the dialogs with operators and managers (Figure 3 and 4). We found that operators

give more concrete evaluations than managers with respect to its “Function”. It implies that operators

especially care how this future tool affects their daily works. From the view of product design, we

should focus on the need of operators. But operator is not the buyer of IoT in this case. Manager or

maybe more high rank position is the decision maker of promoting control system to IoT in practice.

The factor of “Cost/Benefit” is what manager really concern. Interestingly operators also care about

the factor of Cost/Benefit and they reflect many negative concrete evaluations, especially worrying

about their salary been changed. Even though the IoT designed for operating WWTP is powerful, an

expensive IoT would be not succeed in such a case which every manager doesn’t want to see the

resistance from operator. So the IoT suppliers have to seek a compromise between function and price.

When both managers and operators accept to use IoT they start to care its “Reliability” in

choosing which service of IoT they can trust. The accuracy and security of data are the highest

concerns during concrete evaluations of managers and operators. However hacker or terrorist might

attack the control system to make a chaos in system operation as far as IoT extending networks

connectivity to different device of WWTP. That is why I highlight IoT not a free or cheap service

because its service needs a security of high cost.

The last original impression is “Design”. The performance of manager in this item only

concentrate on the abstract reasons, that is to say manager cares about what corporate image would

be connected with using IoT. We suggest the supplier of IoT to taken into account of enterprise social

responsibility in environmental protection during designing IoT for operating WWTP.

3.1. Technical demand of IoT in WWTP

We screen some critical demands out of Table 1. What kind of technical support does the IoT

supplier have to provide for these demands? We makes an evaluation as Table 2. The architecture of

IoT was generally divided into three layers: Perception Layer, Network Layer, and Application layer.

Obviously the ability of perception is the most important service when these experts of WWTP take

into account of IoT. Perception layer is in charge of converting the information to digital signals,

which are more convenient for network transmission. This process of perception is based on several

sensing technologies. However, some objects might not be perceived directly. Right now sensors of

water level, dissolved oxygen, and sludge interface have been popularly used in WWTP. Air sensors

with respect to odor and volatile organic compound are mature in technical development but not

popular in use yet. But some sensors, like detecting the shift of dewatering machine and measuring

polymer concentration, are still in developing.

Application Layer constitutes the front end of the whole IoT architecture through which user can

obtain any kind of decision support. In this study, we provide cloud service including device’s

knowledge, operating discipline, emergence response and electric form of inspection to the operator

on patrol through an App installed in mobile phone. Moreover, this layer provides the connection

with actuating devices in distance. So expert system in cloud is able to automatically manipulate the

distant device for avoiding the situation going into chaos. Usually pumping system is only operated

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

448

by water level, but operation of pump in practice needs more expert’s experience. Actually the inflow

of WWTP is dynamic, the flowrate and the concentration of wastewater is variant and not the same

as the condition of original design. Even a small rainfall, a significant raise at inlet flowrate could

suddenly happen. Such a changing inflow will cause an unstable operation of WWTP, moreover

severe situation during storm will induce combined sewage overflow. Thus operating rules extracted

from historic records or expert’s experiences from long career are of critical in the automatic control

of pumping system, and are suggested to be developed as a technical service from IoT. Based on

such a smart water management model, the IoT suppliers can access a wider global market via

providing decision support, monitoring and water governance of a pumping system.

Activated sludge process is very popular used to degrade the nutrients, e.g. BOD, in wastewater.

Most of sludge in this process is alive and aerobic, so a lot of air is continuously transported into this

process via blower. A complex biodegradation is only executed by those activated sludge. So we

have to waste the old sludge out and recycle the active back. This is not an easy job to operator, as

we see, most of demands in Table 2 focuses on sludge. We suggest the supplier of IoT to make data

mining from mega data of monitoring system in activated sludge process and then to provide

operator a web-service with artificial intelligent about feeding sludge.

Next we evaluated the measurement of oxygen profile at aeration tank, the measurement of

concentration at dosage, the alarm of health risk and the alarm of machine shift as the items which

need technical support from network layer in IoT. So far the signal processing, the noise filter, the

detecting way, the communication path for the measurements in these procedures are still immature.

It is an opportunity for those IoT suppliers if they own critical patent at these new measurements.

3.2. Optimization of IoT in WWTP

After re-organizing the messages of evaluation hierarchical maps from Figure 3 and 4, we create

three procedures as below to fulfil optimization of IoT we proposed in this study.

Principle I: Minimizing the negative concern from managers is the first step, so the IoT supplier

have to meet data management in a high reliability.

Principle II: Then IoT supplier have to fast fix disorder, provide an efficient service at data

management, effectively reduce the staff’s accident to maximize the positive cognitions from

managers, but any plan for principle II must be not against the first principle.

Principle III: “simple”, “easily access data”, “real-time control” would be essential functions in

order to maximize the positive cognitions from operators. However designing these function must be

not against principle I and II.

As you see in Figure 4 negative concerns connected with reliability are primarily focused on

“security” and “noise at monitoring”. Indeed there is a growing worry that control system of WWTP

is too vulnerable to prevent cyber-attack. In addition to malicious intruder, adopting easy but

vulnerable coding method, open to connect other networks, insecure remote connection are

recognized to escalate the cyber risk of control system. In terms of security technologies and

experiences, SCADA is more mature to securing control system than IoT at present. For meeting

principle I, we suggest the decision maker of WWTP carefully extends the IoT tentacle on the basis

of SCADA to operation.

To be contrary, the IoT supplier must make much more efforts on developing web services with

predictive analysis to forecast system’s risk and cloud knowledge base with prescriptive analysis to

avoid staff stuck in the trouble of system’s disorder. Any service created for principal II must be

qualified by the standards of high information security. Here I suggest the control system and the

web service adopt different communication networks and make a gap to avoid connecting each other

networks for security. For example, the control system is connected with SCADA on the fiber

network and the predictive analysis and the prescriptive analysis from IoT are transfer to smart phone

on the wireless network.

Optimize IoT for Operating Wastewater Treatment Plant based on Visualizing User’S Thinking

449

Although manager controls the budget and owns the power of making decision to upgrade control

system to IoT, operator will be in the closest relationship with IoT of all staffs in WWTP. Nature of

IoT being a tool designed for assisting operators to serve their duty more efficient highlights an

essential precondition that operators must be willing to use it. “simple”, “easily access data”, “real-

time control” are the top 3 of features which be able to catch the eye of operators. But there is a tug

of war between “simple” and “easily access data”, also between “simple” and “real-time control”

under the above principals. We suggest the IoT suppliers to make a fast copy of system monitoring

data on different mirror server then to let operators easily access what they care about but can’t let

them touch the server of control system in practice. And we suggest a double-check procedure is

necessary before putting a command of real-time control into action, that is to say, launching real-

time control to cease system’s disorder must be reconfirmed by more than two staffs.

Figure 3. The integrated evaluation Figure 4. The integrated evaluation

hierarchical map from operators. hierarchical map from managers.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

450

Table 2. Evaluate the technical support of IoT to smart control of WWTP.

The critical demand to smart control

Technical support of IoT

Perception

Network

Application

1

Automatic control of pumping system

○

○

2

Adjust air supply of blower

○

○

3

Sludge pumping

○

○

4

Detect the oxygen profile at aeration tank

○

○

5

Automatic removal of scum

○

6

Staff security

○

○

○

7

Automatic control of deodorizer

○

○

8

Preparation of chemical dosage

○

○

9

Automatic dosage feeding

○

○

10

Operate & monitor sludge digestion

○

○

11

Detect the shift of dewatering machine

○

○

PS “○” means that technical support of IoT is needed in this item.

4. Conclusions

As more and more wastewater treatment plants been built and in operation, IoT with novel sensors,

wireless communication and smart control will become the part of control system in WWTP. At

present IoT technology is moving rapidly and its market is very competitive. We suggest that

“reliability” is the first criterion in priority during adopting IoT. The decision maker of WWTP had

better add the IoT object into control system only being passed the qualification of information

security. And we also suggest adding a gap to separate control system and web service running on

different communication networks.

“simple”, “easily access data”, “real-time control” are the top 3 of IoT’s features operators care. Is

it necessary to promote the control system of WWTP to IoT? This study suggests WWTP step-by-

step expand its IoT networks and only open its connection with different network after double-check

security.

Acknowledgement

The authors express deep gratitude to the National Science Council in Taiwan for the financial

support (NSC 106-2622-E-242-001-CC2).

References

[1] Rose K, Eldridge S and Chapin L 2015 The Internet of things: an overview_ understanding the

issues and challenges of a more connected world The Internet Society (ISOC)

https://wwwinternetsocietyorg/iot

[2] Chen X, Liu X and Xu P 2015 IOT-based air pollution monitoring and forecasting system

2015 International Conference on Computer and Computational Sciences (ICCCS) 257 –

260

[3] Robles T, Diego M R A, Navarro M, Calero R, Iglesias S and Lopez M 2015 An IoT based

reference architecture for smart water management processes Journal of Wireless Mobile

Networks, Ubiquitous Computing, and Dependable Applications 6(1) 4-23

[4] Vermesan O and Friess P 2014 Internet of things-from research and innovation to market

deployment River publishers Denmark

[5] Thierer A and Castillo A 2015 Projecting the growth and economic impact of the internet of

things George Mason University, Mercatus Center, June 15, 2015

http://mercatusorg/sites/default/files/IoT-EP-v3pdf

[6] Ma M Y, Wei C C and Lin Y C 2014 An attractiveness evaluation of picture books based on

Optimize IoT for Operating Wastewater Treatment Plant based on Visualizing User’S Thinking

451

children's perspectives Proceedings of UMAP 2014 posters, demonstrations and late-

breaking results 87-92

[7] Chang H C and Chen H Y 2017 Exploration of action figure appeals using evaluation grid

method and quantification theory type I EURASIA Journal of Mathematics Science and

Technology Education 13(5) 1445-1459, DOI 1012973/eurasia201700679a

[8] Sanui J 1996 Visualization of users' requirements: introduction of the evaluation grid method

Proceedings of the 3rd Design & Decision Support Systems in Architecture & Urban

Planning Conference 1 365-374

[9] Ma M Y, Chen Y C and Li S R, 2011 How to Build Design Strategy for Attractiveness of New

Products Advances in Information Sciences & Service Sciences 3(11) 1-10

[10] Wei C C, Ma M Y and Lin Y C 2011 Applying Kansei engineering to decision making in

fragrance form design Intelligent Decision Technologies 85-94 Berlin Heidelberg: Springer

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

452